Growing¶

Bioreactors¶

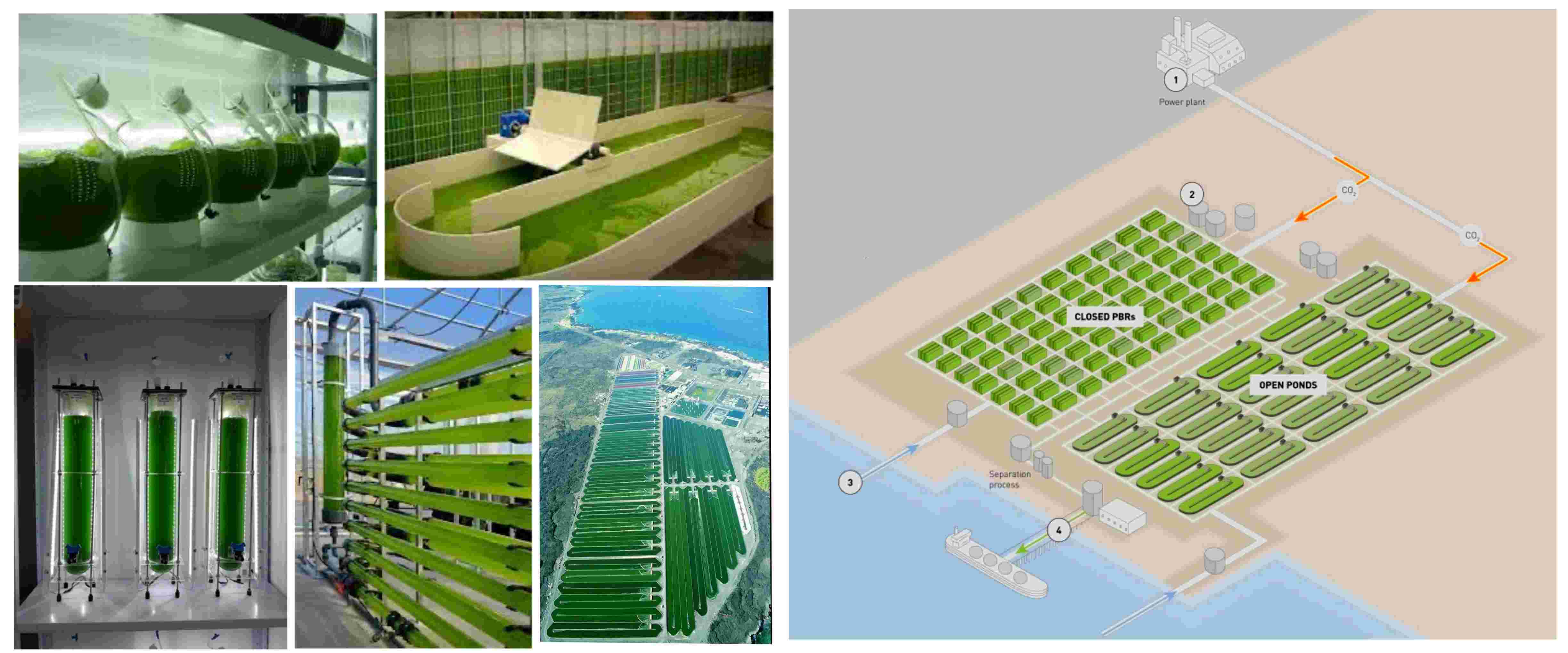

Each type of bioreactor has its own advantages and disadvantages in terms of efficiency, productivity and production costs.

The choice of bioreactor type will depend on the type of microalgae to be cultured, the objective of the culture and the resources available for production:

-

Stirred tank bioreactors: these are the most common bioreactors and consist of a tank with agitation to keep the microalgae in suspension and supply air and nutrients.

-

Tubes: use transparent tubes or columns that allow light to pass through for photosynthesis and gentle agitation to keep the microalgae in suspension.

-

Membrane: they use semi-permeable membranes that allow the exchange of gases and nutrients, and keep the microalgae in suspension.

-

Flat plate: they consist of a flat plate with channels that supply nutrients and air to the microalgae, and allow gas exchange.

Bioreactors are closed and controlled systems used to produce microalgae on a small and medium scale, while microalgae macroculture refers to the large-scale production of microalgae in ponds or open-air lagoons.

Several factors, such as light, temperature, nutrient concentration and pH, can be controlled and adjusted to optimize microalgae production. In addition, bioreactors offer the possibility to produce microalgae all year round, regardless of weather conditions.

