2. Digital bodies¶

( All images are mine unless marked with a hyperlink )

![]()

Research & Ideation¶

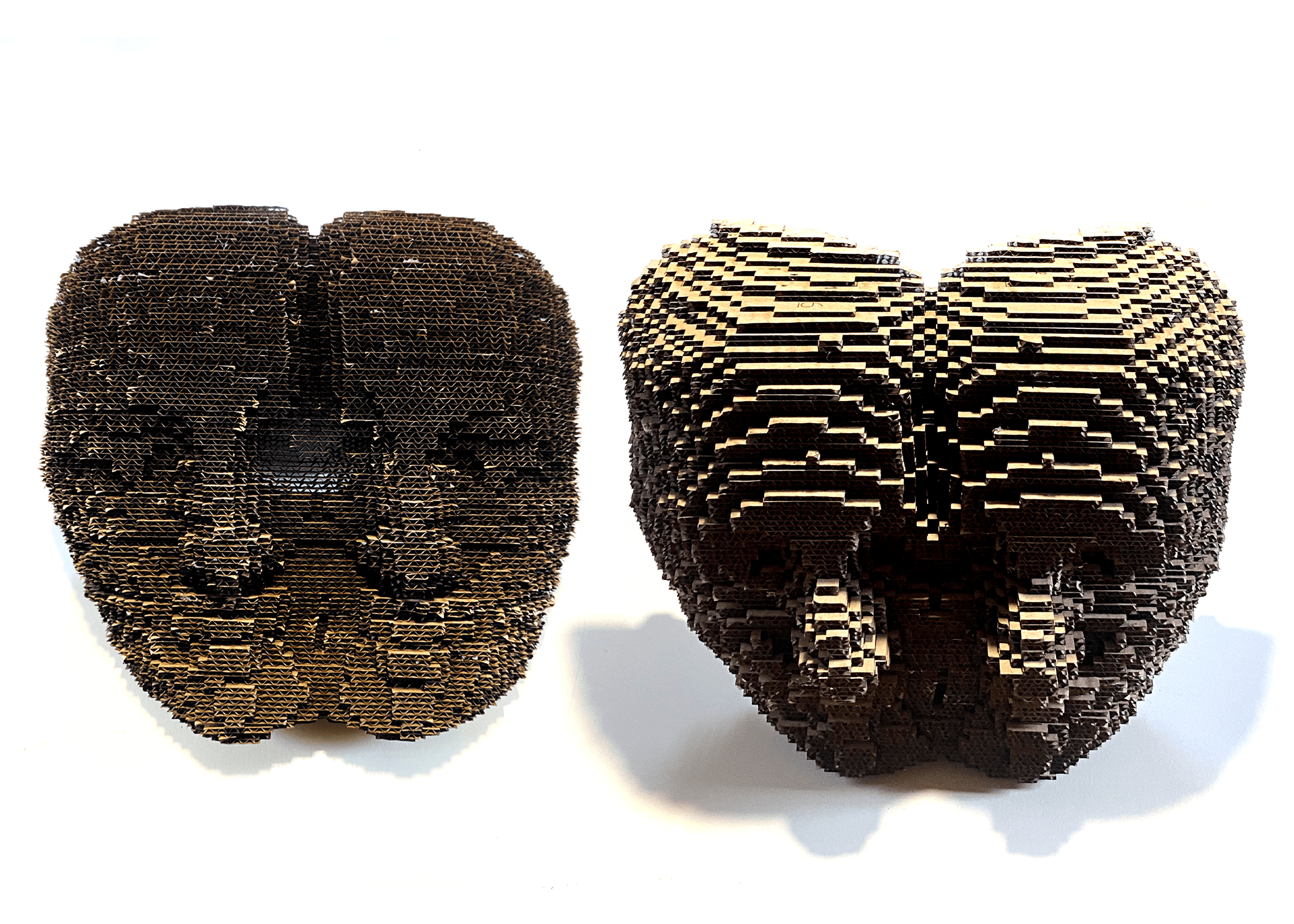

Things i'm interested in

*Intentional glitches, pixelation

*Chimeras, combined bodies, clones

*Anonymity, obstruction of idenity

- Glitched Image

- Combined bodies

- Human glitch Massanetto

- Monica Piloni

- Jordan Hemmingway

- Image by Valentin Herfray

