9. S O F T _ R O B O T I C S¶

Think about = Soft, Movement, Inflation and Deflation

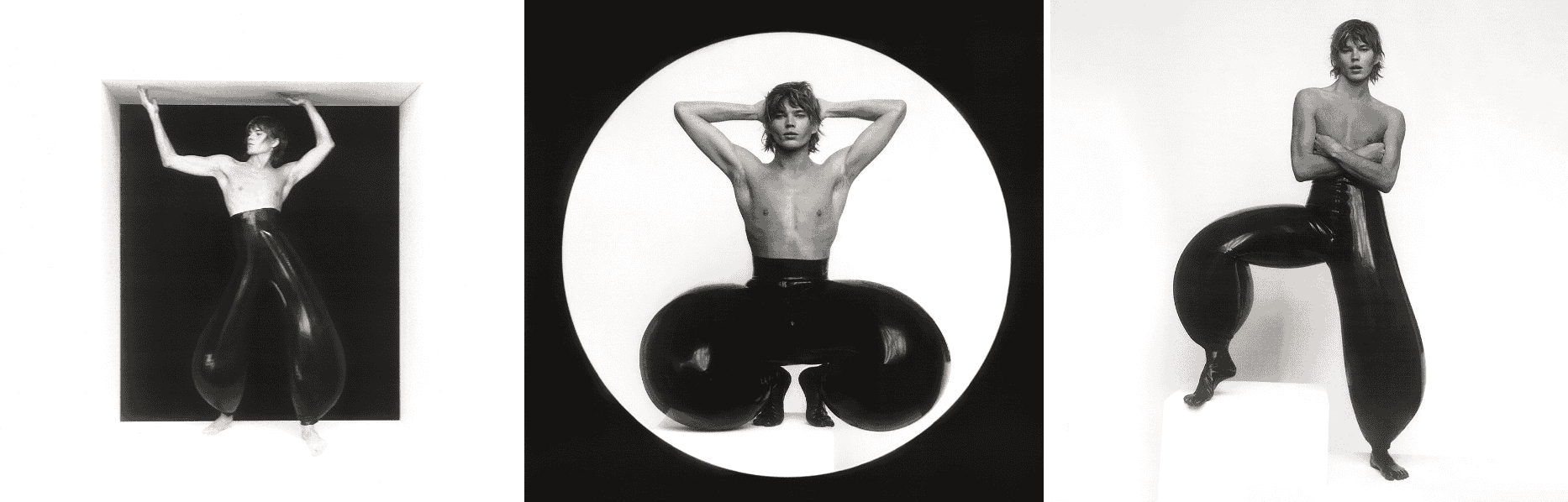

I N S P I R A T I O N¶

Harri is an Indian-born artist and designer based in London.

In 2020 he graduated from the Menswear MA at the London College of Fashion

The super-wide inflatable trousers consist of up to 30 individual latex panels.

This look is achieved by pumping the trousers with air via a seven millimetre-wide inflation valve at the bottom.

See more at HARRI

R E S E A R C H¶

Pneumatic Artificial Muscle with Bellows

Pneumatic Pouch Motor (hinge type)

Pneumatic Pouch Motor (muscle type)

Build-It-Yourself Soft Robotic Glove

3D-printed Folds-based Soft Actuator: Different Configurations

A Collapsible Soft Actuator Facilitates Performance in Constrained Environments

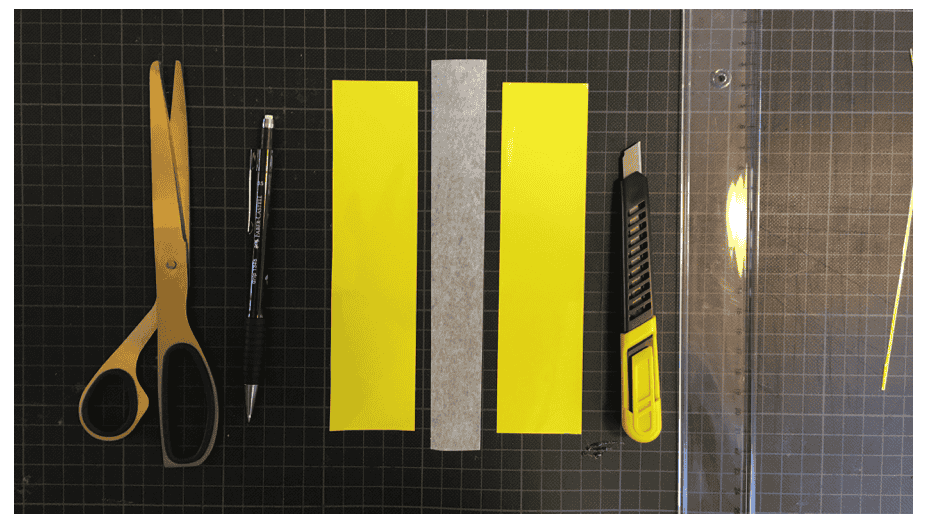

M A T E R I A L S¶

Some of the materials to use with Soft Robotics =

Heat press vinyl, baking papeer, scissors, PTU, straws, air compressor, inflation pump, silicone, gelatine, moulds