In summary, bioreactors are ideal for controlled, small-scale production of microalgae, while open-air macroculture is more suitable for large-scale, low-cost production, although it is subject to greater environmental risks and challenges.

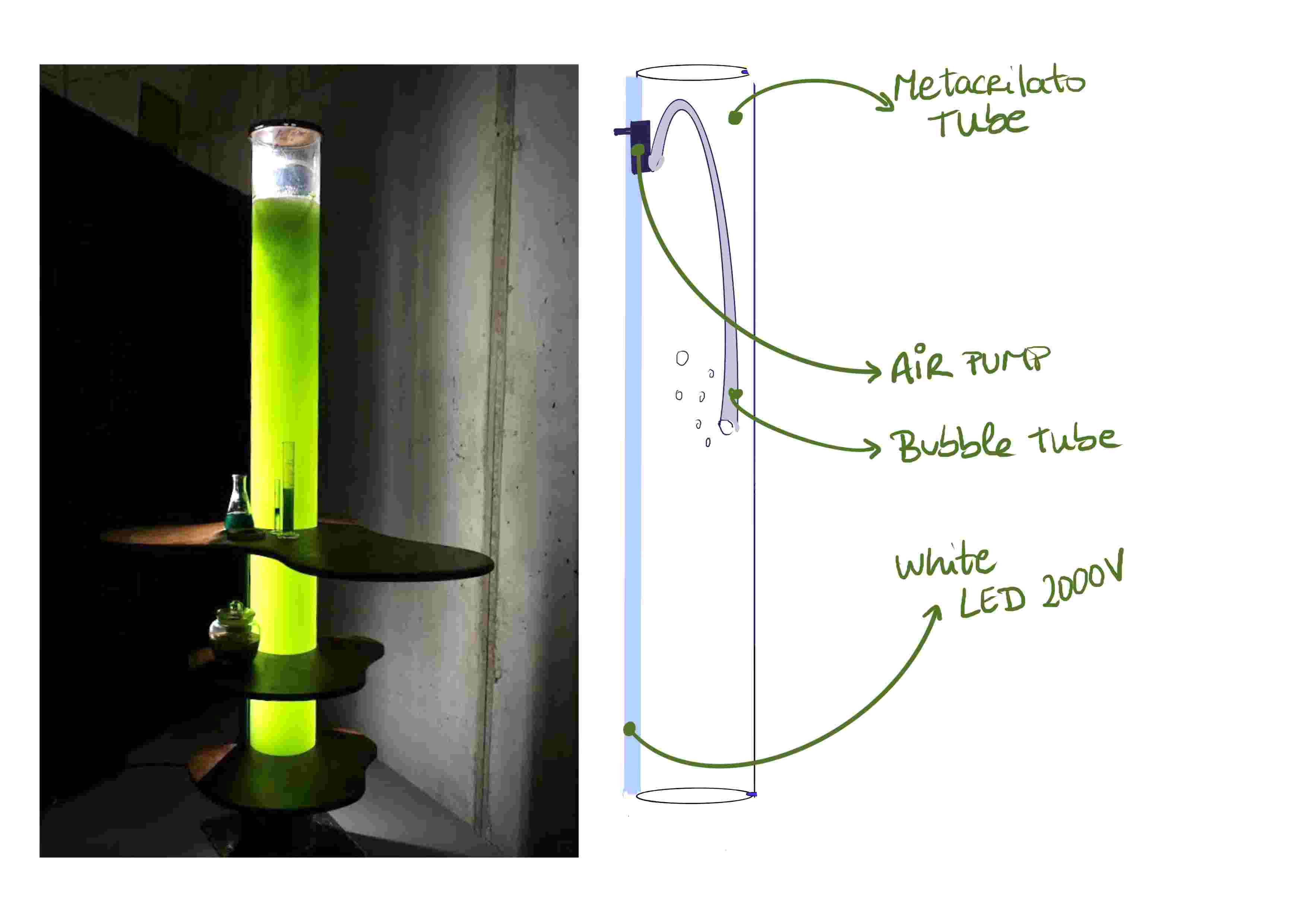

BmLab Bioreactor¶

The tube I bought for my lab is a methacrylate tube 2 meters high and 200cm in diameter. You can fill up to 60 liters, that means you can grow large amounts of biomass.

In my case, I got the tube in a plastic store that was on clearance, but on the internet there are several stores where you can get the tube.

If you want to build a domestic laboratory like BiomassLab, it is important that the tube has the same dimensions, because being a smaller scale, the production, nutrients and biomass will be very different amounts.

