Problematic

Knee complications and knee injuries are so common, that it is considered as a quiet epidemic. Knee pain can be experienced by youths as well as adults and older people, and is not only caused by injuries. Knee pain is often the result of “inappropriate biomechanics” leading to increased force on the knee like patellofemoral pain syndrome or knee conditions like osteoarthritis. Often, patients feel restricted in their abilities to perform household or recreational activities and are scared to push their knees due to fear of causing further damage to their knees. Even after treatment, it takes a lot of work and patience to regain trust in the injured knee. Anterior cruciate ligament tears are common among athletes. These can cause significant emotional distress due to the long downtime from sport as well as predisposing the patient to the development of earlier knee osteoarthritis. Some ACL injuries require surgery with months of post-operative rehabilitation.

Treatments can vary a lot, depending on the type of injury or knee pain. After an injury, resting, applying cold, compression and elevation is recommended, followed by rehabilitation when the condition gets better. For chronic knee pain, it is recommended to see a specialist such as a physiotherapist, and creating an exercise program personalized and adapted to the patient's pain. Psychological treatment can be taken to learn to better distinguish hurt from harm and to counselling to reduce fear of movement. Drugs and medications can provide temporary pain relive, but do not contribute to improve the patient's condition.

Reserch and planning

I feel it's important to talk about my journey from the beginning, since I had so many doubts. I knew from the start that my projects were ambitious, and that it's hard to get something working as I would dream of in so little time. With the covid-19 pandemic, I had to work from home most of the time. Getting oragnised was not an easy task! My research notes and planning is still available, I used my very chaotic miro board to take notes during the process.

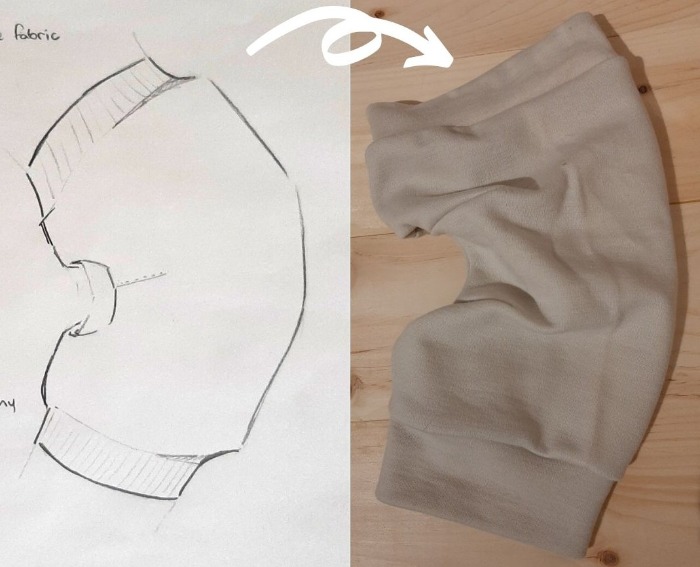

First design

For the first idea, I had in mind that I wanted to help reduce the pain caused by a knee injury. By supporting a bit of the weight with inflatable robotics, and by stabilising the knee, It would be an everyday solution.

...But all ideas are ment to evolve, right?

I booked an apointment with a physiotherapist, for myself, but also to talk about solutions and elements to help ease the pain on the knee. The last thing I want is to create something that could be dangerous for an injured knee! First things first, knee injuries are unique to each individual. There is no such thing as "the most common type of knee injury" so I would like to concentrate on my particular case; I got injured when I was 16 years old, while speed skating. A stretched ligament. Ligament never fully heal, so I was at risk of hurting myself again, wich I did, a couple of years later. After this injury, the pain stayed everytime I skated, and no treatment from specialists could help me. Radio or magnetic resonance imaging could see a clear problem. Since then, I use a knee brace for sports and activities that could pu my knee at risk.

Since each injury is unique, and since we can't really see what is the problem inside, physiotherapists have to listen to their patients and their reactions. It's hard to prove that something is helping, and that we really found the source of the problem. Injuries like mine are usually due to muscle imbalance. A proof that we discover more about this topic each day: my phisiotherapist told me that we recently dicovered that most of knee injuries are actually caused by back problems. It's also hard to make a difference between something that is working and something that gives us a placebo effect. He told me that ice and heat are not prooven to help reduce the pain. It might help some people, so they still recommend patients to try it, but it might just be recomforting. It has ben prooven that ice can reduce inflamation tho, but in my case, it's not prooven that it would have any use.

