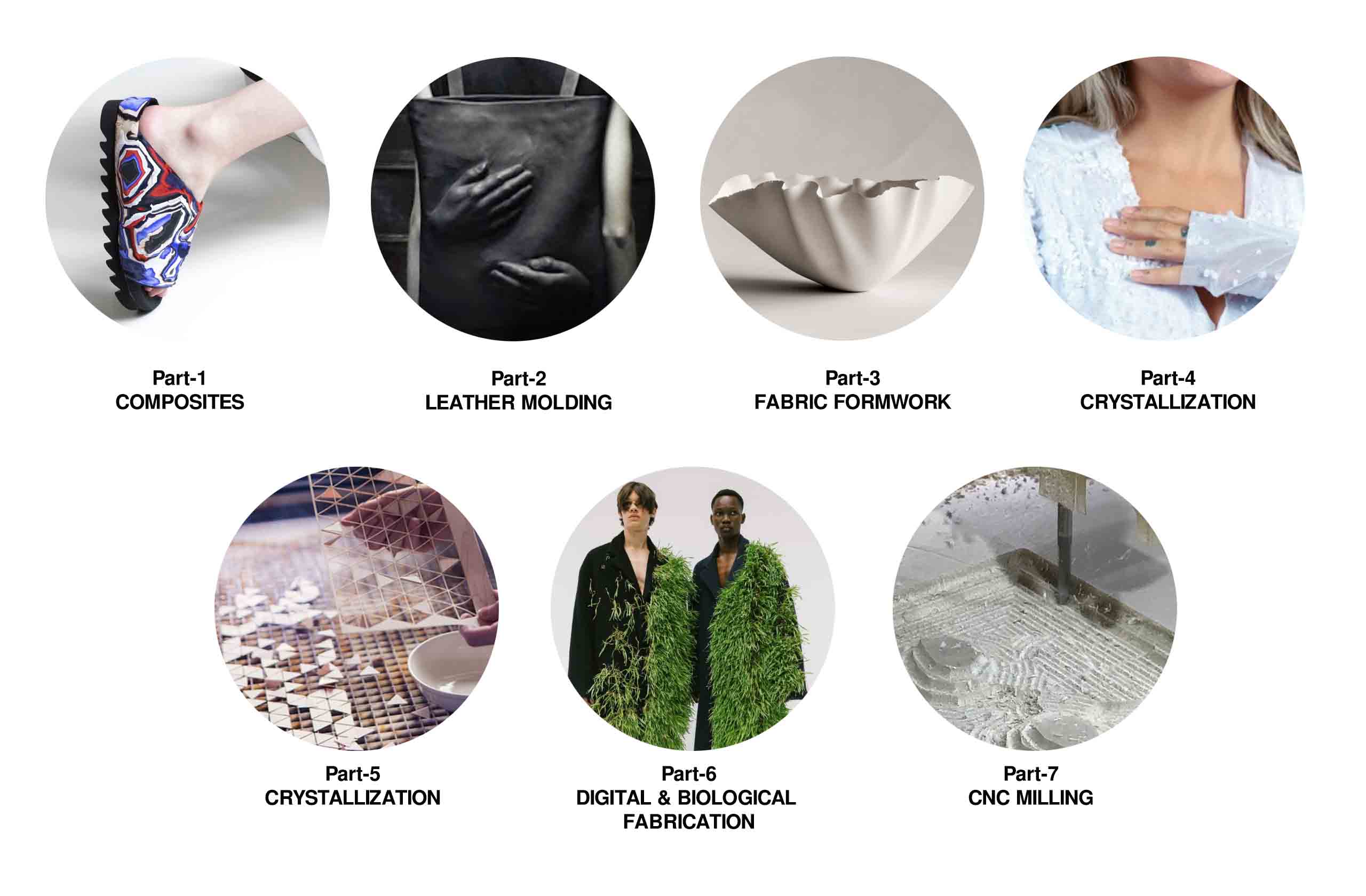

9. Textile Scaffold¶

Oh my gosh! Another exciting week has begun. I'm going to experience everything for the first time. I've never worked with crystallization, CNC, wood textiles, composites, etc. A week of learning is going to be incredibly exciting and amazing.

Based on the above, I will be focusing on a few topics because we will not have enough time to cover all of them.

Crystallization¶

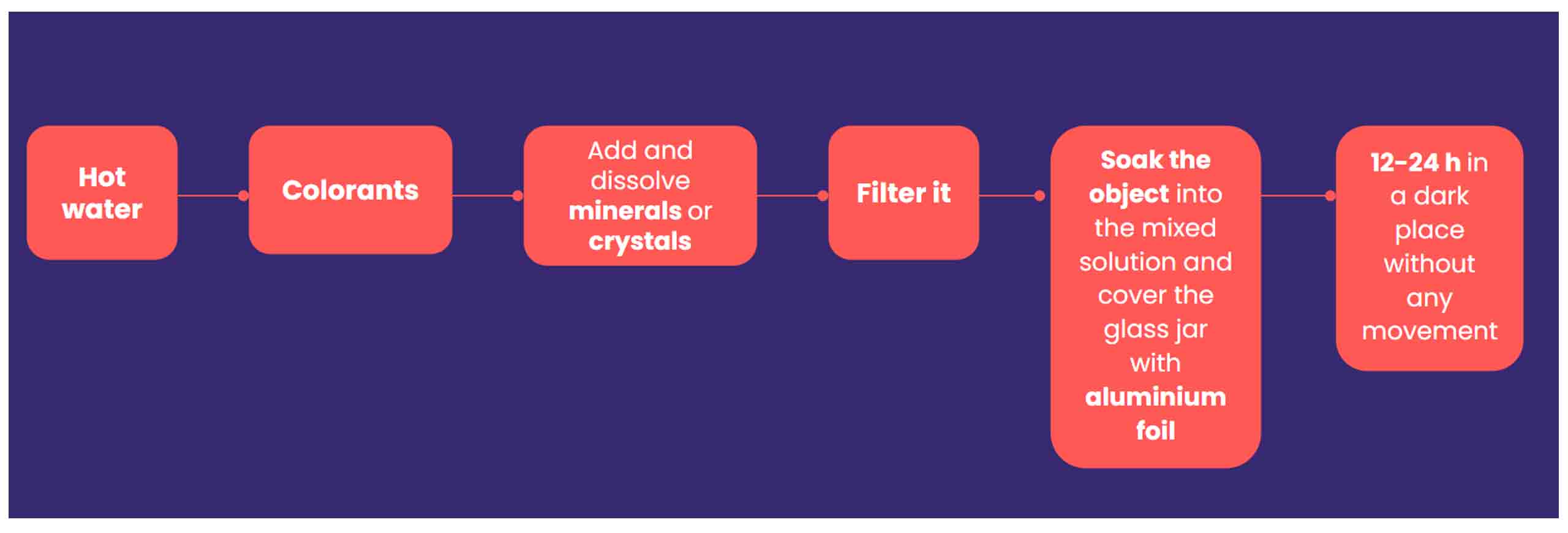

Recipe¶

Below are the Crystals and its recipes to experiment.

Process

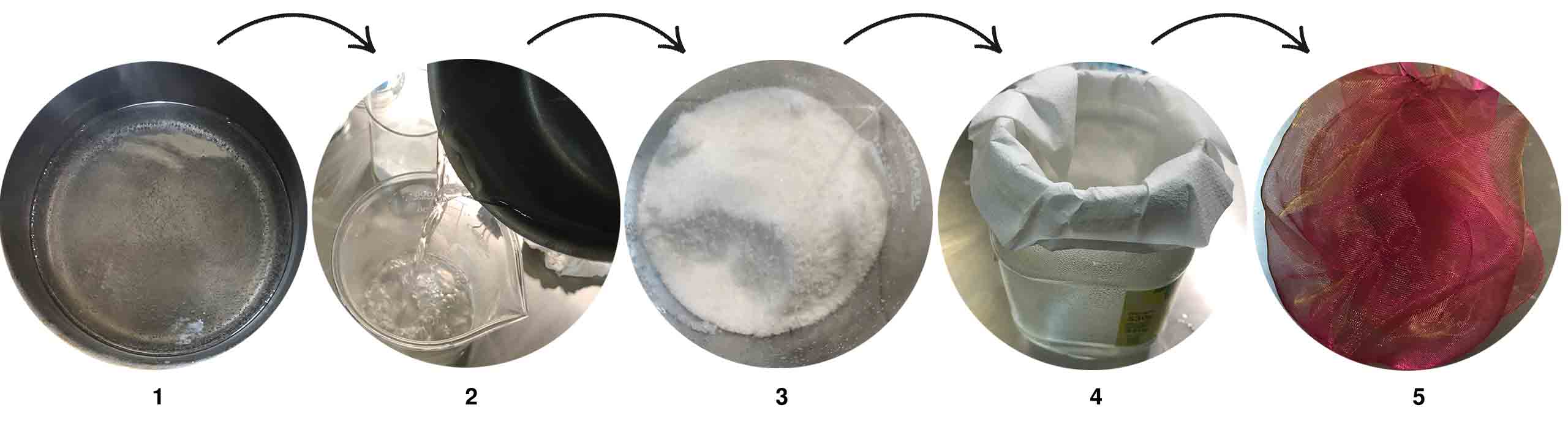

Borox Crystals with Mesh Textile¶

Borox

- Naturally occurring compound

- Laundry booster

- Soft crystals

- Dissolve in hot water

Required Materials

Borox Process

1- Take 400ml of water

2- Boil the water

3- Add and Dissolve the crystals.

