6. BioFabricating Materials¶

Research¶

"Recent far-reaching advances in synthetic biology have yielded exciting tools for the creation of new materials. Conversely, advances in the fundamental understanding of soft-condensed matter, polymers and biomaterials offer new avenues to extend the reach of synthetic biology. The broad and exciting range of possible applications have substantial implications to address grand challenges in health, biotechnology and sustainability. Despite the potentially transformative impact that lies at the interface of synthetic biology and biomaterials, the two fields have, so far, progressed mostly separately. This Perspective provides a review of recent key advances in these two fields, and a roadmap for collaboration at the interface between the two communities. We highlight the near-term applications of this interface to the development of hierarchically structured biomaterials, from bioinspired building blocks to ‘living’ materials that sense and respond based on the reciprocal interactions between materials and embedded cells."The living interface between synthetic biology and biomaterial design Published: 31 March 2022 by Nature Materials website

picture taken from diva-portal

References & Inspiration¶

As Bio mean save our Nature and more sustainable, I got inspired by both youyangsong & Officina Corpuscoli works

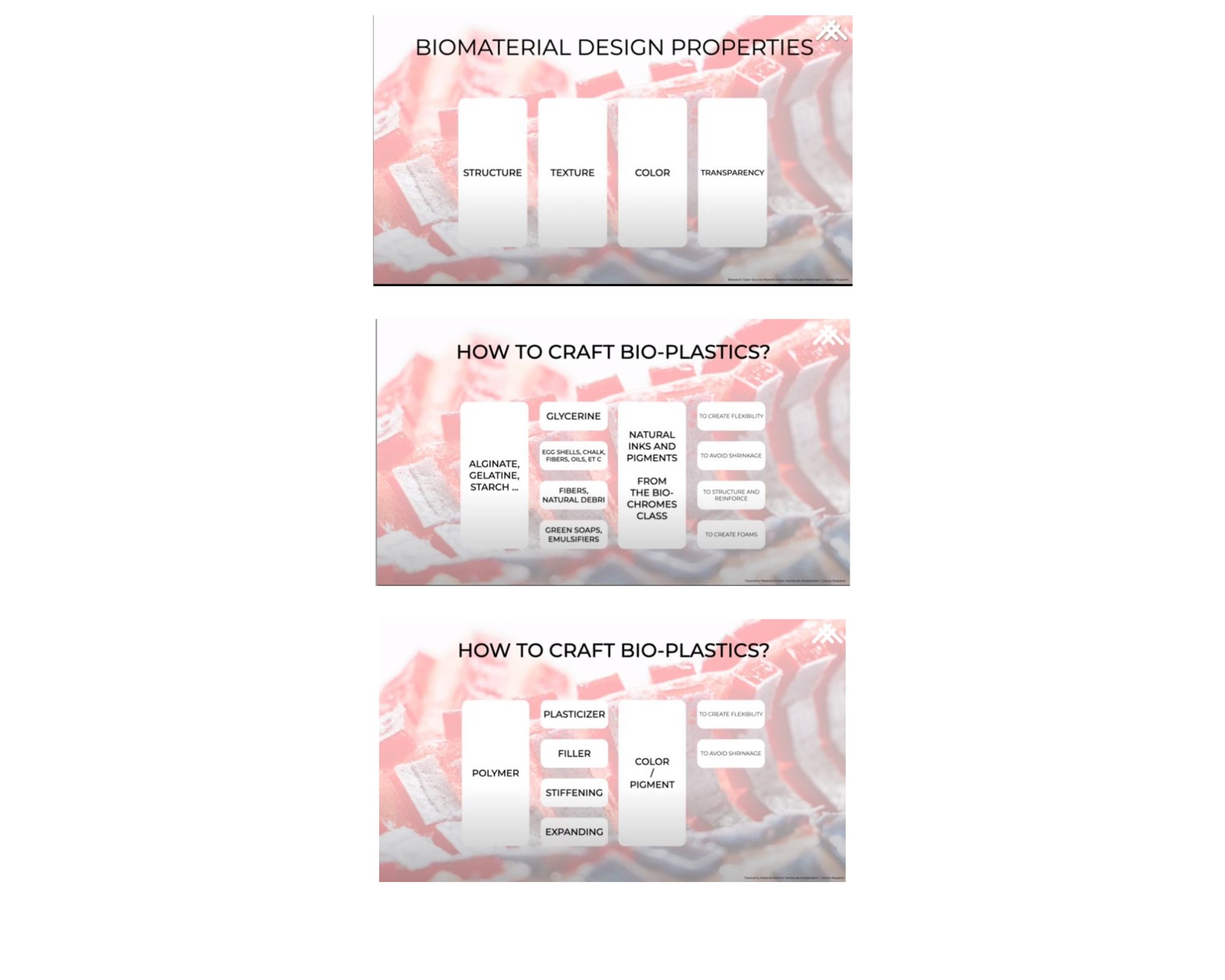

The bioplastic is an ecological alternative to plastic. There are many possibilities to create it and save Nature, however this week we were focus on bio based materials process which divided into crafted or grown materials.

