11. Implications and applications¶

This is an overview of the problem I want to solve and the long-term goals for the project:

For the final project (and beyond) I want to investigate how we could build on innovations in bioprinting to produce garments straight from cell-grown fibers, drastically reducing energy consumption and creating a new localized supply chain tailored to meet the demands of a new creator’s economy (Web 3.0).

goal:¶

Fashion bakery: A production method that is simple enough that the full process from cell to finished garment can be done in a design studio while at the same time being flexible and adaptive to different designers’ requirements.

framework:¶

Simple: that the full process from cell to garment should be possible to produce in-house

Low quantity: the technique should not require scaling to be feasible for designers

Cost-effective: Be a competitive option for small scale designer brands

Flexible: should be able to meet different designers artistic requirements.

Problem:¶

There is two main problem with 3D printing garments:

Material: None of current plastic filaments are meeting the basic requirement of consumer: flexibility, breathability, absorption, and drape

Print volume: since clothes are relatively large and flexible it is difficult to build efficient build platforms without the need of support structures.

Both of this problems might be able to solve with new recent innovations in the field of bioprinting:

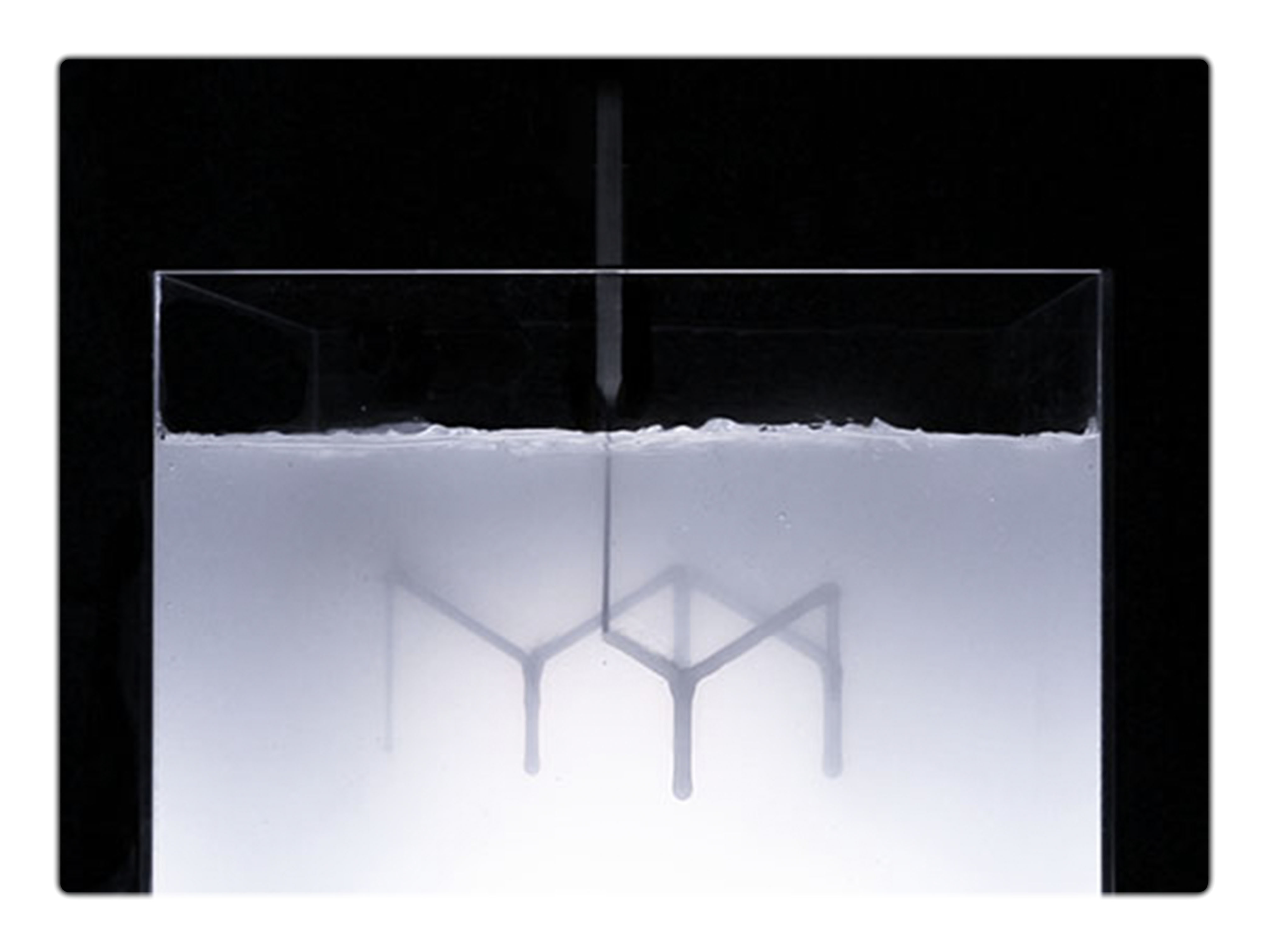

FRESH bio printing¶

Freeform Reversible Embedding of Suspended Hydrogels (FRESH)

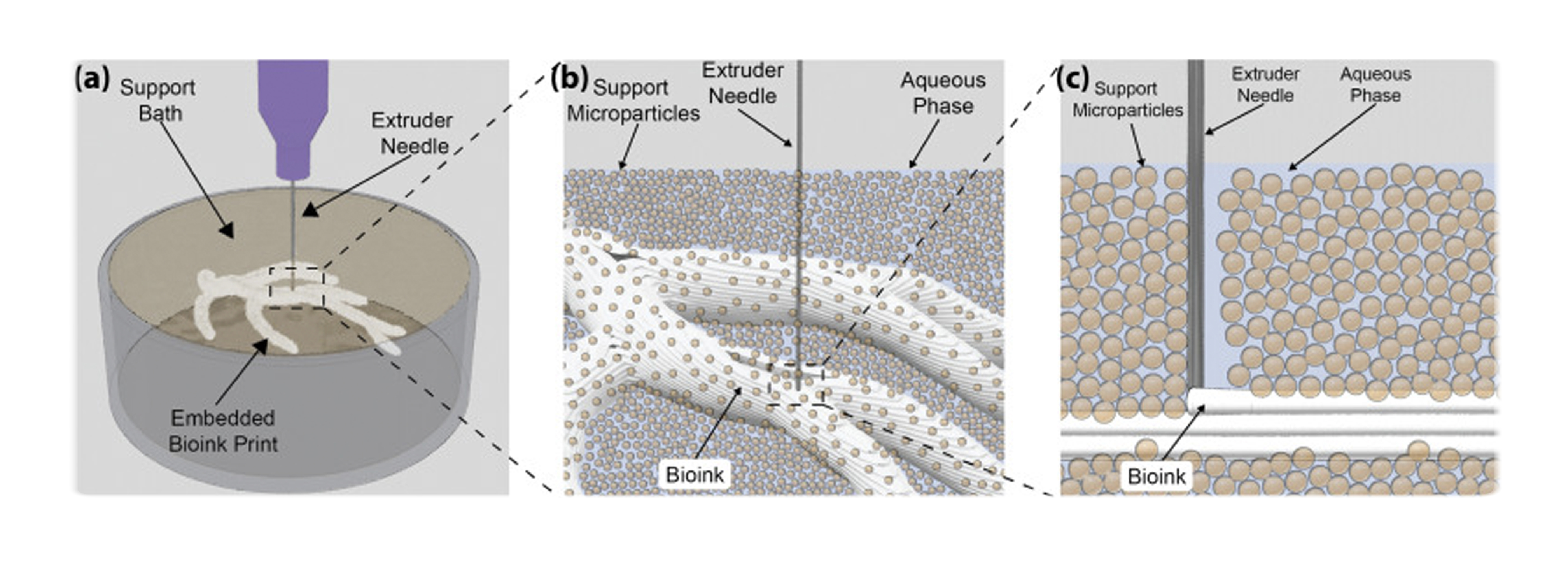

The problem with printing fluid material such as bioinks is that it is hard to sustain it´s shape, especially for larger prints Dr. Angelini from University of Florida introduced the idea to print using a suspension bath of microgel.

What is microgel? Dr Angelini explains using hand sanitizer as an example, the reason why the air bubbles inside the bottle doesn't raise to the surface is because under low levels of applied stress, jammed microgel behave like elastic solids trapping the bubbles inside the liquid, however when we pump out the liquid through the nozzle it flows like any “normal” liquid. In short the material is a solid when still and a liquid when put under stress.

