Silk Research¶

Silk is a protein biopolymeric material that is spun into fibers by arthropods such as silkworms, spiders, scorpions, mites and flies. All of these silks have different properties due to the amino acid sequence and conditions like climate, environment, reeling speed and nutrition of the organism (source). This page is dedicated to information about B. mori silk specifically. A cocoon is formed by a single filament, 600 to 1500m long wrapped around the silkworm, forming a protective cover that (when the species existed in the wild) would defend from the environment and any predator attack during the metamorphosis.

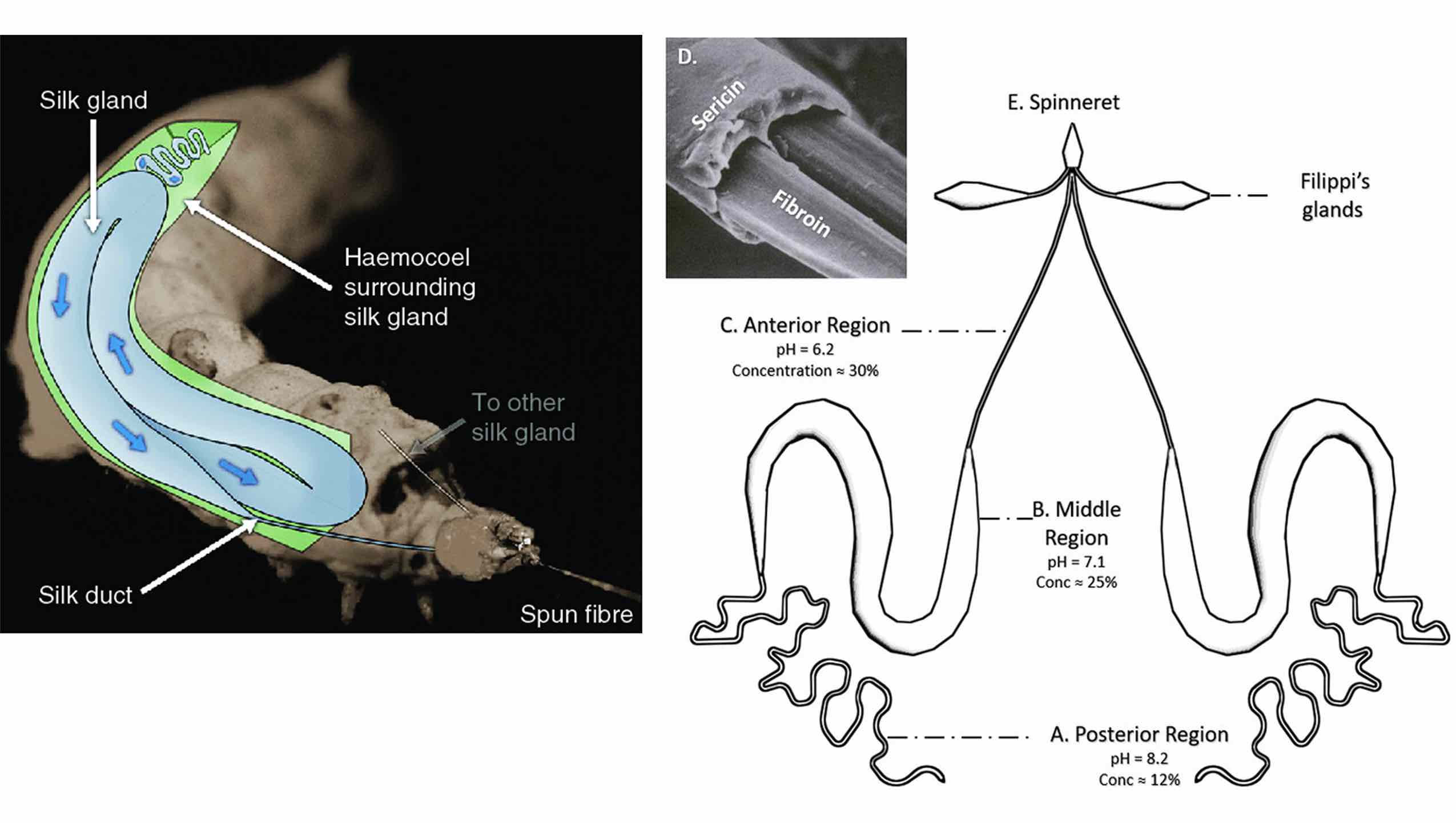

This image shows the silk gland inside of the larva. It can synthesize 20–35% of its own weight in protein in the 3-8 day spinning period.