Crafted materials:

there are many similarities between the recipes. most what we need is a polymer, plasticizer, water.

Crafted material Recipes and experimentations:¶

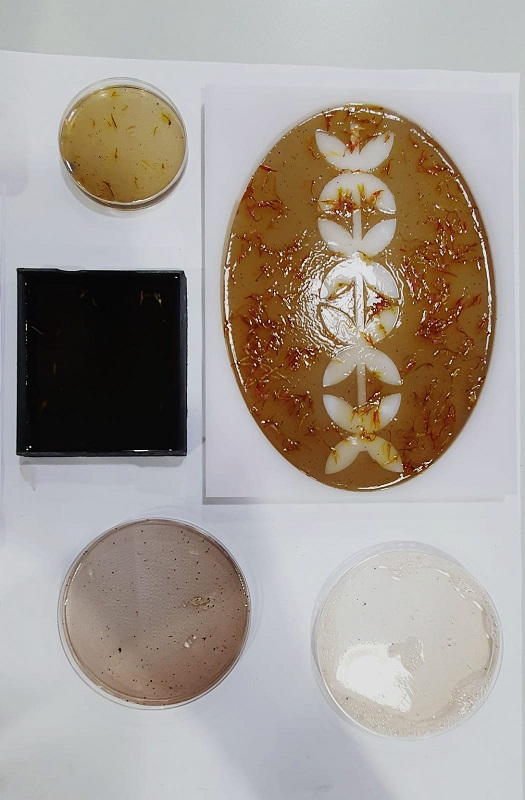

we already will used some of the biochrome materials additives and coloring agent in our experiment as shown in the below picture:

