6. BioFabricating Materials¶

CIRCULAR ACTION¶

In the last fifty years, the increase in the consumption of processed foods has meant the production of enormous amounts of food waste, which is no longer edible and must be managed in some way, with very negative impacts on the environment.

New fashion brands, products or other creative companies are already working to respond to the new demands for innovation and sustainability, creating high-quality fabrics and materials capable to unite ethics and aesthetics, conserving the planet's resources for future generations.

With this exercise I have also thought about the importance of using local products. Value the product that we have nearby and reuse it. Being able to give a second life to a material that generates a lot of waste is just the beginning of a great circular action.

INSPIRATION¶

ART AND SCULPTURE¶

Bio-Digital sculptures "HORTUS XL" by ecoLogicStudio

A digital algorithm simulates the growth of a substratum inspired by coral morphology. This is physically deposited by 3D printing machines in layers of 400 microns. Among the oldest organisms on earth, cyanobacteria’s unique biological intelligence is gathered as part of a new form of bio-digital architecture. The behaviour of the spiders and the production of silk is re-programmed through the design of the 3D printed substructure and of its geometrical features. The result consciously seeks productive ambiguity, revealing in the alien beauty of its silky morphologies

- Here more very interesting design and biology proyects.

ARCHITECTURE AND ENGINEERING¶

Neri oxman and her team have been my first reference and motivation. Knowing his work and the different innovative projects got me interested in this idea of biomaterials and sustainable design. Oxman’s goal is to augment the relationship between built, natural, and biological environments by employing design principles inspired and engineered by Nature, and implementing them in the invention of novel design technologies. Areas of application include architectural design, product design, fashion design, as well as the design of new technologies for digital fabrication and construction. Neri Oxman Website

FASHION AND MATERIALS¶

Peelsphere is a trurtly circular material mode from fruit waste and Algae through advanced material engineering. It is designing by redefinding fruit waste, reducing carbon footprint and design for circularity. The materials created are durable and biodegradable. Born at the intersectionality of design, material science and sustanibility.

Coocking New Materials by Youyang Song

DUTCH DESING WEEK 22 (GET SET)¶

A quick tour of the 2022 design fair. Creative, sustainable and incredible projects that I liked the most. After visit this year design week, the mention it is very clear: It´s time to prepare, It´s time to act.

It has been my first year that I have visited one of the most popular design fairs and I have been amazed at all the projects and designers who works with the awareness of the critical state that the planet suffers. Therefore, Biomaterials, Science, Biology and Technology take part in every corner of Eindhoven

A quick tour of the 2022 design fair. Creative, sustainable and incredible projects that I liked the most. After visit this year design week, the mention it is very clear: It´s time to prepare, It´s time to act.

It has been my first year that I have visited one of the most popular design fairs and I have been amazed at all the projects and designers who works with the awareness of the critical state that the planet suffers. Therefore, Biomaterials, Science, Biology and Technology take part in every corner of Eindhoven

Check my powerpint with my favorite projects of Design Week

BIOMATERIALS¶

One of the exciting things about biomaterials is just how accesible they are. Often they can be created from what you already have at home or with ingredients available at the grocery store.

RECIPI I

GELATIN RECIPE WITH CELLULOSE:

200ML WATER

30G GELATIN

3.5ML GLYCERIN

3ML PURE ALCOHOL

50G OF CELLULOSE OR SKOBY

How to make:

-

The mixture of water with cellulose must be beaten well until it is a uniform pasty liquid.

-

When mixing the gelatin and starting to heat the mixture loses a lot of texture and becomes liquid.

-

Let it boil little by little and do not stop moving the mixture.

-

Heat for 5 minutes, then turn off the heat and leave to cool for 5 minutes while you move it.

-

Finally pour into the mold.