What worried me the most is this (I definetly should have tought about that before): Knee brace are mostly designed for right after an injury, while you want to give it a rest, and rehabilitate it slowly. During the healing stage, the knee is delicate, and is at risk to get hurt again with a wrong movement. It's best to protect and stabilize it. Once the healing stage is complete, the knee needs to be stronger to prevent future injuries. Doing some exercices, and then using it nomally should do the trick most of the time. It's not recommended, at this stage, to use the knee brace regularly. It can be used in exeptionnal situation where there is a high risk of injury, but if a brace is worn at each workout, the knee will become lazy. Muscles will be weaker, and this could not only lead to muscles imbalence, but to another injury too.

So my knee brace simply cannot be designed for a regular use.

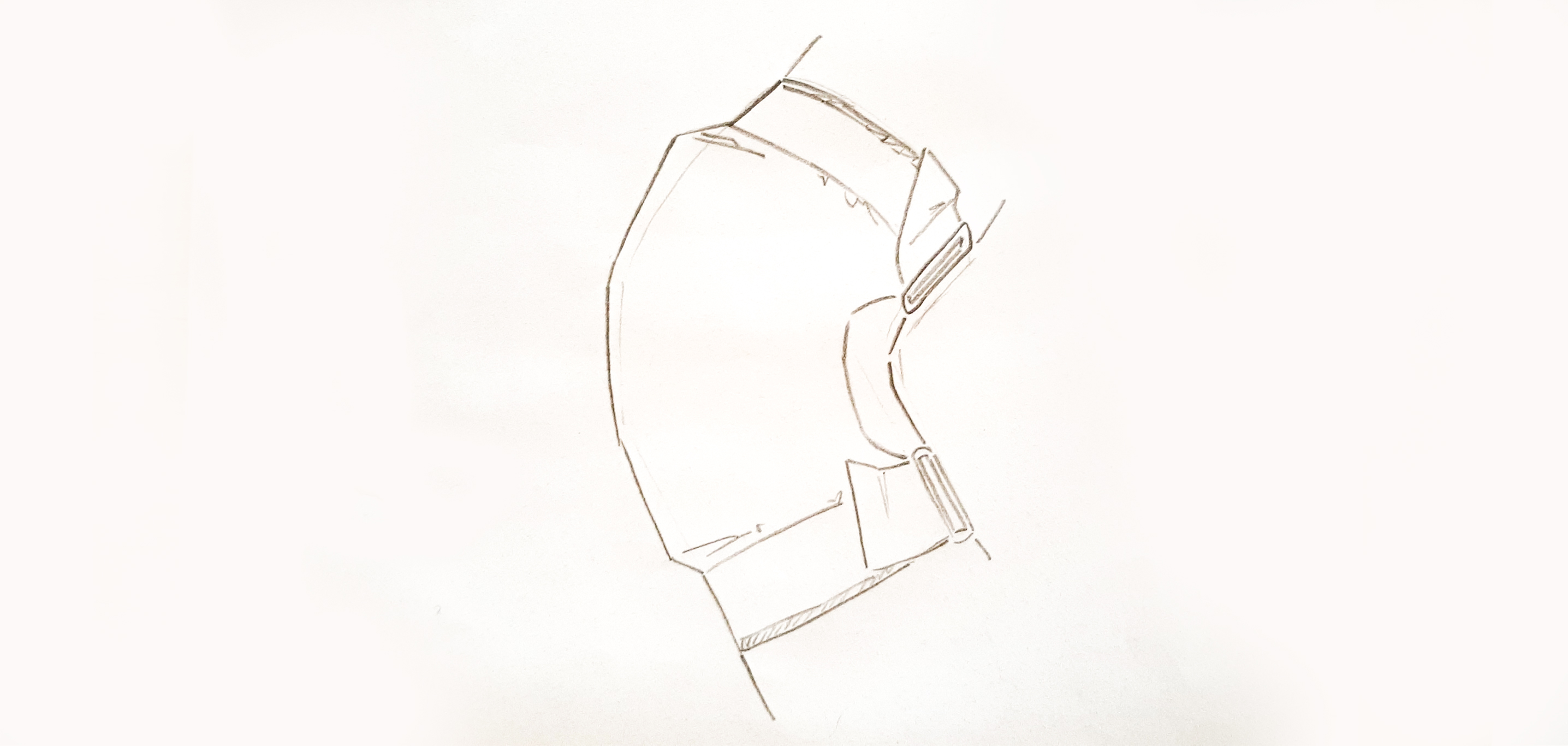

Second design

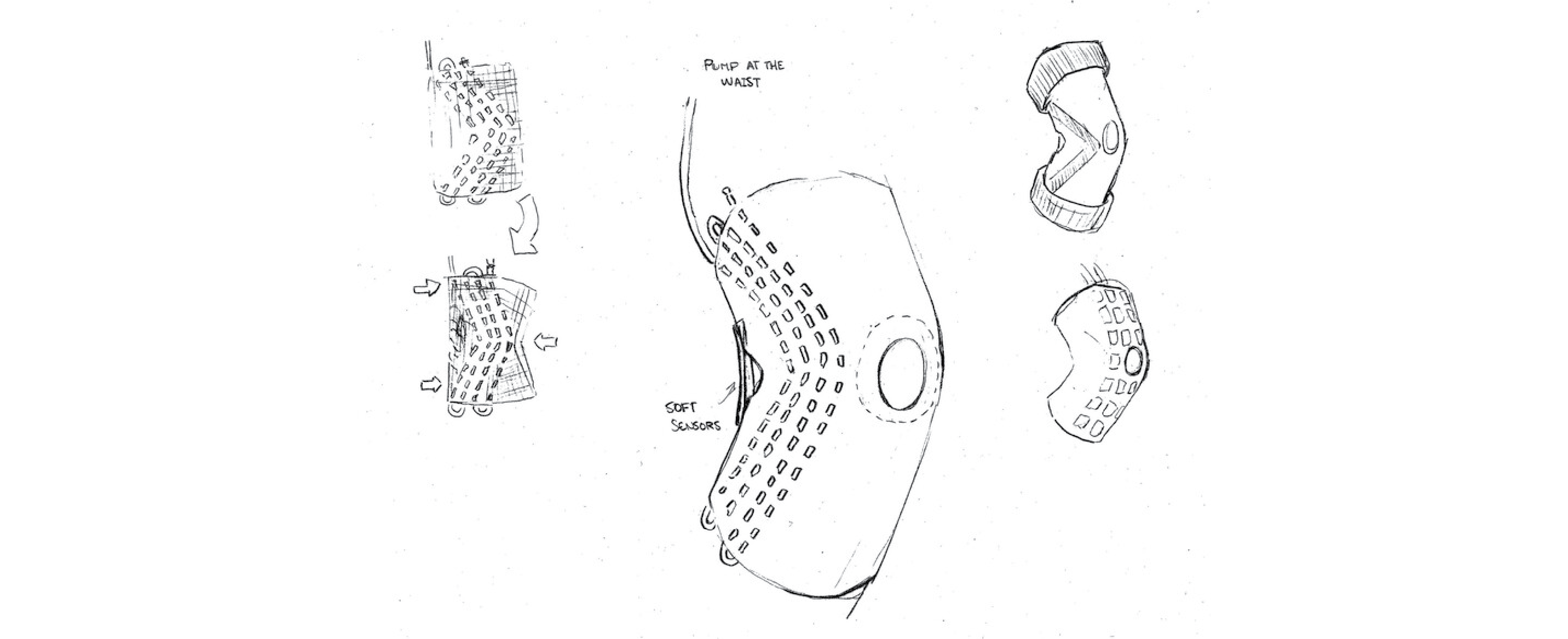

My product had to be better attapted to the reality of the patient. The firsts weeks of my project were dedicaded to the development of an idea that would really help the costumer, and that would still be acheivable in the time left. My Miro board evolved with my ideas; and to better guide my decision, I made a list, and did a bit of research, about everything I could integrate in a kneebrace to help the condition of the patient. my ideas were presented in a group so we could discuss the adventage and dissaventages of each one.

