7. Computational Couture¶

Research & Ideation¶

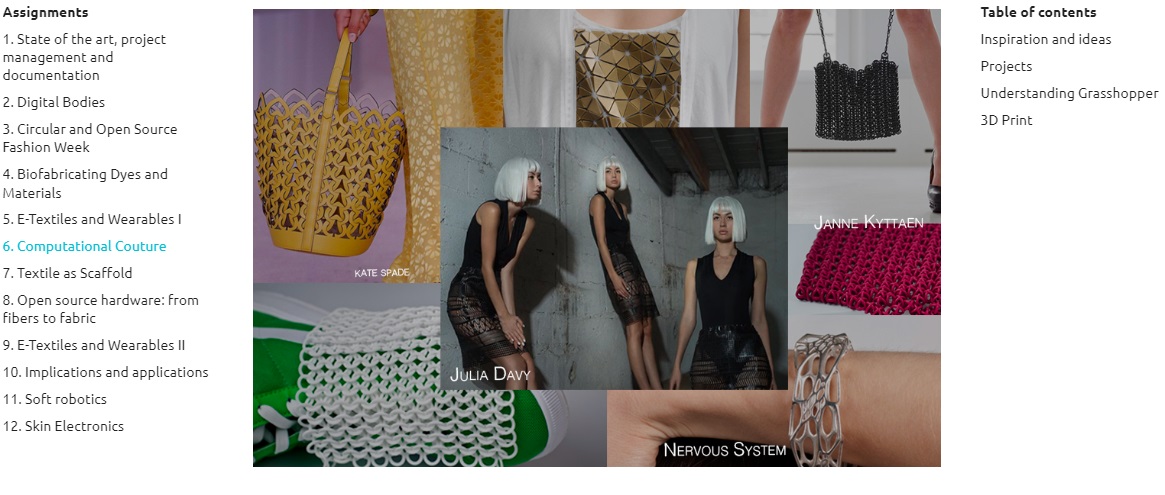

I was lucky to check Ana Correa about her assignment in Computational Couture, and see other people applications. Below picture is from here website page:

Also I have check some other pervious student work at the same assignment from Techworks Amman 2021-22_Haneem Jaafreh.

As my interest in 3D Printing falls in a couple of different categories & application ,specially when you start thinking too much about is it the way to have more freedom in creating any design you dream of. Then the question led to other like how to combine 3D printing with different application and mixing design . In this assignment I decide to focus on Islamic pattern and check how to fit it in some design application :

