12. Soft robotics¶

ARTIFICIAL MUSCLES¶

Picture taked by engadget

Picture taked by engadget

Artificial muscles are the core components of the smart and interactive soft robotic systems, providing the capabilities in shape morphing, manipulation, and mobility. The domain of soft robotics is forming as a new frontier of kinetic designing. Not only creating many new possibilities for robotics but also in architecture, design and art. Challenging conventional design this experiments suggest soft responsive.

This week has been very interesting. All the theory that Adriana Cabrera and Lily Chambers have given us has been awesoome. The soft robotics provides many possibilities as I indicated above which can be played/used in many areas thanks to technology. Apart from the movement, taking into account everything we have been experiencing in the previous weeks, thanks to 3D printing, laser cutting, different novel materials and others, the imagination is immense to create what you want. Read on to see what I've worked on this subject :)

REFERENCES & INSPIRATION¶

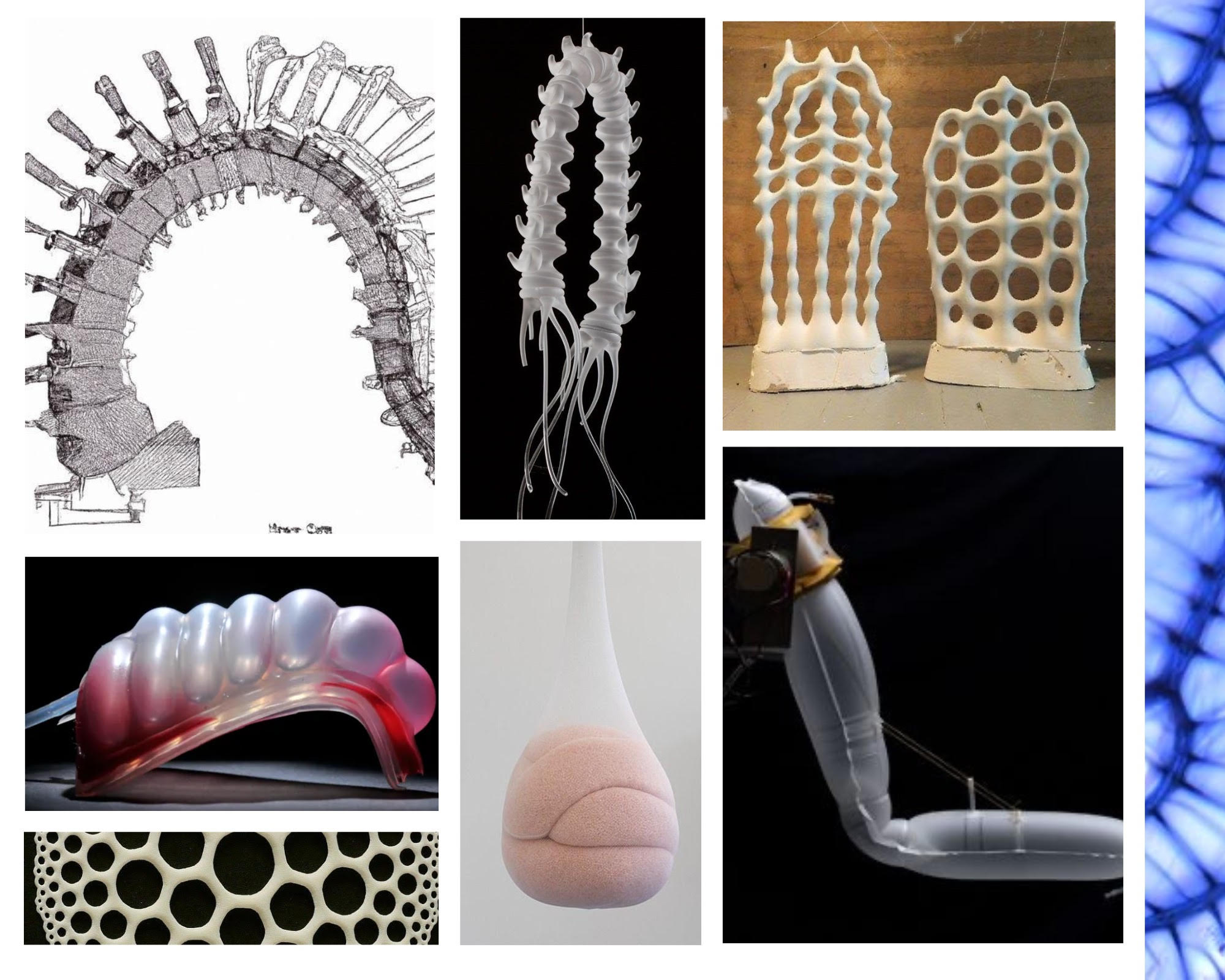

collage made by canvas

collage made by canvas

OpenAI / NARCOSE / Ernst Haeckel / Mike Goodlett / Furl

Weekly inspo Folder

Lucy and Bart

LucyandBart are an artist duo formed between Lucy McRae and Bart Hess, both art directors and innovation consultants. They share a fascination with genetic manipulation and beauty expression. Unconsciously their work touches upon these themes, however it is not their intention to communicate this. They work in a primitive and limitless way creating future human shapes, blindly discovering low–tech prosthetic ways for human enhancement.