P R O C E S S¶

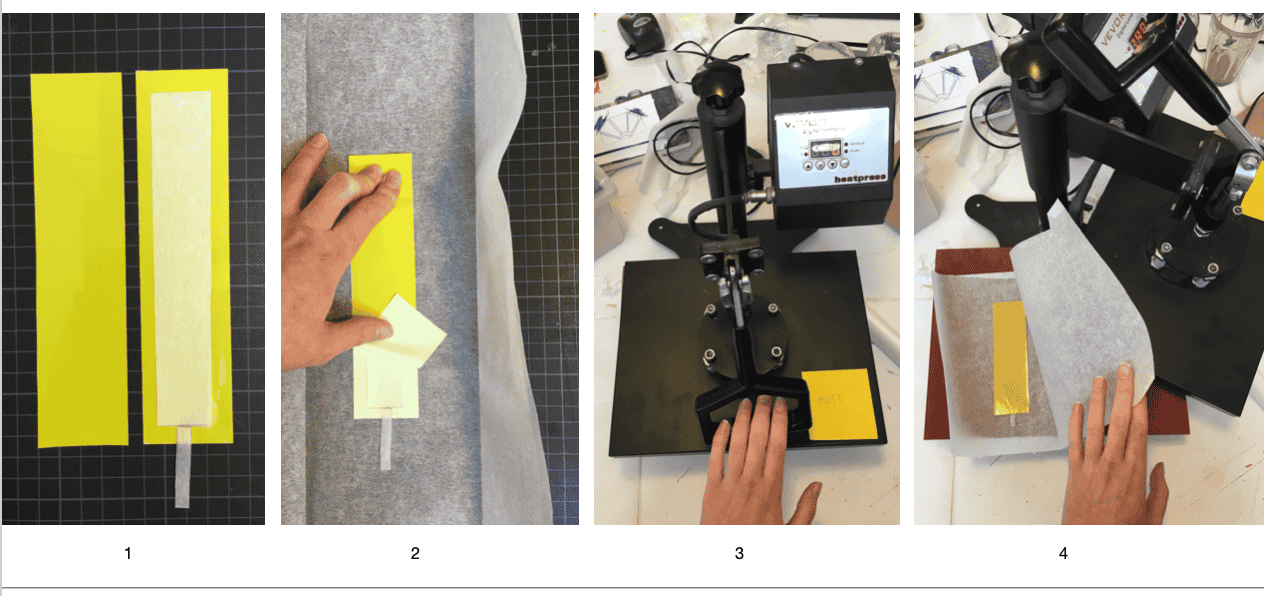

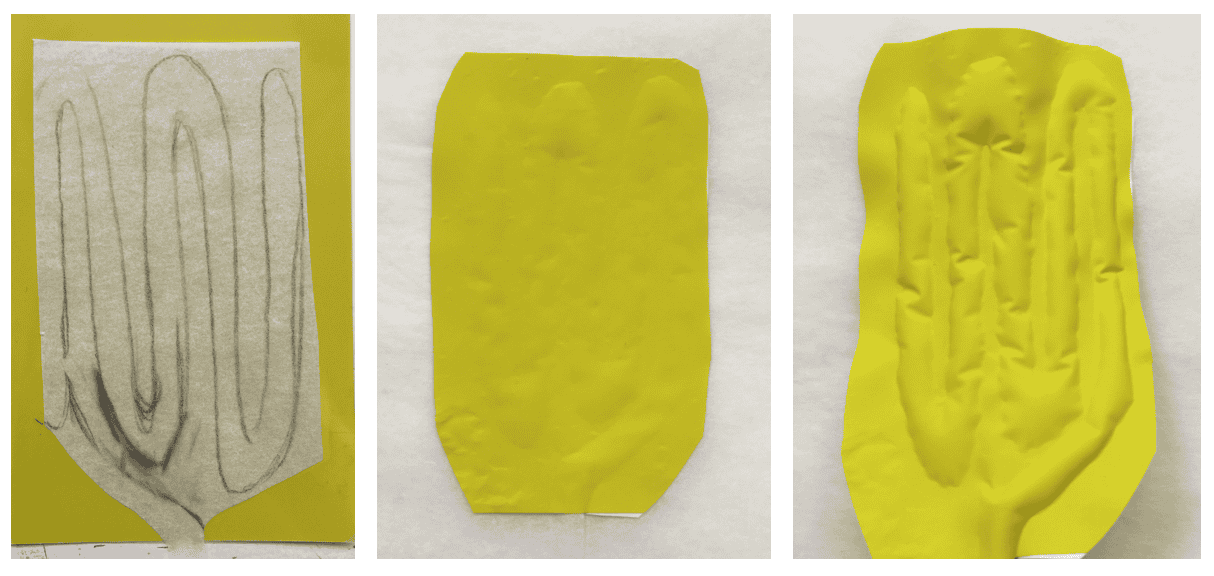

H E A T _ P R E S S¶

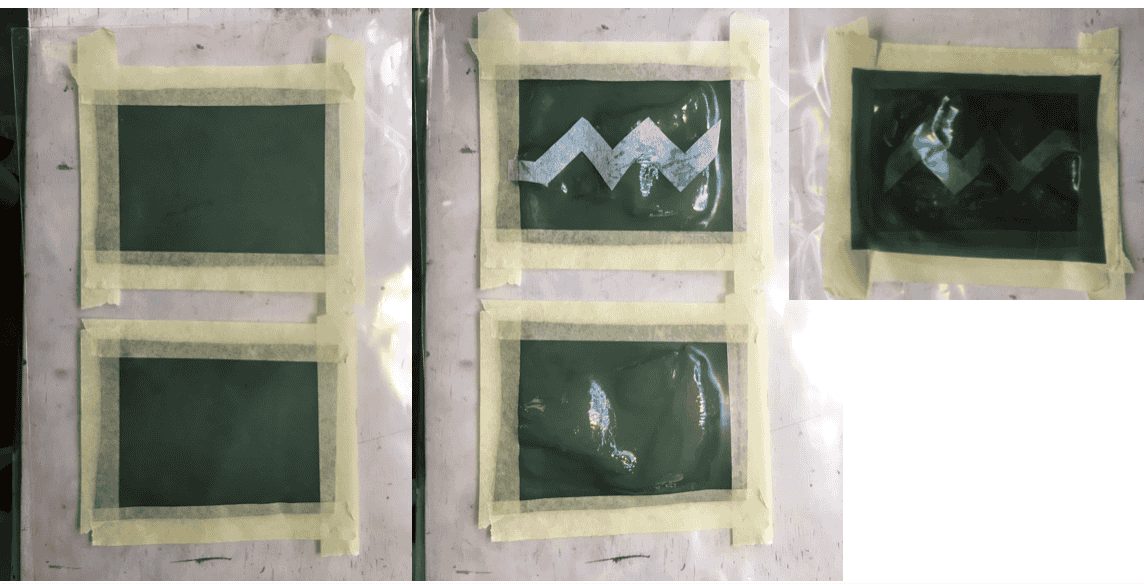

- Using Thermoadesive Vinyl + Baking Parchment to create soft robotics

_ 1 Make design on baking paper (ensure you leave a blow opening) and create vinyl outer design