Tools¶

Materials:¶

- TPU Filament for 3D printer FDM

- PLA Filament for 3D printer FDM

- Stretchable Mesh Fabric

Process and workflow¶

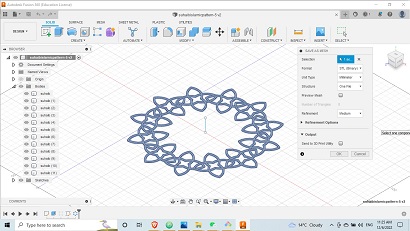

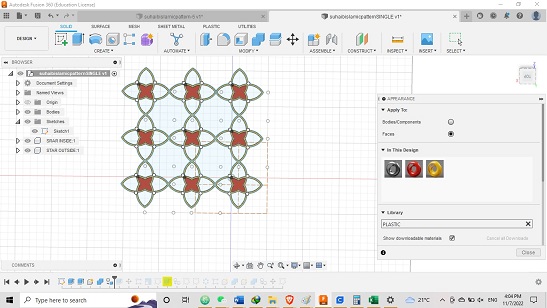

Using fusion-360 ...¶

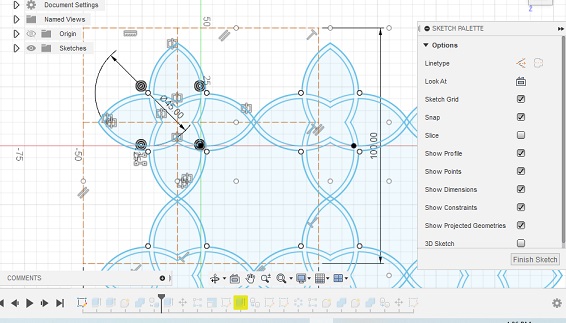

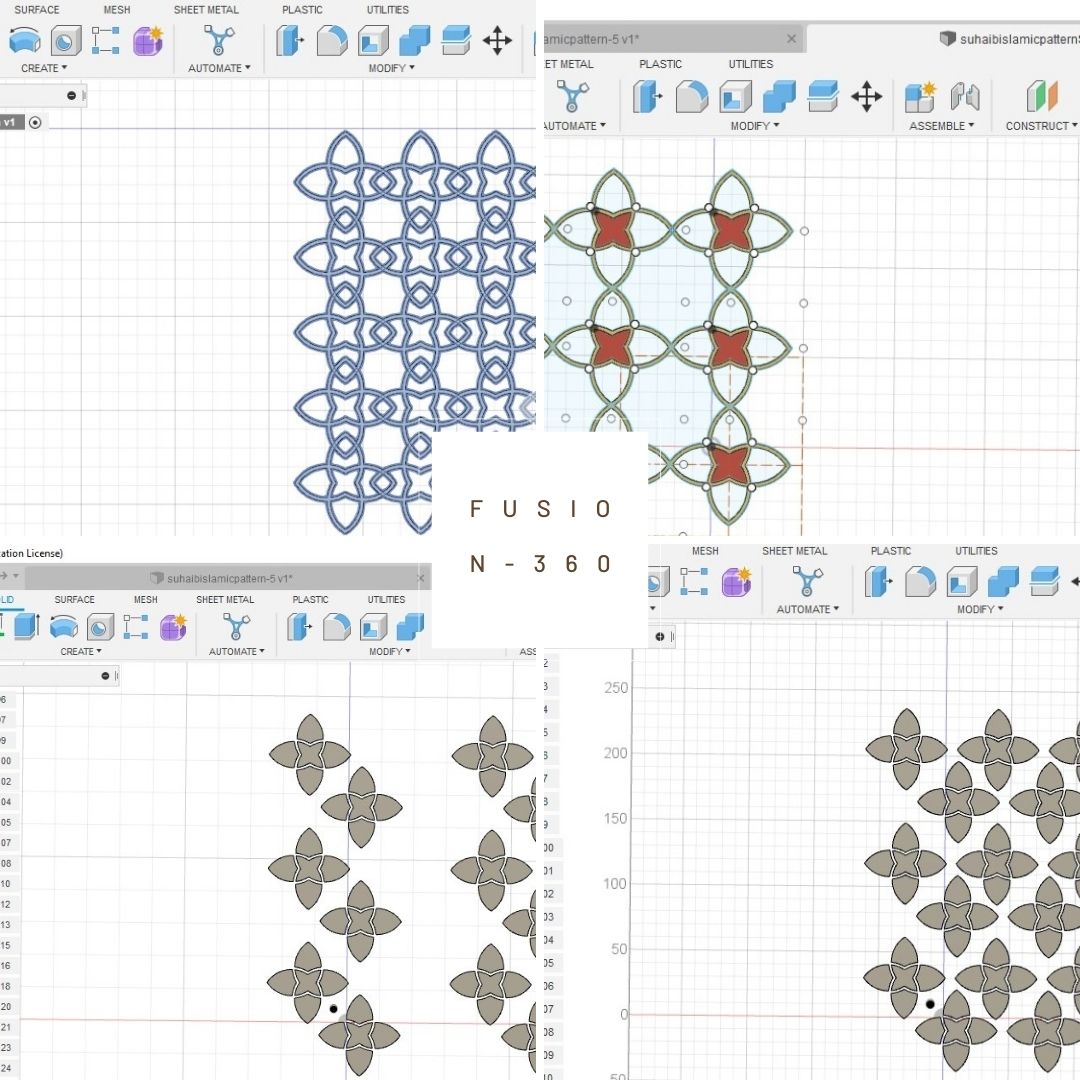

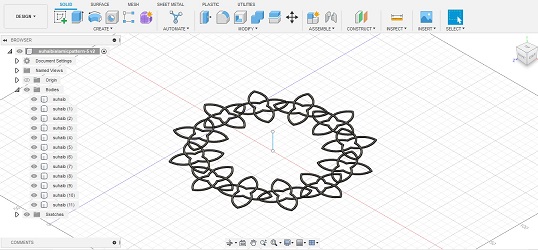

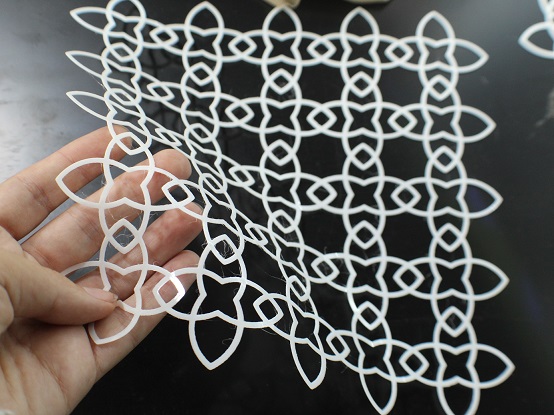

as my skill start developing in 3d fusion and able to make some pattern from scratch. I was focusing on Islamic pattern and how to mix it with different applications.

Remember in fusion fristly step is to design a skitch which i get inspired by arabic pattern useing arc and circle i was able to design a moudle . using make pattern feature can make multiple moulde in difrent rows and columns to achieve diffrent designs. after that we can extrude the design to create a closed mesh (.stl)

- export the design as STL file to be sliced in Cura

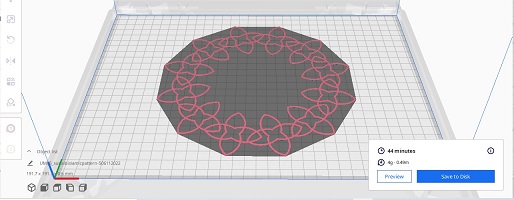