This image shows the silk gland inside of the larva. It can synthesize 20–35% of its own weight in protein in the 3-8 day spinning period.

Structure¶

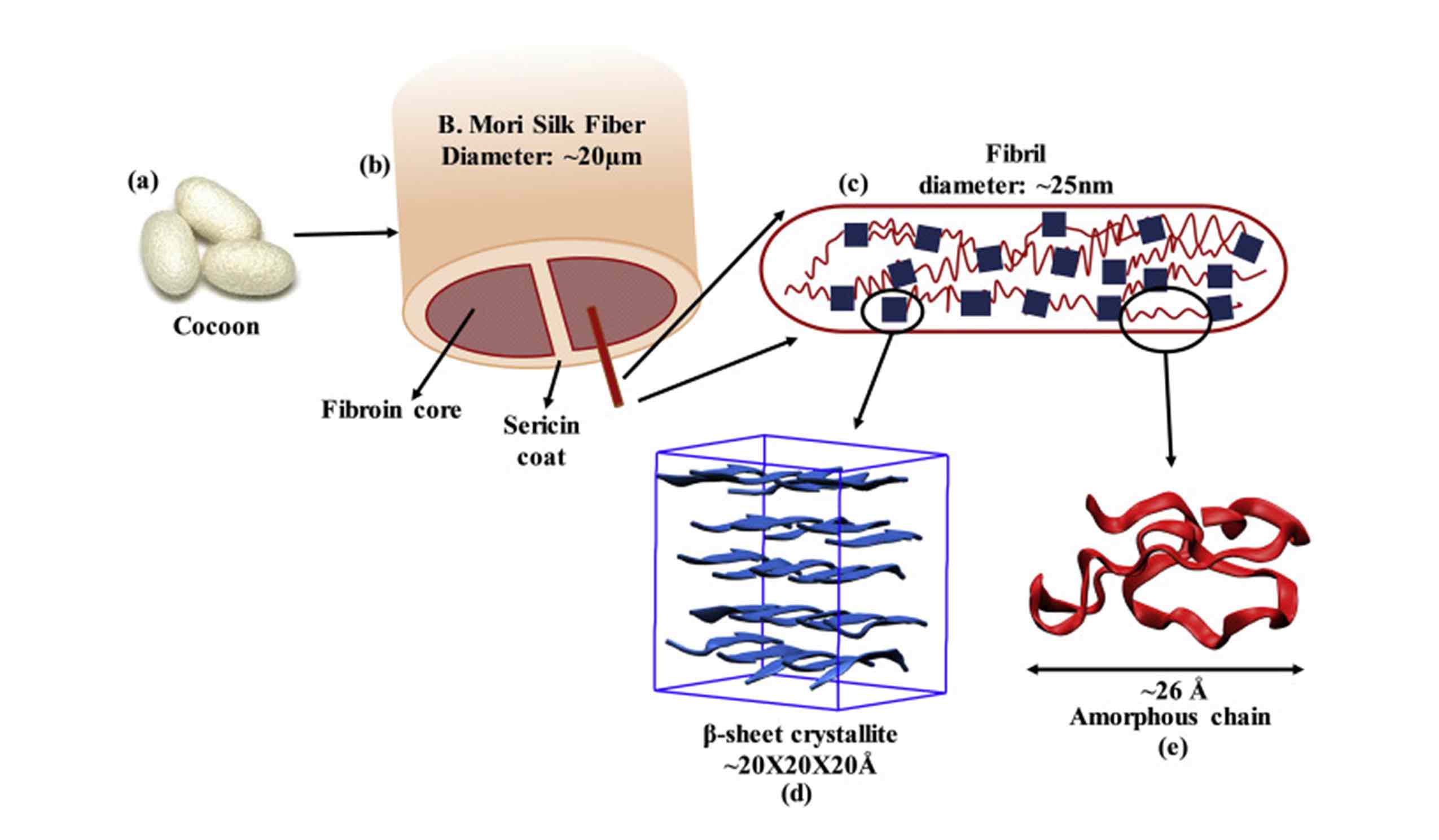

Silk fibers consist of two fibroin filaments each produced by one of the worm’s salivary glands during spinning. Both filaments are then covered by sericin, an adhesive and hydrophilic protein. Silk fibroin fibers are about 10-25 µm in diameter with the sericin coating ranging 1–2μm in thickness. The composite of silk is about 75% fibroin to 25% sericin.

Fibroin

structure is formed by highly repetitive sequences composed mainly of glycine (43%), alanine (30%) and serine (12%). Other amino acids such as tyrosine (5%), valine (2%), and tryptophan are present in smaller proportions. It is a semicrystalline protein composed of organized beta sheets and amorphous regions that provides structural stability and mechanical resistance to the cocoons.

Sericin

is mainly composed of glycine, serine and aspartic acid. It is an amorphous proteinic coating that acts as an adhesive, holding the woven fibroin together and maintaining the integrity of the cocoon (source.)

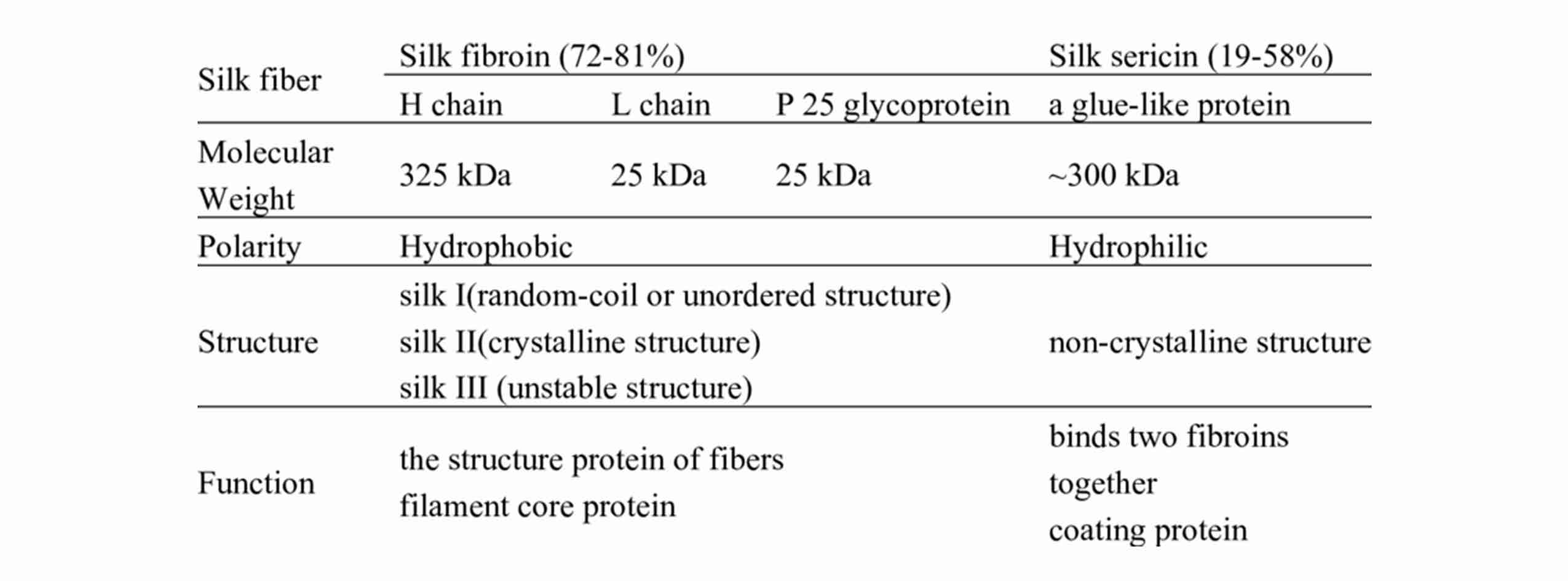

In this chart silk I refers to unspun natural form of fibroin, silk II refers to spun silk and silk III refers to regenerated silk.