__ 2 Place baking paper design inbetween vinyl (both shiny sidees facing out and matt sides in) + wrap in baking paper

___ 3 Put in heat press (140 degrees C for 15 seconds)

____ 4 Take out + peel off plastic protective layer carefully + ready to inflate!

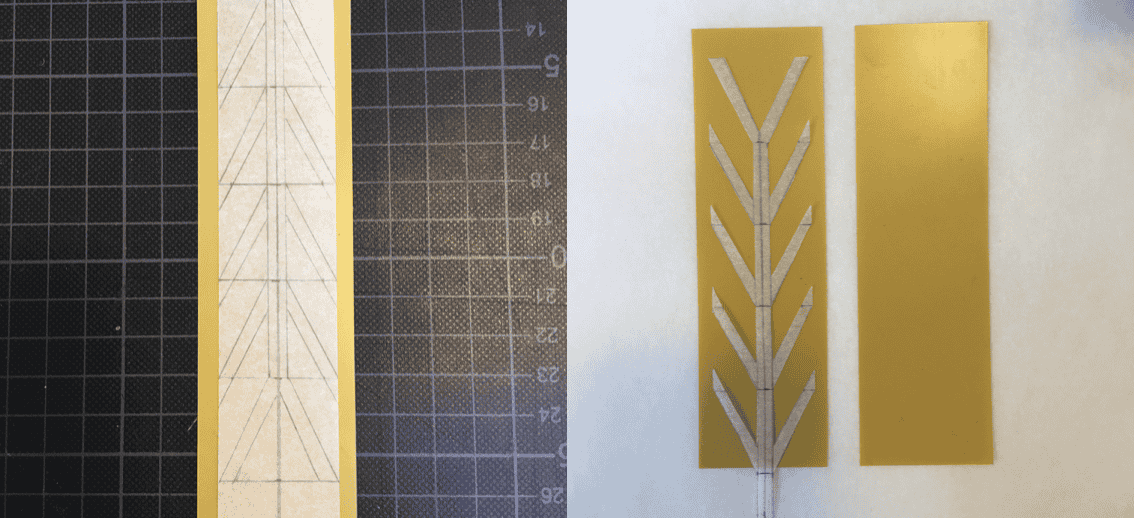

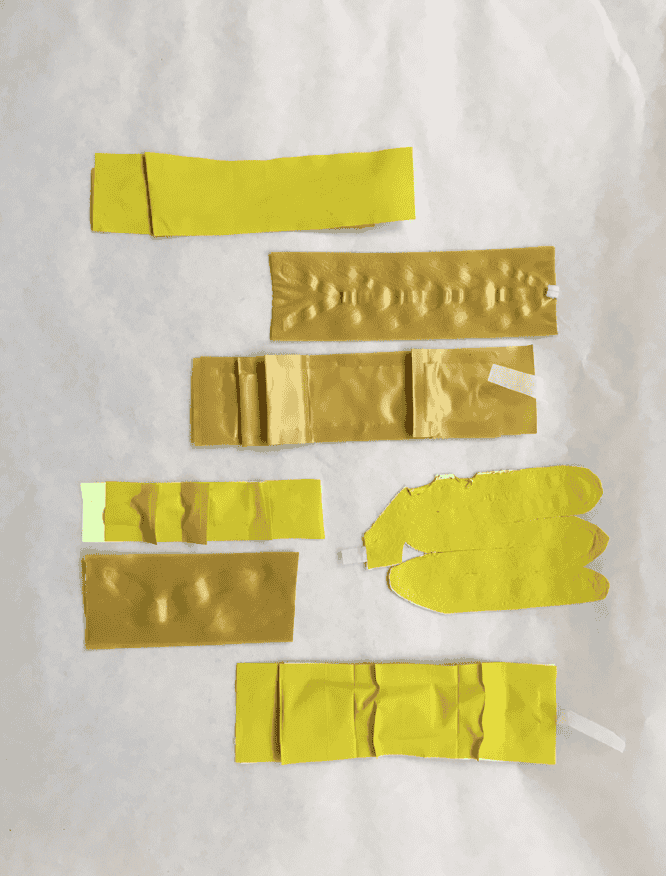

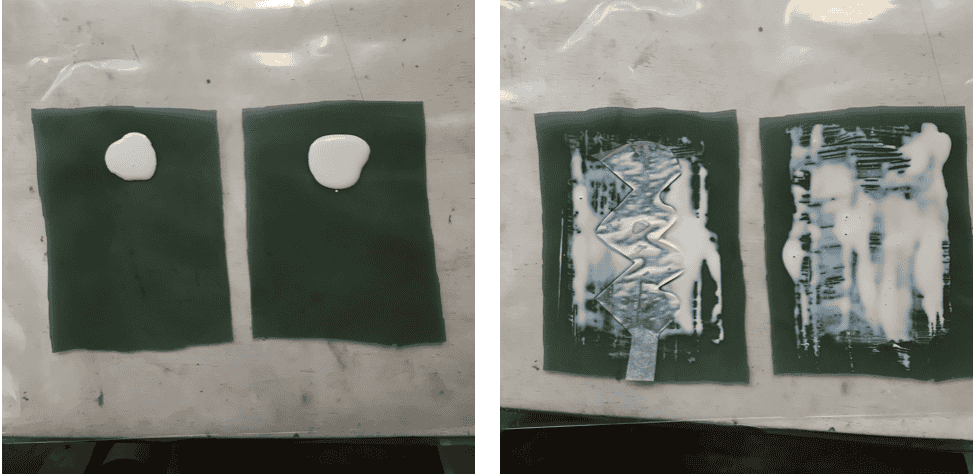

Some designs to experiment with the pathways of air

Not so successful experiments

-

I found when peeling off the protective layers the vinyl didn't stick that well in some places.

-

I then expiremented with taking the protective layer off and then heating it - which was too hot and melted it.