This makes the perfect support medium for 3D printing.

Microgels can be made of:

• Gelatin

• Alginate

• Carpool

• agarose

• cell/speroid slurry

• cell- laden

needle movement in the support batch

needle movement in the support batch

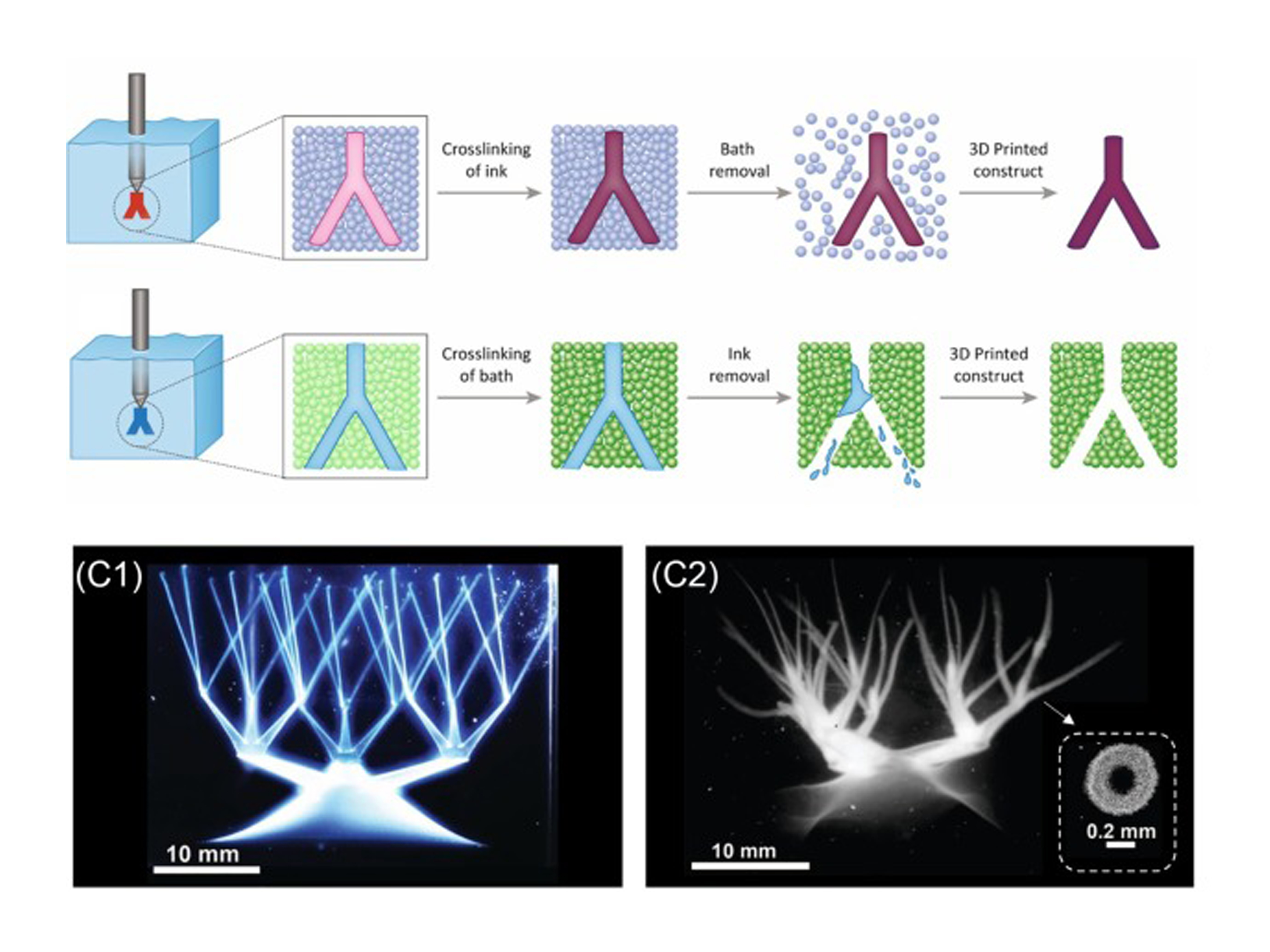

pink: bioink printed in microgel blue: reversed microgel printed into a bioink reservoir

pink: bioink printed in microgel blue: reversed microgel printed into a bioink reservoir