Properties¶

Silk is the lightest natural fibers with a tensile strength superior to other biomaterials like cotton and PLA. It is stronger than an equal thickness of steel wire. These properties are mostly due to its cross-linked configuration, something that can be controlled in silk regeneration.

| Density | Tensile Strength | Breaking Elongation | Breaking energy (toughness) |

|---|---|---|---|

| 1.17g cm^-3 | 0.5 gigapascals (GPa) | 15% | 6 × 104 J kg−1 |

- Hygroscopic - The polar residues in fibroin make it a hygroscopic material (can absorb moisture from the air). Water is mainly accumulated in the amorphous regions while the crystalline units hinder the access of water molecules. Water absorption can change the properties of the fibroin to be more malleable, then they return to normal once the water is removed.

- Thermal Regulation - Fibroin acts as a thermal insulater to protect the pupa inside.

- Gas Selective Permeability - The composition, silk weave, and shape of a cocoon allows it to regulate the diffusion of gases, such as CO2, N2, O2, and water vapor during metamorphosis.

- Antibacterial - This is still debated.

- UV-protection - This property is derived from the flavonoids in the mulberry leaves which carry through to the silk and act as a chemical UV shield.

- Optical Properties - Regenerated SF films and fibers have high visible-light transparency (>95%), low absorbance along the UV–vis region, and high refractive index. They also show low roughness and can be patterned to modify the light behavior.

- Electrical properties - The silk cocoon membrane has an inherent ability to sense environmental conditions. Changes in temperature or humidity are translated as electrical signals from the cocoon to the pupa. The elctrical conductivity depends on the water content (dry conditions result in high resistance making it like an insulator and wet conditions result in a reduction in resistivity making it conductive) The current flowing across the silk is possibly ionic and protonic in nature. Studies show that this property make silk a potential material for battery technology, bio-sensor, humidity sensor, steam engines and waste heat management.

- Chemical and Metal Absorption - possible applications in air and water polution filtration.

Wearable benefits¶

Silk is hypoallergenic due to the sericin repelling dust mites, mold, bacteria and other allergens. The natural cellular albumen found in silk helps to speed up the metabolism of skin cells, ensuring that they’re turning over and replenishing (this is why it has been used for wound dressing and tissue regeneratin). Also silk fabric absorbs less moisture off the skin compared to cotton and other natural fibers so this is helpful for moisture retention for those with dry skin. Silk is a natural heat regulator, maintaining cool and consitstant temperatures which may help menopausal hot flashes.

Biodegradability¶

Cocoons have been adapted to remain stable without degradation for a long time. Environmental conditions such as humidity, light and temperature affect this, along with material shape (fiber, film, sponge, etc.) and the structural composition. Controlling these factors allows one to control degradability. In biomedical applications in vitro the degradation of silk mostly comes from proteolic enzymes. Silk will break down in compost in 1-4 years depending on the environment.

Biocompatability¶

This property describes the compatability of a material with living tissue: biocompatible materials do not produce a toxic or immunological response when exposed to the body or bodily fluids. The small polypeptide chains and peptides derived from fibroin degradation do not cause a large hypersensitive response in the human body so it is deemed a biocompatible material (FDA approved). Silk has been employed for sutures and ligatures for nearly 2000 years. In recent technology it has become valuable in many more biomedical applications like controlled drug delivery, tissue engineering scaffolds, bone regeneration devices and other implants because of its strength, biocompatibility, and programable biodegradability. Fibroin can be constructed as hydrogels, fibers, sponges, films and more for these purposes.

B. Mori Spinning Process and Data¶

- Silkworms spin the cocoon from outside to the inside.

- Average spinning speed is 9.4 to 9.6 mm/sec.