-

You must take into account that the mold is aligned correctly

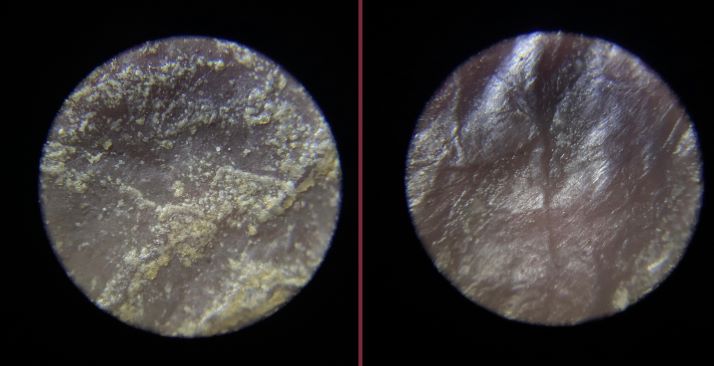

Afeter 7 days drying

Notes:

I expected more volumen in my biomaterial, looking more like the mold, but it seems that the water has absorbed a lot. Cellulose gives it a lot of rigidity but it also evaporates when it dries because it is mostly made up by water. I will continue experimenting for better results.

3D-BIOPRINTING FABRICADEMY 2022

RECIPIES¶

A single formula can give you up to seven different material outputs, varying amounts and chemical measurements. Therefore, experimentation and documentation of the process is very important.

GELATIN¶

225ml water without chlorine

30gr gelatin

3.5ml Vegetable Glycerin

5ml white vinegar (to disinfec)

48ml liquid cellulose

Process

1- Mix all the ingredients cold in a saucepan until there are no lumps and the mixture looks homogeneous (10 minutes)

2- Bring to medium heat and keep moving

3- When you see the white foam remove

4- Empty the mixture into the container. Avoid porous surfaces.

AGAR AGAR¶

400ml water without chlorine

12gr Agar

18gr of Glycerin

4ml white vinegar

40ml liquid cellulose

Process

1- Mix everything cold until there are no lumps and it looks homogeneous.

2- Bring to heat and let it boil

3- When it boils, lower the temperature and stir for 15 minutes.

4- After 15 minutes take out the mold

5- Once 5 hours have passed (depending on humidity) remove from the mold and leave

another surface

6- Drying will take several days, always depending on the humidity.

ALGINATE¶

25gr Sodium alginate powder

50/60gr Glycerin

600ml Water

Calcium chloride 10% - 300 ml (30 gr in 300 gr of water)

Process

1- Once the mixture is done, take a syringe

2- Carefully introduce in a single shot to the calcium

3- Let threads 10 seconds amd remove from broth.