4- Filter the crystallised water

5- Soak the object into the mixed solution and cover the glass jar with aluminium foil

6- 12-24 h in a dark place without any movement

Final Result

Leather Moulding¶

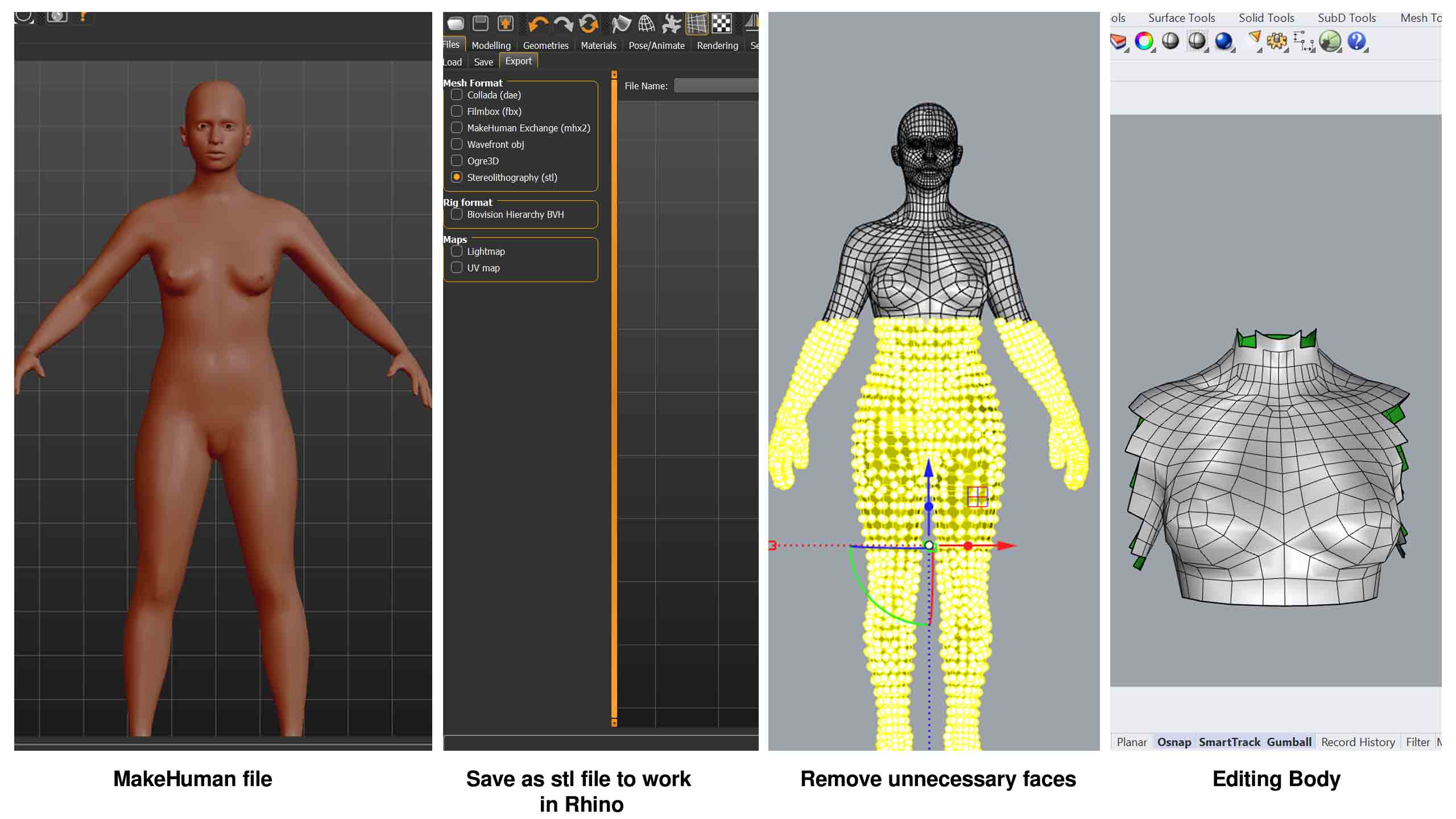

Design¶

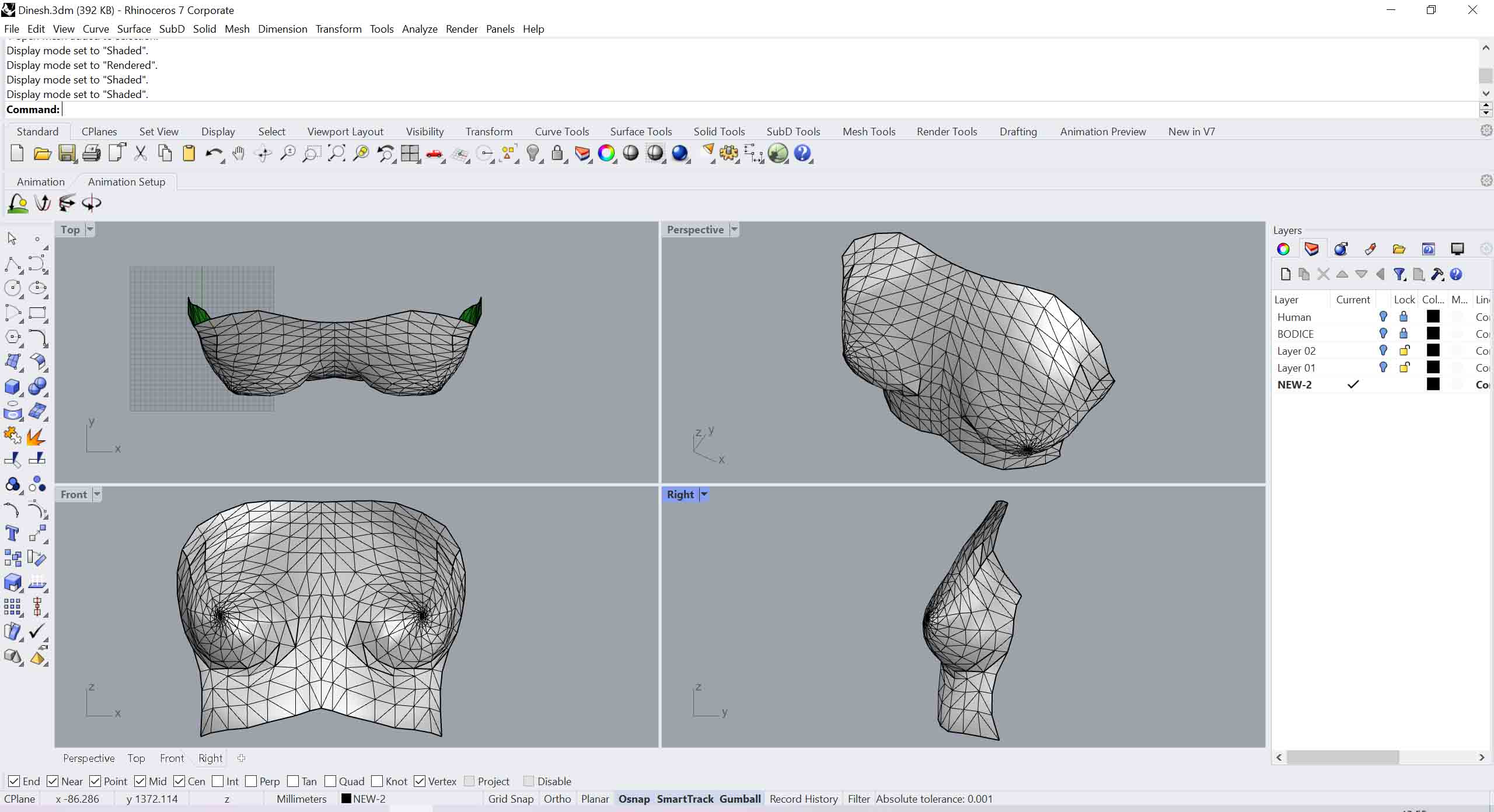

MakeHuman and Rhino process

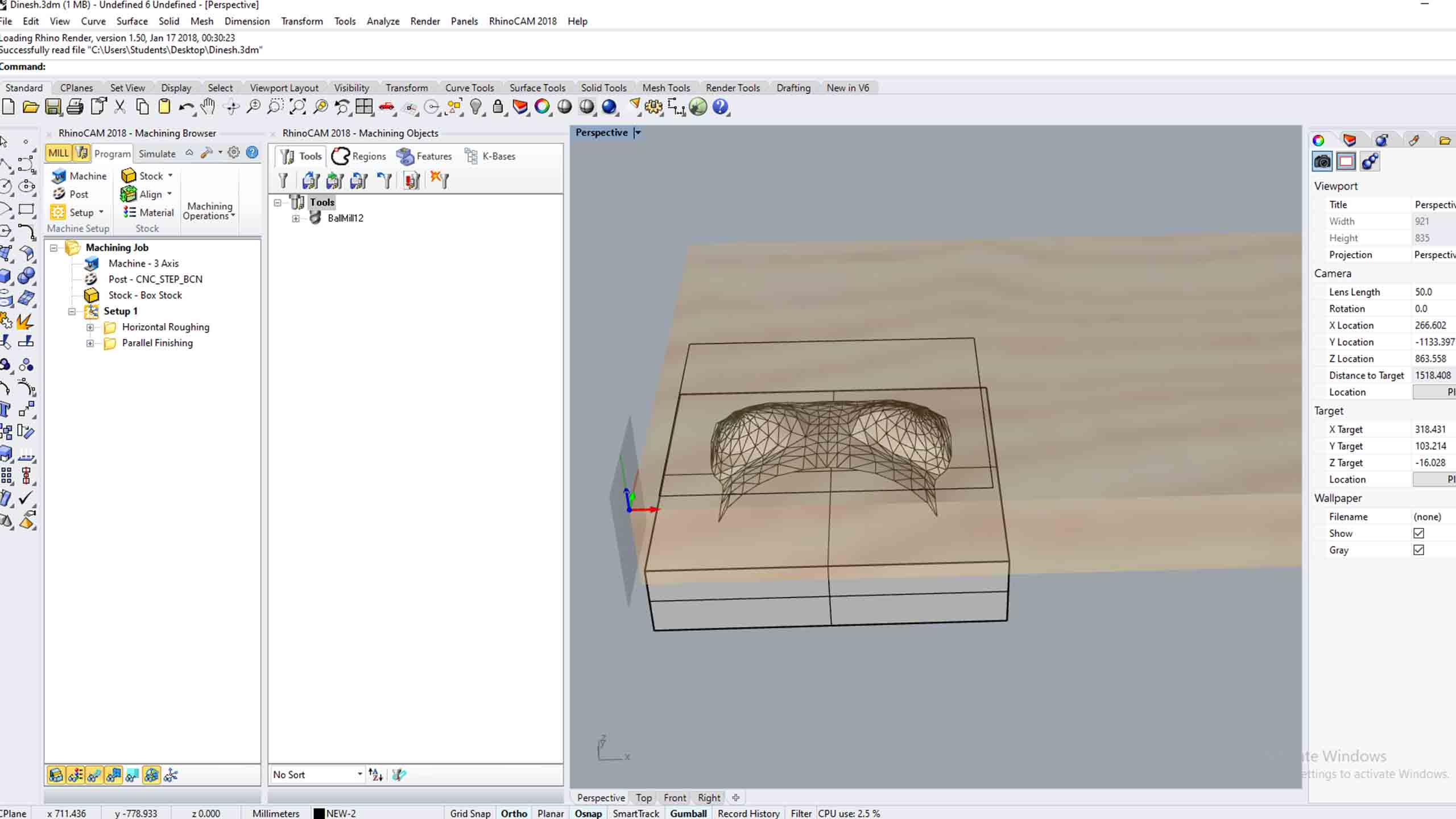

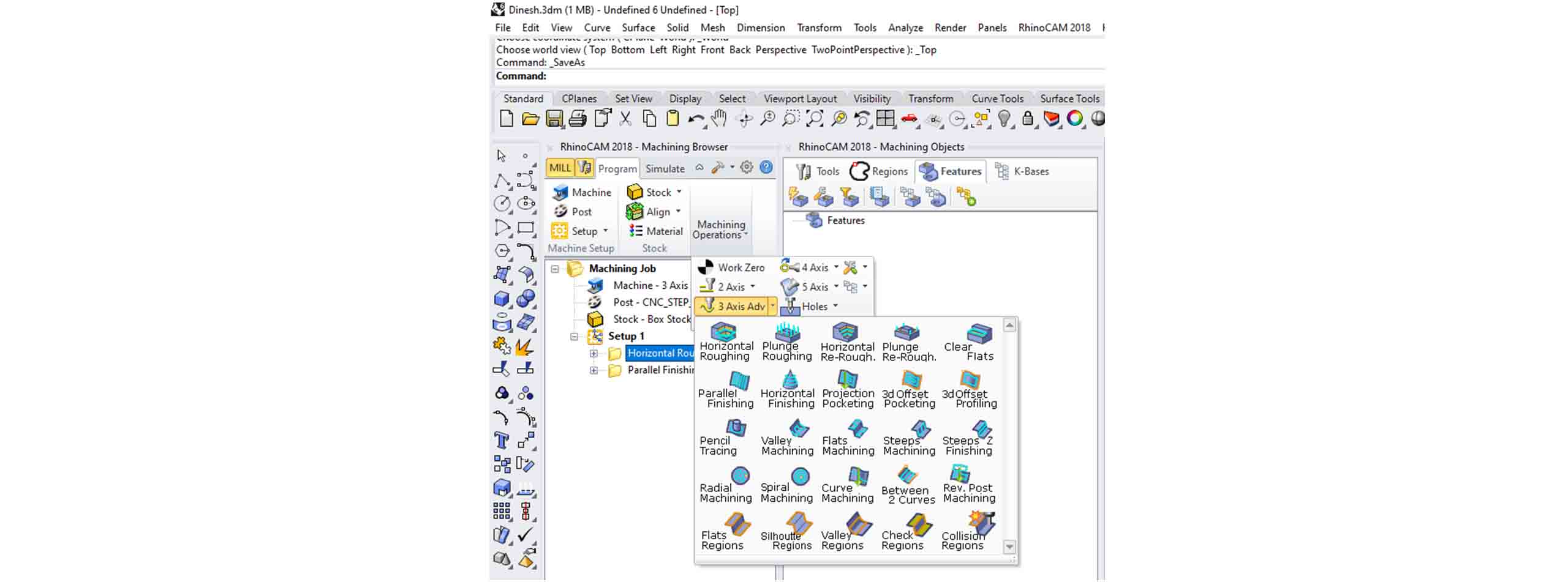

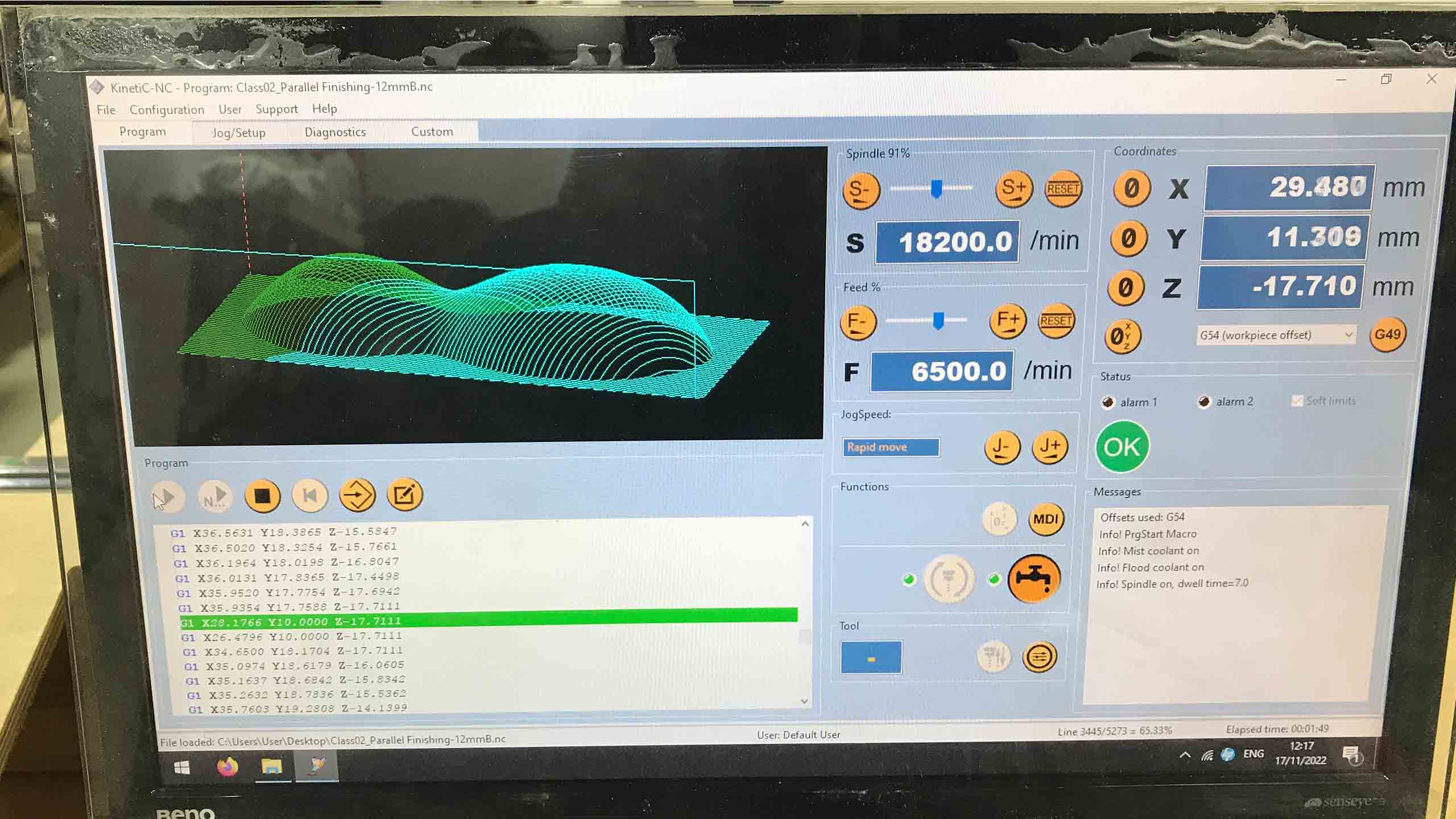

Rhino CAM¶

Rhino CAM workings

Rhino CAM Settings

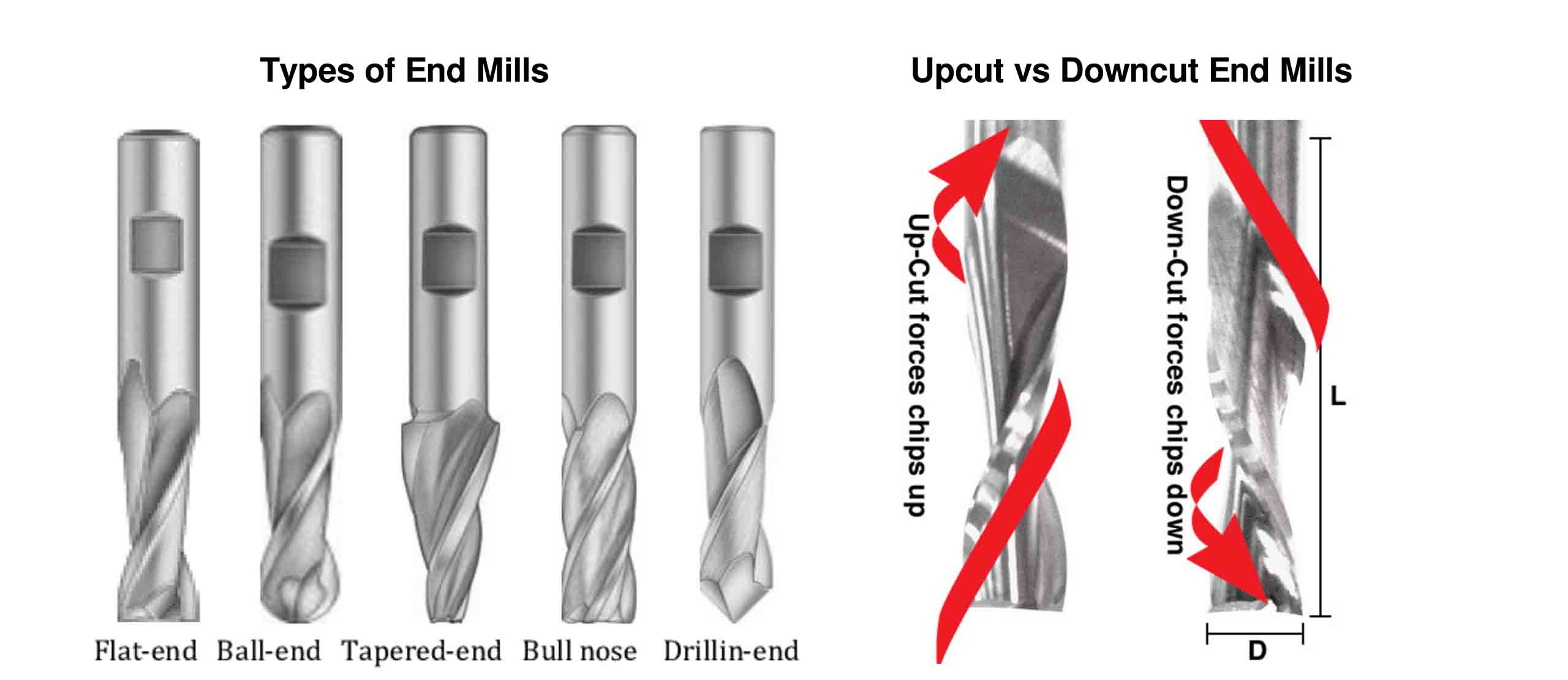

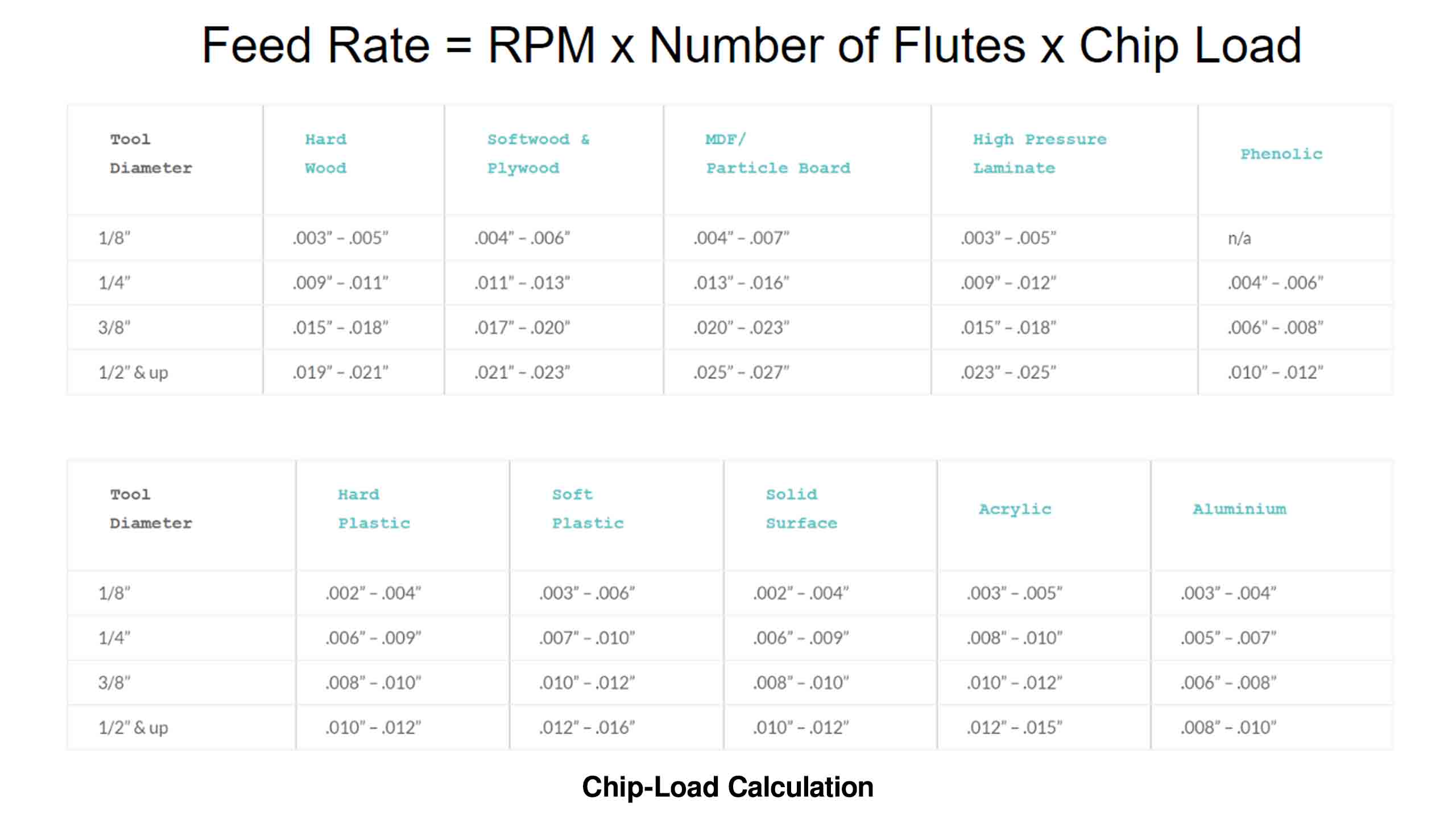