Tools were used for all recipes :¶

- pots, jars, Electric Cocker

- spoon, tongs, Wooden stick, Wisk & petri dishes

- acrylic molds

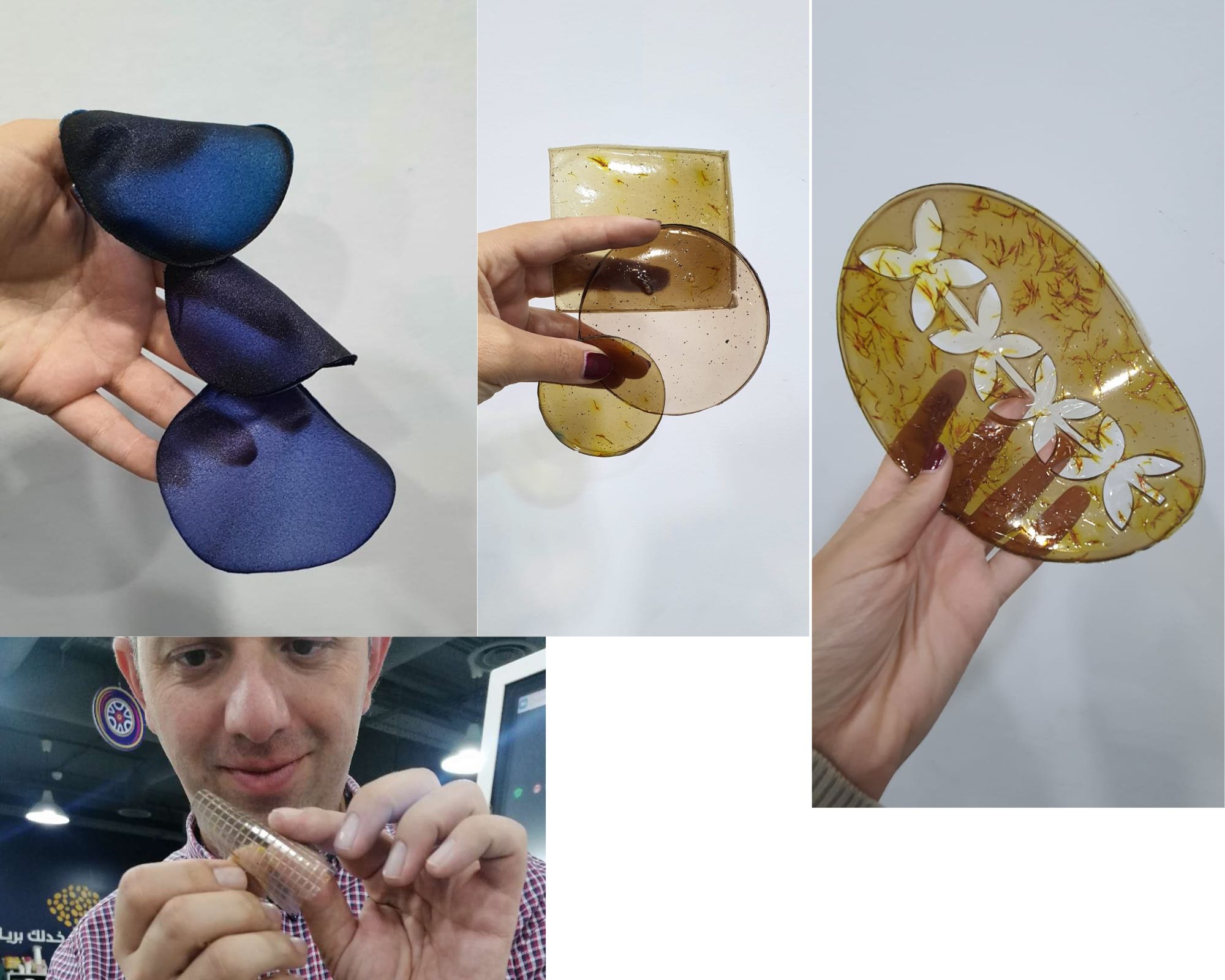

BioSilicone with Galantine:¶

Galantine is a bio polymer element from meet industrial and can be used as bio based alternative to be mixed with other natural ingredient to create a Flexible and rigid plastic material that can be used in different application materials

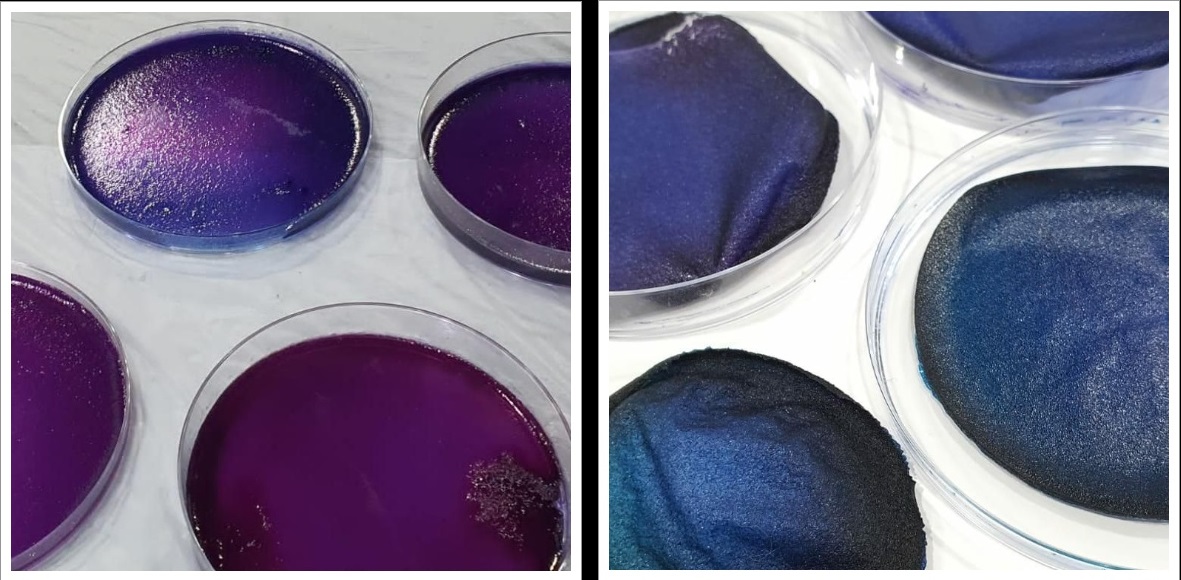

we reused as team leftover dye baths of cabbage from the BioChromes week as solvents, since my experiment was on hibiscus I used hibiscus dye path for my own experiment .

Recipe:¶

- 24 gr Galantine

- 12 ml Glycerine

- 120 ml Dye Bath of cabbage \ hibiscus

- Safflower, Sumac & Egg shells as an additive.

Quick summary of the process:

We started by heating the water up to almost 80°C then we added the plasticizer first (glycrine) and we stir it very good after that we add the polymer (gelatine).