4- And just let dry 24h

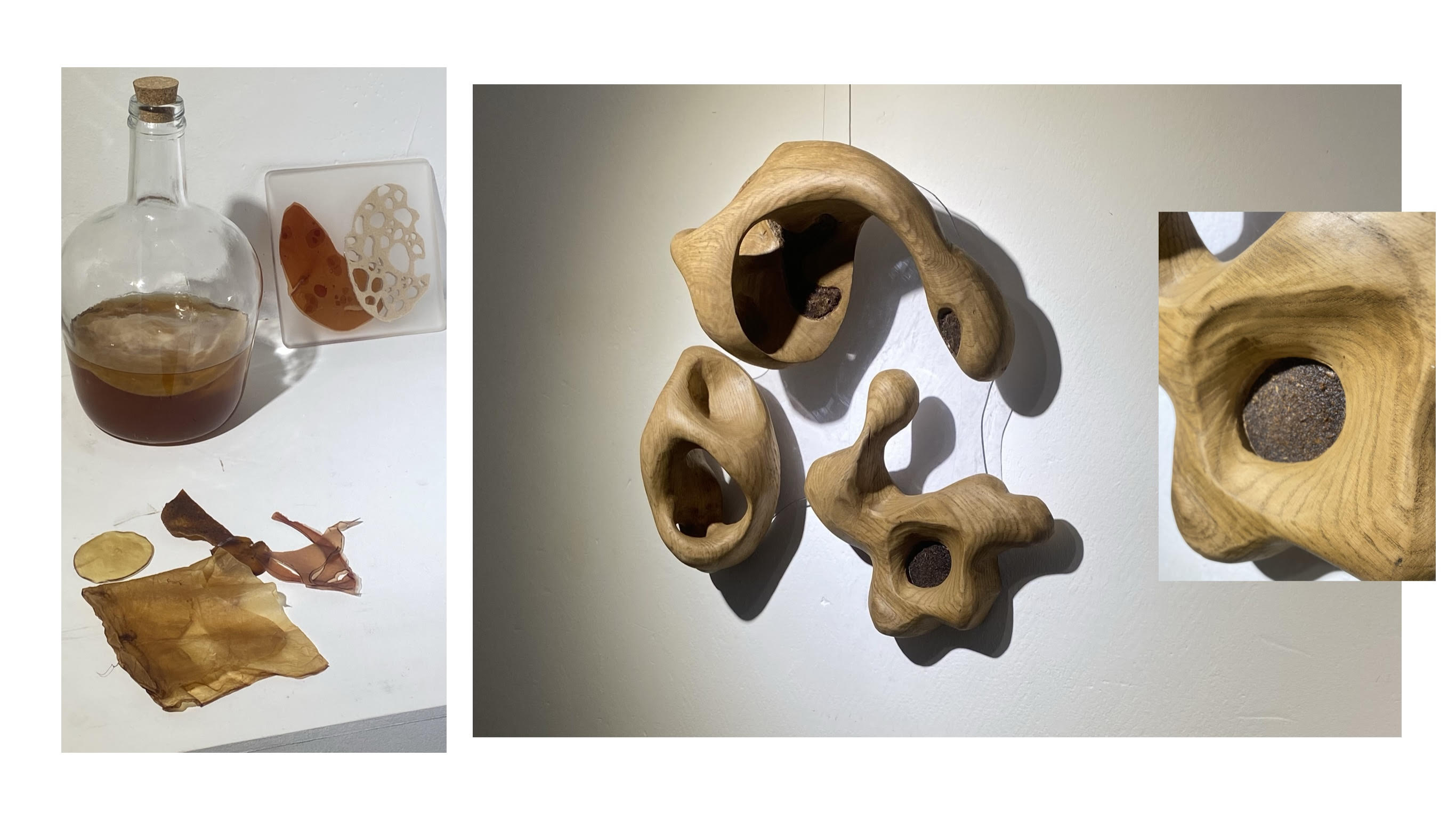

BACTERIAL CELULOSE¶

To grow bacterial cellulose, I use a fermentation technique:

Static Cultivation: It is used to produce vegetable leather and bacterial paper. It is true that the development of biofilm growing is longtime (3 weeks) depending on the climate, it is much faster in warm areas.

TO PRODUCE Kombucha we need: 7 glasses of water 1 of sugar + 2 tea bags and TO SPEED up growth add 1/2 glass of fermented tea and small piece of scoby (but it is not necessary)