CNC Milling¶

Saftey Tool

While working with CNC machines, it is important to wear safety gear.

CNC Meaching Setting

Clamp all the 4 sides before milling.

Computer Settings

Milling Process

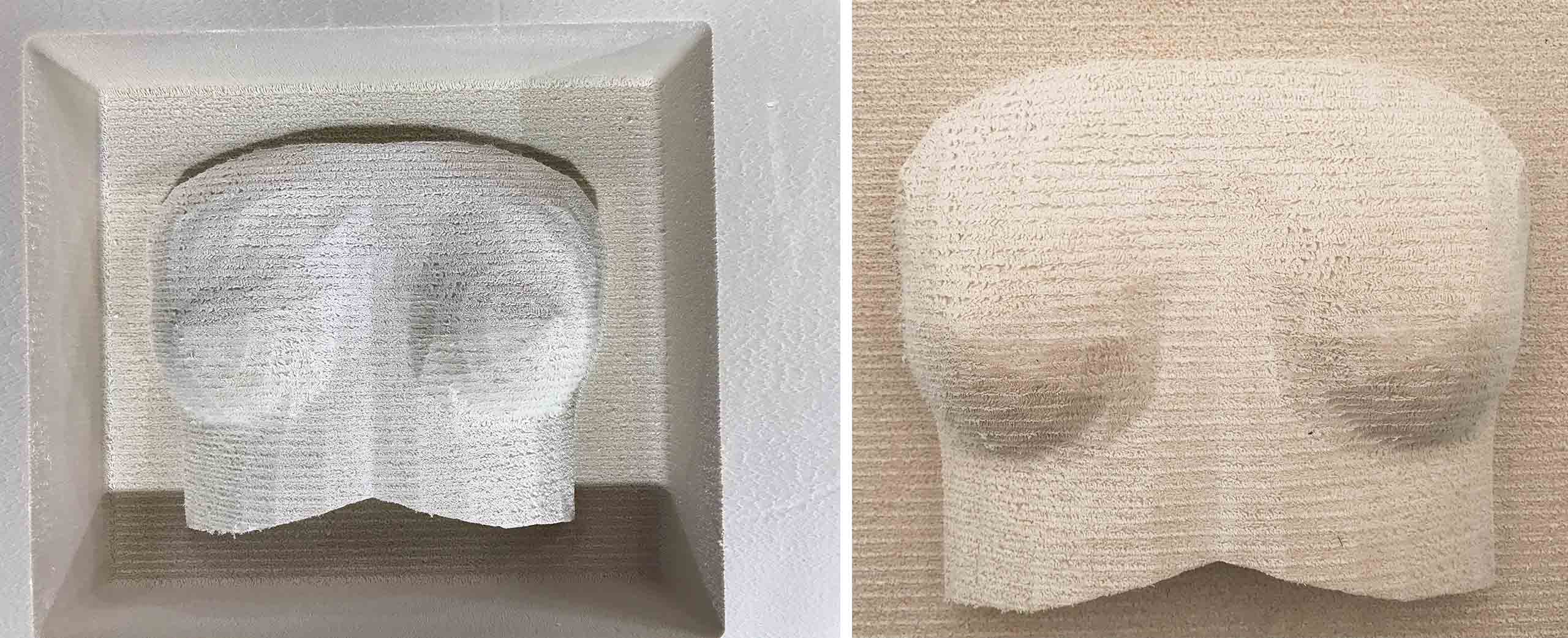

Final Mold

Leather Molding process¶

The moulding here is made from leather scraps. I cut them into strips, then weaved and stitched them together. Here are some pictures showing how the process is done and how it looks stitched.

The following process shows how stitched leather is moulded.

1- Place them in cold water and let them soak for an hour.