Pleaseeee check this Ted talk to know their work and freak out everything that art and technology can flow in the body!

Francois Mangion and Becky Zhang

Furl Combines Electroencephalography (EEG) with advances in soft silicone casting of “air muscles”. EEG allows sensing of human brain functioning so that our environments begin moving and responding to our very thoughts. The designed components have a wide palette of deformation patterns of inflation.

CERO9

GOD! Super interesting the work and arquitecture of CERO9. Cristina Diaz Moreno and Efrén Gª Grinda they are directors and founders of the internationally recognized studio. Amid.cero9 was founded in 1997. They investigate the intersections between architecture, culture and nature. They combine conceptual constructive precision and spatial nature creating new and impressive buildings of great beauty. Have a look at their website for more inspiration.

GRASSHOPPER

It let's you simulate unconstraint particles, fluids, rigid and soft bodies, textile and spring system, inflatables and a combination of all these materials in one scene at unparalleled speed. DOWNLOAD FLEXHOPPER

FABRICADEMY STUDENTS

PROCESS¶

WEEK KEY:

-

Biomimicry

-

Locomotion

-

Pneumatics

-

Flexures

-

Molding and casting

Inspirational works and highlights from the Soft Robotics lecture by Andriana Cabrera and Lily Chambers.

Inspirational works and highlights from the Soft Robotics lecture by Andriana Cabrera and Lily Chambers.