Using Cura ...¶

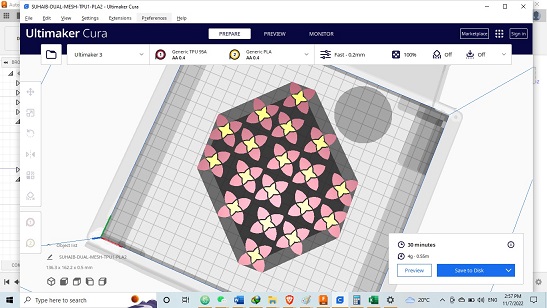

After genareting Stl files in fusion you have to export the mesh and upload it in Cura. I started to learn how to prepare the file in Cura and know which printer to choose, available filament then playing with setting to save time in 3d printing.

Cura is a slicing open source software by ultimaker that allows you to prepare 3D mould for printing. You can slice model for different machine and different settings depending on the design and filament material chosen.

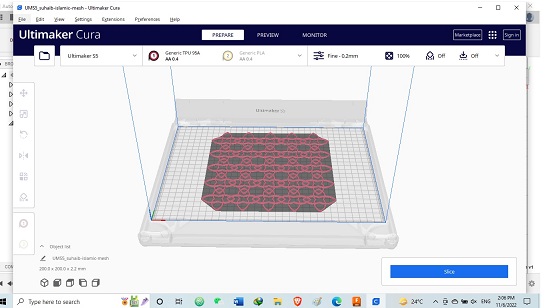

3D printing TPU¶

Slicing setting :

Printer: Ultimaker s5

Material: Genric TPU 95A

Layer height: 0.20 mm

Infill Density: 100%

Infill Pattern: Lines "highly recommended "

Printing Temperature: 228 °C

Build Plate Temperature: 60 °C

Print Speed: 25.0 mm/s

Enable retraction

Retraction Disance: 6.5 mm

Retraction Speed: 15.0 mm/s

Fan Speed: 20%

Build Plate Adhesion Type: None "Recommended to use None" .