2- Bring the water to a boil and place the fabric and baking soda in it for 2 minutes.

3- Once all the water has settled, cover them with mould and plastic to vacuum.

4- Allow the leather to mould in the vacuum for two hours or more.

Final Mold Look

Resin Moulding¶

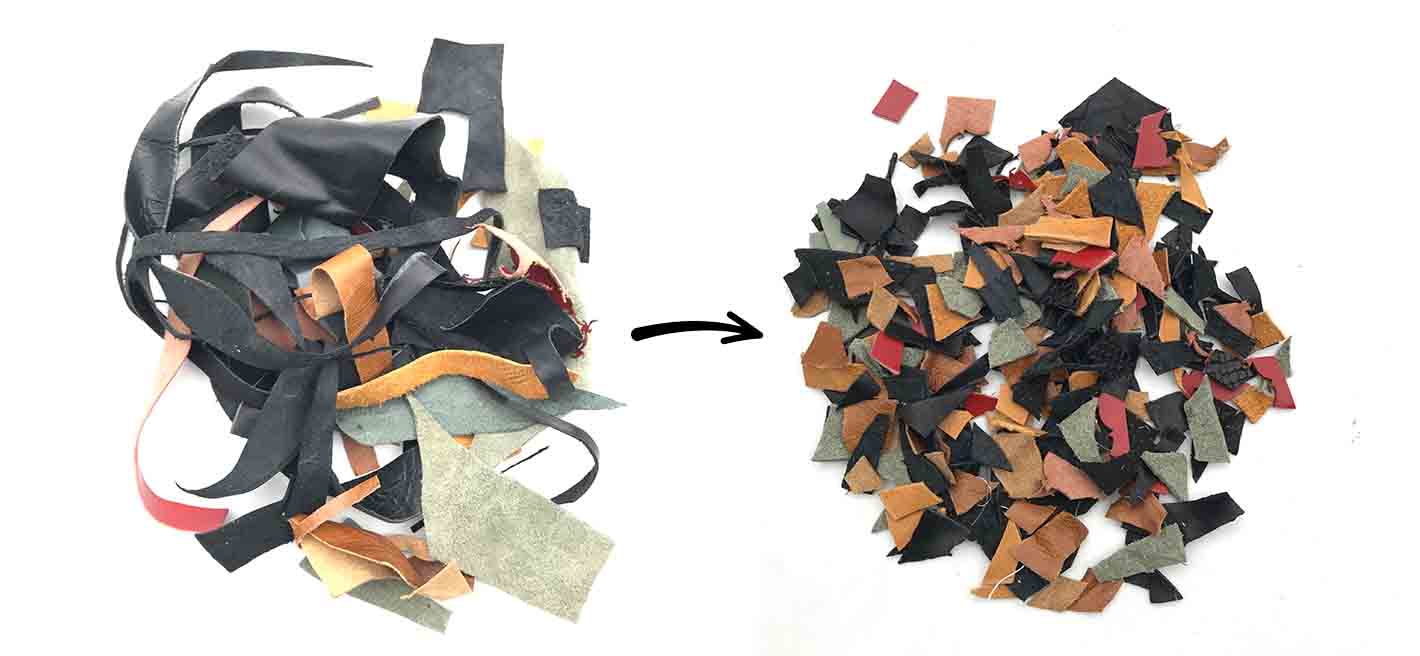

As part of the Resin Moulding experiment, I reused all the leather scraps from the previous leather moulding experiment.

Process

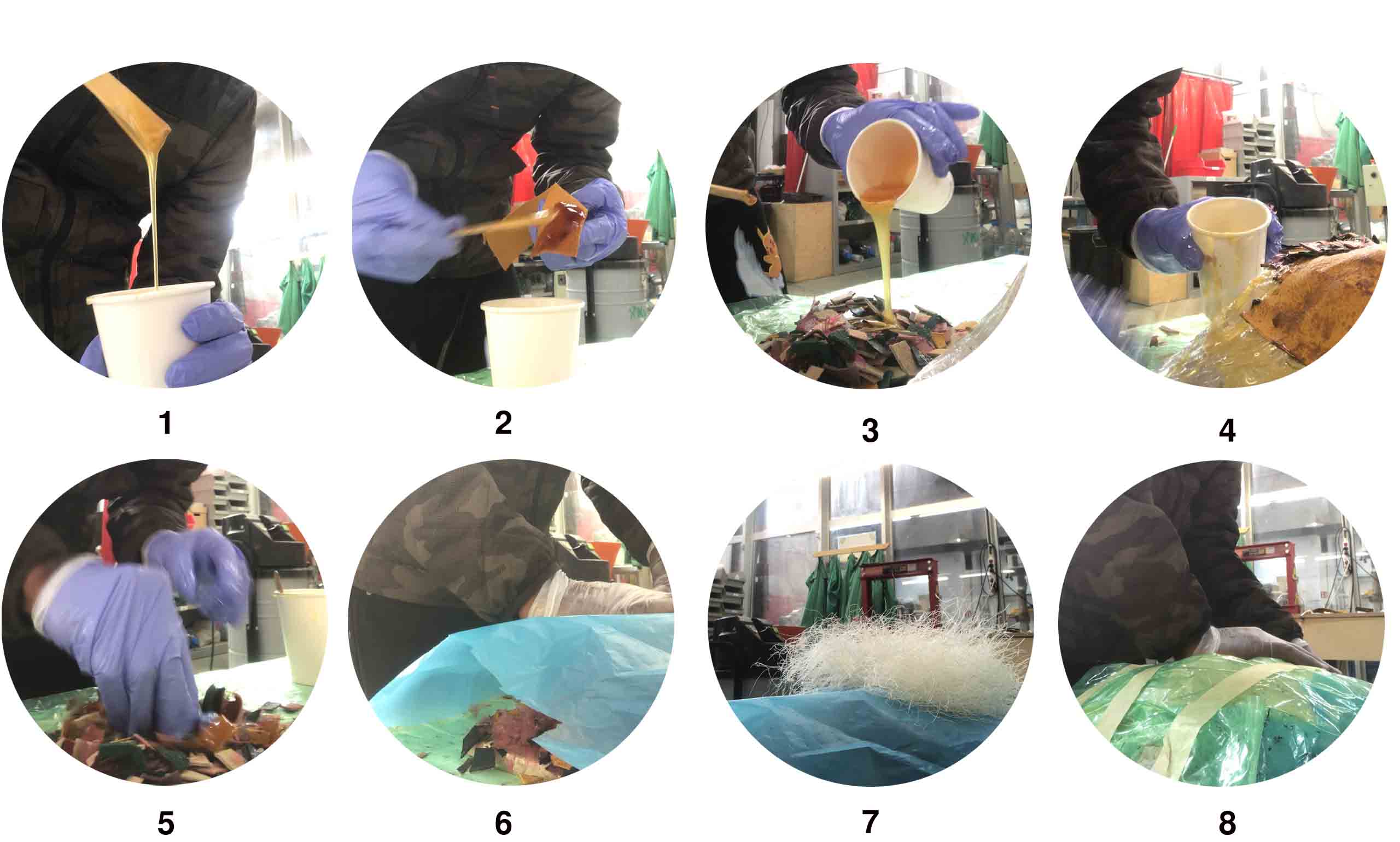

1- To make the model, I mixed 100grm resin with a 35grm mixture.