FLUFLI EXCERCISE¶

INFLATABLES WITH BAKING PAPER¶

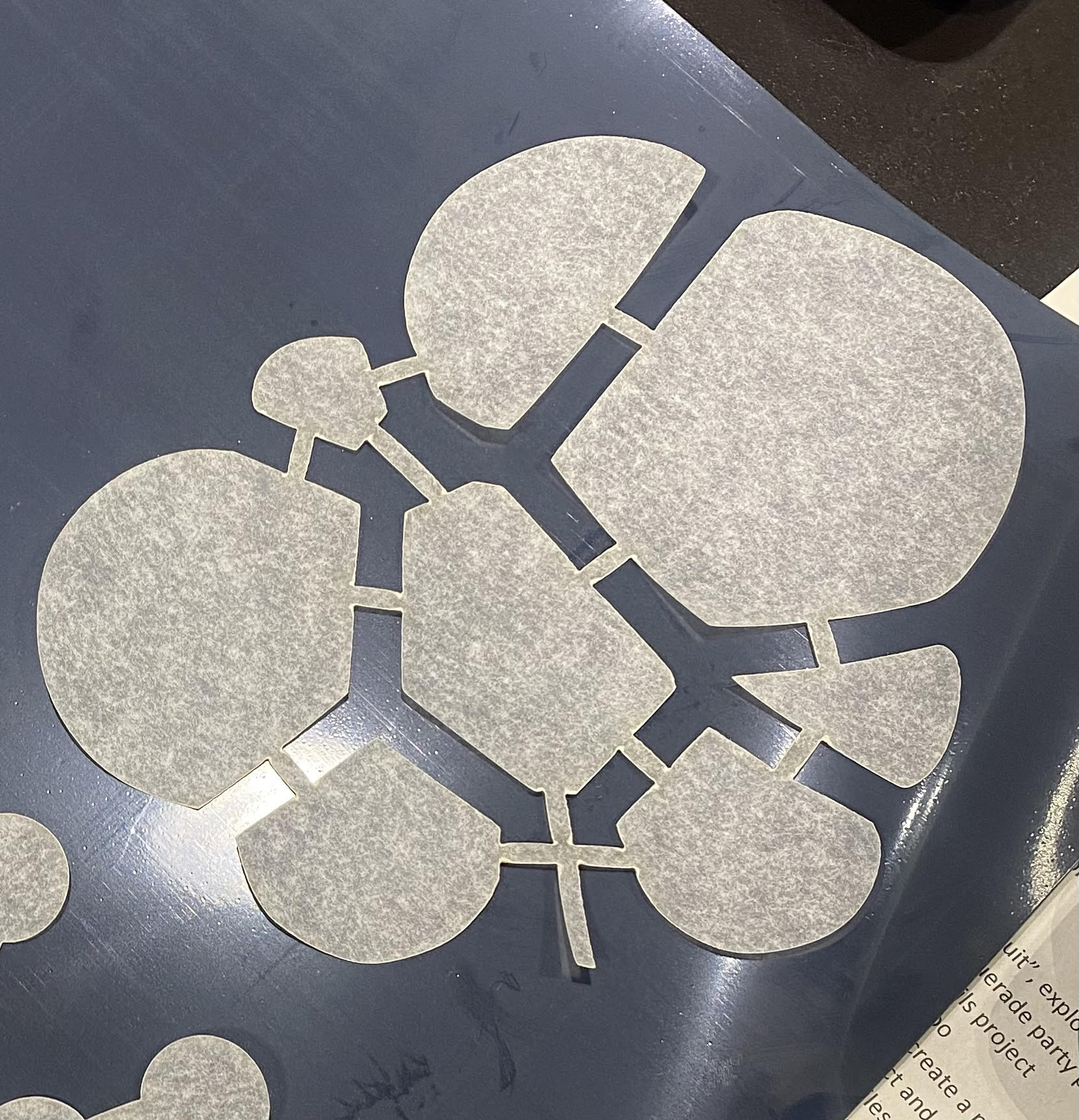

LASER CUTTING¶

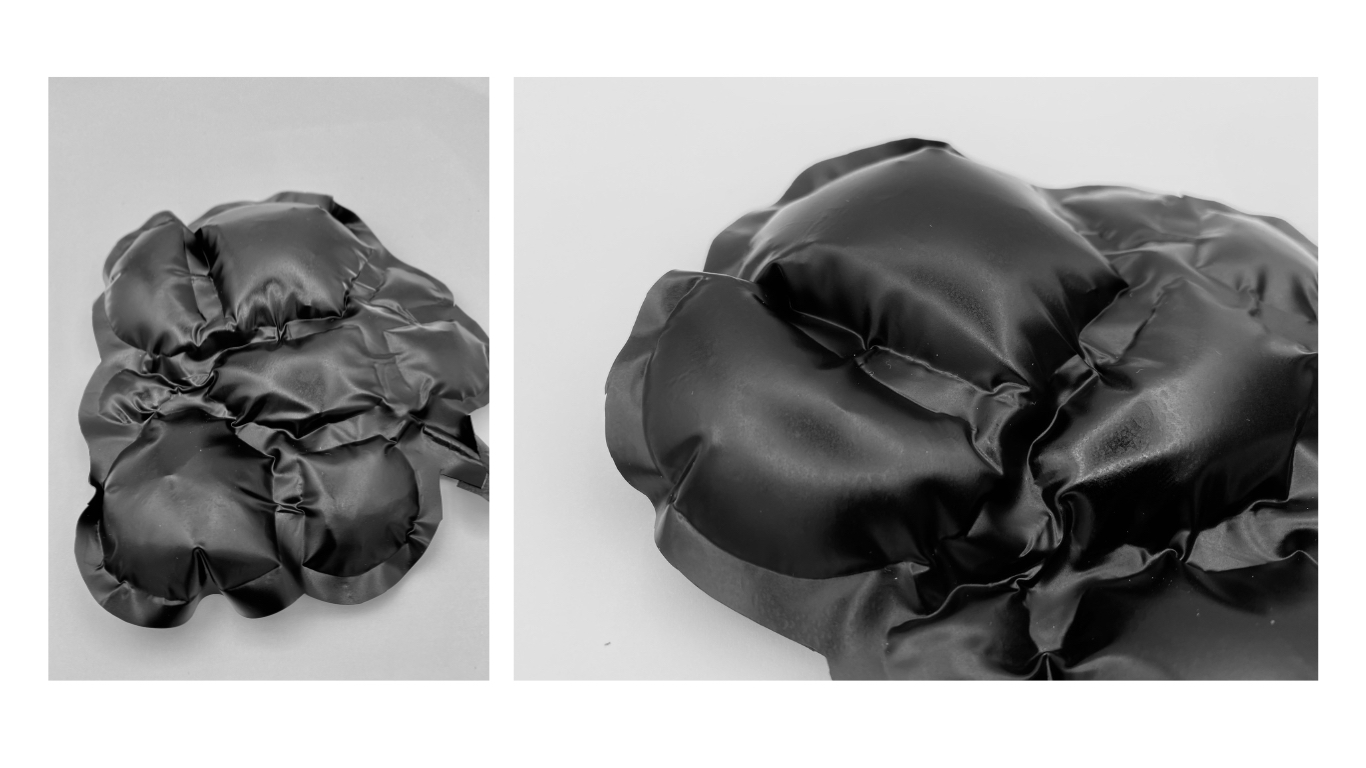

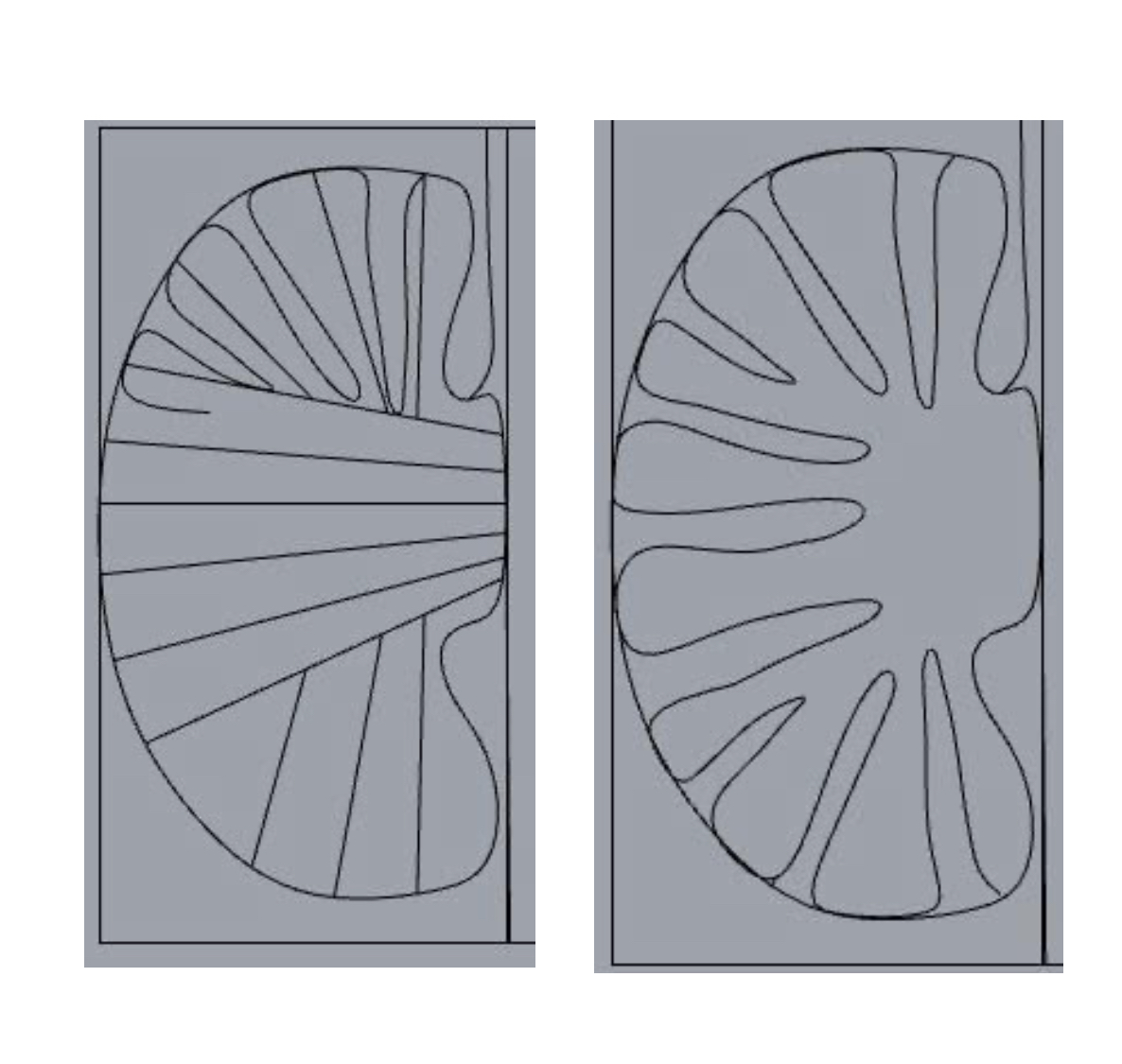

This first inflatable is designed in rhinoceros. One of the priorities required by this subject is the knowledge and practice of this software. I didn´t want to complicate alot with this design, the intention has been to create a bubbling that with the air could be inflated. The outer material is black which it difficults a little to see when it swells.

Inside the plastic is the baking paper that prevents the black plastic stick so the air could pass.

This first inflatable is designed in rhinoceros. One of the priorities required by this subject is the knowledge and practice of this software. I didn´t want to complicate alot with this design, the intention has been to create a bubbling that with the air could be inflated. The outer material is black which it difficults a little to see when it swells.

Inside the plastic is the baking paper that prevents the black plastic stick so the air could pass.

The baking paper has been laser cut with the following characteristics:

| SPEED(mm/s) | MIN/MAX POWER% |

|---|---|

| 150 | 20-24 |

Once the paper is cut, we will have to paste it with vinyl paper. With a little heat and patience, it will finally stick to those pieces where there is no baking paper. In this way, the baking paper will create holes where the air passes through and inflates.

