PROCESS¶

PREFERENCES¶

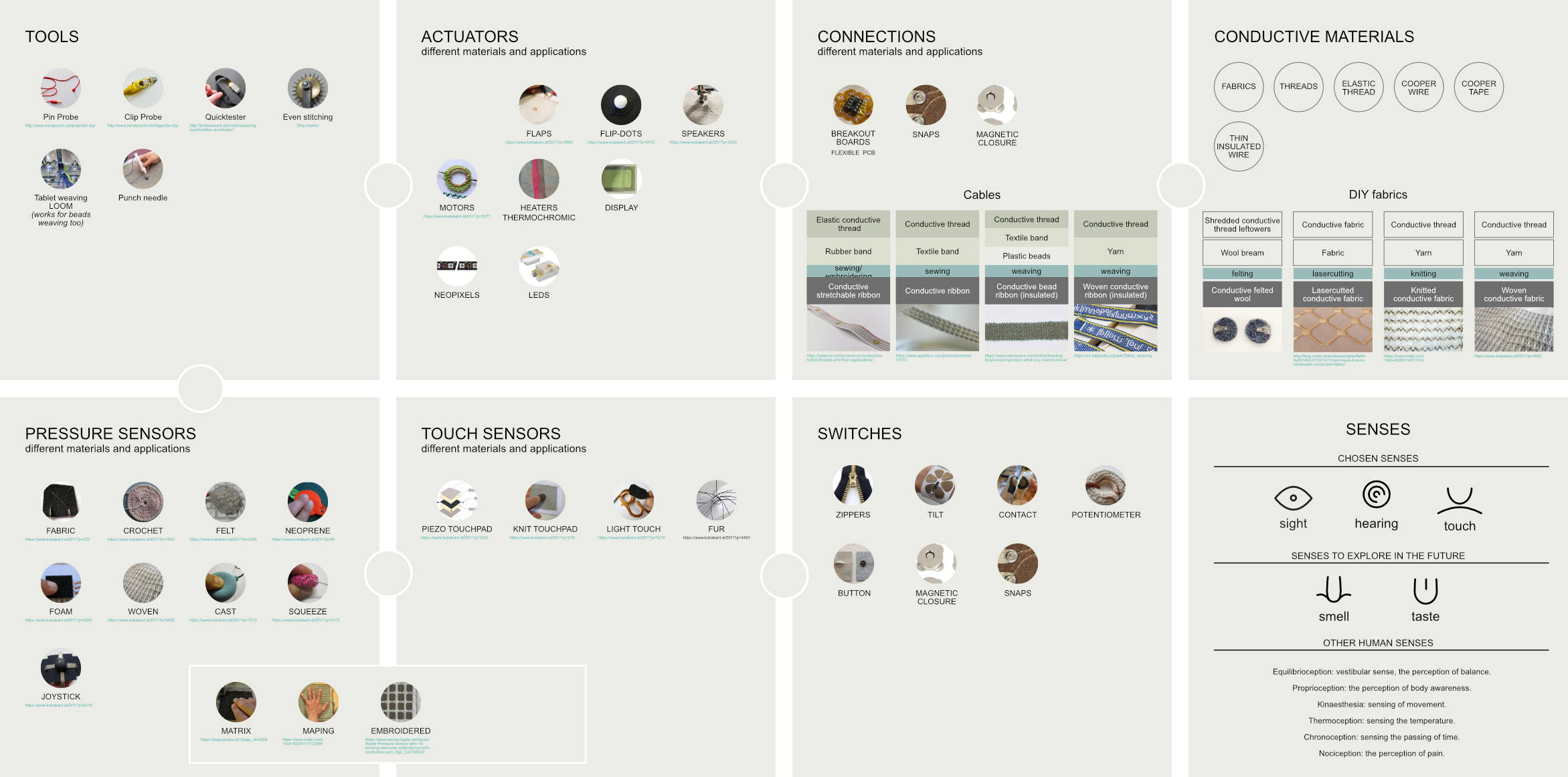

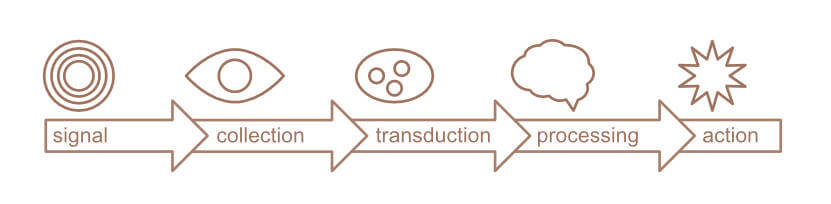

Conducted the research of the senses, sensors, materials, tools, and instruments guided by the explored human and animal senses. This helped me to decide which sensors I should start with.

