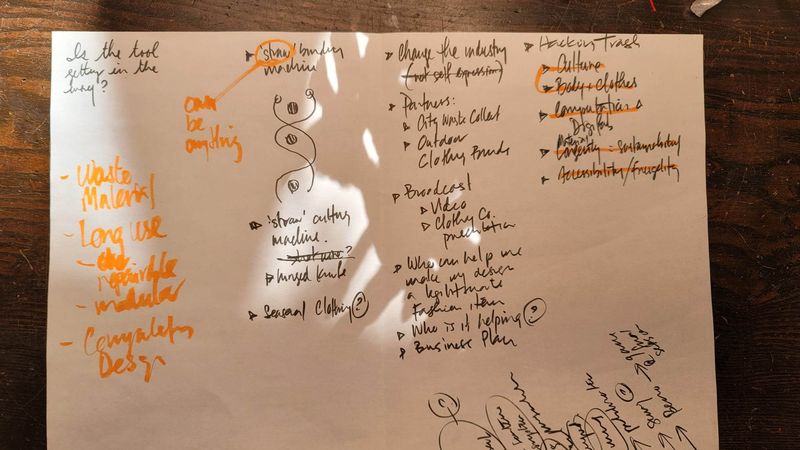

Process¶

Ideation¶

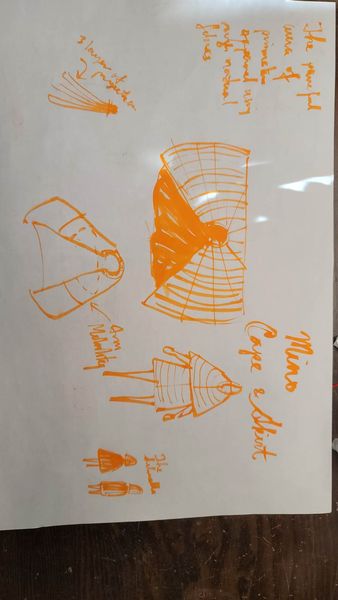

The Traditional Mino is water-repellent and is...

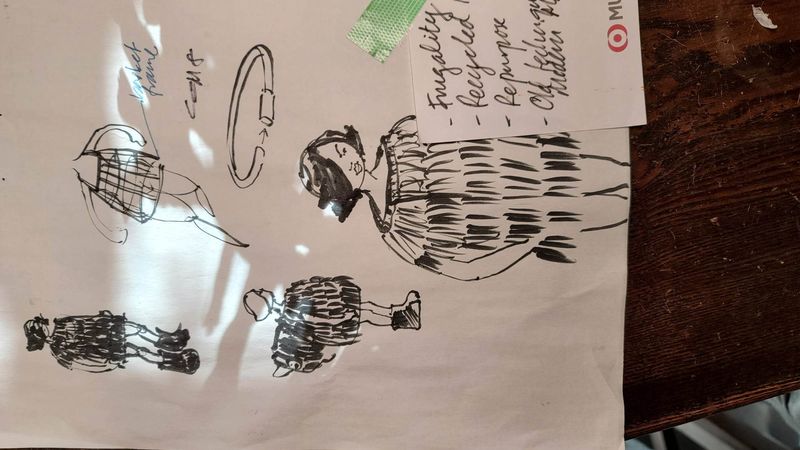

- Frugal/Affordable > construction from inexpensive (usually free), easy to find, natural materials

- Modular > assembled of modules of straw, it is simple to repair...simple to adjust sizing

- Lightweight & Breathable > hollow tubular shaped straw encourages water to flow down its length...are light and moves to allow airflow into the garment

- Freedom of Movement > constructed as an open garment, the Mino is not fully waterproof but allows excellent and unrestricted arm and leg motion