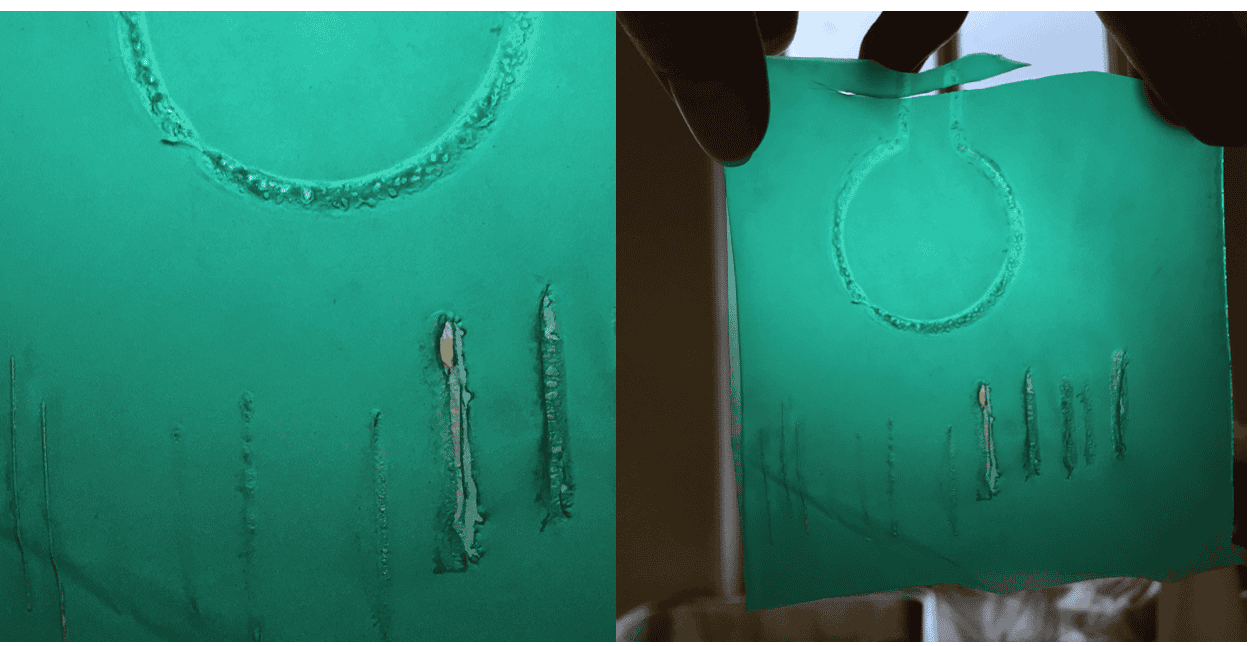

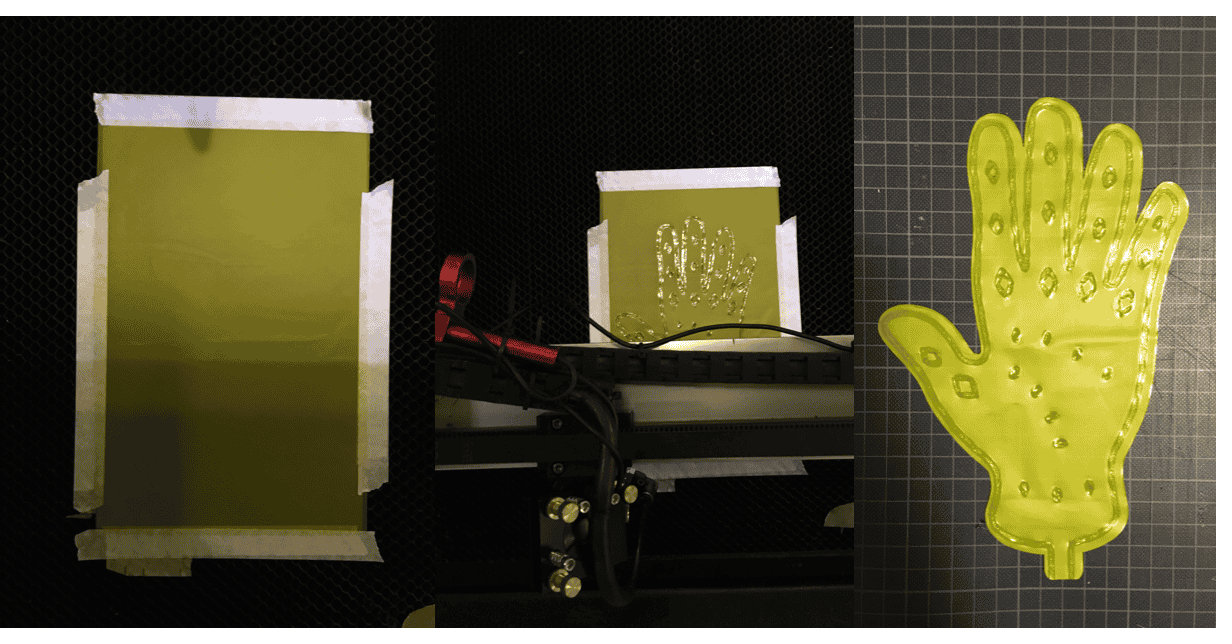

L A S E R _ C U T T E R¶

- Using TPU material + laser cutter to make soft robotics

Testing the TPU with various laser settings in order to get a cut line and a weld line

L A S E R _ S E T T I N G S

CUT LINE

100 - Speed

35 - Power Max

10 - Power Min

Use the normal jig to focus laser

WELD LINE

80 - Speed

40 - Power Max

10 - Power Min

Use all the jigs (38 mm) to unfocus laser

NOTE

-

Weld line before cut line

-

When changing the height of the laser focus, the laser tends to slightly move (allow for this in design)

-

Make sure there is a weld line inside the cut line

-

Allow for opening for inflation (10mm for a straw)