SENSES¶

Chosen senses: touch | sight | hearing

Senses to explore: taste | smell

Other human senses:

Equilibrioception: vestibular sense, the perception of balance.

Proprioception: the perception of body awareness.

Kinaesthesia: sensing of movement.

Thermoception: sensing the temperature.

Chronoception: sensing the passing of time.

Nociception: the perception of pain.

Senses that humans don’t have:

Electroception: the ability to feel electrical fields around us. Sharks can detect electrical fields in their environment, including those emitted by prey it cannot necessarily see.

Magnetoreception: several mammals, such as bats, can sense the Earth’s magnetic field and use it to navigate.

Polarized light: many animals, including insects and birds, use polarized light to decide which direction to go in.

SENSORS¶

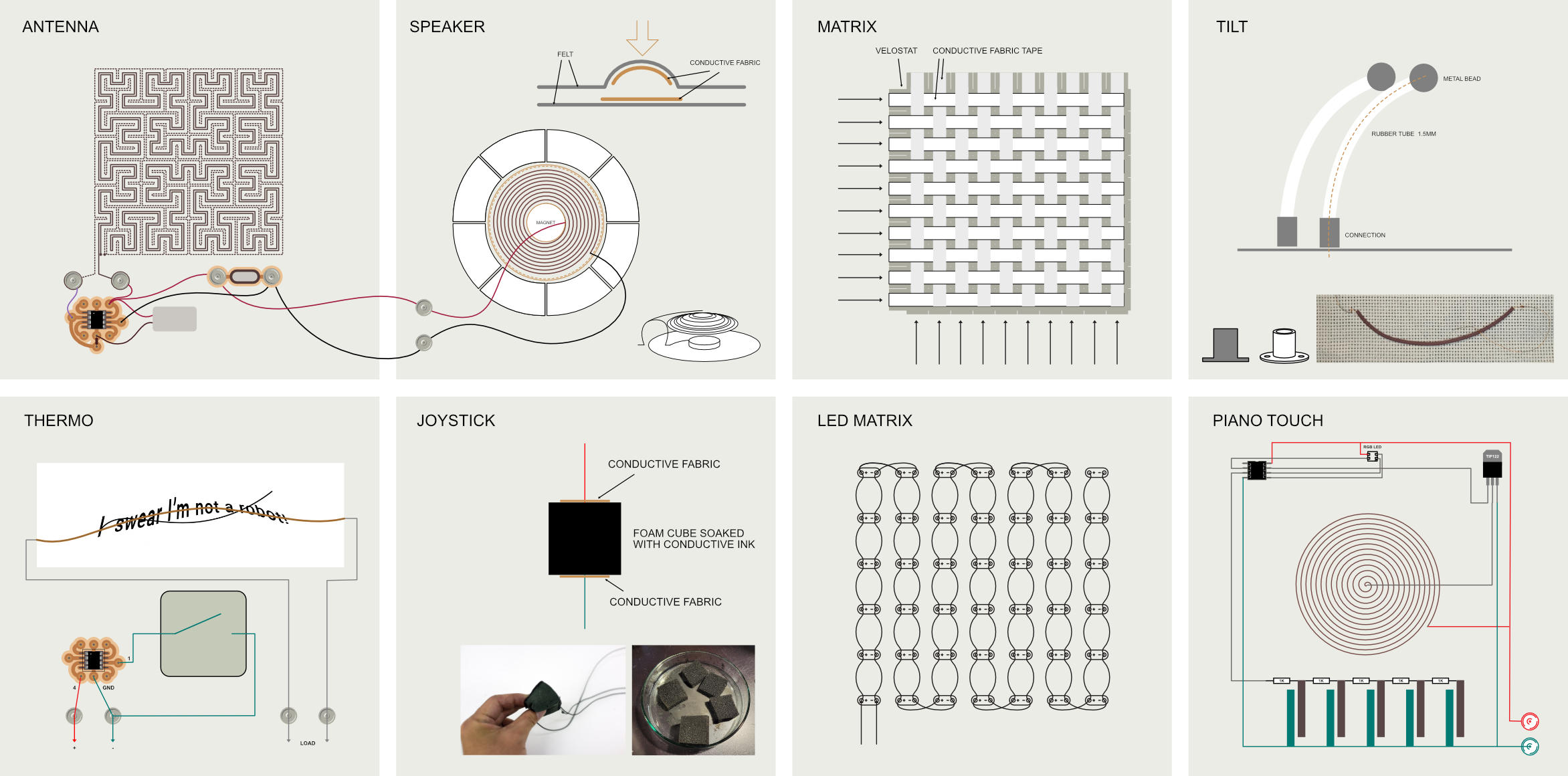

Also started to sketch the possible sensor swatches.

ANTENNA: touch sensor reacts to making the sound on the buzzer. Following this Arduino Theremin example.

SPEAKER: would like to use the swach I made during Circular Open Source Fashion class and to make work that puffiness for the speaker.

MATRIX: pressure sensor made from conductive textile tape and Velostat.

TILT: rubber cords, metal beads and conductive thread to make hanging “flowers” where conductivity would happen then metal beads touch each other.

THERMOCHROMIC: disappearing inscription with digital pressure sensor.

JOYSTICK: the foam soaked in conductive ink, pressure sensor cube. Following this Foam Sense example.

LED MATRIX: LED's matrix actuator.

PIANO TOUCH: embroidered speaker and capacitive sensors. Following this knitted speakerexample.

