07 BC fermentation

The Kombucha fermentation was made inside a growth box with 3 seedling heat math’s to regulate temperature. The temperature was held between 30-35 °C PH value 2-4.

For the fermentation bath, we used regular plastic boxes.

1) Boil the water for 30 min to sterilize before letting it cool down to 30 C°

2) Ad sucrose, nitrogen source as well as small piece of SCOBY mother

3) Add the ingredients to the vessel and tie a cotton fabric cover as a lid, this will protect the fermentation bath from flies and mosquitos while still allowing it to breathe.

4) Do not move or shake the fermentation bath before harvesting.

5) Monitor the temperature and PH values during the process.

Note: Be sure to properly sterilize all equipment before inoculation; wipe the growth box, working table, and fermentation vessel with alcohol. Smaller objects like fabric lids and tools can be sterilized in a pressure cooker.

Reciepe: kombucha¶

Reciepe K-A.

• 3L Water

• 30 g Green tea

• 300 g Sugar

• 150 ml Natural vinegar

Reciepe K-B

• 3L Water

• 30 g Green tea

• 300 g Sugar

Reciepe K-C. 25/1

• 1L Water

• 1L Beer (Argus Suave)

• 100 g White sugar

• 100 g Brown sugar

Reciepe K-D 4/2

• 1L Water

• 1L Beer (Argus Suave)

• 100 g White sugar

• 100 g Brown sugar

• 110 ml reciepe K-C

Reciepe K-E 20/2

• 45 gram tea

• 300 gram suger

• 3 liter water

Reciepe K-F 20/2

• 15 gram coffee

• 540 gram suger

• 3 liter water

Reflection of the BC fermentation process:¶

Though optimal fermentation condition was not this research's main point, some observations could be made.

K-A and K-B failed because of contamination.