- Easy to Fabricate...anyone could do it

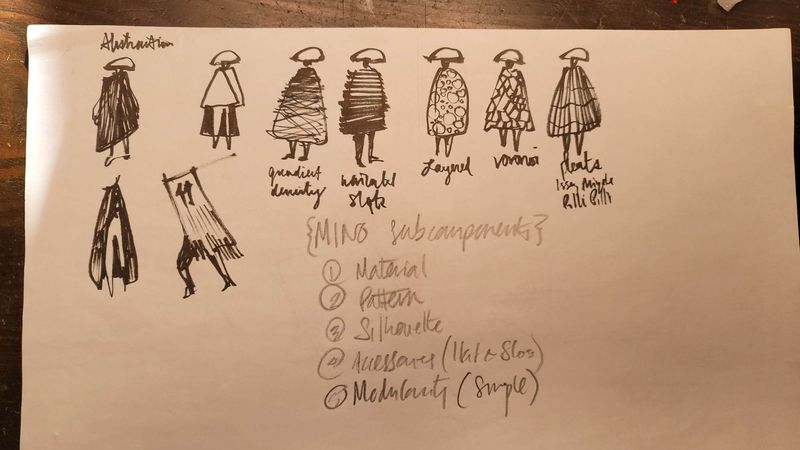

The Modern M1N0 will try to capture some of the best characteristics of its traditional inspiration, while...

- employing modern materials (cheap/free, easy to find, inherently waterrepellent, lightweight)

- utilizing modern fabrication techniques (not certain how yet)

- an easy to understand and easy to execute process > accessibility...without having to suffer the 'technological anxiety' that comes with complex techniques

- employing some biochromes (color for some aspect of the garment)

- enhancing with electronics to add a new level of 'Utility'

For the M1N0, the plan is to...

- collect and use scrap modern water-resistant/water-proof material (discarded umbrellas, etc.)

- utilize inexpensive DIY Home Center material to construct the water repellent modules

- develop a modular system to create bunches of the scrap textile...to be used to construct rain shedding layers

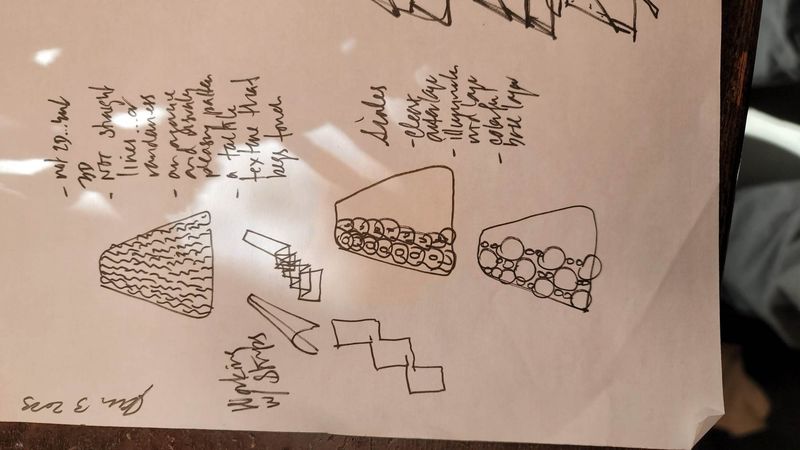

- Use computational design (organic geometries) and digital fabricaion techniques (vinyl cutting)...to produce aesthetically interesting, rain shedding 'textile' modules for the M1N0

- enhance visibility of the M1N0 in dark rainy conditions with electronics and illumination enhancement