2- To make the bust circle more contrasting, I first applied it to the leather strips.

3 Using the smaller pieces, I mixed resin with them and poured it into the mould.

4,5- I also applied some resin on top of the mould and spread the pieces on top of the mould.

6- Cover the mould with a poured plastic sheet.

7- Spread the nest material over the sheet to absorb the excess resin.

8- Wrap it in the bigger's plastic sheet and seal it to vacuum it.

Final Result

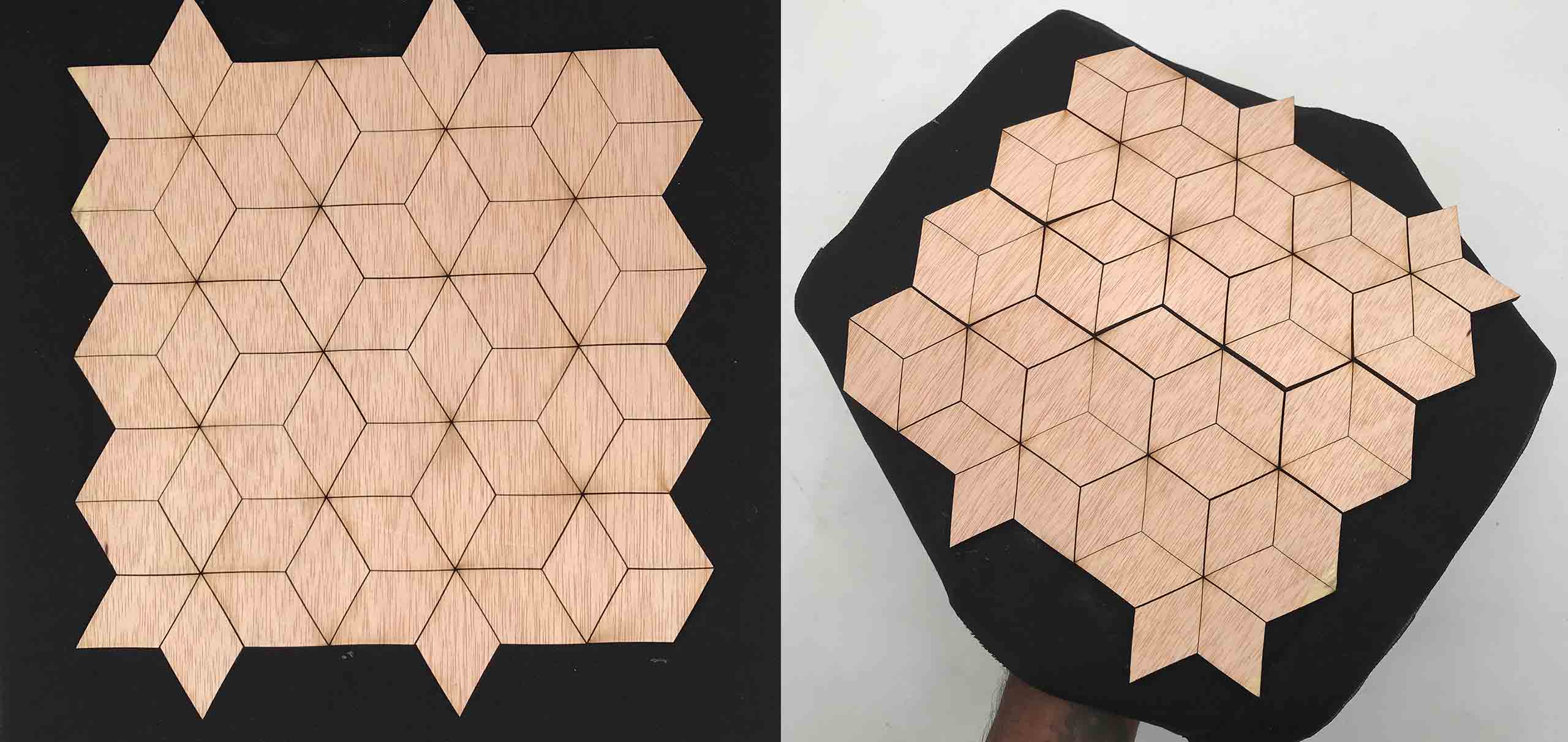

Wood Textile¶

Reference

Wooden Textiles -- Designer Elisa Strozyk | euromaxx here

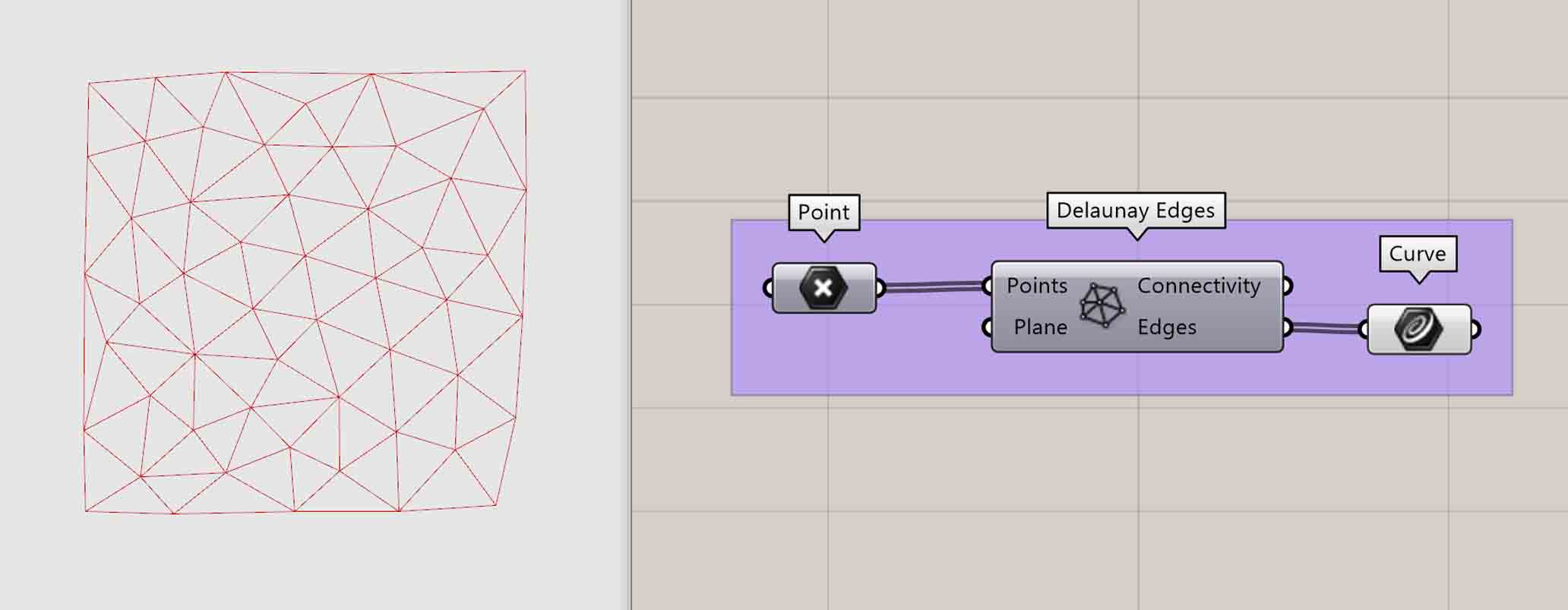

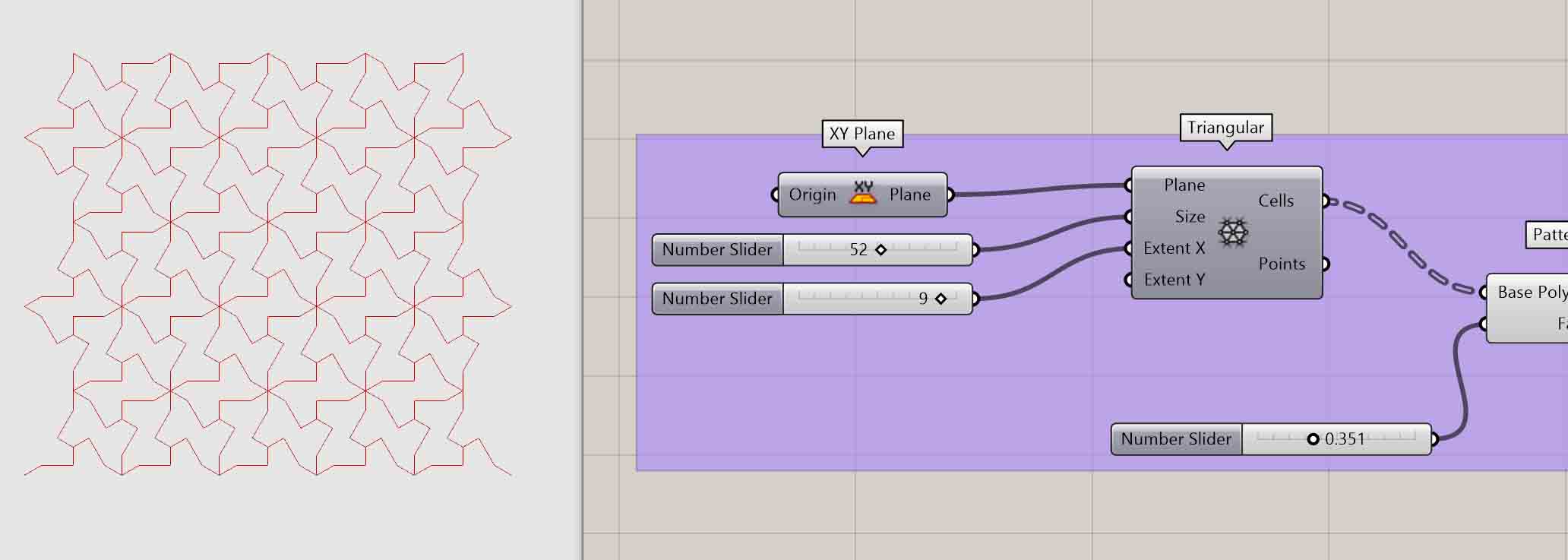

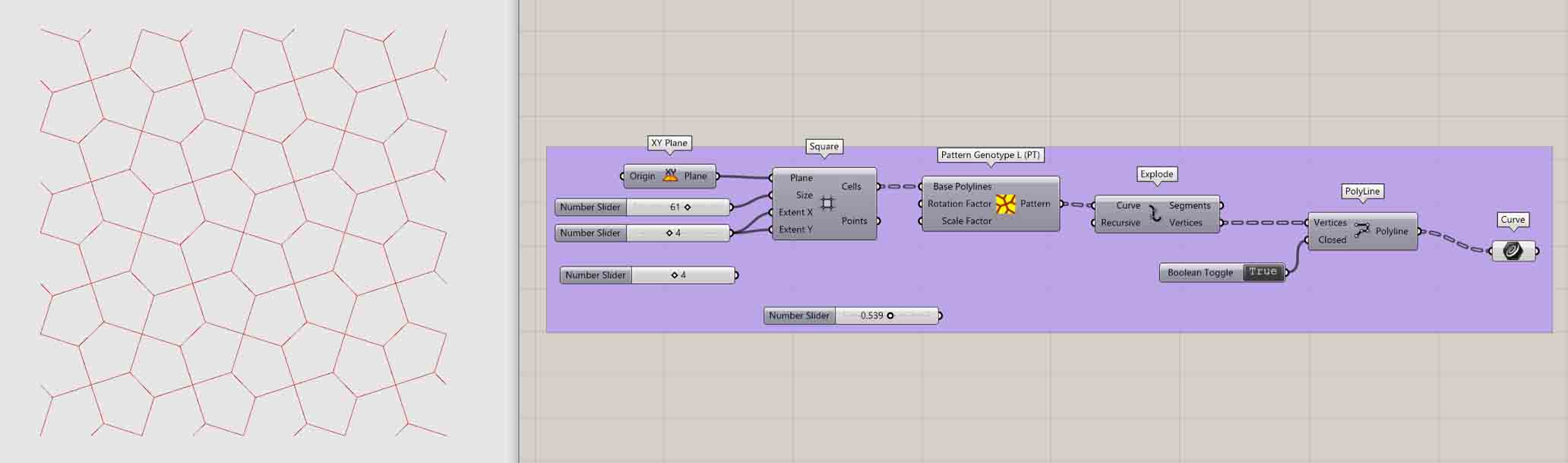

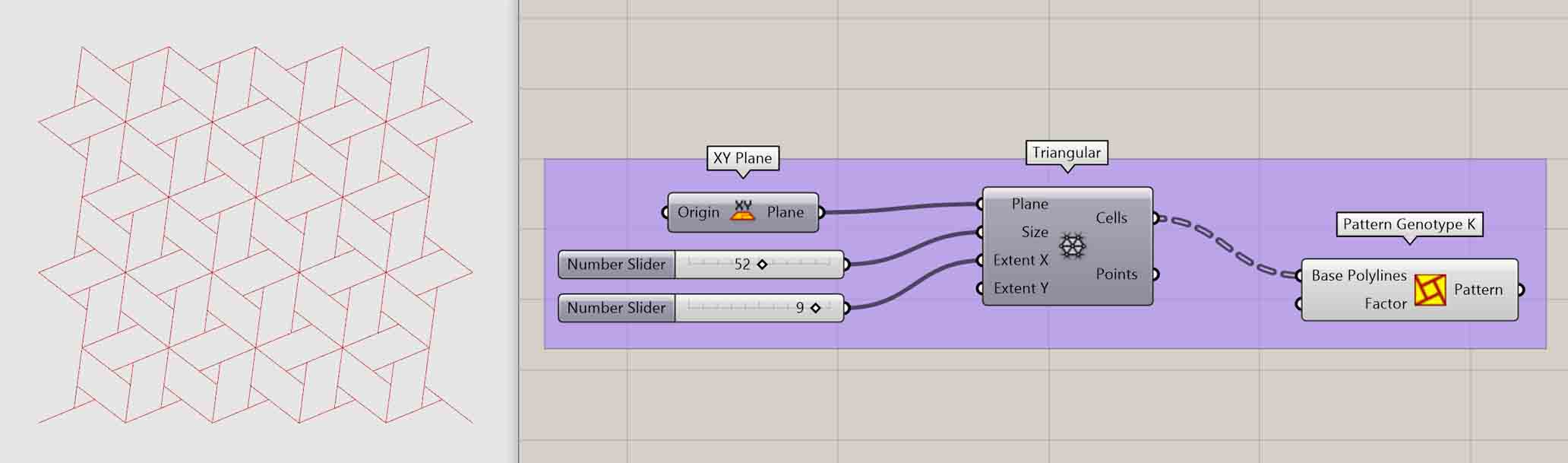

Design¶

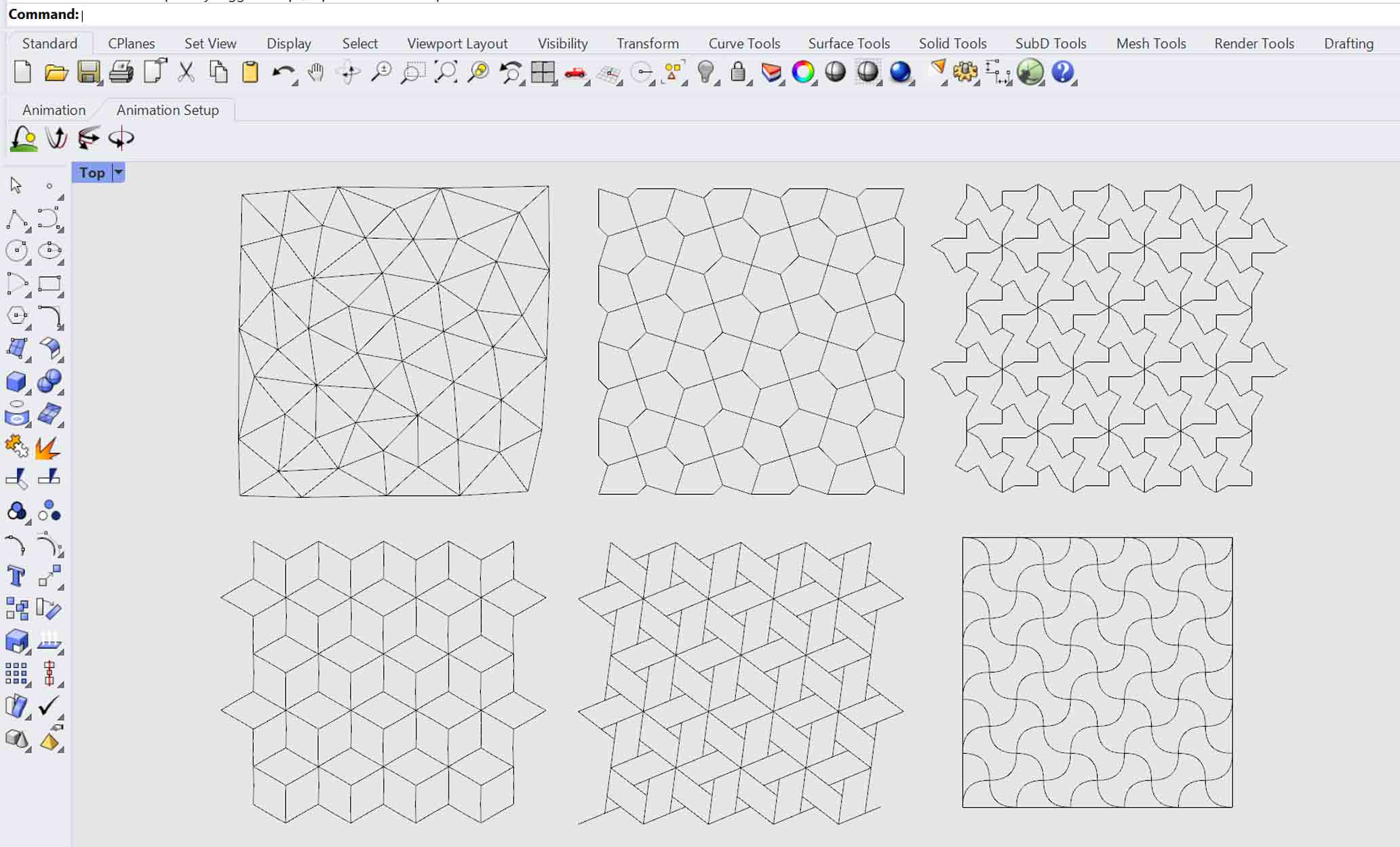

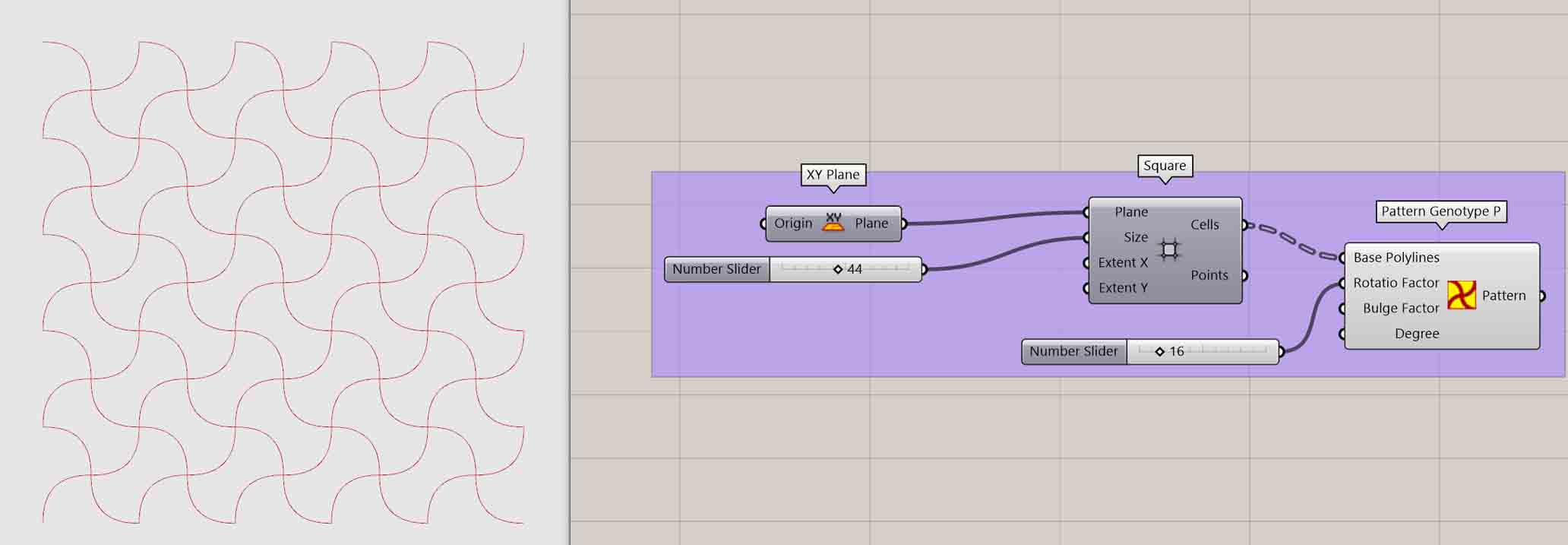

Below are the final designs and its script.