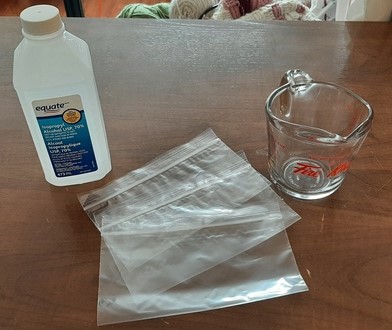

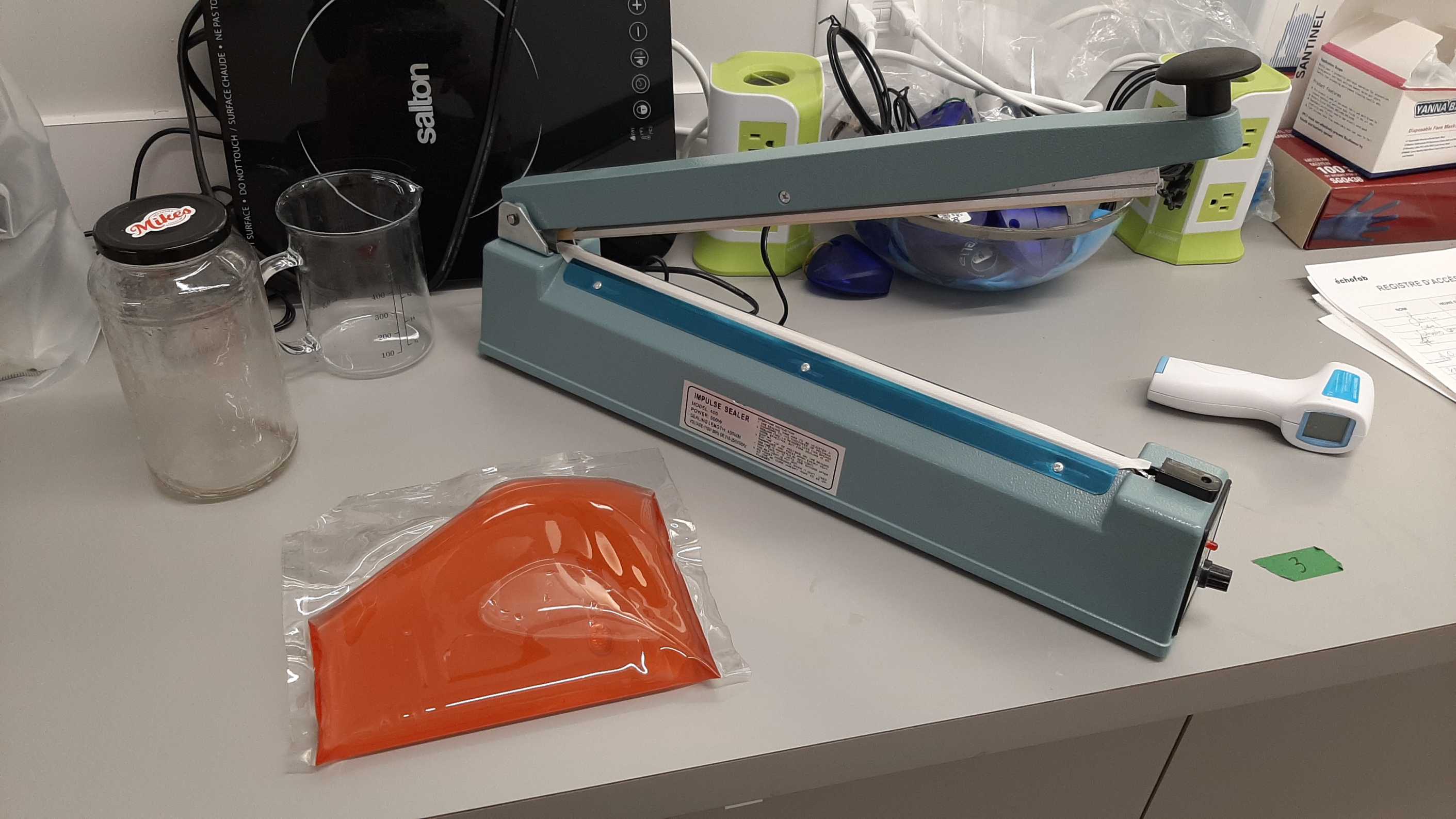

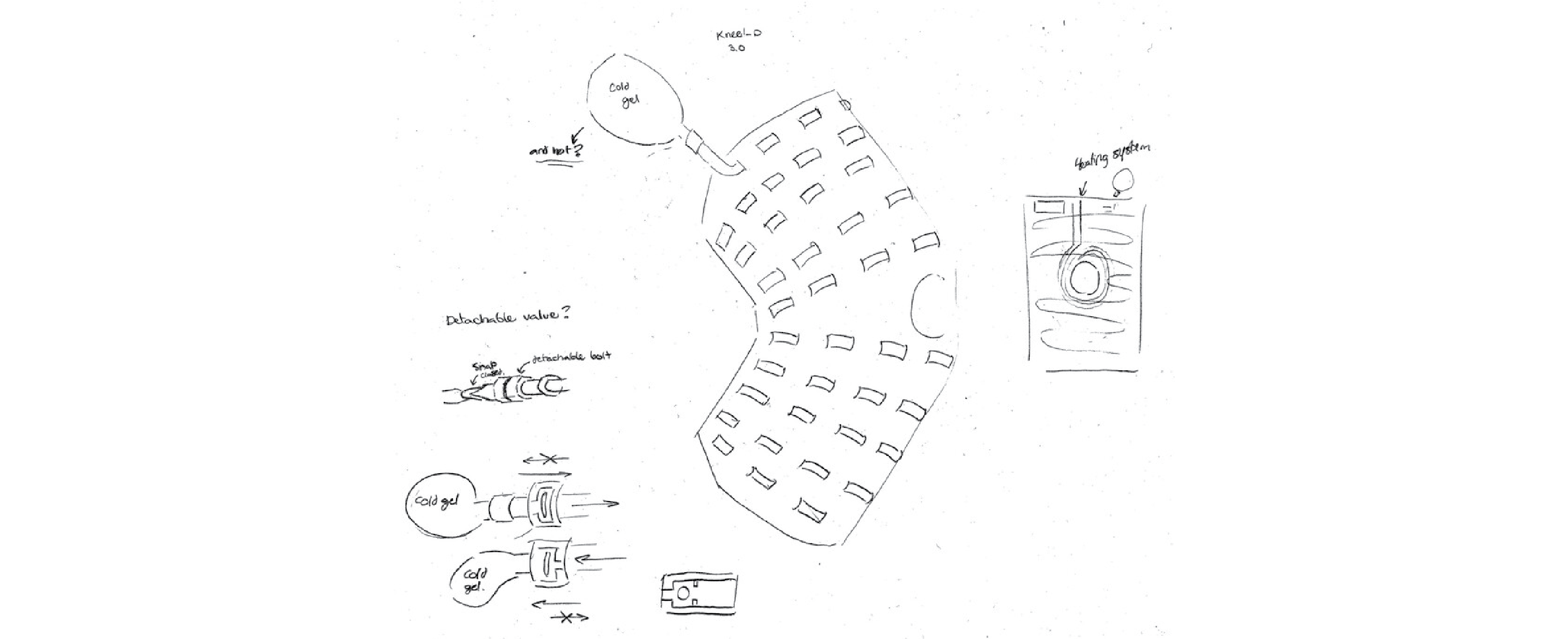

Heat and cold were the elements I choose to integrate in my final project. They can reduce pain, but aren't too technical, so it's easier to create a working product and to get it approved. They are also nice elements to wear, and it would be a nice thing to develop.