Growing¶

Try 1 (FAILED)¶

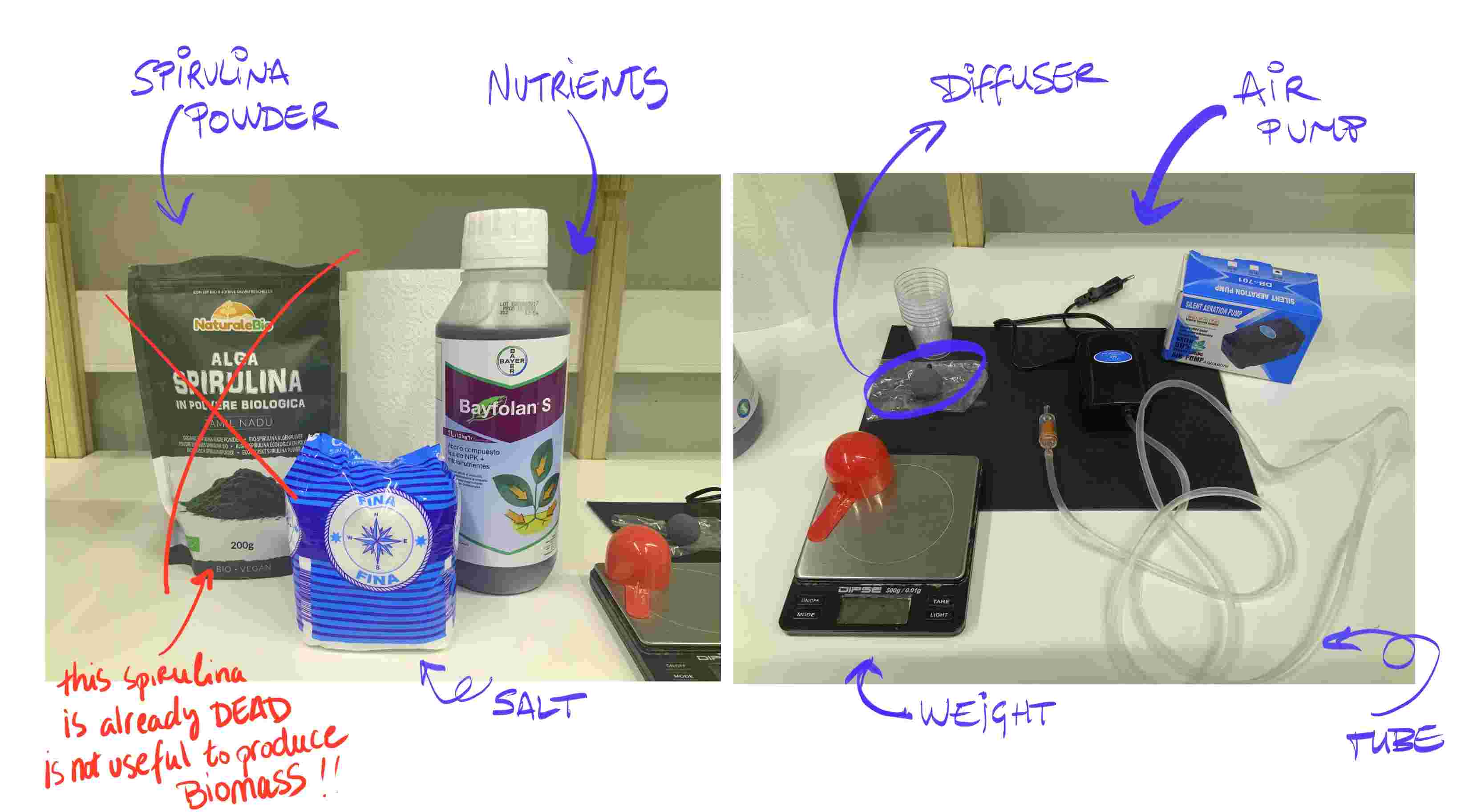

- Materials

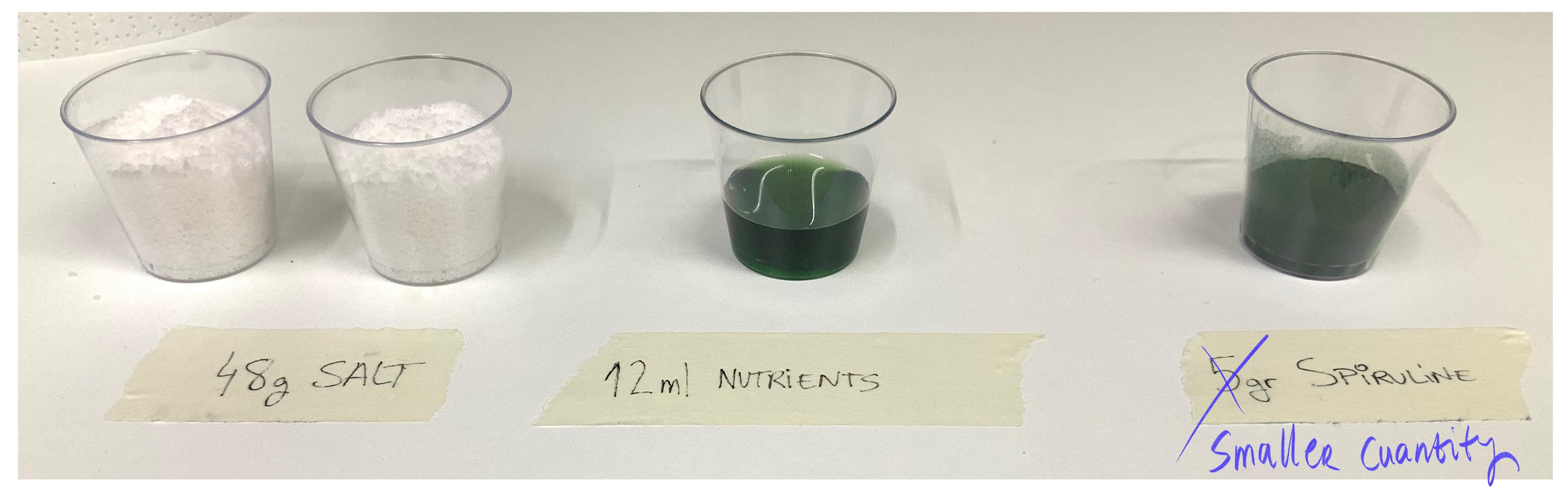

- Production

I introduce this video to visualize the processes better, but this first attempt DOESN'T WORK. I have started this project from the unknown and I have been experimenting the crops while I was being formed.

The only thing that happened here is that the water will start to decompose from being in contact with the air. The bagged spirulina I used is already harvested and dried, which has no live microorganisms to help reactivate the culture as a strain.

After two weeks of waiting for something to happen, the only thing I noticed was that the water gave off a bad smell. There was also no sign of mass as the water did not solidify at all (this can be seen by the lowering of the surface, so it is advisable to mark the measurement at the beginning of the process).

I see interesting to show the mistakes for those who are also starting with the world of microalgae because we could fall into the same confusions.