QUICK PROTOTYPE¶

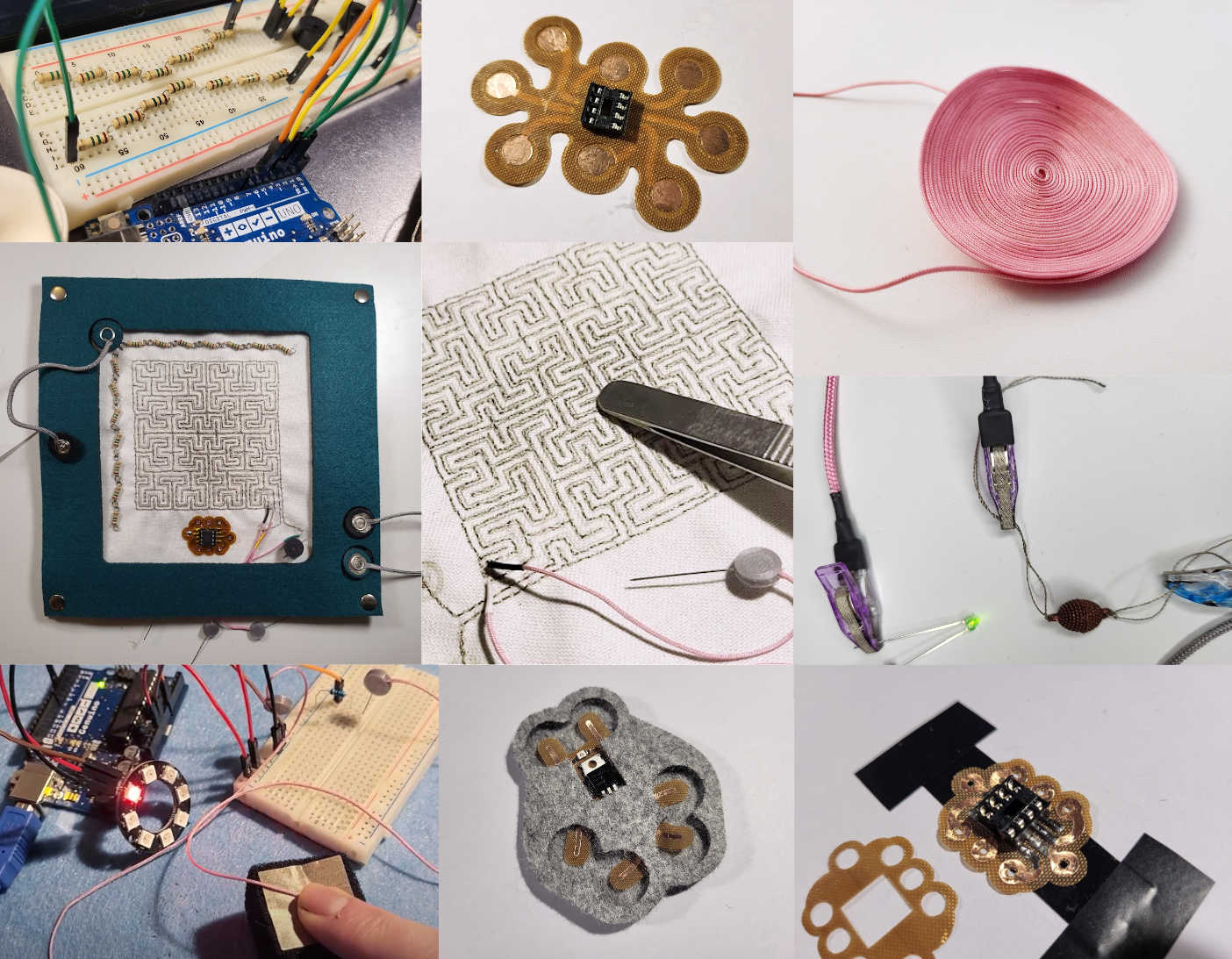

I decided to start from touch sensority.

The first prototype was made using a punch needle with conductive thread and faux fur.