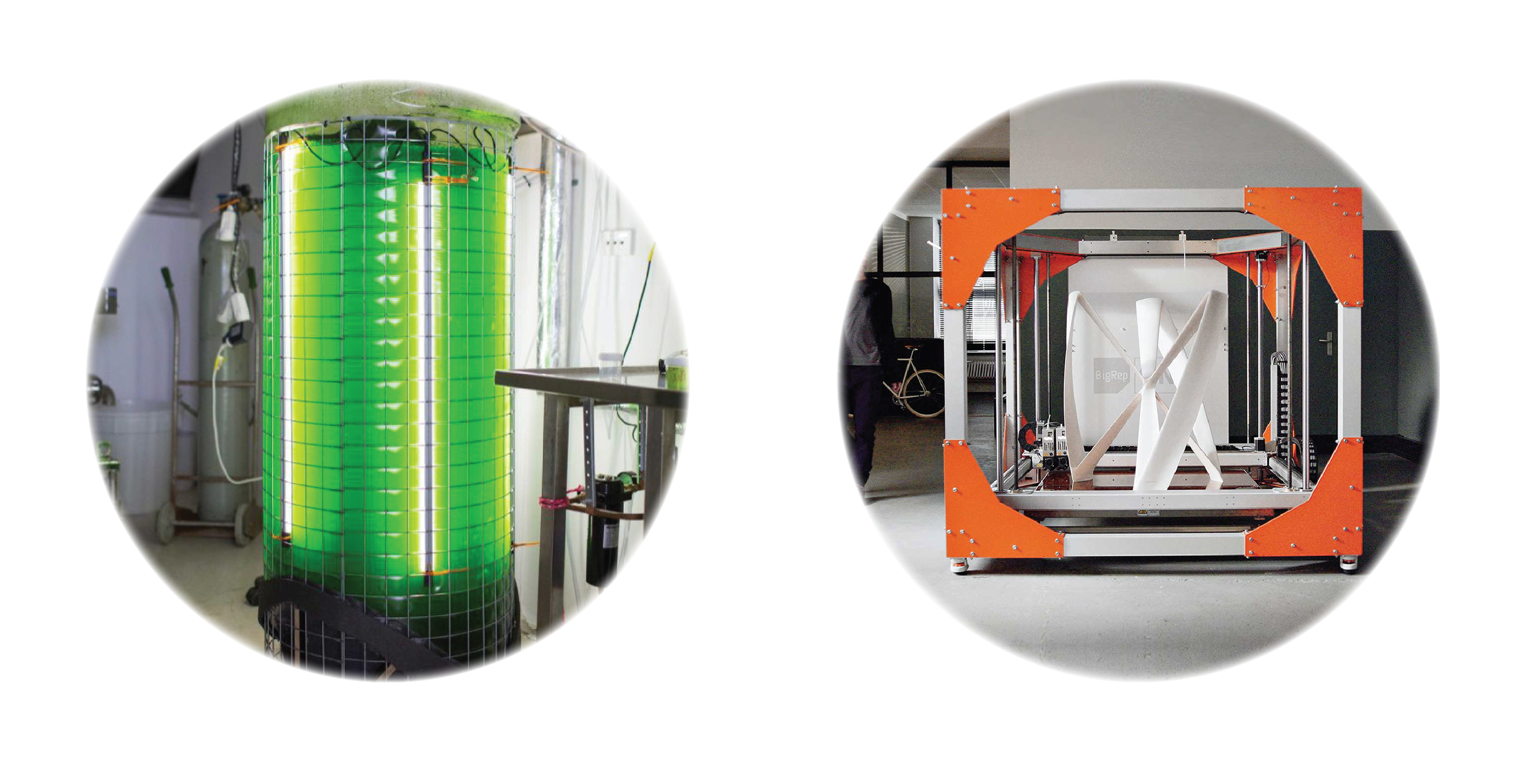

Similair experiments have been done by the Soft matters Media lab at MIT using traditional 3D printing. They have been able to develop a technique called RLP (rapid liquid printing) for printing large format hard object much faster then with tradional 3D printing tecniques.