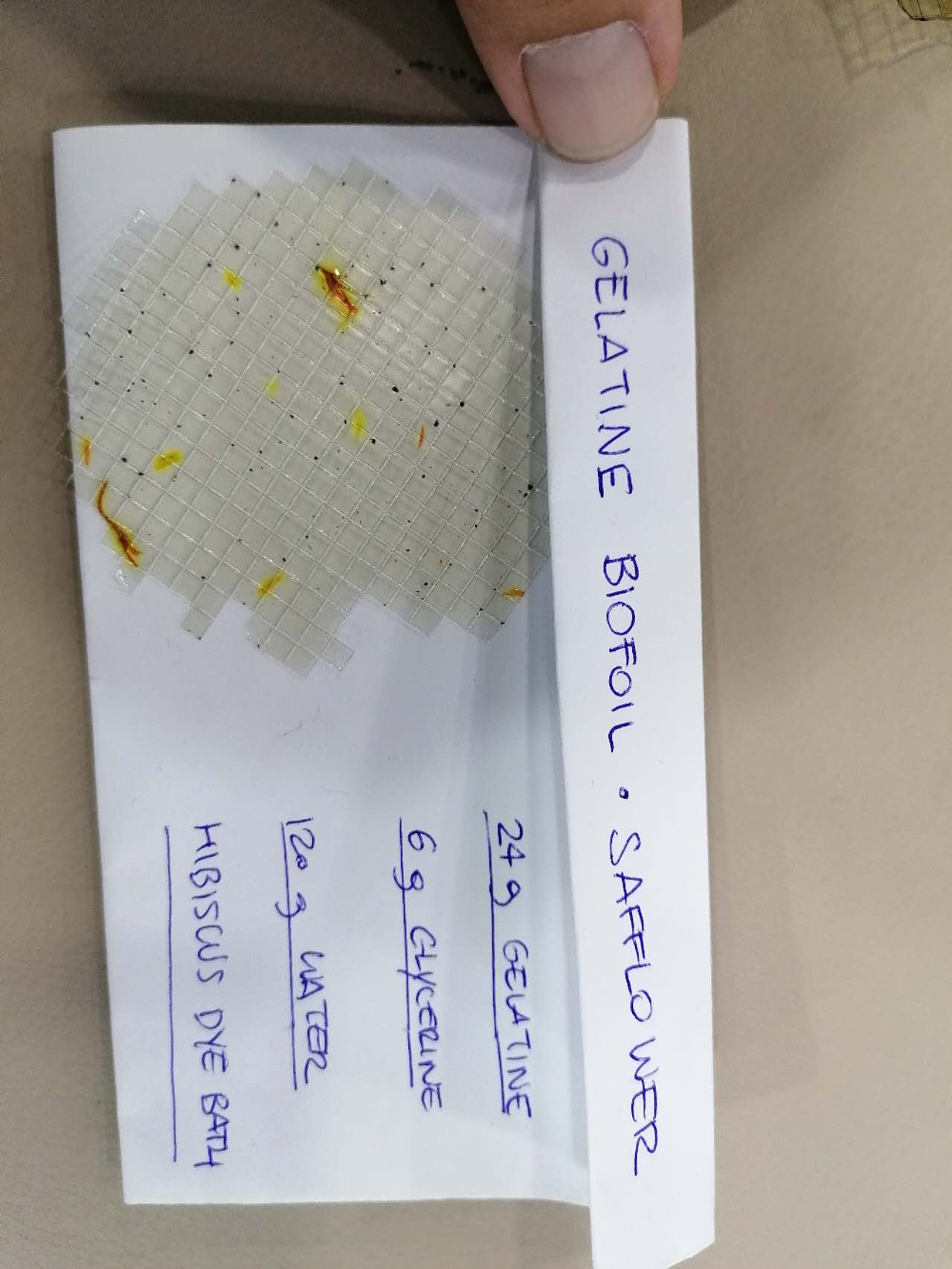

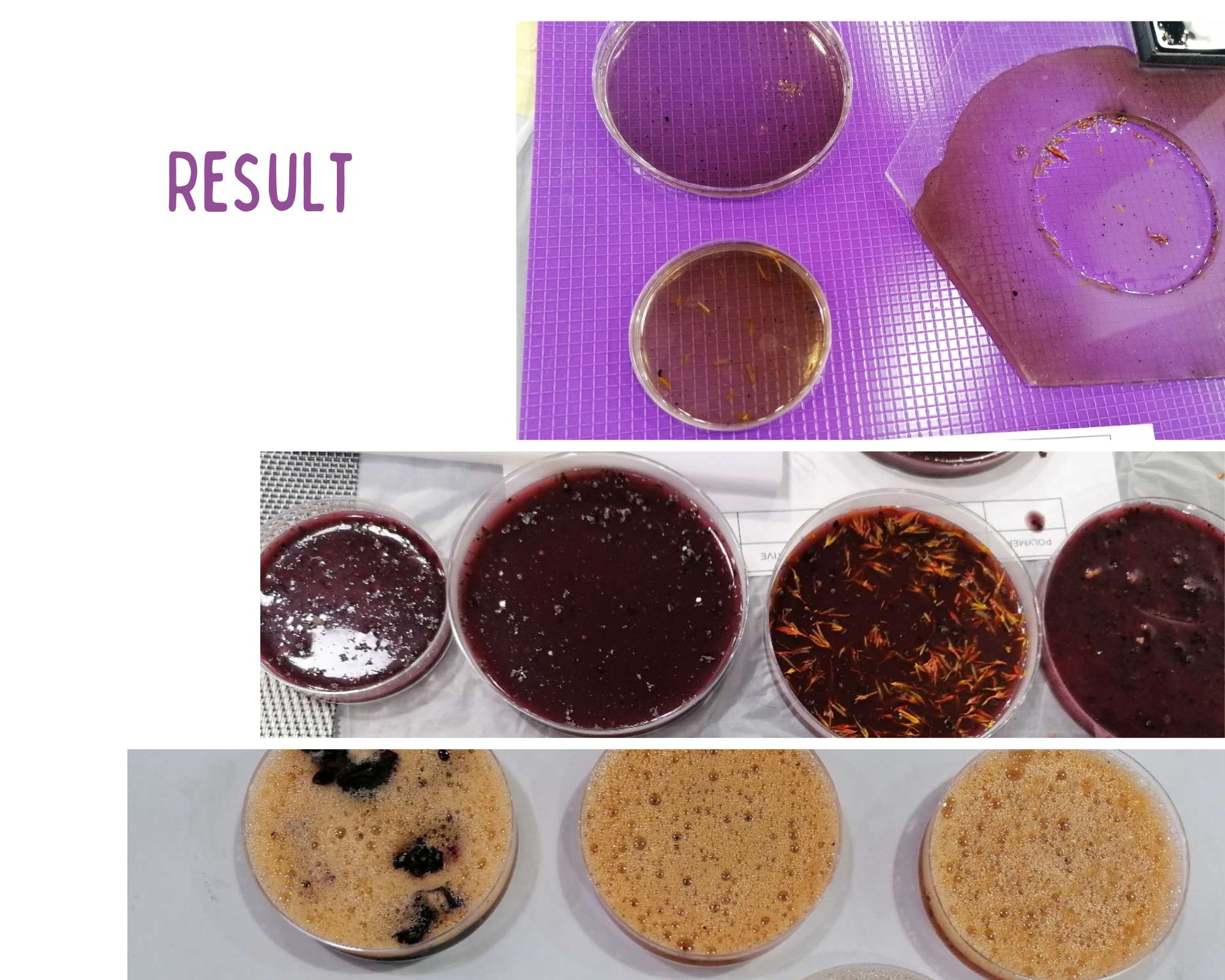

BioFoil with Gelatine :¶

Recipe:¶

- 24 gr Gelatine

- 6 ml Glycerine

- 120 ml Dye Bath of Hibiscus

Similar to the previous recipes we heat up the water, add the plasticizer first and then the polymer. Once it cools we did with this recipe is that we casted the bio-foil on dried perti dished from the biochromes week, and the beautiful shades we got from biochromes week got stuck to the cast.

note that the BioFoil is more fragile compare with bio plastic mention in the above pictures