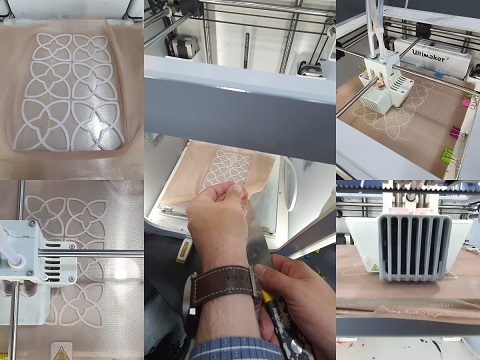

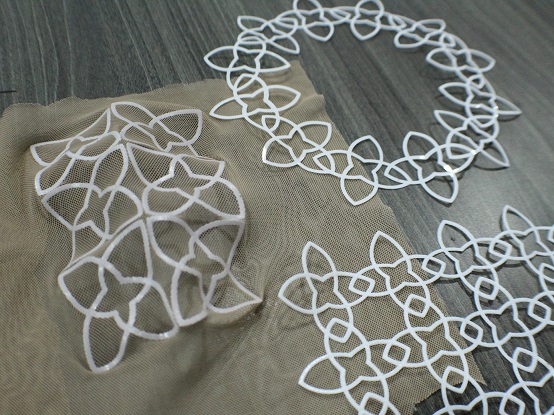

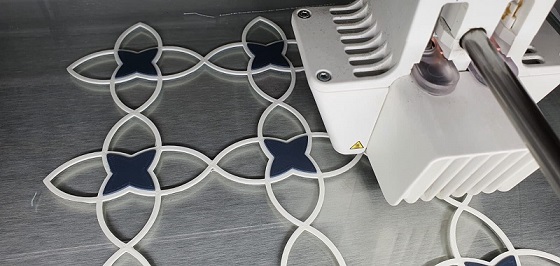

3D printing on fabric (TPU on stratchable mesh Lycra)¶

we cut fabric after mesuring the bed size on the 3d printer, after that we clip the fabric on the bed and make it straight to have a nice printing.

Important Note: in order to have a nice printing we use sandwich technique which gives more strength to the fabric and consists of printing one layer of tpu beforehand on the bed, insert a pause in the printer and resume the printing normally.

Slicing setting :

* printer ultimaker 3

* TPU filament

* infill 100%

* infill pattern lines

* build bed temp. 60

* no support

* no adhesion

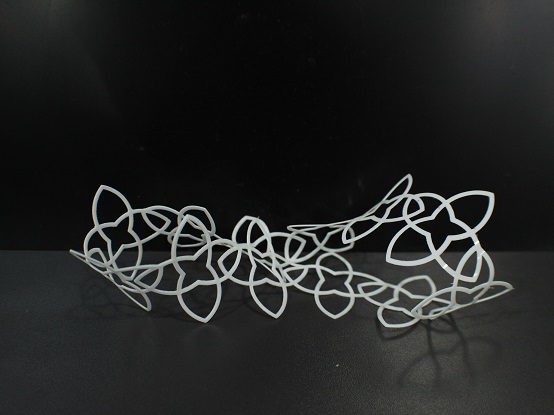

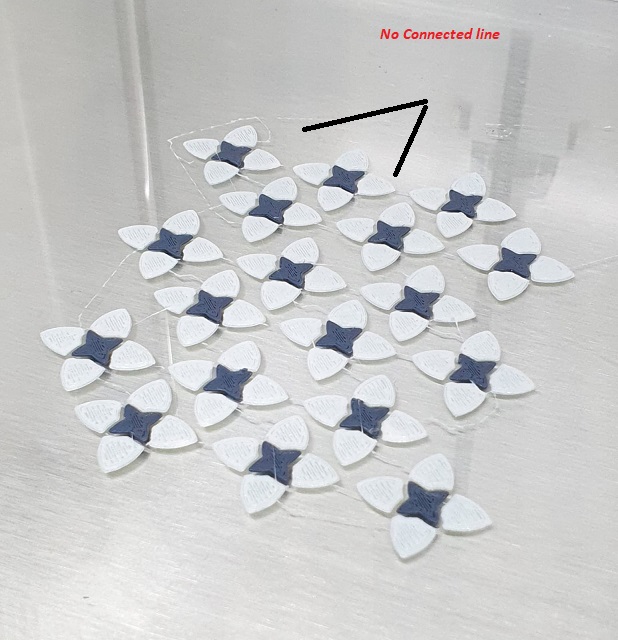

Final results (TPU Flexible printing):