EXPLORING THE MATERIALS¶

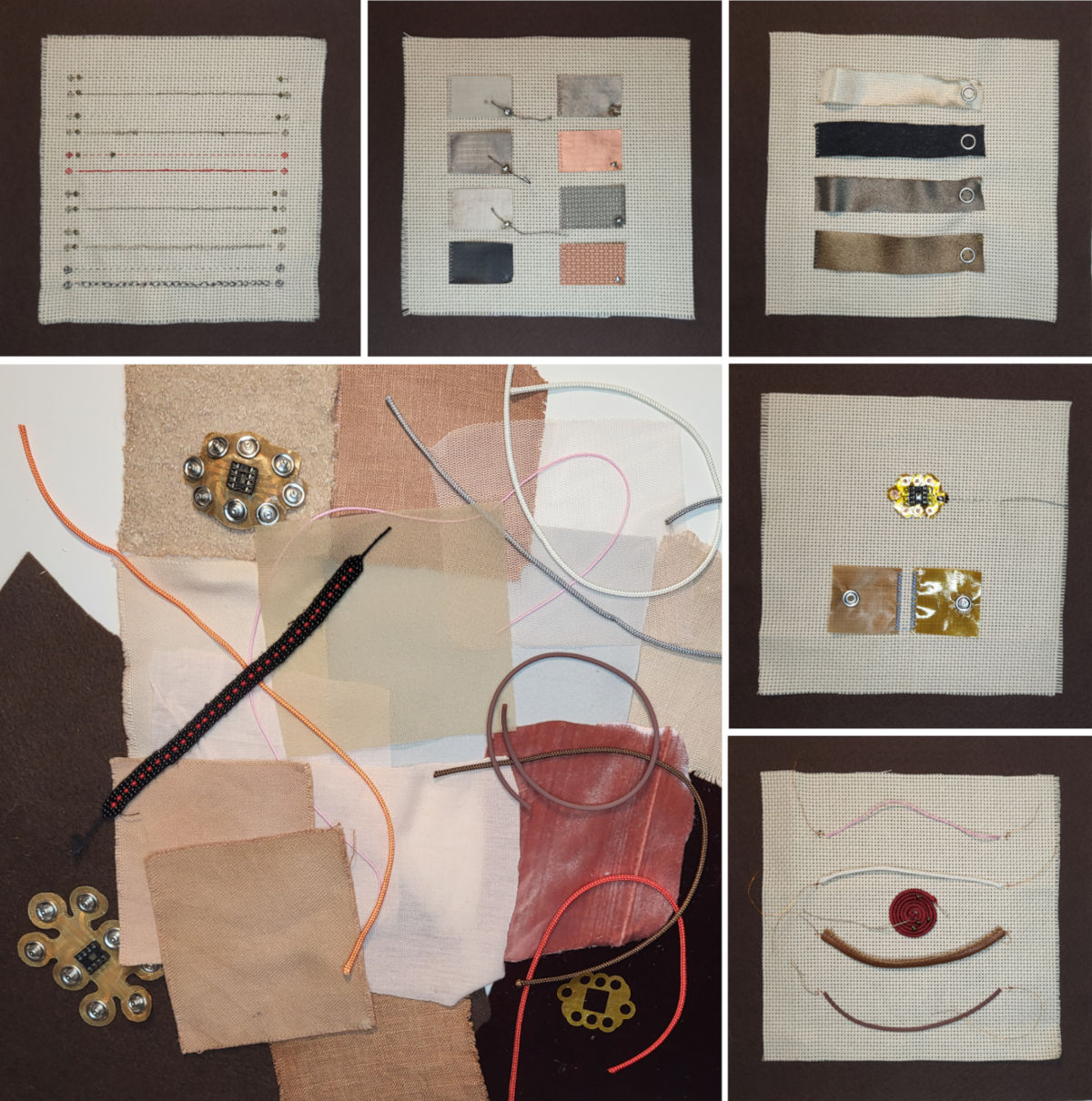

Gathered and tested the materials I have: conductive threads and fabrics, metal fittings, non-conductive materials and fabrics.

MAKING THE TOOLS¶

Followed Irene Posch textile electronics tools documentation to make such tools as Pin Probes and Clip Probes.

So I made the Banana plugs with crocodile clips for multimeter, Clip Probes and Pin Probes just with pins.

Inspired by Irene Posch tools I created metal snap-fastener connections[^1] using 3mm and 1.5mm felt, 2mm Griffin® braided nylon cord and 6 Ω/m conductive thread.

EXPERIMENTATIONS¶

There is a lot of experimentation, maybe even too much, because as I got deeper I realised how many possibilities there are, so the desire to try out materials only grew.

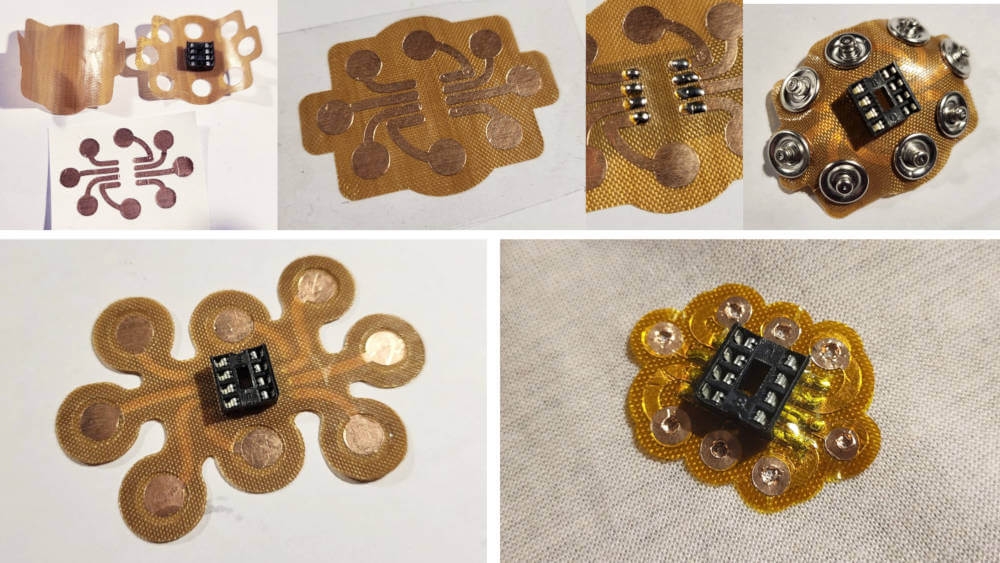

FLEXIBLE PCB¶

I started with a PCB for the ATtiny85 microcontroller. Tried new material - PTFE impregnated varnish fabric. It is an excellent electrical insulator, this is why it is often used on printed circuit boards and electrical cables. I used the plotter to cut PTFE fabric, copper tape, and Kapton tape layers. It was tricky to work with Kapton tape as it is very thin and sticky but transfer film for vinyl worked out.

What didn't work:

When I tried to attach the metal press buttons on the PCB joints, I noticed that the PTFE fabric would tear and the entire board would bulge due to the tension in the riveting areas.

It also started to disintegrate when I tried to sew the PTFE fabric. In the next step, I will try to cut holes for sewing, and also test if the layer of Kapton film reinforces the PTFE fabric.

PROCESS VIDEO¶

MENTORING NOTES¶