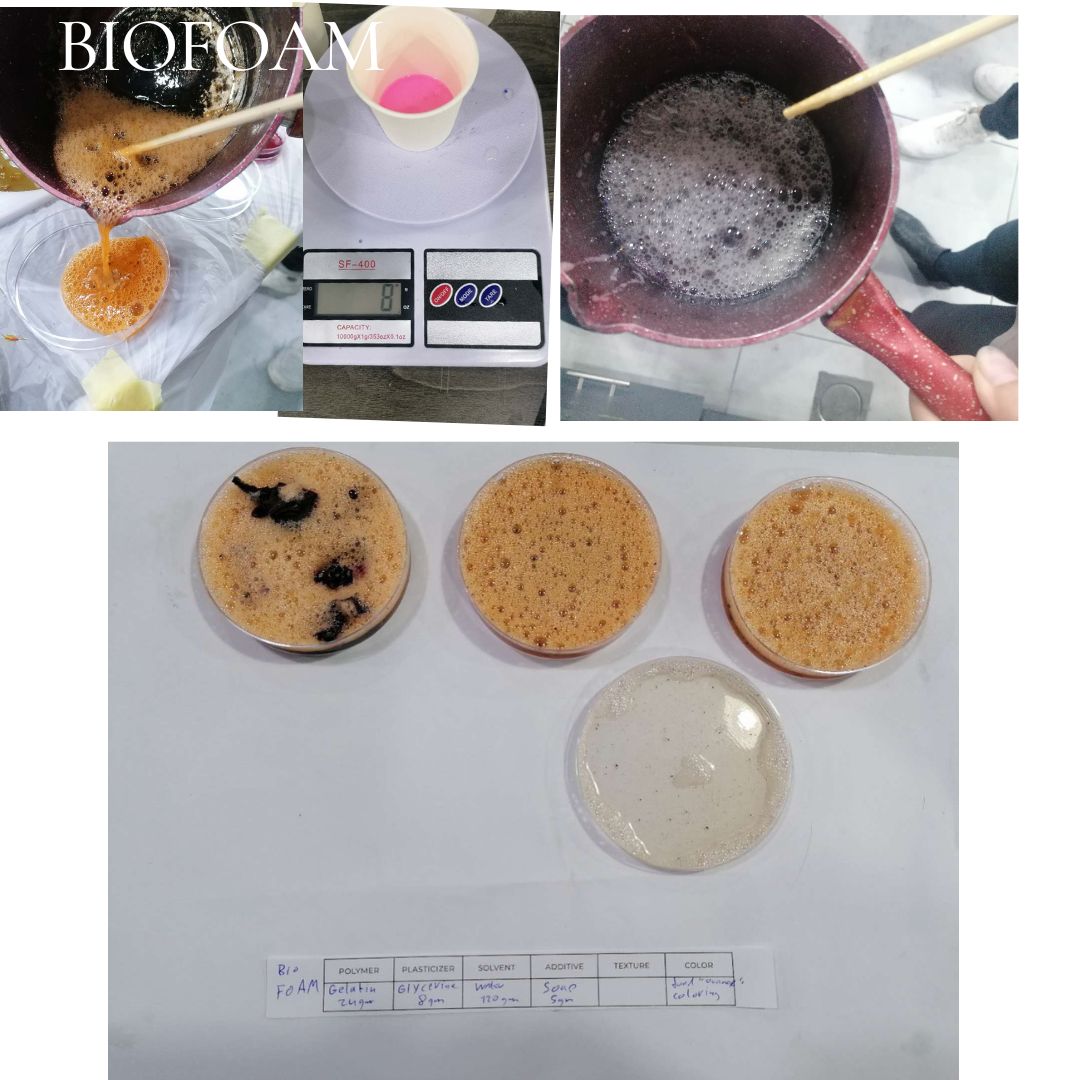

BioFoam with Gelatine:¶

The process to produce is same as the both experiments above just before we cast in petri dishes then we add some detergent element "Dish Soap" and we stair it until it got embedded with the solutions .