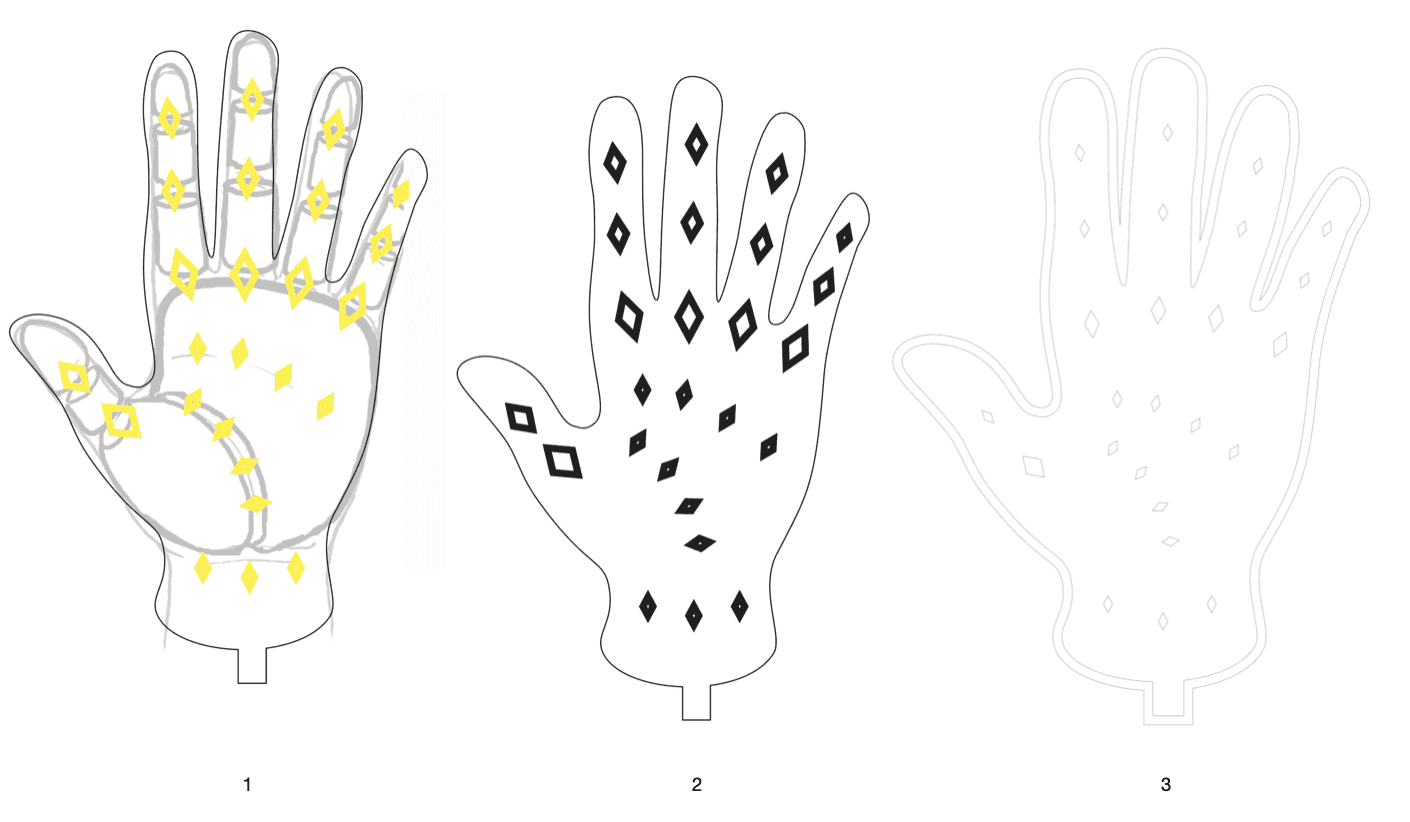

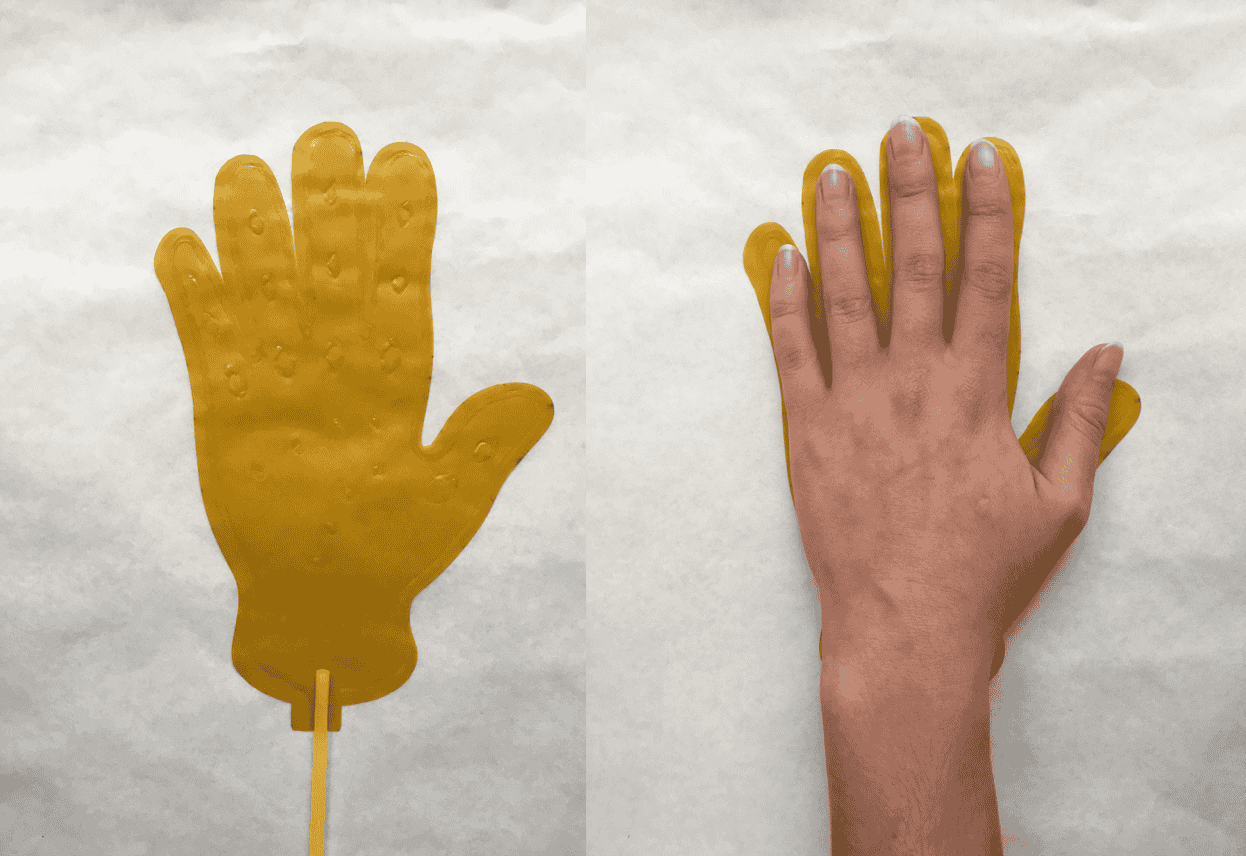

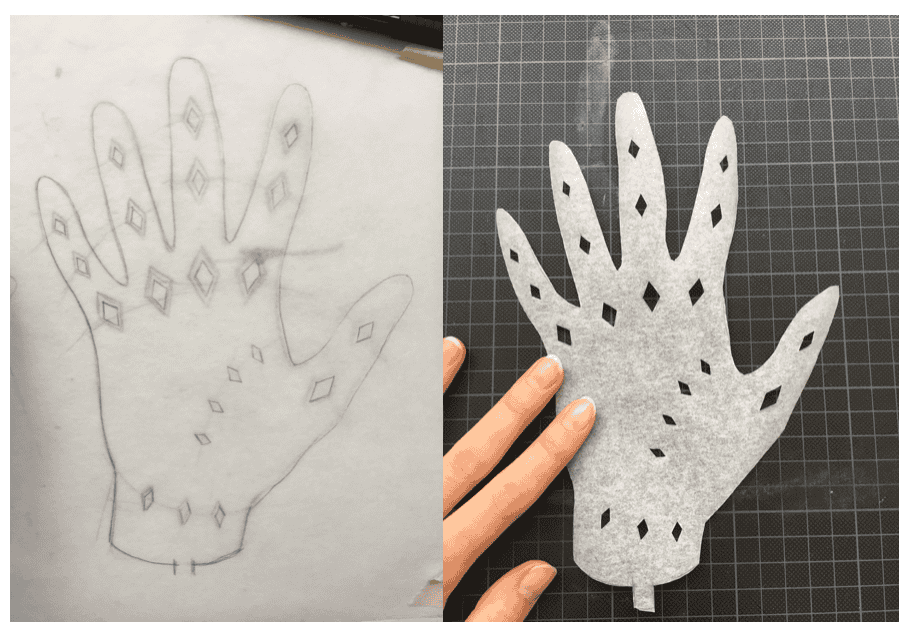

I decided that I wanted to make a hand that mimicked the movement of fingers, palm & wrist.

_ 1 Using illustrator I traced out the design from a reference image, and make diamond shapes for the joints

__ 2 I checkeed to see if the weld line would intersect the cut line by putting the stroke up to the size it would be

___ 3 Offset outer line to make cut line. Make the cut + weld lines diferent colours for the laser to read. Export as DXF file

- Iron PVC fabric gently to get rid of any creases / wrinkles.