RLP

RLP

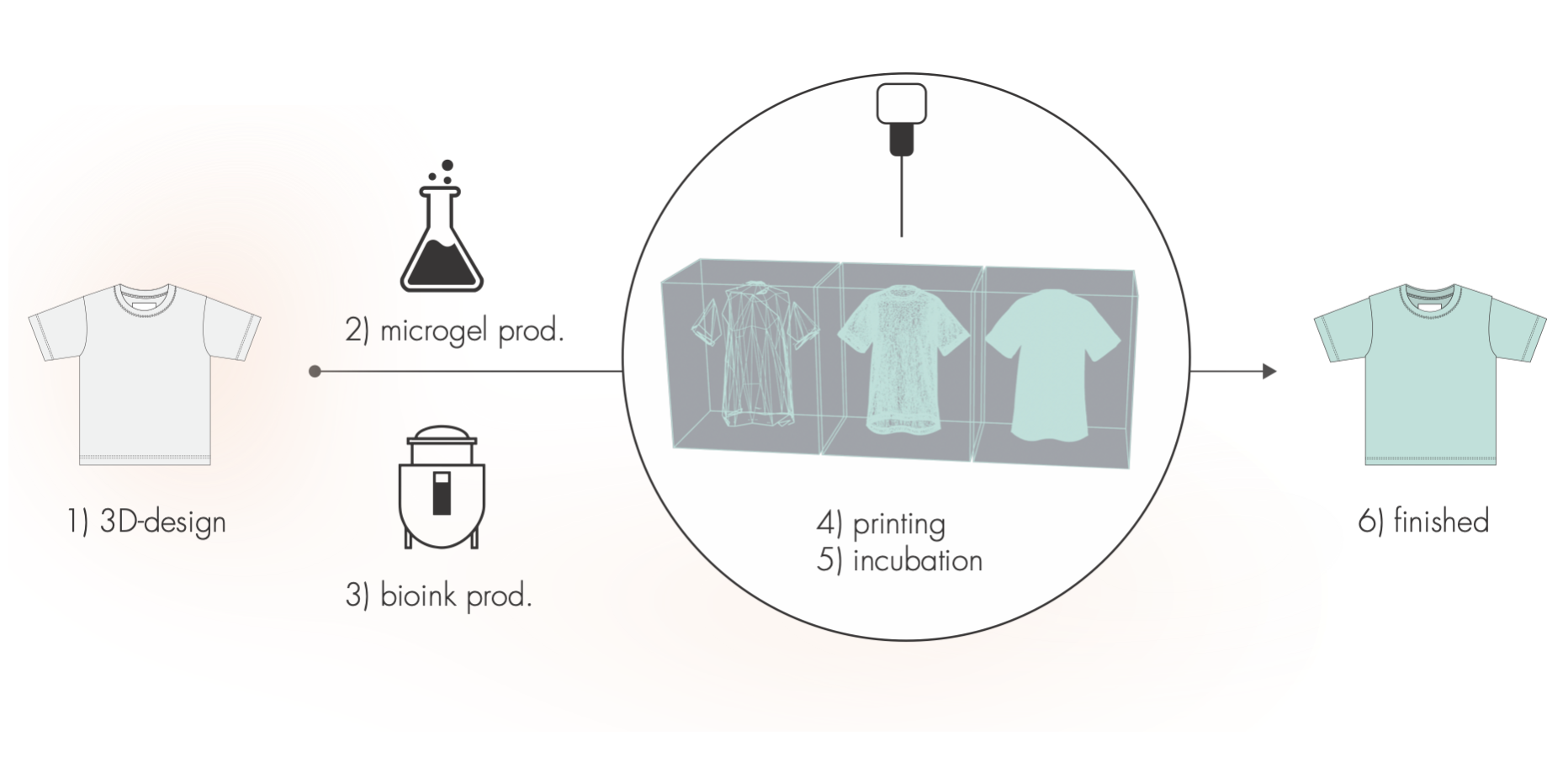

Solution¶

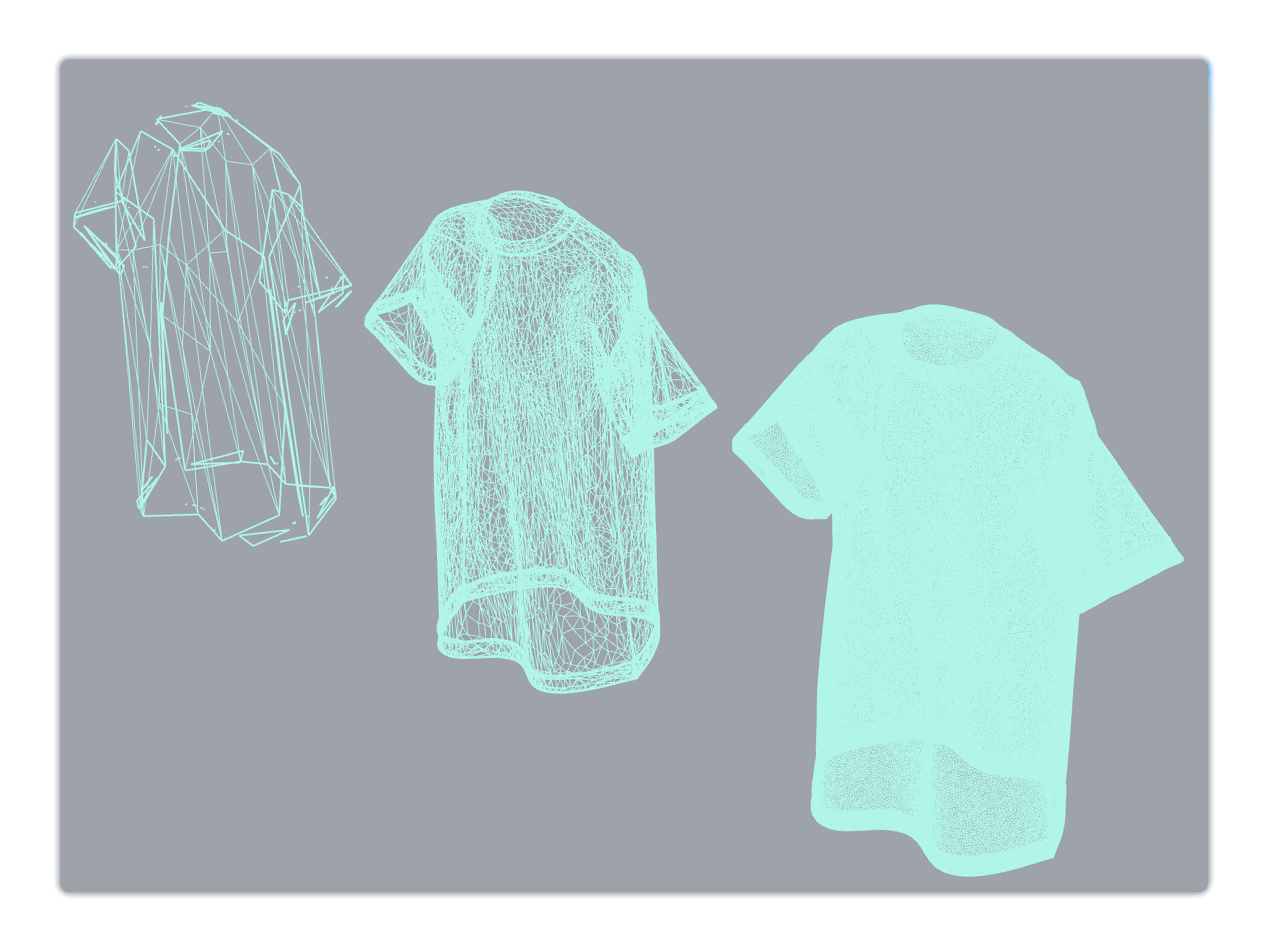

So what about if we would be able to guide nature grow our garments from our free hand 3D sketch?