- Image via tumblr

- Glitched texture

- Faces

Software¶

Modeling¶

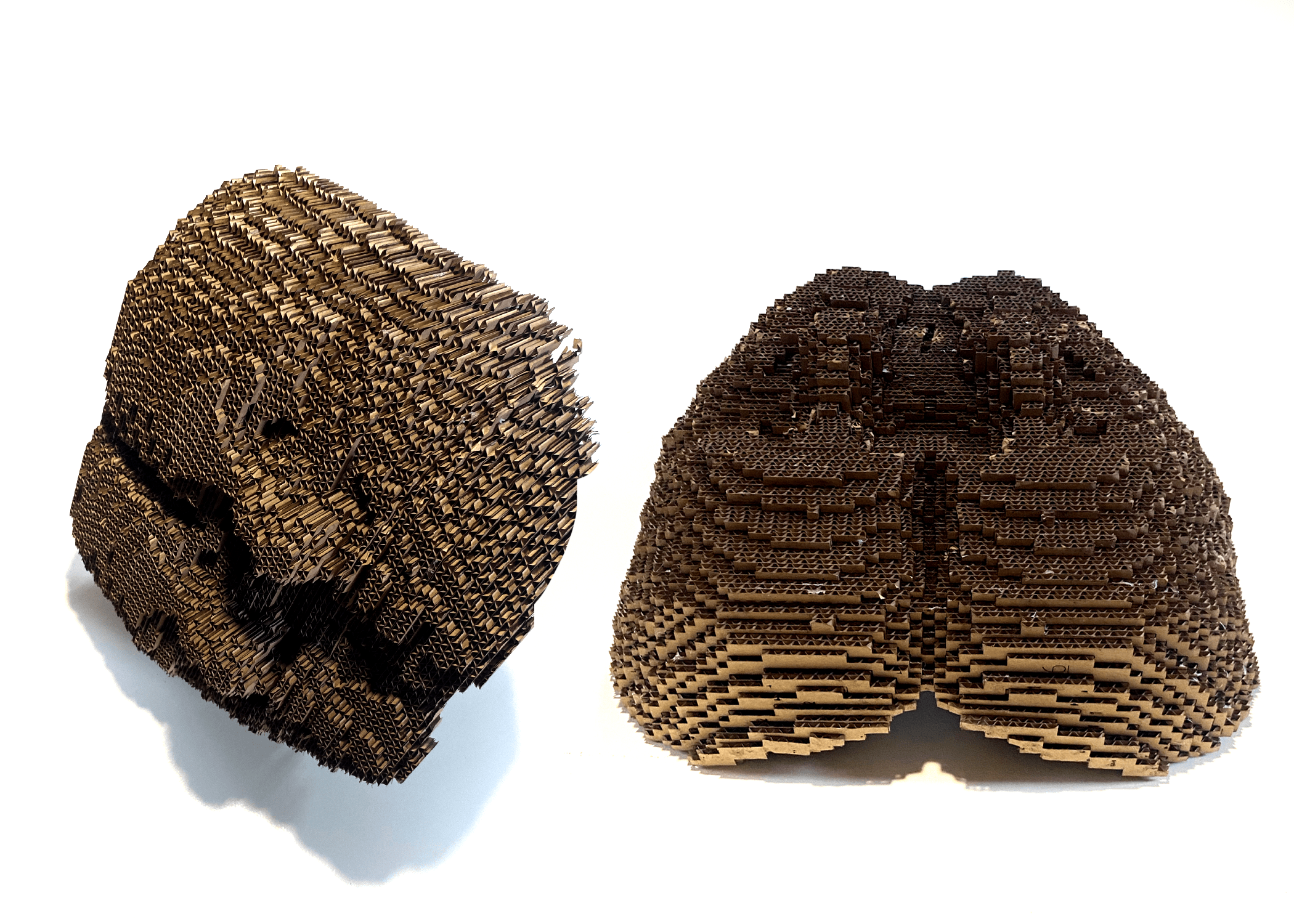

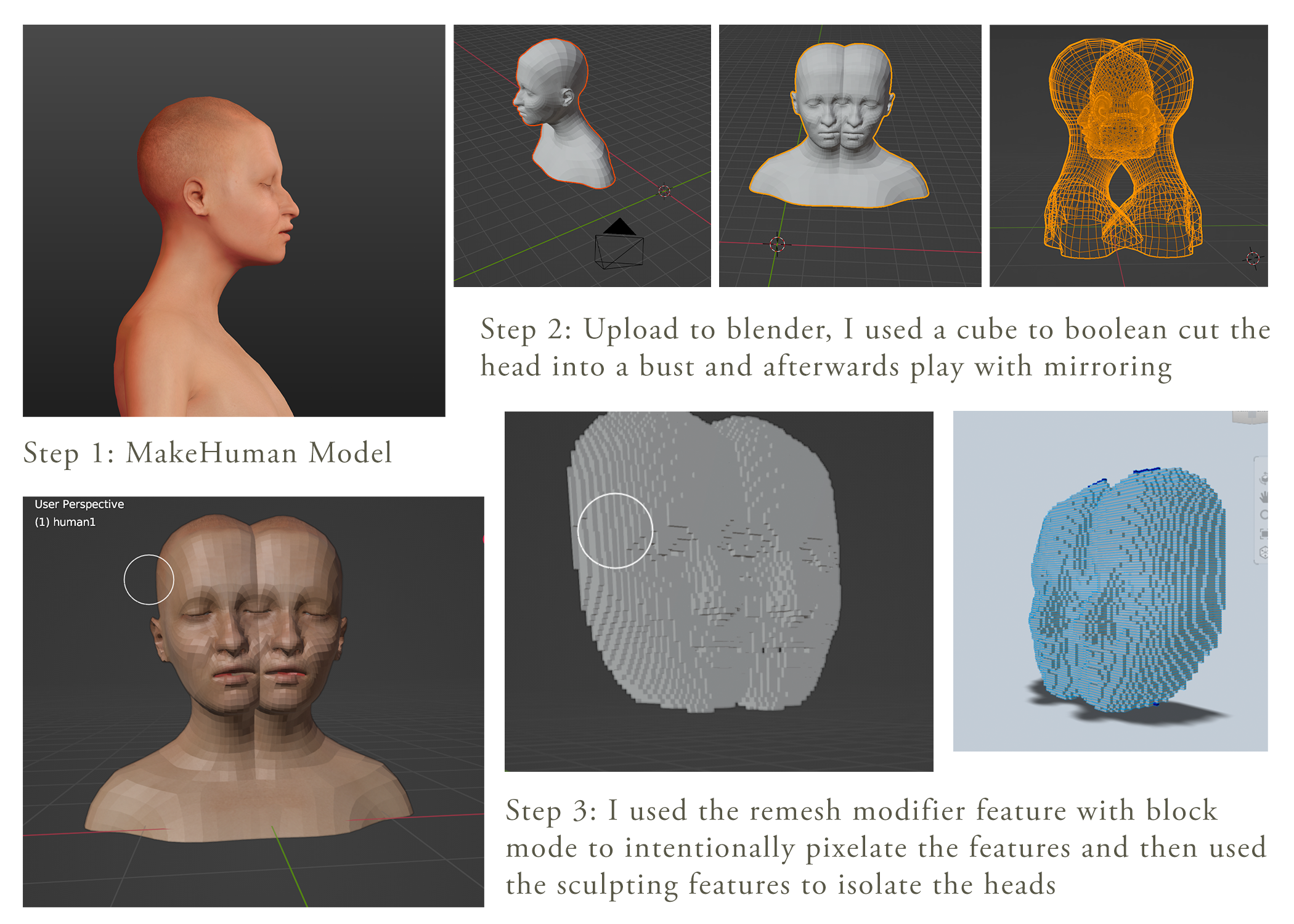

I have some rhino expirience but mostly for flat patterns for the laser cutter and have not done too much 3D modeling. I ran into some issues at the start of the week because I had already used up my 90 day free trial. I tried making new accounts but had no sucess. I'm waiting to get approved for a student account but until then I decided to try out blender.

I was intersted in leaning into the digital nature of 3D modeling and trying to intentionally pixelate/glitch objects. I originally planned on trying to use a grasshopper plug in for rhino but after I switched to blender I discovered it is an availible effect as well.