Use nylon setting and place inbetween two layers of baking paper

- Hand size is similar to my own hand

I decided to alter the size and make the hand bigger and joints smaller to allow more airflow and thus hopefully more inflation

NOTE

- Laser weld line is not that precise in size (keep in mind for designs with small details)

After this I decided to try the baking paper and heat press method with the hand deisgn to see if there was more precision.

It did not, but here are some nice images of the proocess:

Observing possitive and negative space

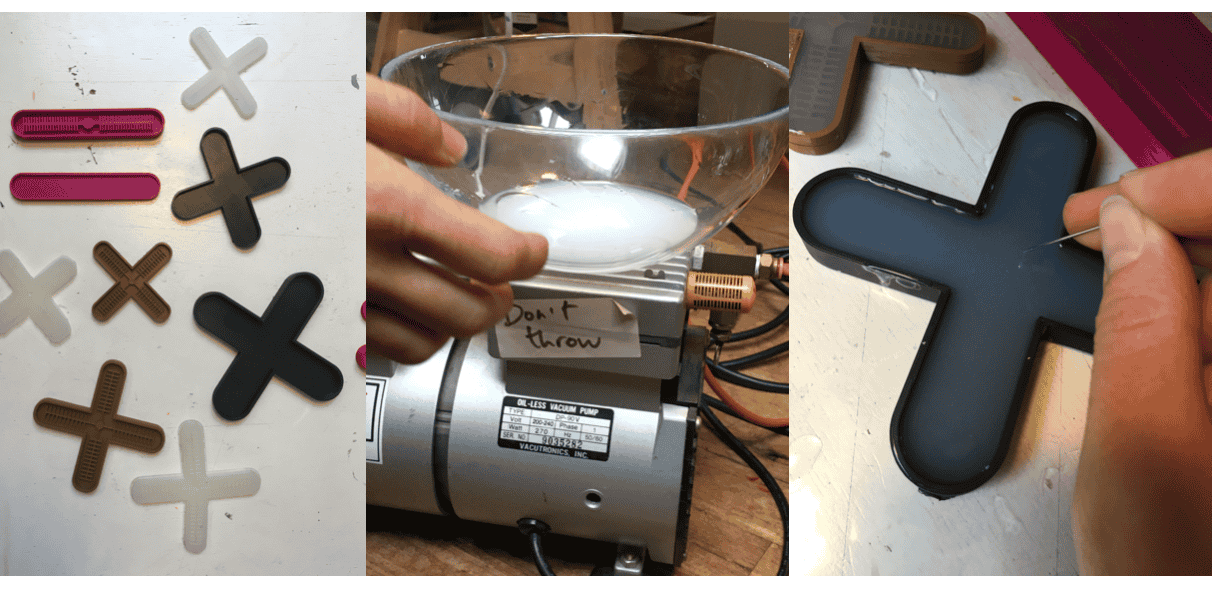

M O U L D S¶

Silicone vs Bioplastic

Casting silicone and gelatin resin into moulds to make soft robotics

Moulds found at Soft Robotic Gripper and Saskia Helinska

Silicone

1 : 1 ratio

50 grams part A

50 grams part B

-

Wait 4 hours for silicone to cure

-

When cured, close the two moulds together in place and seal using a small batch of fresh silicone

NOTE

Be very careful not to introduce any air into the mixture. Airbubbles are the enemy for inflatables!

