05 Fabrication research studies

I always dreamed of fabricating with 3D printing before attending Fabricademy, I have absolutely loved the computational couture week, learning how to fabricate the parametric files using additive manufacturing technology. It has helped me to explore every possible way. Taking it further to work on the final project would need a bit more research to achieve the desired result. So below are some interesting findings I have come across and documented so it will be useful in future for everyone.

Self forming Structure by Gabe Fields¶

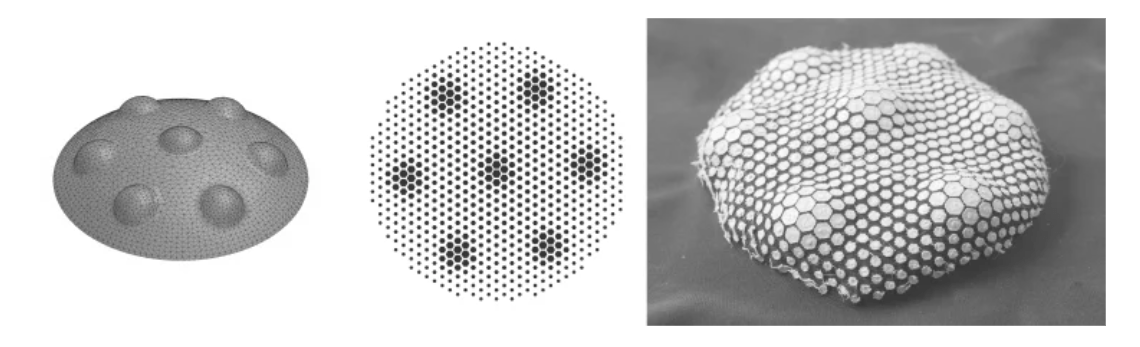

The idea of Gabe Fields was to 3D print the fabric on its own in order to generate three-dimensional shapes. The printed plastic inhibits the contraction of the surface, guiding it to take a shape upon release.

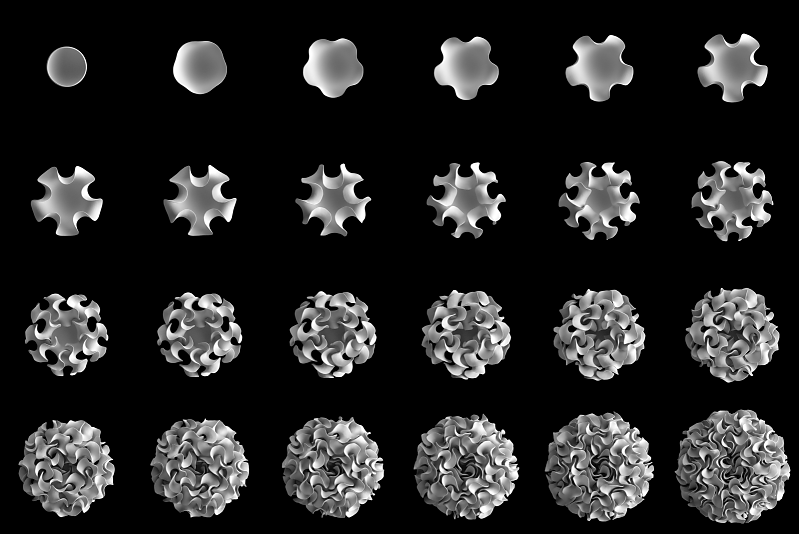

Using a differential growth parametrically, identifying the type of geometry is important to make the surface contract to form the 3D shape, this process resembles what she mentioned. Floraform is a generative design system inspired by the biomechanics of growing leaves and blooming flowers which explores the development of surfaces through differential growth.It was very interesting to to identifying the 3d object and flaterning to print on the elasticated fabric to find the 3d form it creates.

Based on the study, I would like to determine how much the minimum or the maximum line thickness contributes to shaping the textile.

Floraform by Nervous system¶

While reading the Gabe fields blog I have come across the floatform by nervous systems, generative design system inspired by the biomechanics of growing leaves and blooming flowers.

A very interesting study of an organism that goes from a single cell to a complex differentiated structure and using computational simulation of differential growth on a thin surface.