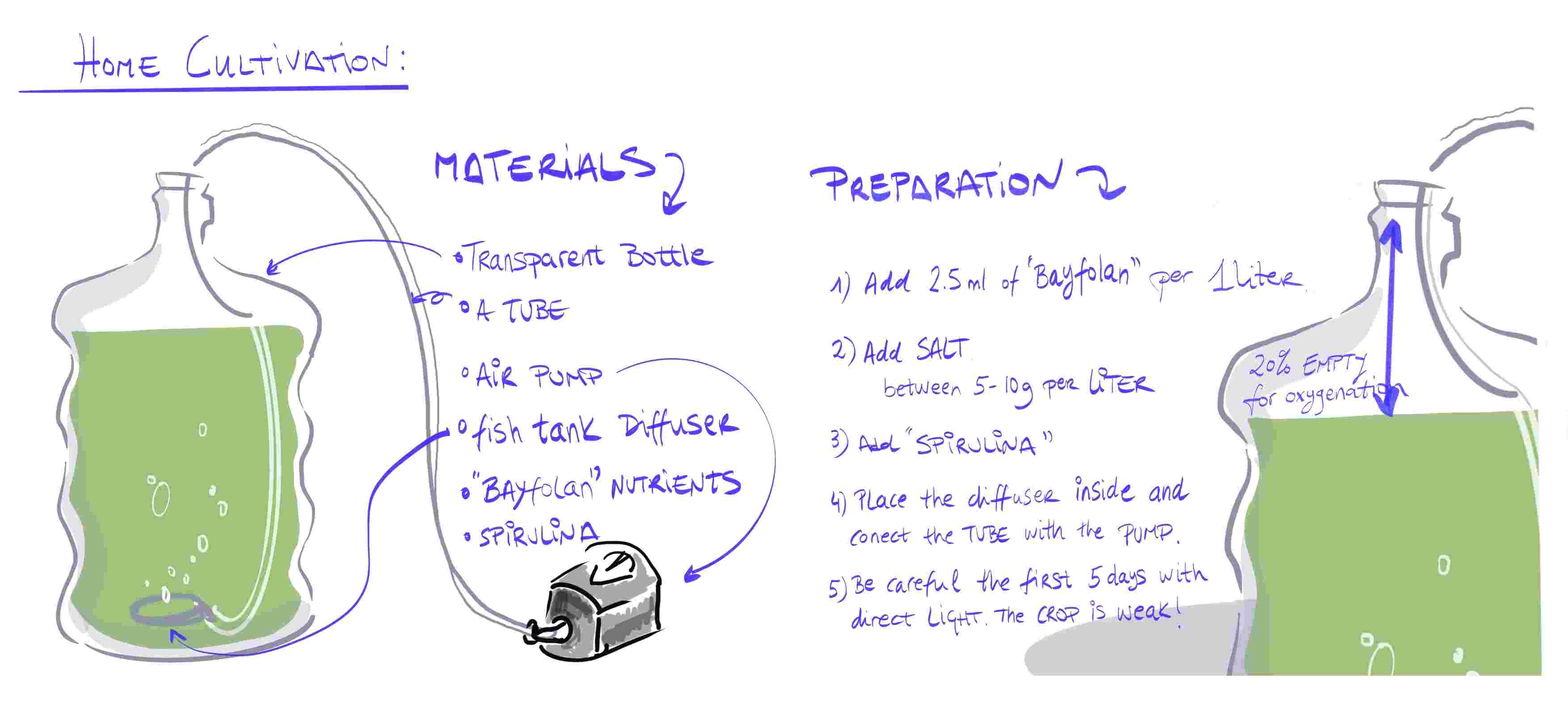

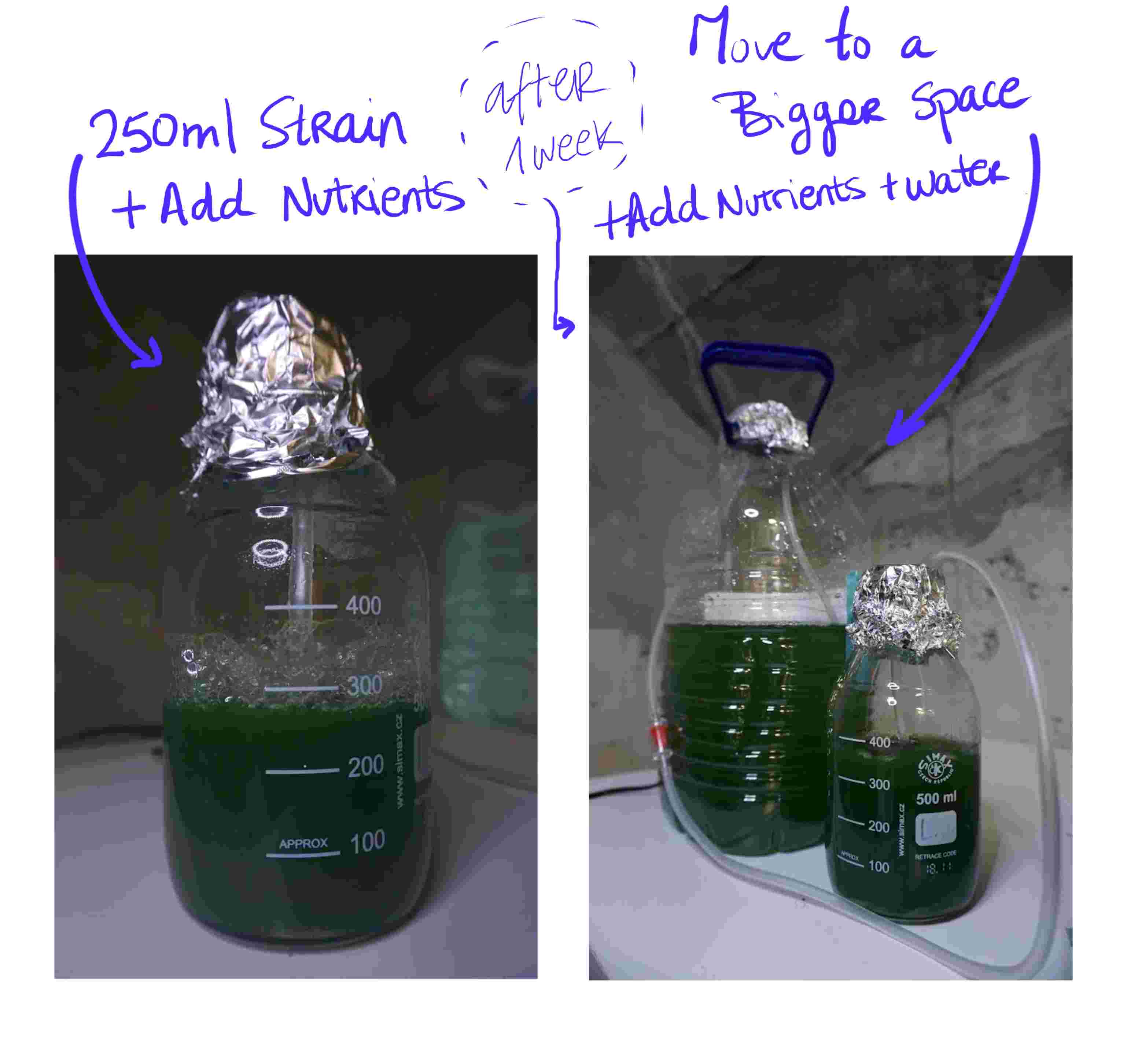

Try 2 (Successful)¶

Get Live Strain¶

In my case, I have been able to contact a macro culture company here in the Basque Country Algaloop. Nowadays you can find everything on the internet and for sure you will find a way to get the fresh biomass.

Here is a link to a store in Barcelona that ships a strain:

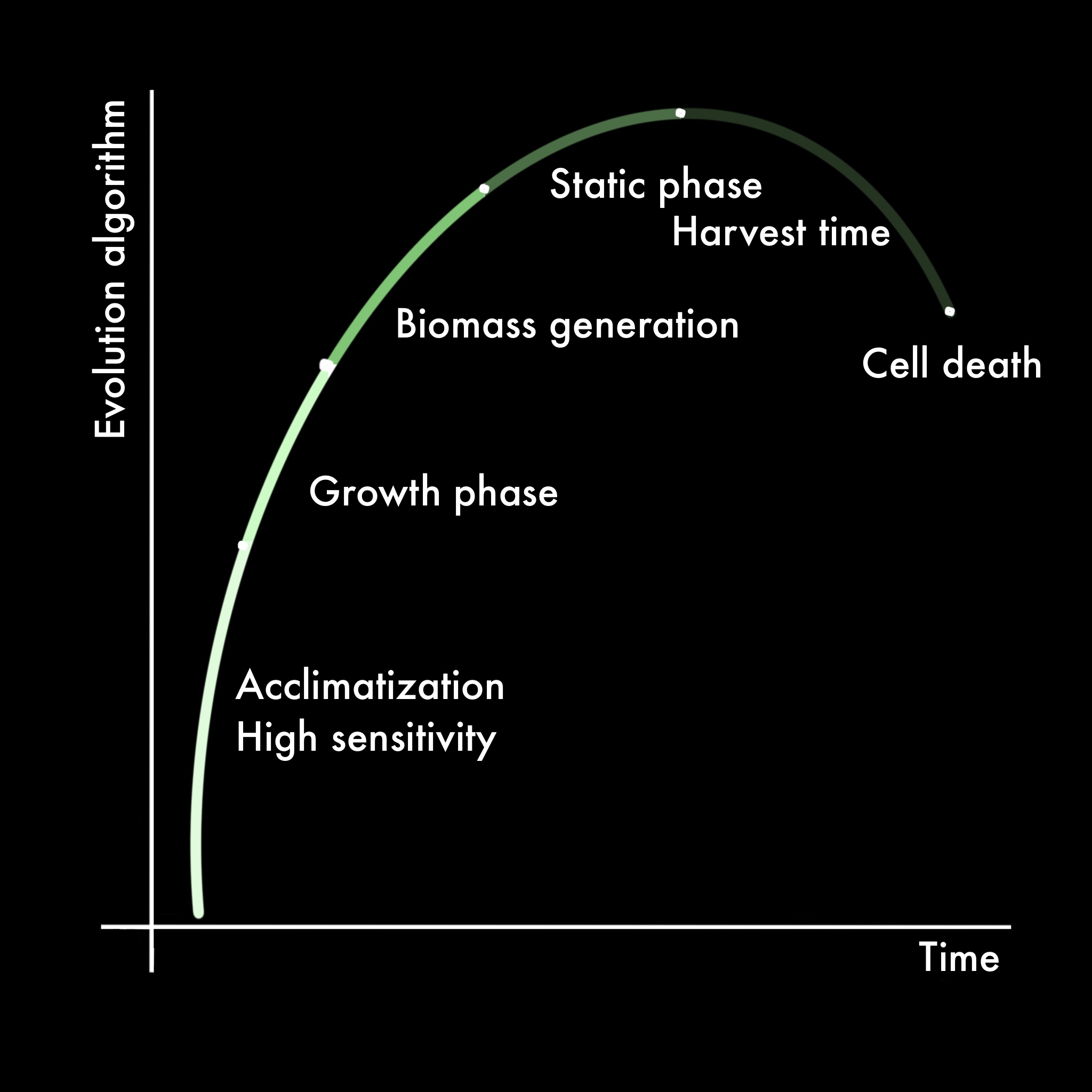

This is the process of 20 days of growth.

Ilumination¶

Light is the first limiting factor in microalgae cultivation.

For the mechanism to work, certain conditions must be respected, especially the supply of carbon dioxide (CO2), water (H2O) and light.

This combination will allow the chloroplasts to transform these elements into energy in the form of carbohydrates (nutrients necessary for the development of microalgae).

Several elements must be taken into account when controlling light:

-

Radiation: the adjustment of light intensity is of particular importance, if not enough light is provided, development is slowed down. On the other hand, if they receive too much light, they will be photoinhibited.

-

Cycles: some microalgae require more light than others. Therefore, their development will depend on the season of the year. By using artificial light, this obstacle is overcome and can be regulated according to the nyctemeral rhythm (day/night) and provide a continuous light source with an adapted spectrum.

-

The light spectrum is defined by the wavelengths of the light emitted. Adaptation of the spectrum makes it possible to optimize the growth of certain microalgae.

-

Access to light: it is important that microalgae receive light homogeneously. These microorganisms have a tendency to create self-shading, which reduces access to light from their neighbors. To avoid this phenomenon, good hydrodynamism is important.

Nutrients¶

Jordan's nutrients are a commonly used culture medium for the cultivation of microalgae, especially Spirulina. This culture medium was developed by the researcher Robert Jordan and contains the following nutrients:

- Sodium bicarbonate 5.88g/L

- Phosphate trisodium 0.165g/L

- Sodium nitrate 0.921g/L

- Magnesium sulfate 0.070 g/L

- Iron Sulfate 0.004g/L

- Sodium chloride 2g/L

Agitation¶

The Agitation llows for an even distribution of nutrients and gases in the culture medium, which can increase the growth rate and biomass production. In addition, agitation also helps prevent sedimentation of the microalgae at the bottom of the culture and the formation of biofilms on the surface of the medium.

It is important to note that overly intense agitation can damage the microalgae cells and decrease the growth rate.

PH¶