Material

-

Clear umbrella plastic...vinyl cut

-

Scrap hi-tech outerwear material...vinyl cut

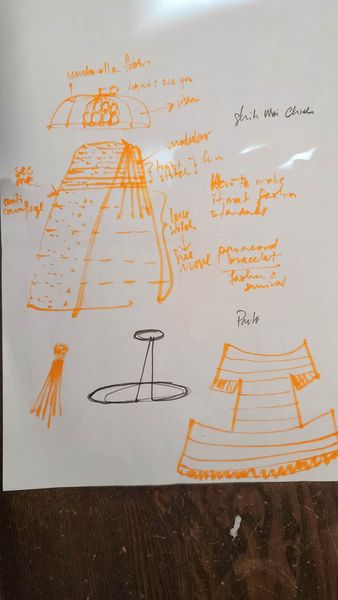

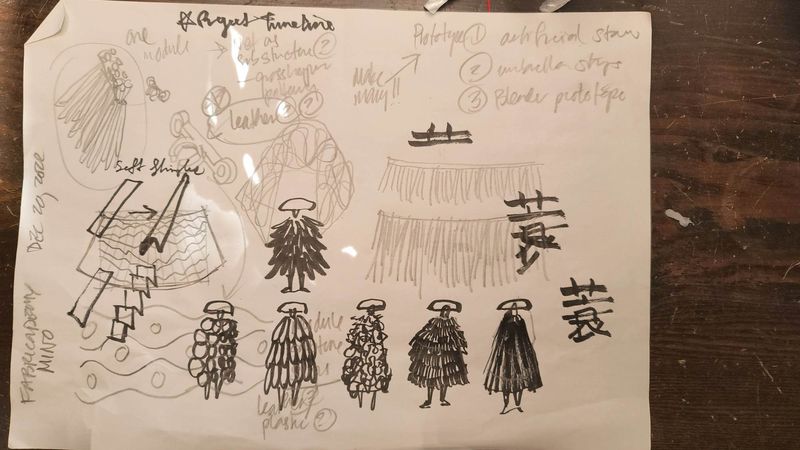

Sketches¶

"In Japan...it is believed that everything that is created...has a soul"

Random thoughts...

The M1NO + Sandogasa Ensemble

Shaping and patternig of the M1N0 external surface

Inspired by an Owl costume from a Japanese fantasy movie

Ideas to make 'texture' from flat strips of umbrella material...

Research/Ainu Crafts¶

Simplicity. Utility. Affordability. Earth Friendly. Who better expressed and lived these ideals than indigenous peoples from the past. I went to Hokkaido to research the Ainu people. The documentation is on this page

Prototypes¶

Prototype 1: Polypropolyne Rope as Textile¶

It seems contradictory to my thesis (addressing the issue of textile waste) by choosing a purchased plastic material for my initial prototype. There are a few reasons why I decided to go ahead with this...

- Aesthetics > The rope looks like straw and exudes modernity

- Cheap and Available > The roll of this rope (200m worth) was rather inexpensive and easy to find in any generic home center in Japan

- Forgiving Material > the material is easy to work with and has a nice, soft, smooth texture that will not irritate the skin (at least when it is new)

- Plastic is not Evil > the association of plastic with the earth's ills has less to do with the material but rather how we (humans) consume it and discard it. What if plastic is considered a precious, affordable, accessible, durable material instead?

200m for about USD10...ubiquitous in DIY home centers

Polypropolyne Plastic Rope

Rope easy to cut and cuts clean...

Prevent rope fraying by melting rope end

Tied with strong fishing line from fishing supply store...

Fishing line looped to capture the 7 rope lengths into a bundled module

Rope modules...20cm and 30cm lengths. Assembling the modules by hand was strangely meditative and relaxing (like knitting?). Is this a pleasure we lose if we use machines to make everything?

Tie the rope modules to the sub-structure paracord rope...

Pushing modules together...how closely the modules will have to be smashed together will be clear after the whole garment is assembled and dressed on a body.

M1N0 Raincoat Weaving Rack...everything I do is a hack.

Accessories¶

Hat > Sandogasa

- bio-chrome coloring > vermillion

- RGB LED enhanced > safety

Plan to install an RGB LED fan on top of the Sandogasa...with a capacitive touch sensor as ON/OFF switch

Sandals > Geta CNC milling seems like it would be appropriate technique for this object.

- But how to "stand on the shoulder of giants" and take it to another level?

- Is it enough to just used a digital fabrication technique to automate a traditionally hand-crafted item?

- Is there a way to use Grasshopper to design the geta?

Mentoring notes¶

Feb 1, 2023: Troy & Claudia

A good session with my advisors. The presentation went surprisingly well. I had thought my subpar final project idea would elicit more critique. Surprisingly, Troy and Claudia approved of my direction and both encouraged me to pursue my path and offered some great advice...

"Using an unconventional material for garment fabrication...good"

"Would not normally recommend...but LED would work well"

"Avoid kitch"

"Avoid 'Costume'"

"Try different colors"

"Look in to straw sandals...like at the Big Buddha temple"