Recipe:¶

- 24 gr Gelatine

- 8 ml Glycerine

- 120 ml Water

- 5 gr Soap

- Color agent Orange

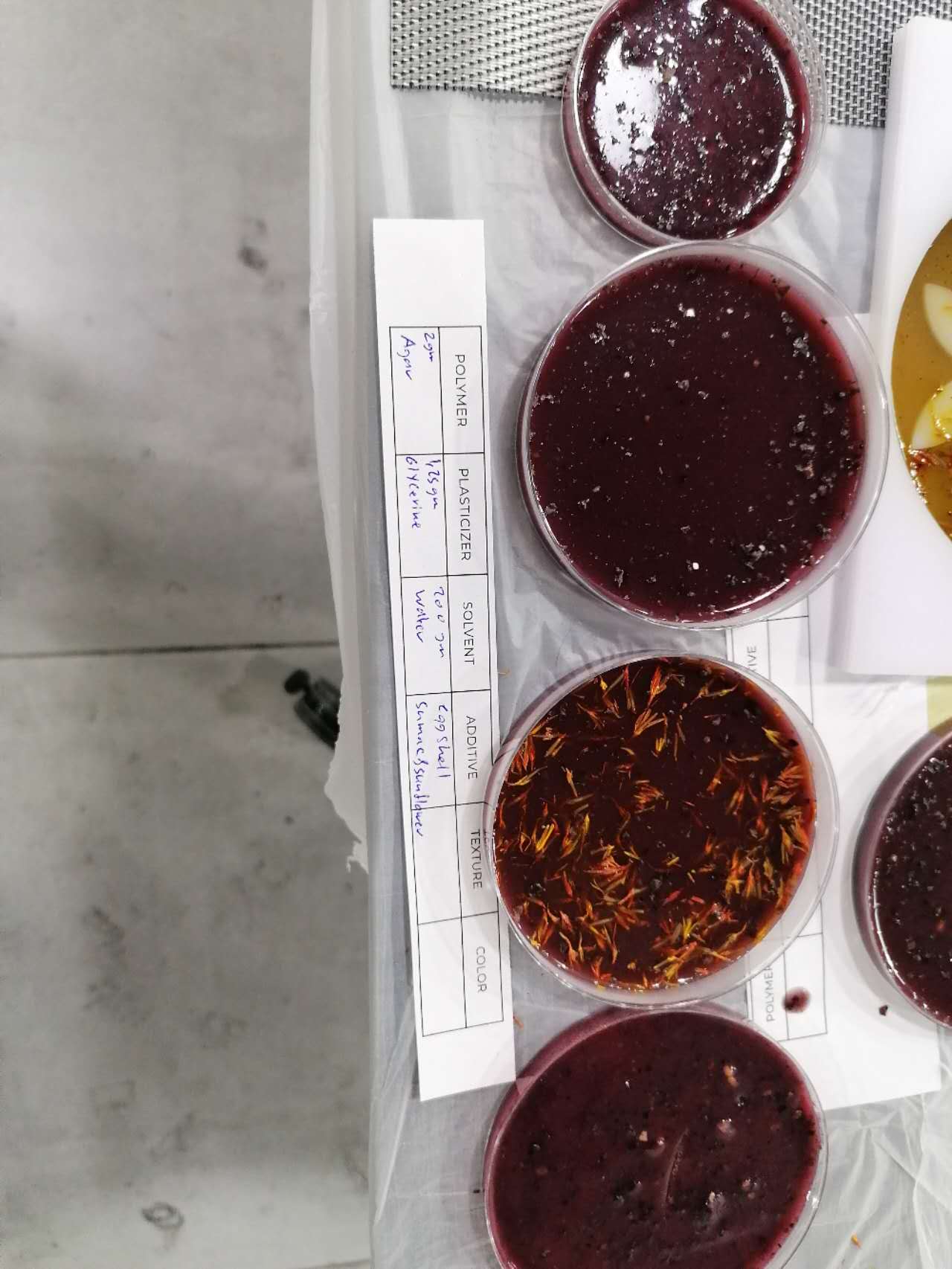

Flexiable BioFoil with Agar Agar:¶

the process is the same as before ,but the bio polymer in case we change it to more water prove so we used Agar Agar that comes from red algae.

Recipe:¶

- 2 gr Agar Agar

- 1.25 ml Glycerine

- 200 ml Water

- Safflower, Sumac & Egg shells as Additive

- This material is fragile and even though the thickness is thin the result is elastic .

RESULTS¶

Growing Bacteria cellulose "Kombucha":¶

Kombucha is a vegan leather that can grow and decompose naturally and safely in the environment .

For more information about kombucha and application you can find in this link .

Phase#1:Create SCOBY Mother¶

Firstly, as Kombucha is not Available in our Lab, we have to Generate it from SCOBY.

SCOBY Recipe: We had the lucky that Ala Janbek have some small sample of Kombucha drink at her house. so we use the following material :

- Kombucha drink (500ml)

- Water (1Lt)

- Black tea (6 bags)

- White sugar (200 gr)

- Organic Black Molasses 2 tea spoon

- coffee Filter

Tools:

- Pots and heaters

- Glass jars

- Cheesecloth or cotton fabric

- Rubber bands

Work Process:

before we had clean and sterilized all equipment and tools .after that we start Boiling the water and add the sugar and stair it until it completely dissolved then add (black Molasses) then tea bags to the solution and let it cold down at room temperate ,after that we had filter it in the glass Jar and cover it with cotton fabric to let it breath ,then put it in warm and ventilated place for 25 days .

Result of Phase#1 :

Phase#2:Create Kombucha Mother¶

Recipe:

- 1L of water

- 1,5 to 3 gr of tea (we used black tea, but it can be any tea, - depending what color of material you want)

- 100 gr of Sugar

- 1 tea spoon of commercial honey

- Vinegar from 0 to 100ml (depending on PH of your liquid)

- SCOBY mother (10cm ø)

- 1 Cup of SCOBY solution.

Tools:

- Pots and heaters

- plastic Tray

- Cheesecloth or cotton fabric

- Rubber bands

Work process:

Phase 2 process is almost same as phase#1 , just small adjustment that I was adding a cup of vinegar and a cup of previous SCOBY solution and we add the mother on top of tea solution we made and let floating on the top of the plastic tray.

Since the black Molasses was not there I add small amount of commercial honey instead of black Molasses.