The pH is a critical factor in spirulina cultivation, as it affects the growth rate, biochemical composition and quality of the biomass produced. Spirulina is typically grown in a pH range of 8.0 to 10.5, with the optimum pH for spirulina growth being around 9.0 to 9.5.

The pH can be controlled by adding alkalizing agents such as sodium carbonate (Na2CO3) or sodium bicarbonate (NaHCO3) to the culture medium. If the pH is too low, a small amount of citric acid or acetic acid can be added to lower the pH.

It is important to monitor the pH of the spirulina culture constantly, as abrupt changes in pH can negatively affect the growth rate of spirulina and the quality of the biomass produced. It is also important to keep in mind that spirulina is sensitive to bacterial contamination, so it is necessary to maintain the pH of the culture medium within the appropriate range to avoid the proliferation of undesirable bacteria.

Filtration¶

Spirulina can be filtered using a variety of methods, depending on the scale of production and the desired end product. Here are some of the most common filtration methods for spirulina:

-

Microfiltration: This method uses a membrane with small pores to filter out impurities and separate the spirulina cells from the culture medium. Microfiltration is often used for large-scale production of spirulina and can result in a highly purified product.

-

Centrifugation: This method uses a high-speed centrifuge to separate the spirulina cells from the culture medium. The cells are then washed and dried to produce a concentrated product. Centrifugation is often used for small-scale production of spirulina.

-

Sedimentation: This method involves allowing the spirulina cells to settle to the bottom of a container and then decanting the supernatant. This process can be repeated multiple times to remove impurities and obtain a more concentrated product.

-

Flocculation: This method involves adding a flocculant (such as calcium carbonate or chitosan) to the spirulina culture to cause the cells to clump together. The clumps can then be filtered out and washed to produce a purified product.

Overall, the filtration method used for spirulina will depend on factors such as the scale of production, the desired end product, and the available equipment and resources. Regardless of the method used, it's important to ensure that the spirulina is filtered and purified effectively to remove any impurities and contaminants.