Machine Prep

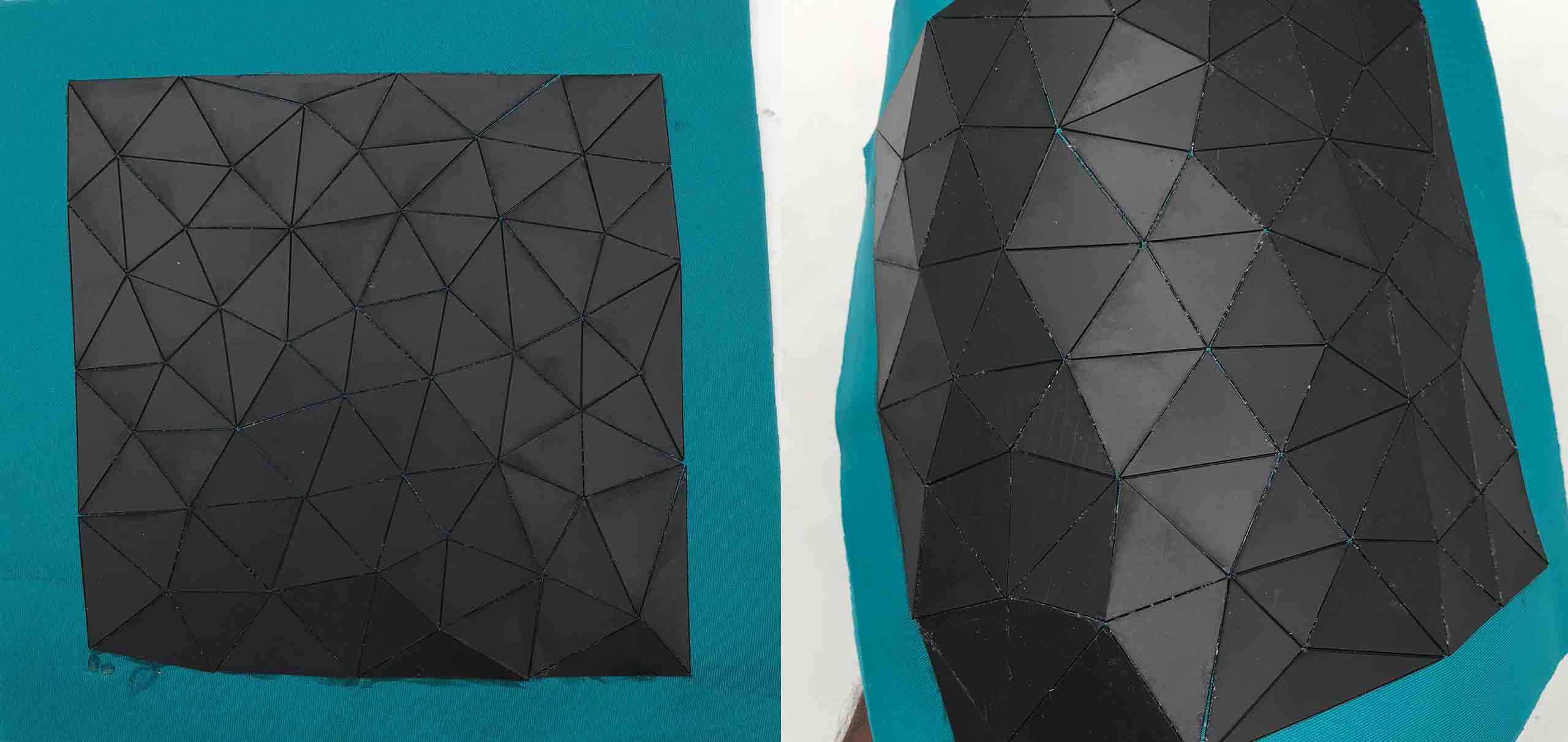

Fabrication 1¶

Process¶

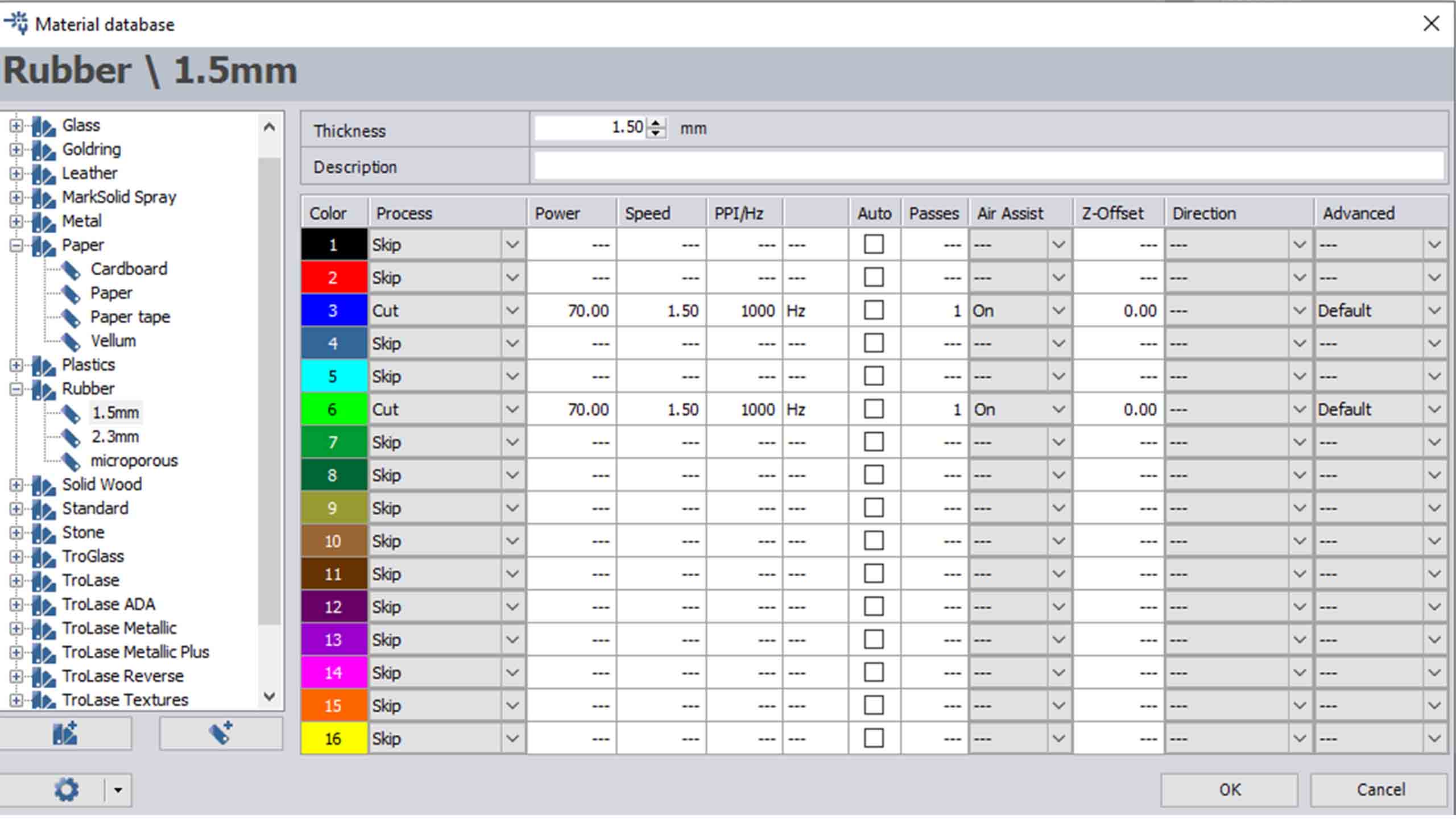

Lacer Cutting Process

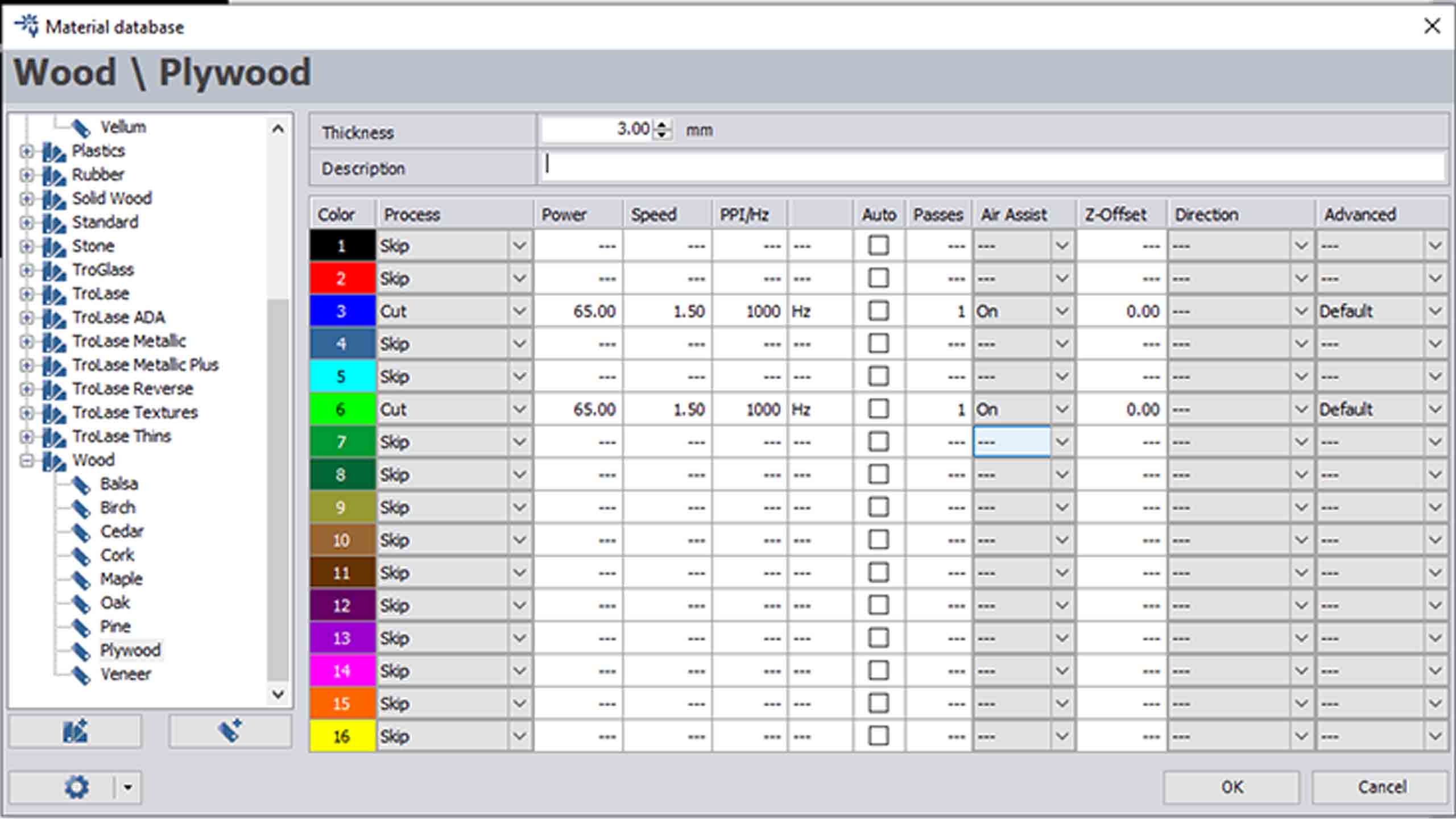

Machine Settings

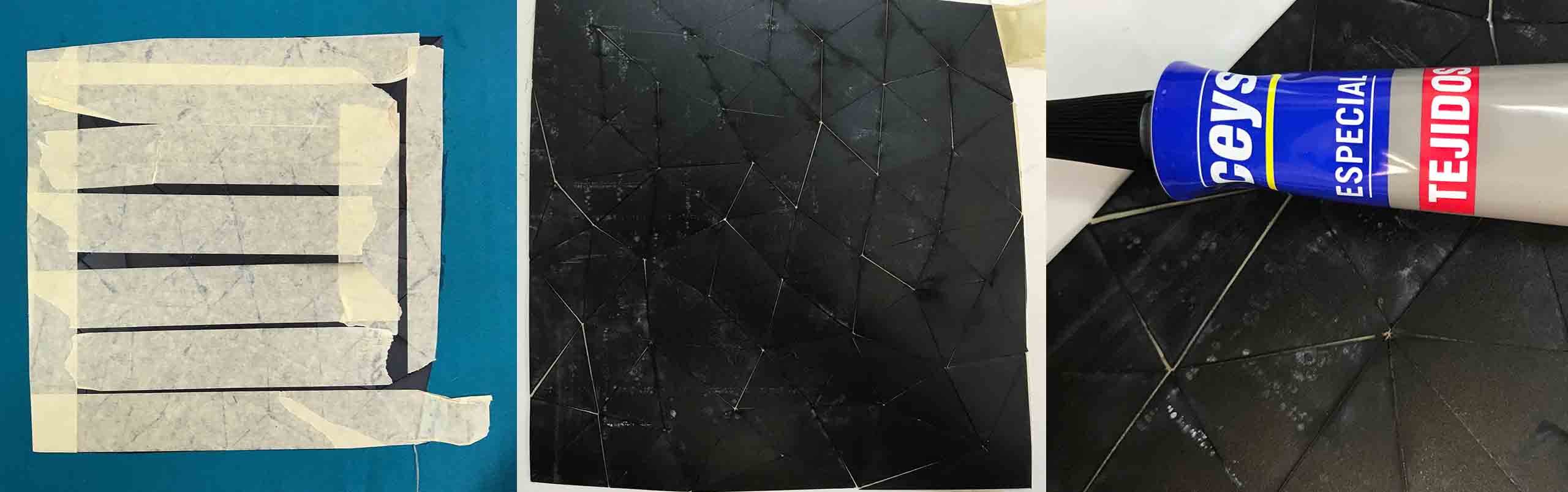