Avoid airbubbles by

-

Not whisk, but fold mixture

-

Pour mixture high

-

Vibration

-

Air compressor vacuum

-

Pop airbubbles with needle

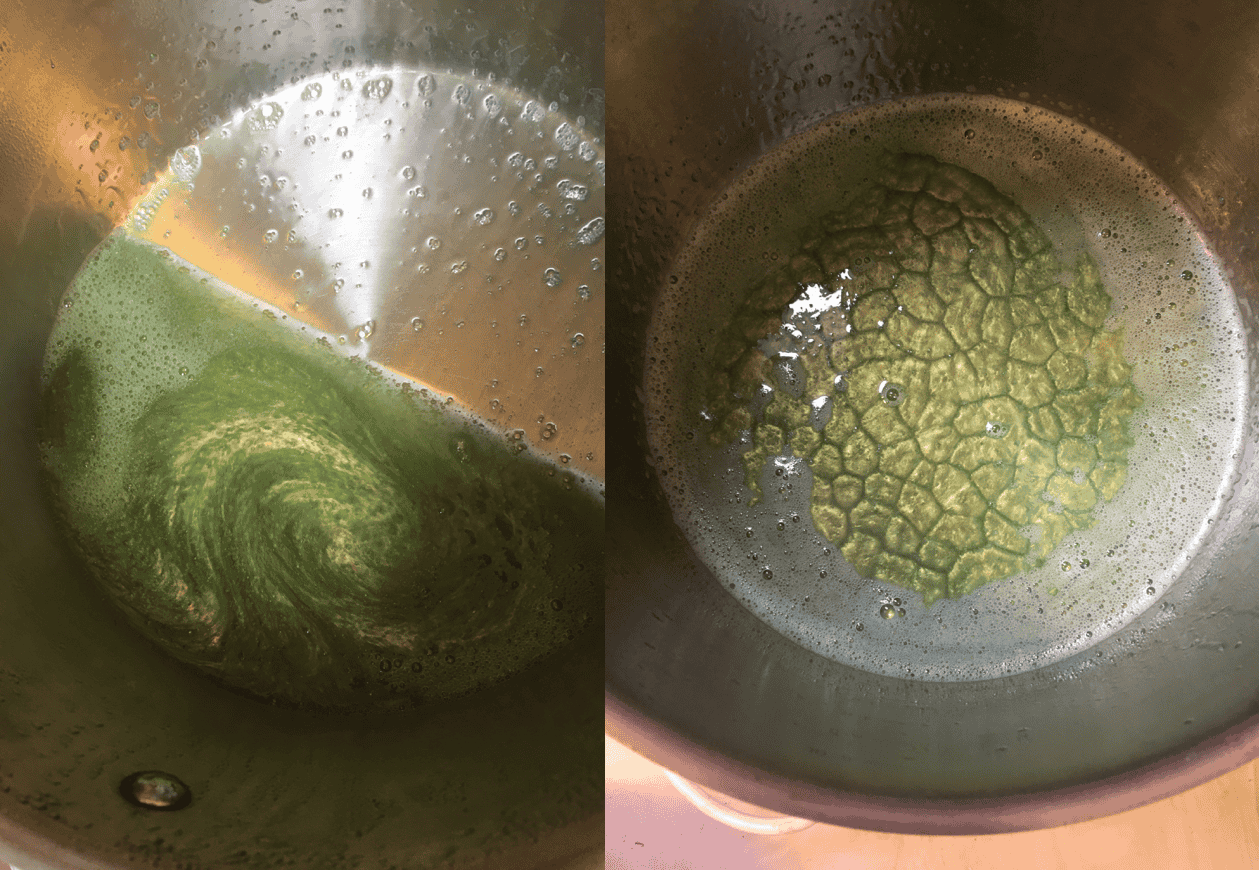

Gelatin

Gelatin Resin mixture with added golden green mica powder to give colour + sheen

1 : 1 ratio

100 grams Gelatin

100 grams Glycerine

500 ml water

Similar process to Silicone, but allow more time to cure

L A T E X¶

Latex is a versatile material with incredible stretch property

I tried various methods and materials to fuse latex in order to inflate:

-

Heat fuse (heatpress / laser cutter) = Did not work x

-

Latex rubber cement (collall brand) = Worked !!!! o

-

Liquid latex bond = Did not work x

-

Silicone bond = Did not work x

-

Bondaweb = Did not work x

Materials for fusing latex

_ 1 White spirits + cloth to prepare latex for glueing & get rid of any powder

__ 2 Collall Latex Rubber Cement & a squeegy to disperse glue

___ 3 Pre-Vulcanised

Still use baking paper as airflow design

Laser cut latex settings

CUT LATEX

50 - Speed

40 - Power Max

10 - Power Min

M I X E D _ M A T E R I A L¶

I decided to try different materials for the heat press method as I didn't like the result of the 2 layers of vinyl

With these tests I used 1 layer of vinyl + 1 layer of polyester fabric which fused well and I was happy with the results

NOTE

Polyester had waterproof layer on the inside which made it less breathable thus better for inflation

V I N Y L + P O L Y E S T E R

With this, I decided to use 2 layers of polyester fabric + bondaweb inbetween to fuse.

Cut out design in the bondaweb (substituting baking paper for bondaweb)

P O L Y E S T E R + B O N D A W E B

This method worked very well

NOTE

When bonding the gelatine pieces together, first heat them up so that it will stick sufficiently

C O N C L U S I O N¶

-

Heatpress = I prefer working with other materials (polyester, bondaweb) opposed to 2 layers of vinyl which don't work as well in my opinion

-

Lasercutter = Bare in mind welding lines are thick, so make design with this in mind

-

Moulds = Silicone appears to work much better the the gelatine resin, however it does seem to burst if given too much air

-

Latex = works well with latex cement, however it is messy and tricky to apply

-

Other Materials = 100% poly with coating and negative design in bonaweb works very well from what I have tested. This fusing gives more possibility to use other materials

F U T U R E¶

-

Would like to develop power for soft robotics with electronic control pump. Example tutorial = Arduino - Control Pump

-

Idea = anatomical muscles in garment that you can pump up on the go!

-

Persue further the different movements and mimic the human body

-

Develop inflatable latex knowledge and expirementation

-

Experiment with the possibility of pumps