Biomass¶

For a more detailed and complete information, Domestic Biomass will be a separate title in this documentation because of its multiple properties and possibilities. there you can read information about:

-

Biomaterials

-

Food

-

Cosmetics

-

Pigments

Clik Here to know more about all the posibilities and benefits that have growing biomass at home.

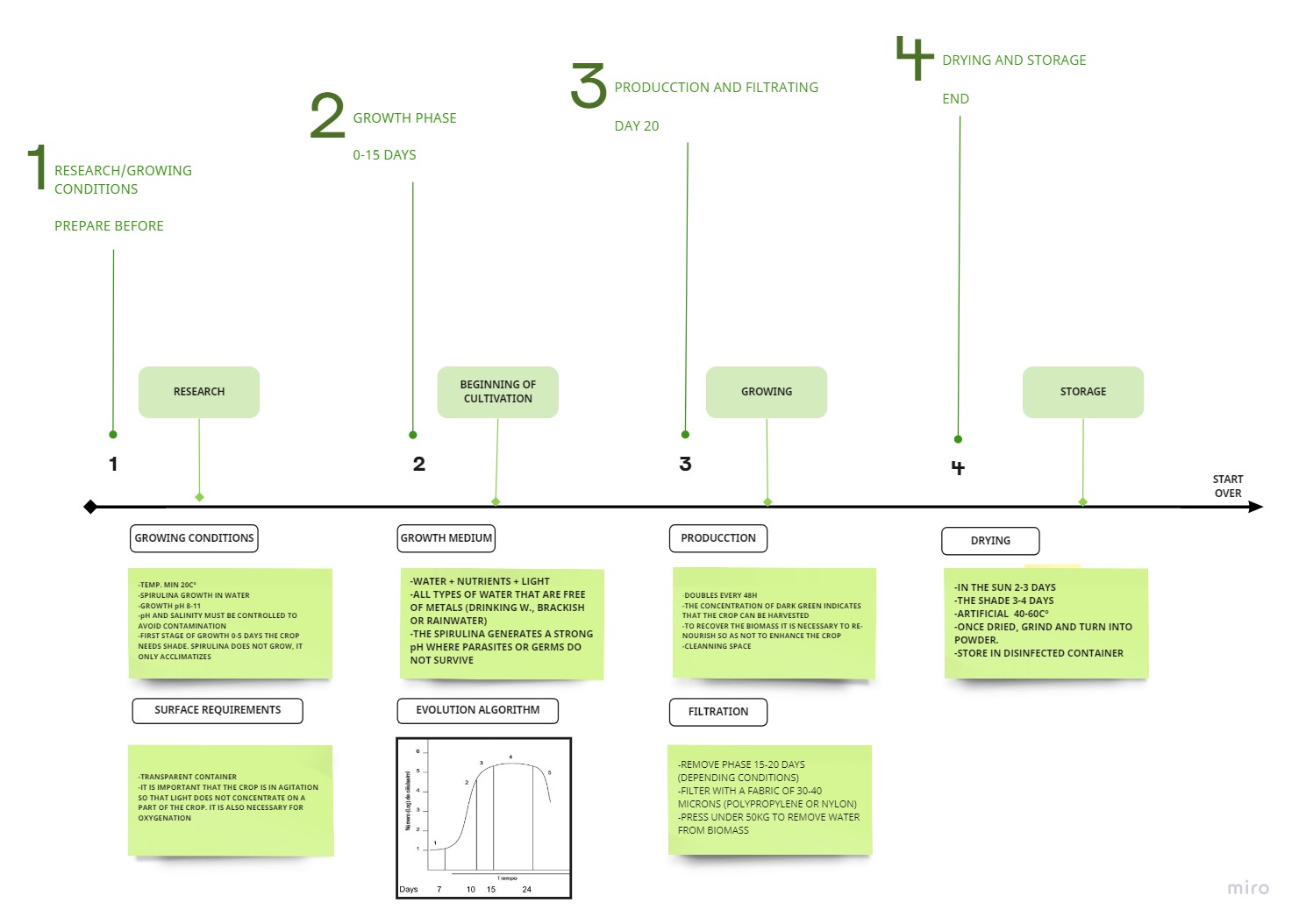

DEVELOPMENT¶

Below I show its gowth development of spirulina. It is necessary to follow the times and take into account all aspects mentioned above to have a successful crop. In the same way, It is also necessary to compile the processes and investigations of the times in order to know their evolution.