Glueing Process

Final Look

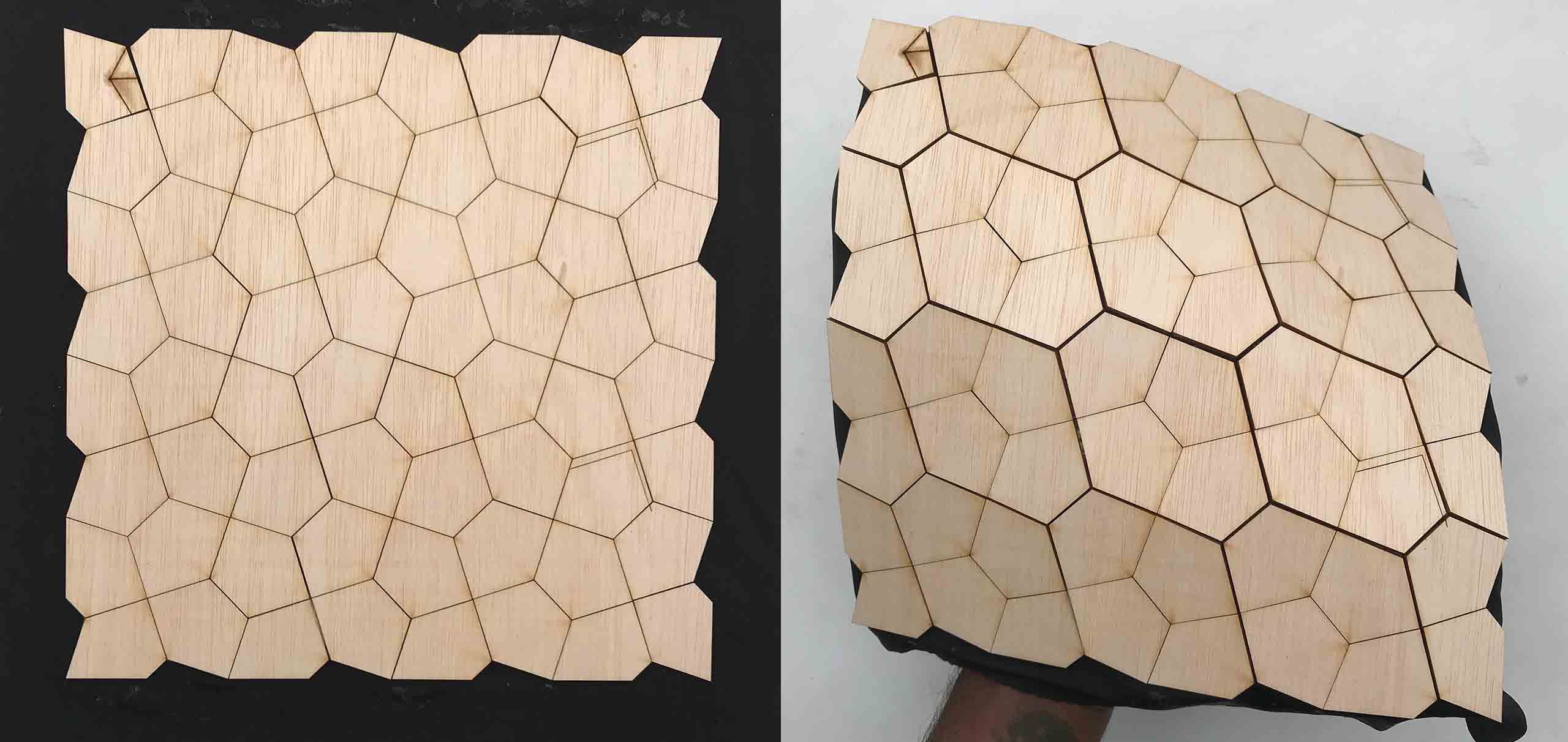

Fabrication 2¶

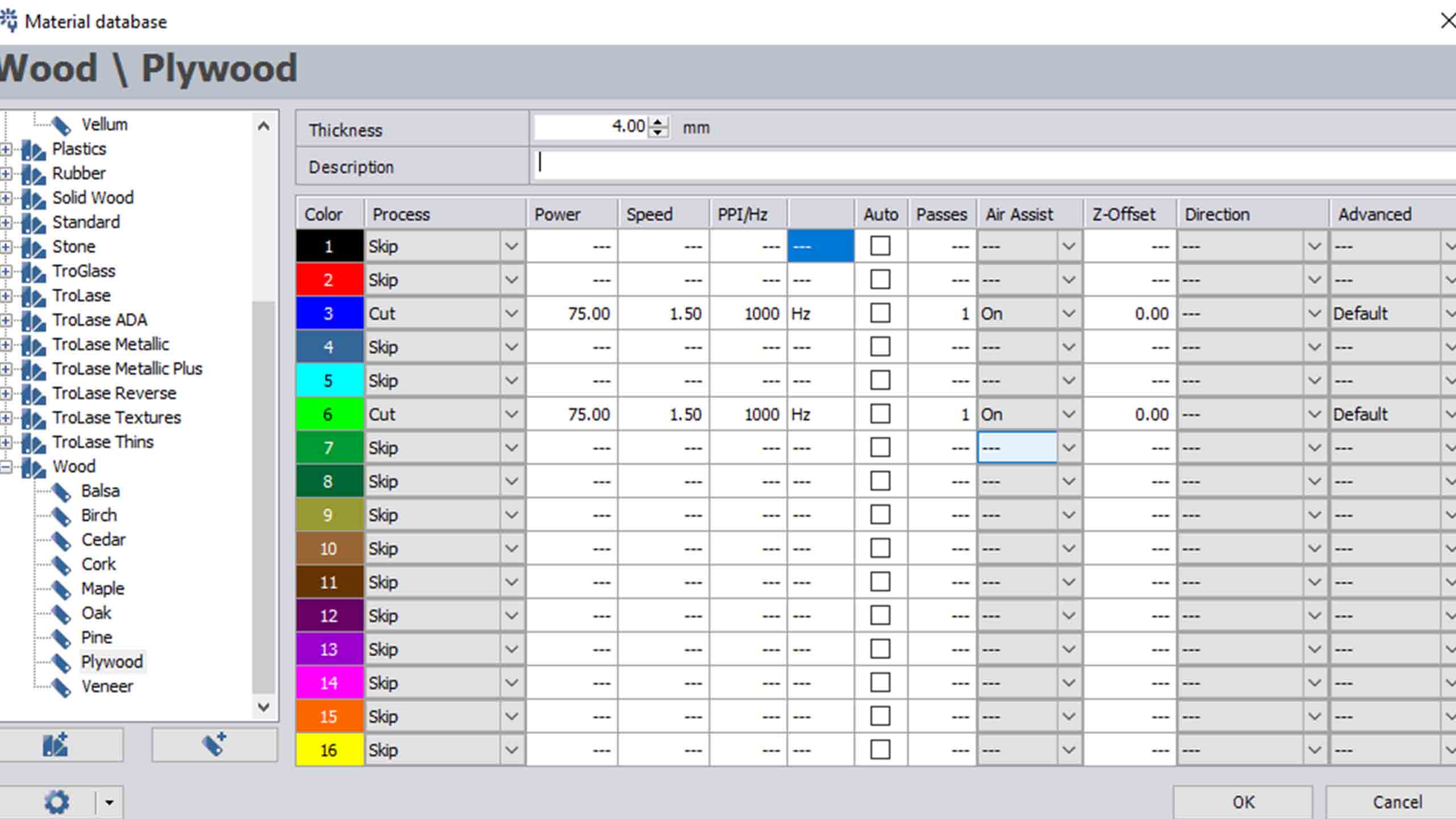

Machine Settings

Final Look

Fabrication 2¶

Machine Settings

Final Look

Thank You