Process from initial sketch to final garment

full process from drawing to final garment

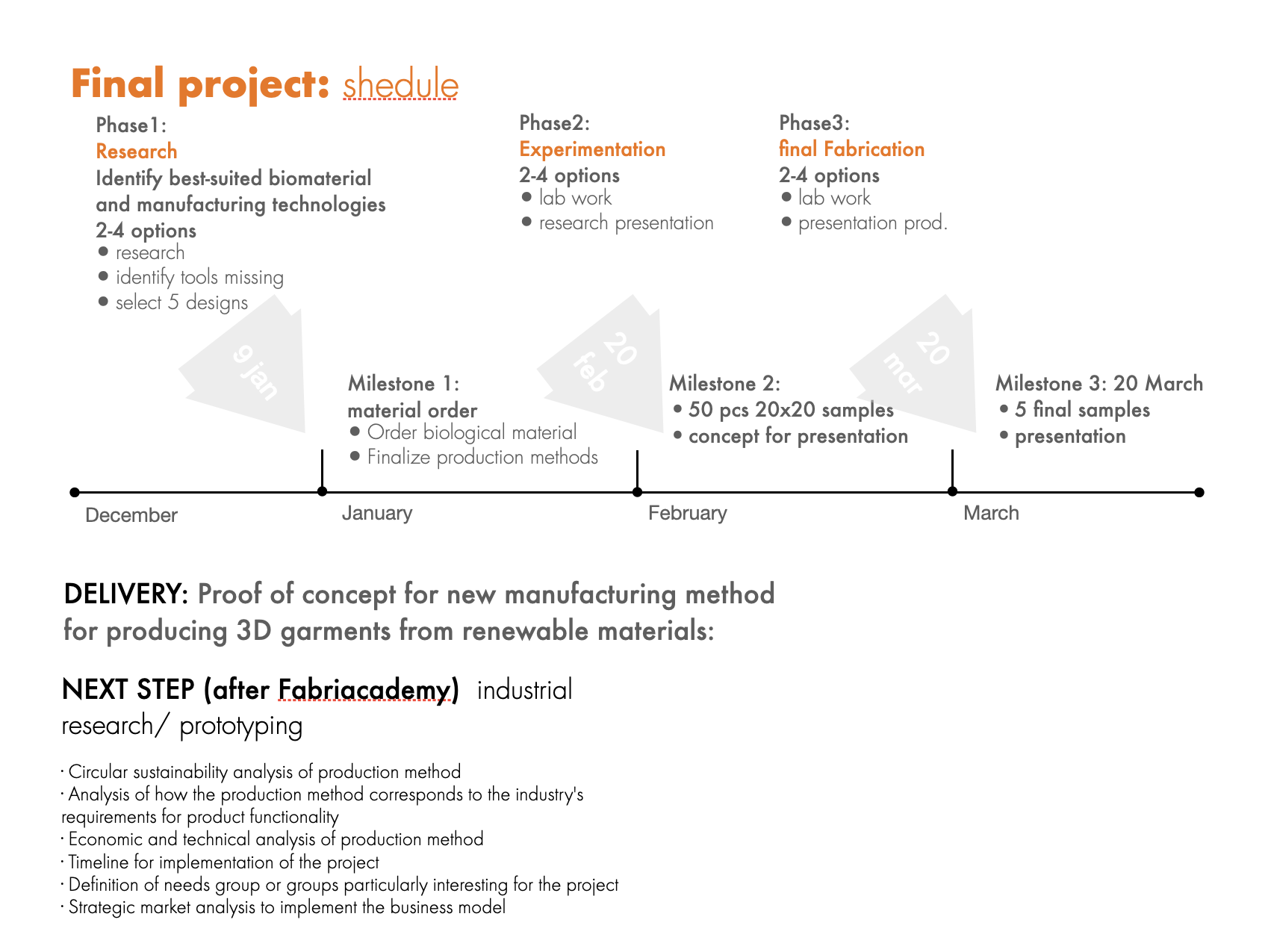

So, what can I achieve in 3 months?

DELIVERY: Proof-of-concept for a new simplified small scale manufacturing method for producing garments from cell to garment circumventing traditional supply-chain

Including:

• 5 Garments (miniature or real size)

• Grasshopper model for fabrication process

timeshedule

timeshedule

Who:

Designers with a need for a distributed sustainable manufacturing method

What:

distributed, circular production systems for the fashion industry tailored to meet the demands of a new creators’ economy.

When:

Coming 10 years

Where:

Globally and locally

Why:

To tackle the root of the problem with today’s supply chain in fashion, which is the assembly type of manufacturing.

final presentation file here