- The silkworm moves its head in figure 8 patterns as it spins.

spinning behavior study

mathmatics of spin

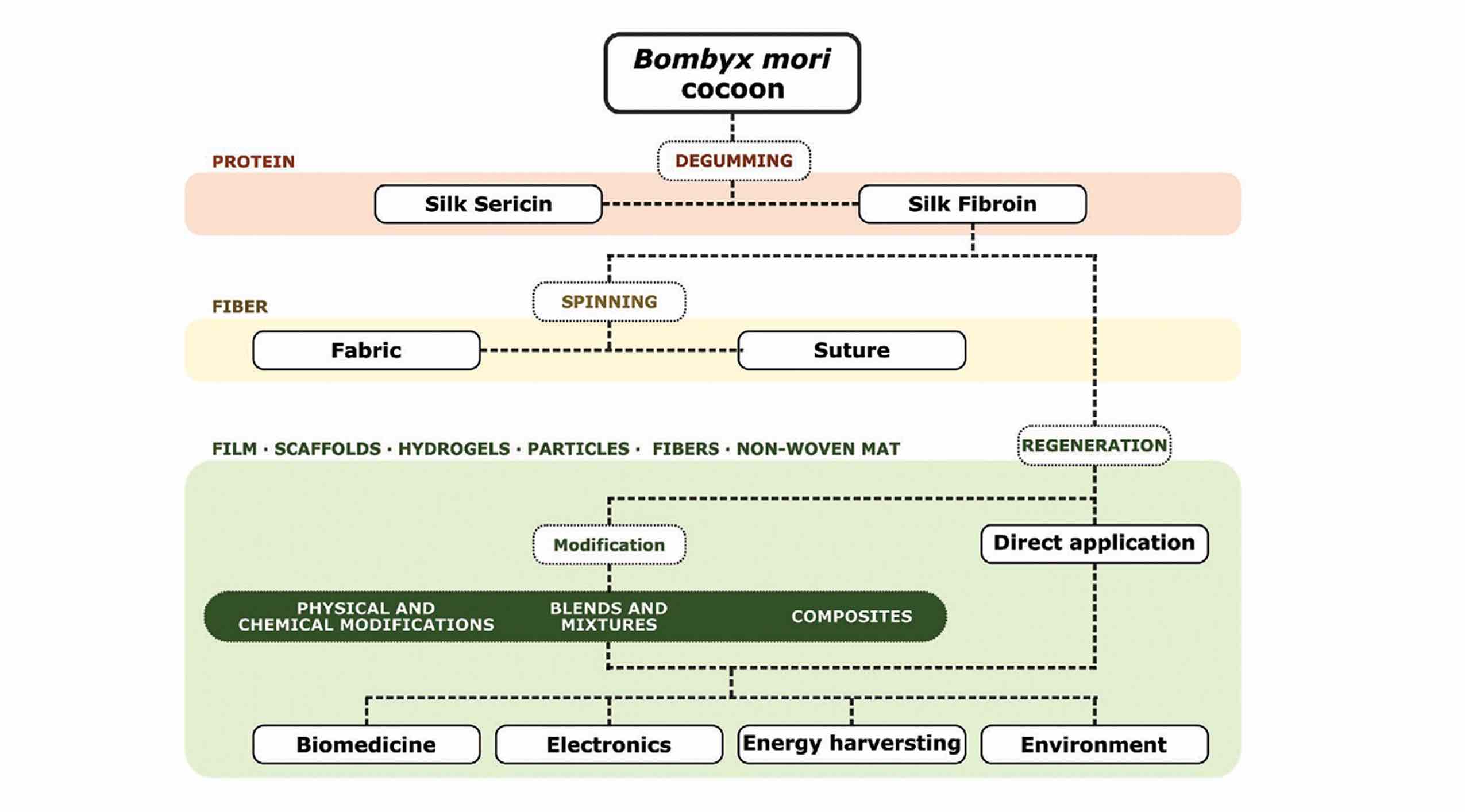

Degumming and Extraction¶

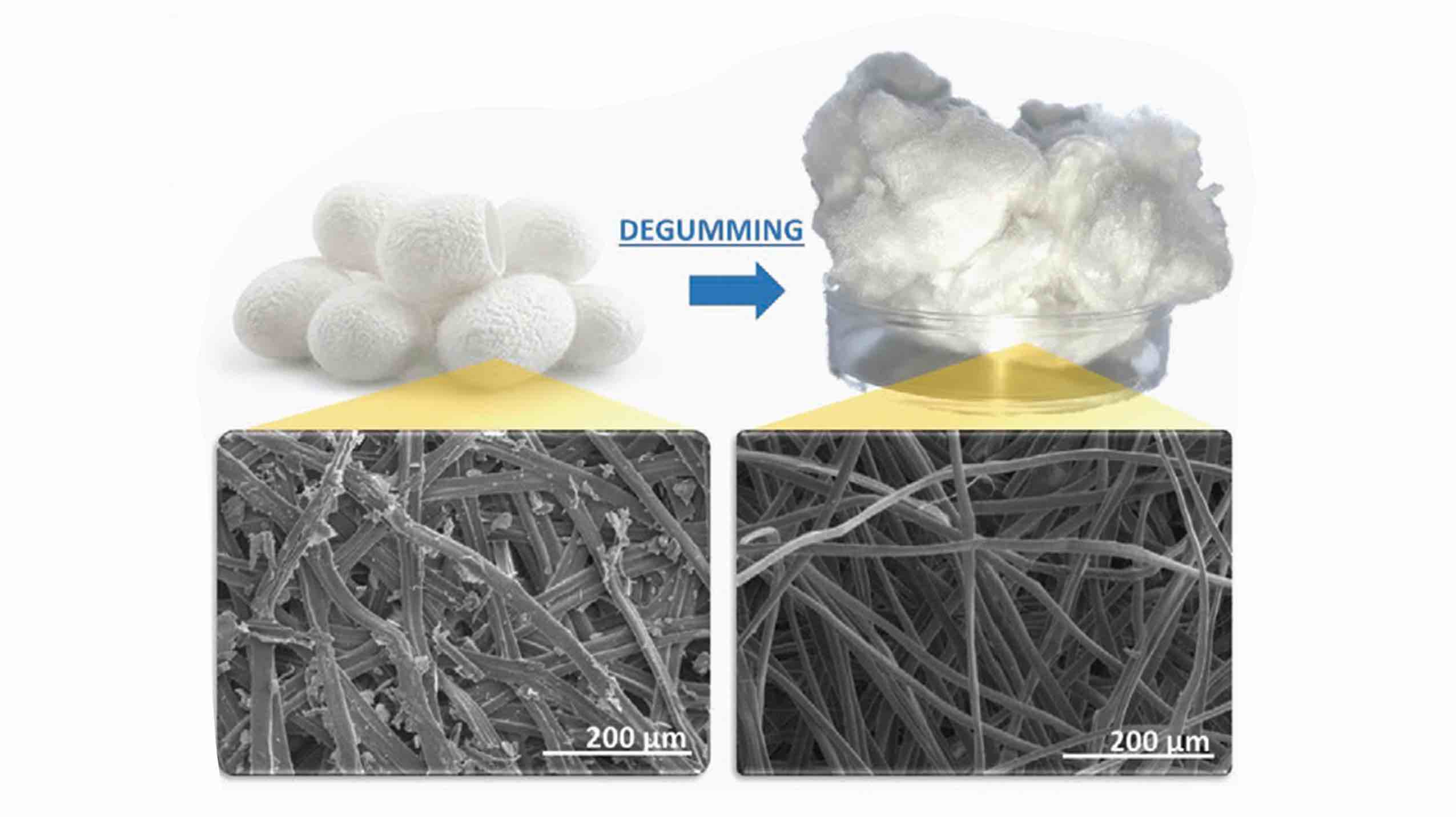

Degumming¶

This is the step to remove the sericin and leave pure fibroin, done in most textile and biomedical application silk processing. Leaving ther sercin has a negative effect on dye absorption luster, handle, whiteness, and breaking length of silk fibres. Different degumming methods result in different fibroin properties, providing environmental, energetic, and economic implications.

- Alkaline degumming - hydrolyses sericin, efficiantly removing it but possibly damaging the fibroin.