This video was really helpful in achieving the pixelation effect

Laser Cutting Process¶

This is the site where you can find a walkthrough of lightburn

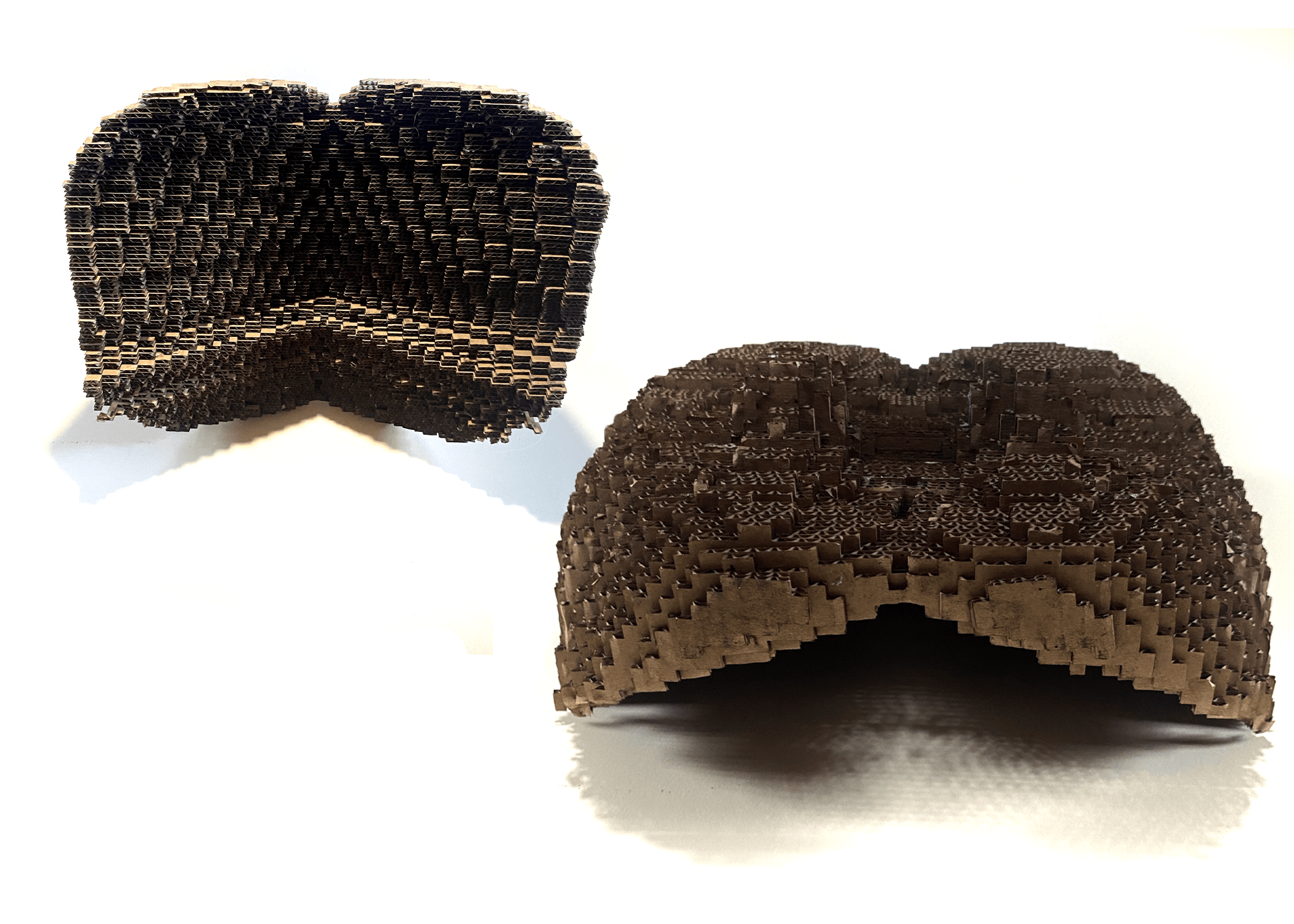

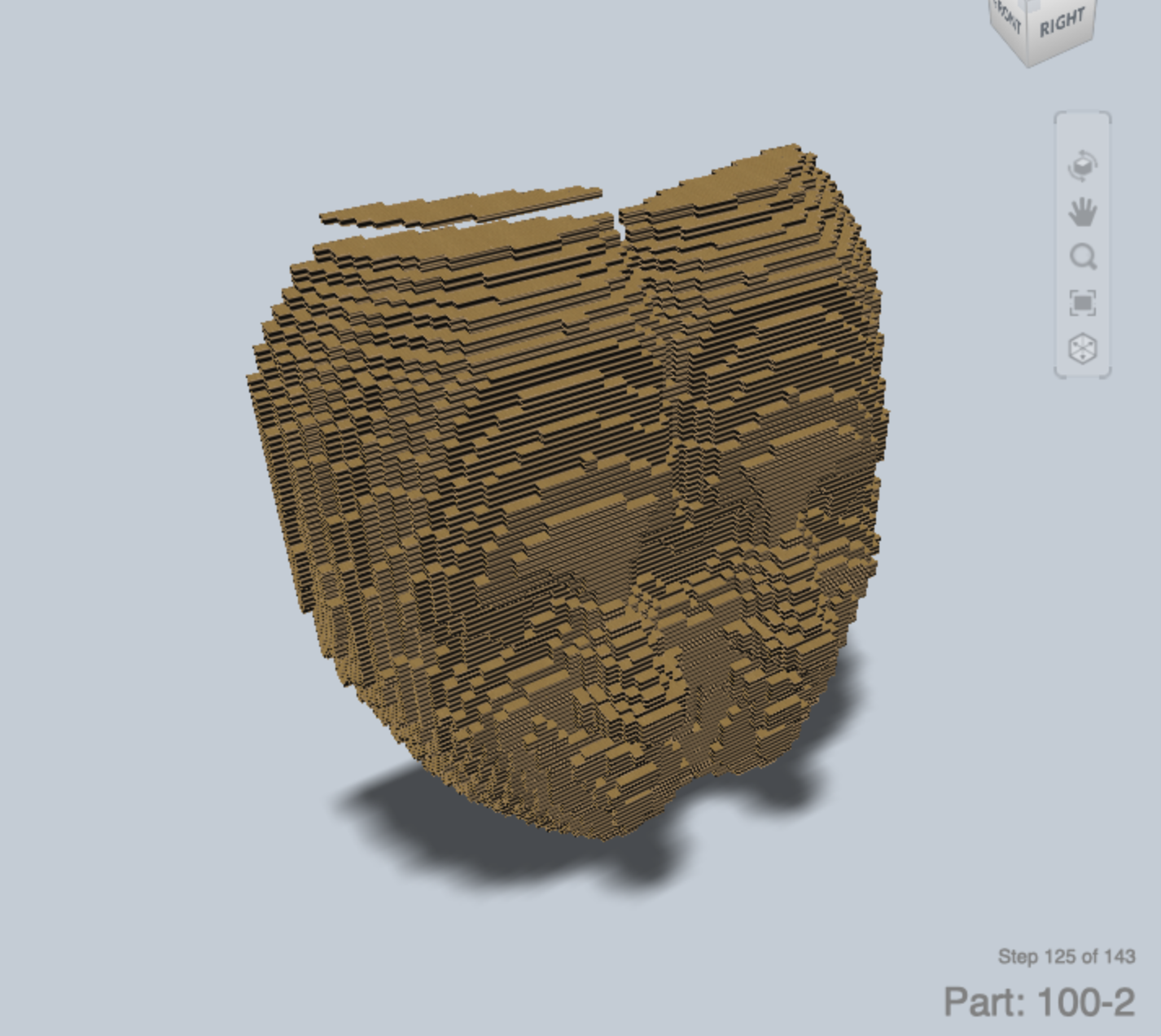

After I was finished modeling, I uploaded the file into Slicer. I played with the sizing to make sure the plans could fit on to three sheets of cardboard in the laser bed. I used the stacked slice mode for construction.

Bit of the construction process

Setting up the Laser Cutter¶

This image is from The WAAG Futurelab has a docuemtation page walking through the use of the laser cutter availible in the lab. You can find this here