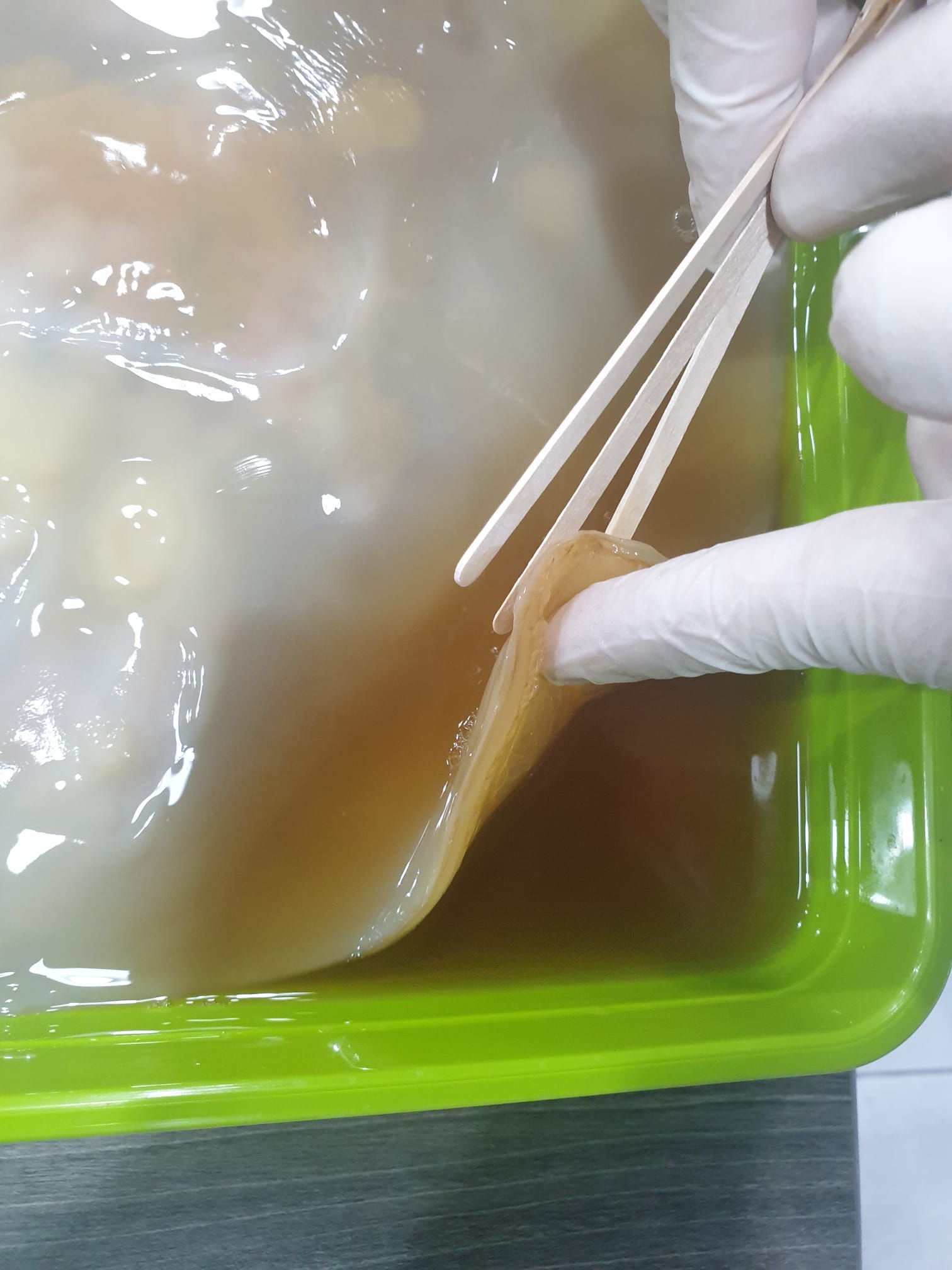

Phase#2 Result:

Now we let it in grow in dark place for 1 month and the speed of growth depends on the room temperature .

Phase#3:Create Kombucha Leather¶

Phase#3 Result: Harvesting the leather before harvest we need to make sure the thickness of the leather is around 1 cm as it will dry and the thickness will be reduce ,so in order to use it in any application need a solid and thinker sheet .

during the growing process is better to check the leather and see in case have any mildew dot on the surface of the sheet ,in case have it is better to spry vinegar to avoid this contamination.

the lather start growing from the Mother Scobey

lather sheet is ready to harvest when the thinkness is approximatly 1 cm

washing the leather sheet

let the sheet dry ,is better in a sunny place ,but since at that time was raining I have to put it inside safe place to dry until the weather getting better and from time to time better to flip the sheet over and spry vinegar to remove any mold. and better to use a wood base so let it observe the water .

After that I had save the new mother in closet again and waiting the result after a 1 month ,hopefully we have a good surface of kombucha Layer.

Here is the final result after drying in the sun 5 days approx.

Second batch Experiment :¶

Here is the pictures and vedio for my second work Experiment ,note this time i adjust and use 1 table spone of comercial honey ,and use 50 ml of phosforic acid.

the tempreture is still in the lab in moring arround 21 C and in night is arround 7 C which affecting the growing process as no stable tampreture .

check my current work