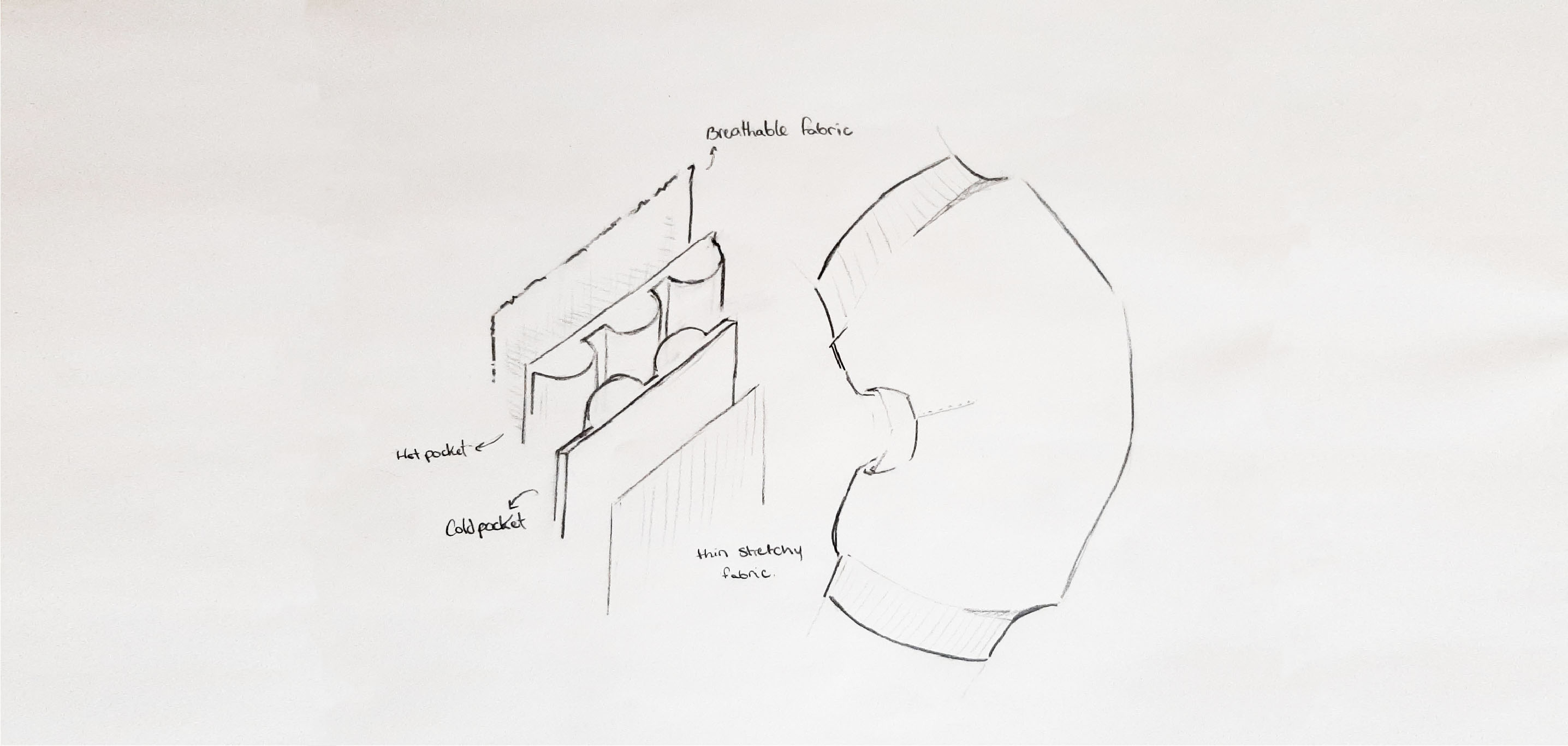

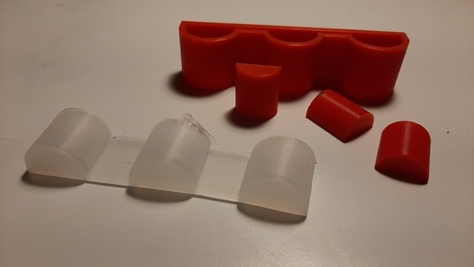

The second design I presented had silicon tubes weaved into it. An external pocket could be heated or cooled, and the mateterial (liquid or gel) coud be pumped in the tubes. The tubes, as they inflate, would apply a pressure and help stabilize the knee. It turned out to be complicated for nothing. My final idea turned out to be very similar to this one.