-

Import your files into lightburn as a dxf or svg file

-

Go to edit in the top menu bar and select "delete duplicates". This gets rid of any duplicate lines so the laser doesn't try to repeat any cuts.

-

Based on the color of layers, you can change machine settings for different lines/shapes.

-

Make sure to turn on the Output, otherwise lines will not be cut.

The settings we used for 3mm thick corrugated cardboard

Machine settings :

Layer 1: Cut = Speed 30.0 / Power 45.0

Layer 2: Inscribe = Speed 50.0 / Power 20.0

Running the laser cutter¶

-

Focus the laser based on the height of the material. Our lab uses a wooden jig to place on top of the desired material. The laser is focused by making sure the head is touching the top of the jig.

-

Turn the laser cutter on and make sure the laser moves to the 0,0 axis

-

Turn ventilation on!!

-

Now you can press play to run the cut in liightburn

-

Watch the machine carefully to make sure there are no fires or other issues

-

After the file has run, leave the top closed with ventilation on for several minutes before opening

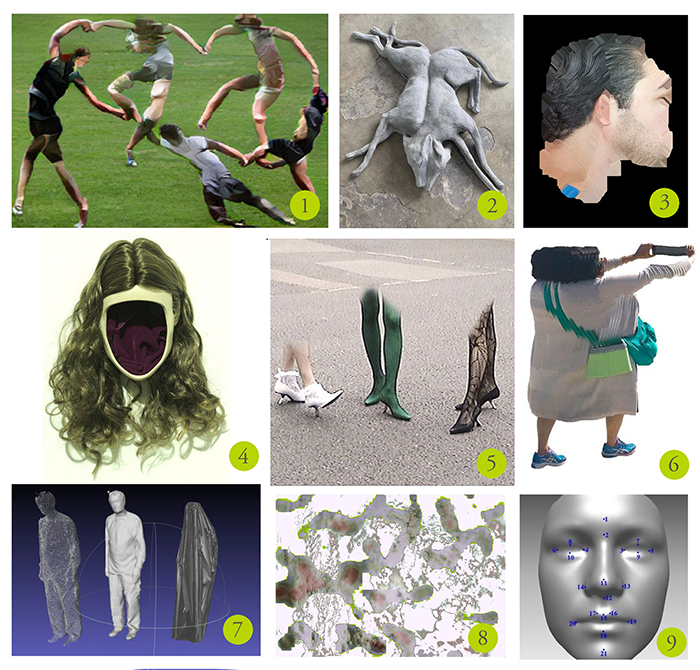

Final Product¶