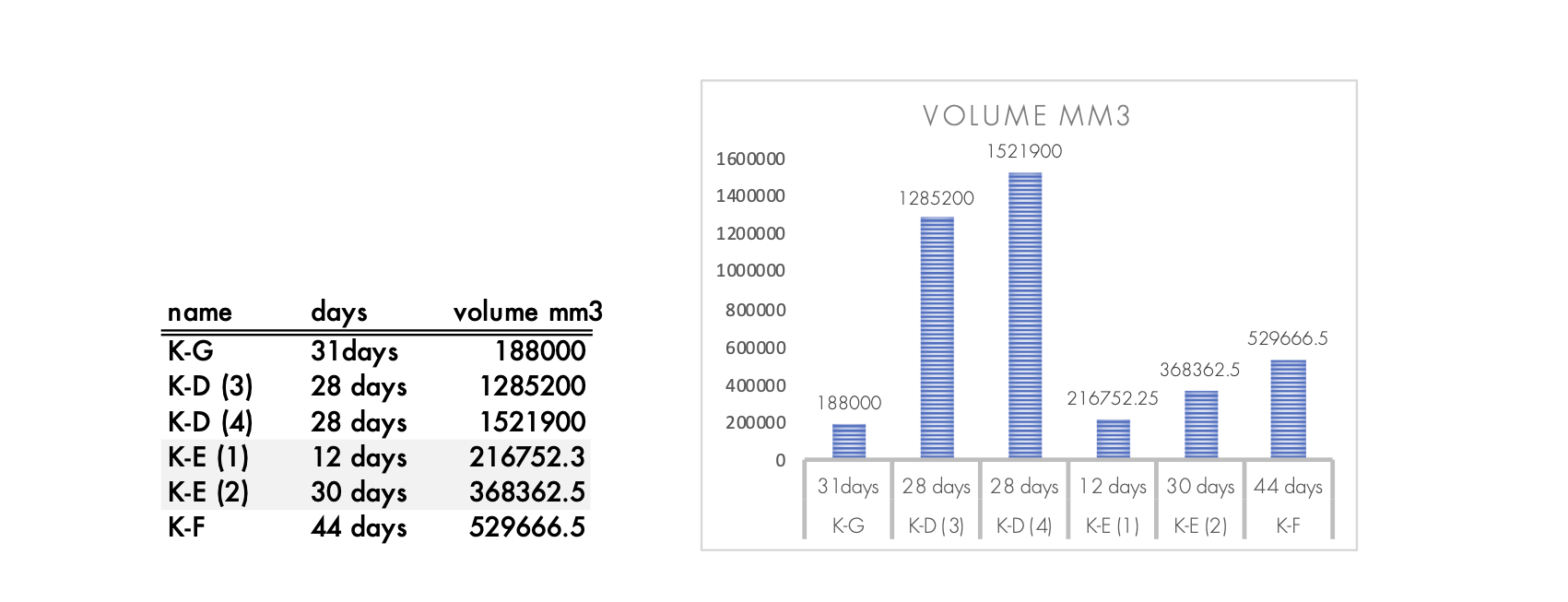

The beer recipe K-D showed impressive growth with more than double the speed of growth. This is likely because of the existing yeast culture in beer that seems to kickstart the fermentation process. However, the quality of the cellulose production is less good the sheets are “puffy” and fragile easily falling apart during handling.

No comparison of purified yield was made but my guess would be that the actual cellulose production from the beer fermentation would not be more than other bacterial cellulose recipes.

No comparison of purified yield was made but my guess would be that the actual cellulose production from the beer fermentation would not be more than other bacterial cellulose recipes.

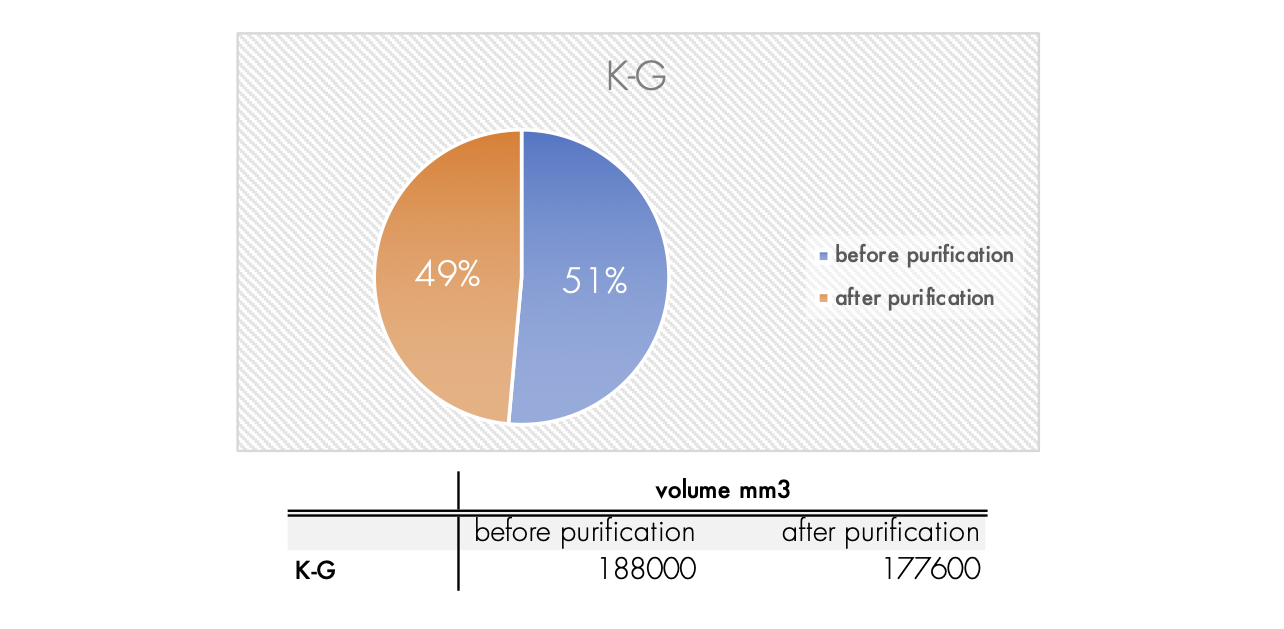

Purification experiment with K-G indicates only 2% loss in volume from the process.

K-E was the clear winner it was producing even and strong pellicles with a far superior yield (compared with K-F and K-G). K-E was harvested after 12 days (K-E(1)) and the bath was left growing (K-E(2)). One explanation for the high yield could be that the removal of top layers allowed new layers to free oxygen supply and thereby increased cellulose production.

K-E was the clear winner it was producing even and strong pellicles with a far superior yield (compared with K-F and K-G). K-E was harvested after 12 days (K-E(1)) and the bath was left growing (K-E(2)). One explanation for the high yield could be that the removal of top layers allowed new layers to free oxygen supply and thereby increased cellulose production.