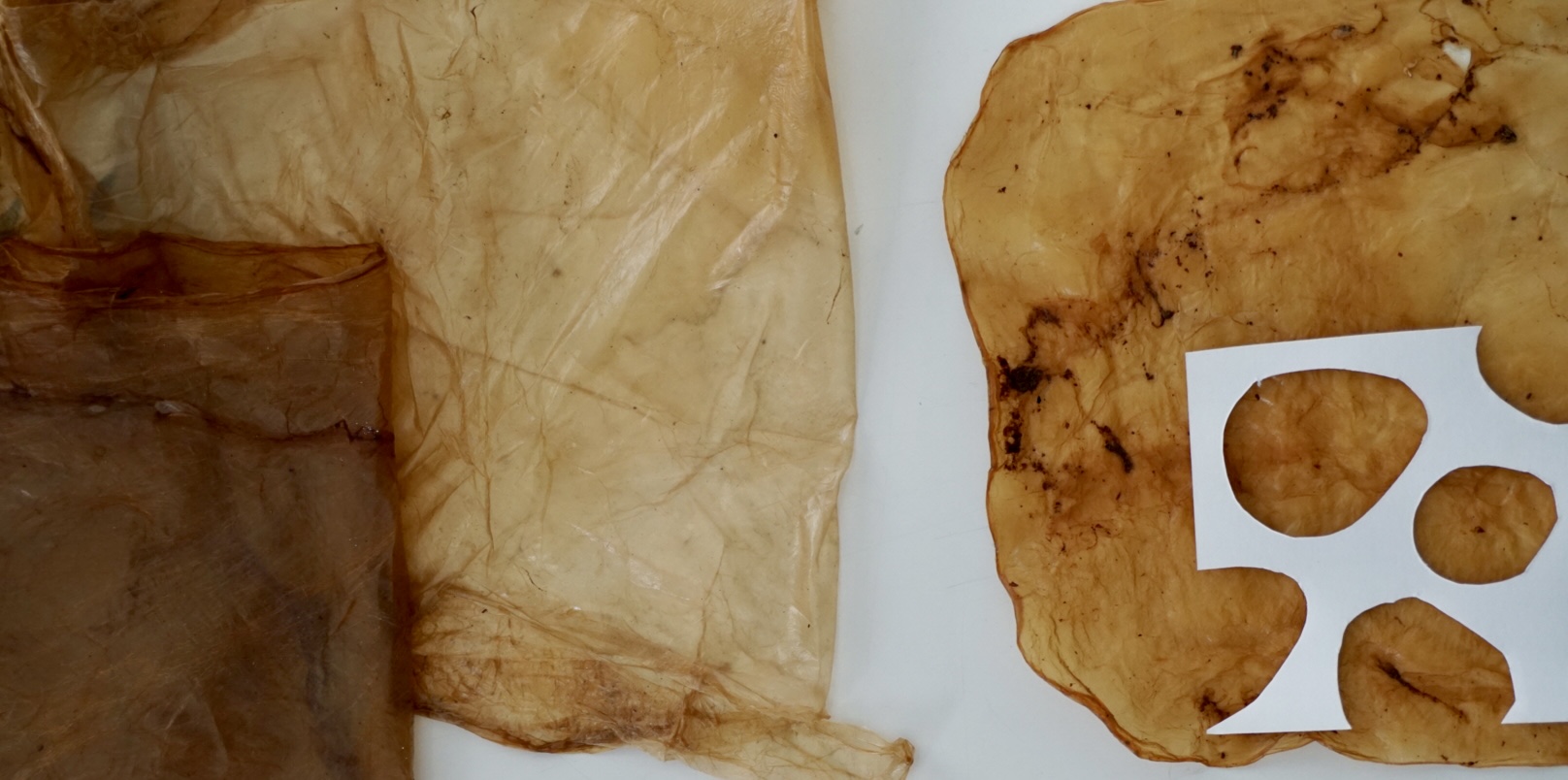

Although kombucha is often referred to as a tea mushroom or kombucha fungus, the brownish-looking gelatinous mass is a symbiotic colony of different bacteria and yeasts that produces bacterial cellulose through a fermentation process. The self-grown material in the dry state resembles leather and has high tear strength and flexibility due to its complex three-dimensional nanostructure. Kombucha microorganism as a self-dynamic material producer is being tested as a textile raw material through experiments, observations and impact.