- Urea degumming - relies on a high level of urea, it can possibly denature the fibroin protiens and it results in waste water. This degumming process requires a Ph level of 11-12.

- Enzymatic degumming - allows the removal of sericin by mild hydrolysis reaction with high efficiency, strong specificity, and low pollution with the only downfall being the expensive cost of the enzymes.

- Soap degumming - is the efficiant, low cost, common method of boiling cocoons in sodium carbonate or sodium phosphate solutions. This requires a specific temperature range between 80C and 100C. It can be improved by adding wetting agents and surfactants like marseille soap to reduce surface tension between water and cocoons.

Sustainable Degumming Development¶

With environmental impacts in mind and now that more benefits/applications of sericin have been discovered, researchers are looking for more sustainable degumming processes that allow for the preservation of sericin as well.

- Papain Degumming - Papain is the enzyme fond in papaya. When reacting with silk it breaks the binding sites between L-arginine or L-lysine residue and another amino acid residue in sericin, leaving just clean fibroin. A study found higher tensile strength using this method than sodium carbonate degumming.

- Steam Degumming - this can be done with a modified pressure cooker and eliminates the use of chemicals.

- Acidic Degumming - Citic acid can be used for acidic degumming, which makes the degumming bath repeatable in use but decreases the dye apsorbtion of the fibroin. This study describes more.

Dissolving Fibroin¶

Dissolution is the process to create a fibroin solution, similar again to that in the glands of the silkworm. All fibroin structures are broken during dissolving and only the primary amino acid composition is preserved. Because of protein–protein self-interactions, some structures like β-sheets and cross-linked configurations can be reformed. This does not happen with the nanofibrils.

Aqueous salt solutions are the most common way to do this due to lower costs than organic solvents like HFIP, NMMO and HFA (these solvents can destroy the fibroin structure and lead to toxic final materials). Salt-based solutions require long preparation times because they must be dialyzed for several days. The most common is CaCl2 and LiBr solutions, with ethanol (EtOH) or methanol (MetOH) added to improve the yield. An acidic solvent method can be done with formic acid, but it risks protein degradation due to acid hydrolysis.

One study suggests fibroin can be dissolved with just CaCl2 at 80 °C. The solution is 6g CaCl2 to 94g MeOH (250ml) for 0.5 g of degummed silk.

State of the Art Applications¶

Silk is a versatile compound that can take forms at macro, micro and nano scales: nanofibers, nanoparticles, hydrogels and microspheres. Emerging additive manufacturing techniques such as bioprinting, stereolithography or digital light processing and 3D printing provide more opportunities for silk based biomaterials. This article provides really helpful explinations of silk material processing.

- Foams -

- Hydrogels - gel aqueous solutions can be produced througha variety of methods such as, vortexing, sonication, applying electrical current (makes an adhesive gel with a polarity that depends on the polarity of the voltage applied) or lowering the Ph. To further stiffen the gel incubate it at 37 °C overnight.

- 3D printing -

- Films - thin fibroin films can be made by air drying, methanol or water-annealing, or electrogelation (controlling the formation and content of silk fibroin nanoparticles from the solution to create an e-gel). To sterilize silk films they can be incubated in 70 °C ethanol overnight then rinsed in water. Patterned films can be made using a polydimethylsiloxane PDMS mold.

- Sponges - silk sponges are 3d porous scafolding materials. They can be aqueous based or HFIP based.

Silk and Cellulose Composite cotton linters were treated with 7% NaOH and 12% urea solution at −12 °C and the dissolved cellulose was used as a matrix. Similarly, waste silk fibers were treated with 5% NaOH for one hour and treated fibers were cut into lengths of 1mm. These fibers were combined (1–5%) with the cellulose solution and cast into films. Films obtained were transparent and addition of silk fibers continually increased the strength and modulus but decreased elongation. (source)

Sources¶

Fibroheal Bandages - silk bandages that cut down healing time due to beneficial properties for the skin

Sericyne Material - 2d and 3d meshed silk samples

Foamed Fibroin Bricks IAAC Project - looking at the use of silk as an architectural material

Silk Lab Application