INFLATABLES WITH SILICONE¶

3D DESIGN¶

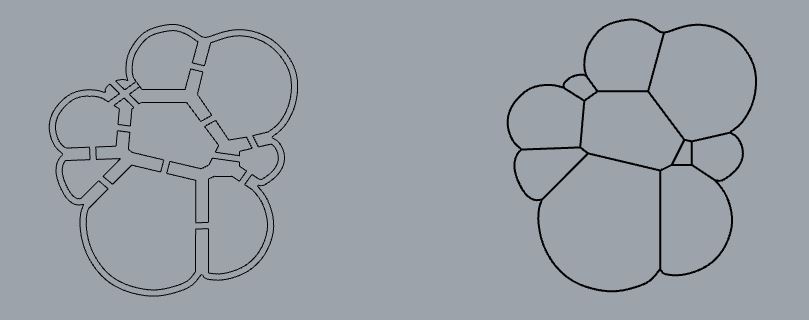

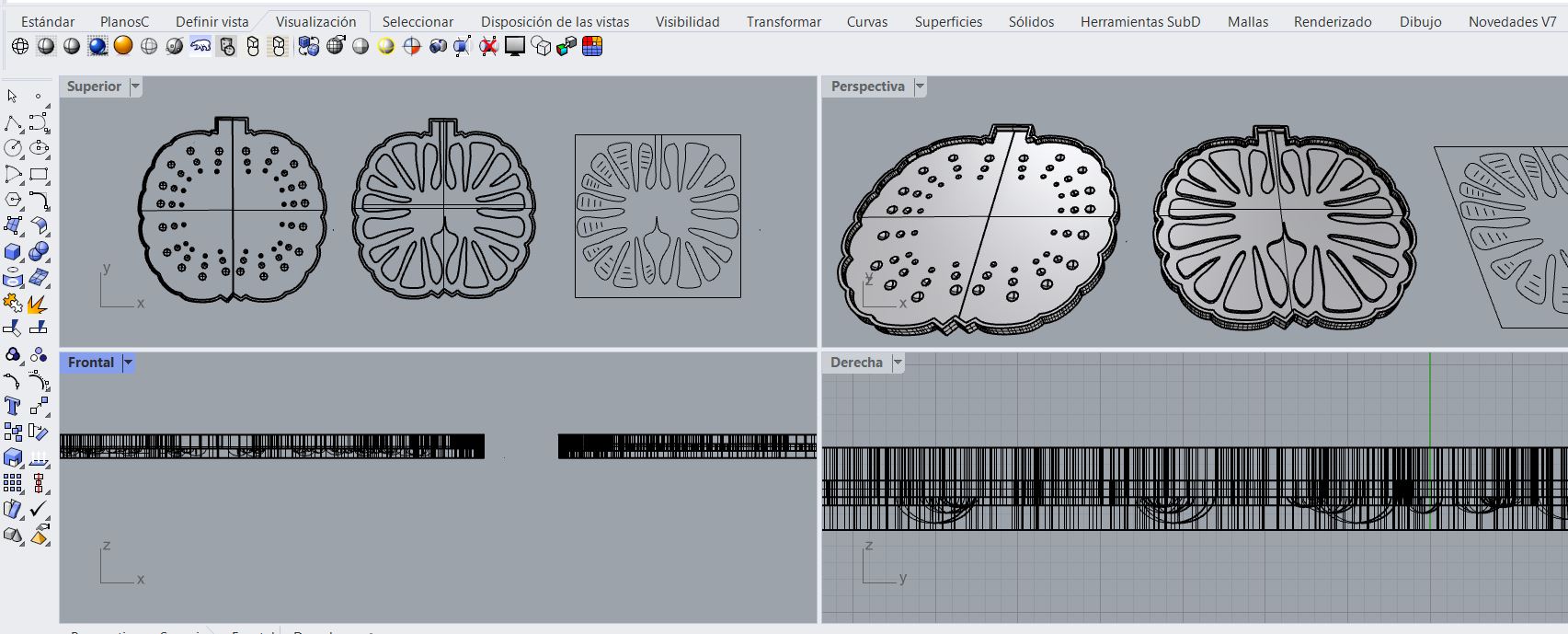

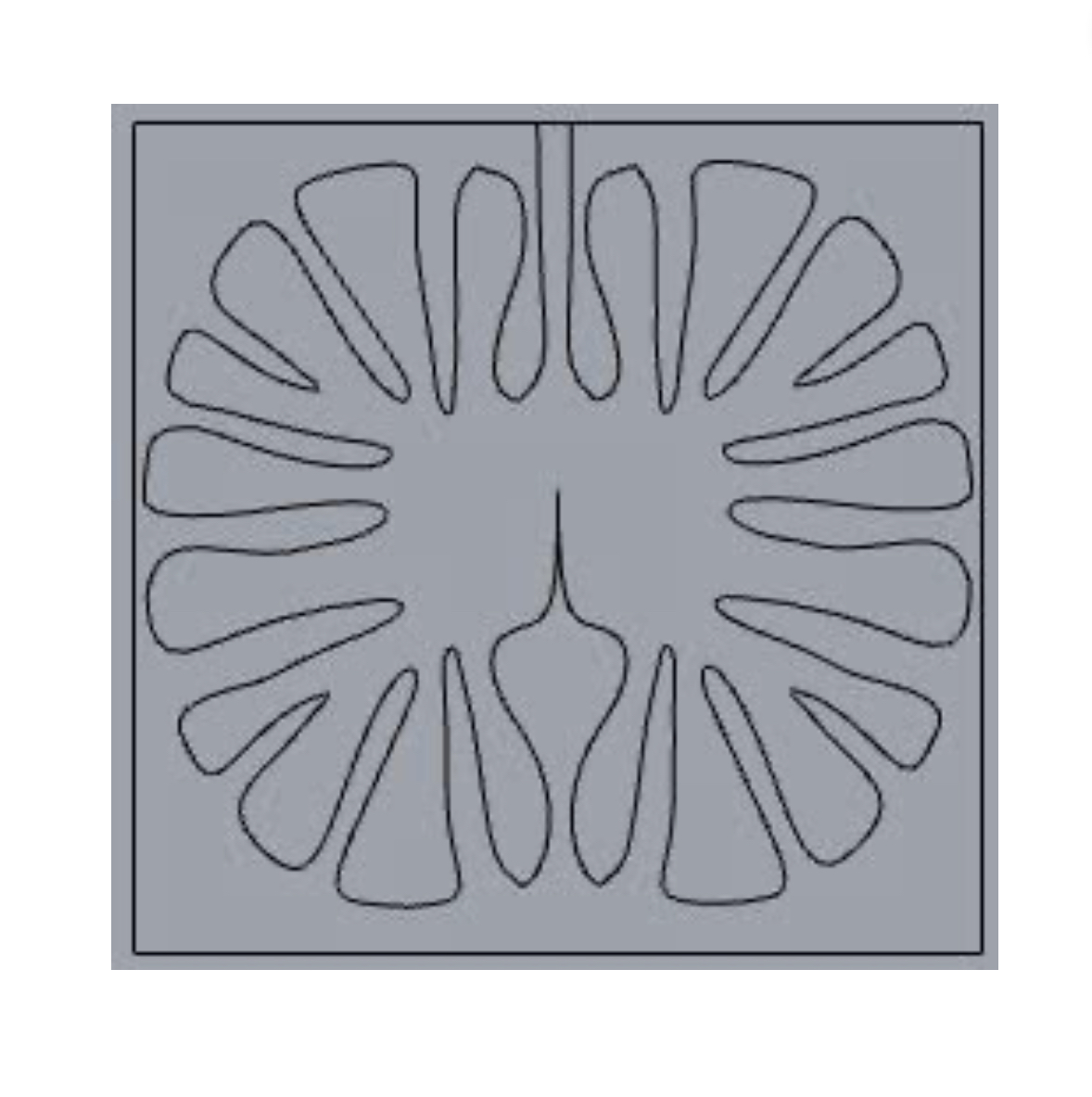

I draw the mold design in rhino symmetrically and simply. The intention has been to create a kind of puffer fish

3D PRINTING¶

| MATERIAL | LAYER HEIGHT | ECTRUDE TEMPERATURE | BED TEMPERATURE | SPEED RETRACTION | RETRACTON DISTANCE |

|---|---|---|---|---|---|

| PLA 0,2mm | 210ºC | 60ºC | 40mm/seg | 35mm/seg | 0,8mm/seg |

SILICONE MIX¶

![]() I used a silicone rubber, Ecoflex 00-30, as a molding material. It comprised of two parts of liquid. After mixing them in a 50/50 ratio by weight or volume, it will solidify in 4 hours at room temperature.

I used a silicone rubber, Ecoflex 00-30, as a molding material. It comprised of two parts of liquid. After mixing them in a 50/50 ratio by weight or volume, it will solidify in 4 hours at room temperature.

Taking advantage of all the class tools, I have also used the Vacumm Pump (bubble remover machine) in this way the silicone is clean avoiding bubbles and air leaks

This has been the result:

DOWNLOAD FILES¶

DOWNLOAD ALL DIGITAL DESIGN FILES DRIVE FOLDER

MAKE YOUR INFLATABLE AT HOME¶

I leave you this video so that you can try to get an inflatable with simple materials or give a second life to the plastic that you have at home. Simple craft to play at home and get funny inflatables. As always... let the imagination run wild!