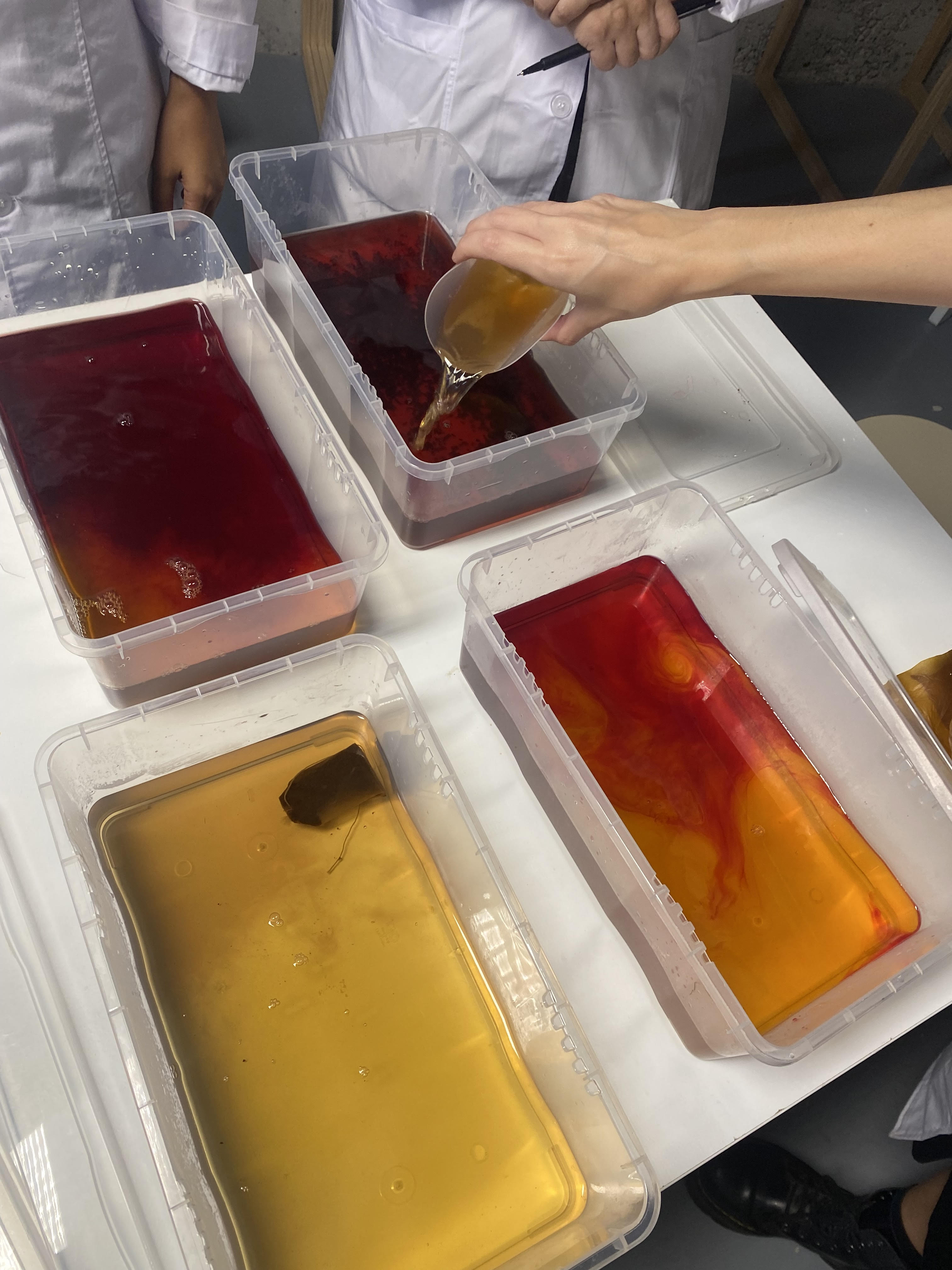

- CLASS EXPERIMENT

In my case, I already have previous experience fermenting kombucha and was able to get scoby leather but all with a brown color. In class we wanted to experiment and see what happens dyeing the te. Will the scoby get a red color? To see the result we will have to wait about 3 weeks and let the Kombucha grow

In my case, I already have previous experience fermenting kombucha and was able to get scoby leather but all with a brown color. In class we wanted to experiment and see what happens dyeing the te. Will the scoby get a red color? To see the result we will have to wait about 3 weeks and let the Kombucha grow

.

BIOTEXTILE CONSERVATION¶

The durability of the materials may depend on:

-

Its components or raw materials

-

Storage conditions (climate, temperature, humidity, etc)

-

Application

Deteriorations in textiles are changes that affect the characteristics of the material from stains, tears, dirt, chromatic alteration to contamination.

All textiles deteriorate due to the intervention of light, insects, microorganisms and air pollution that, alone or together, cause a considerable loss of tensile strength and flexibility. Oxygen in the atmosphere affects all organic substances to varying degrees. The rate of deterioration varies according to the environment and the nature of the textile biomaterials. The main factors that favor the deterioration of textiles can be categorized into three groups:

Mold prevention tips:

-

Do not expose the biomaterial excessively to direct light

-

Do not be in very humid places or come into contact with moisture. (Ideal temperature between 18 and 21 degrees)

-

Do not let in a place with polluted air (for example in a bathroom cabinet)

-

Avoid places with a lot of dust, dust attracts microorganisms and insects.