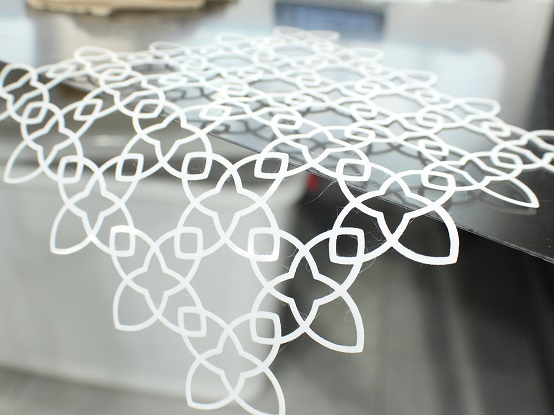

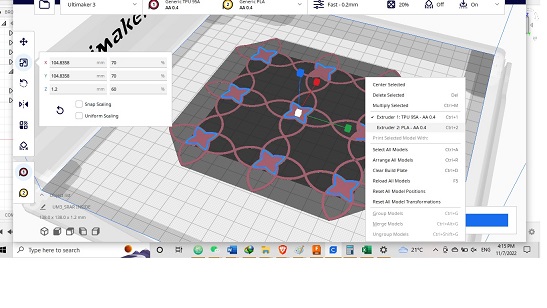

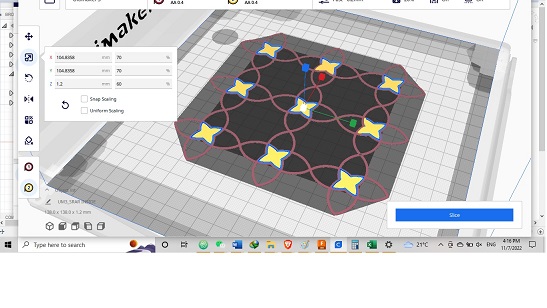

3D Printing 2 colors with PLA¶

Fusion: When printing 2 colors,you should export it into two different mesh inside cura ,then you have to assign each mesh into specific extruder and choose the color available . in my case I chose white and gray PLA filament to play with the shape of the islamic pattern.

Cura:

I assigned the first design to extrude No # 1 and the second design for extruder No # 2 ,and slice the same setting below for PLA .

Slicing:

Printer: Ultimaker s5

Material: PLA

Layer height: 0.20 mm

Infill Density: 100%

Infill Pattern: Lines "highly recommended "

Printing Temperature: 205 °C

Build Plate Temperature: 60 °C

Print Speed: 25.0 mm/s

Enable retraction

Retraction Disance: 6.5 mm

Retraction Speed: 15.0 mm/s

Fan Speed: 20%

Build Plate Adhesion Type: None "Recommended to use None" .

Printing:

Final result (PLA 2 colors):

- Above picture is my second trial with two colors (PLA ,PLA) with same islamic pattern but extruded in opposite way.

Challenges i was faceing it while printing through Cura :

1-Some challenging I am facing it during the design as when make the pattern then want to combine it with lines , to make the finish as one piece other wise it may go wrong and you lose ur effort .so double check after cilice the pattern.

2-Depend on the filament you are using here are small tip to consider to check it and adjust it according to your design inside Cura setting as it affect printing time:

Printer: Ultimaker s5

Material: Genric TPU 95A

Layer height: 0.20 mm

Infill Density: 100%

Infill Pattern: Lines "highly recommended "

Printing Temperature: 228 °C

Build Plate Temperature: 60 °C

Print Speed: 25.0 mm/s

Enable retraction

Retraction Disance: 6.5 mm

Retraction Speed: 15.0 mm/s

Fan Speed: 20%

Build Plate Adhesion Type: None "Recommended to use None" .

3-Useful link for details of recommended printing setting

- The above design is very good to print on fabric as it will be embeded on mesh fabric.

Experiments¶

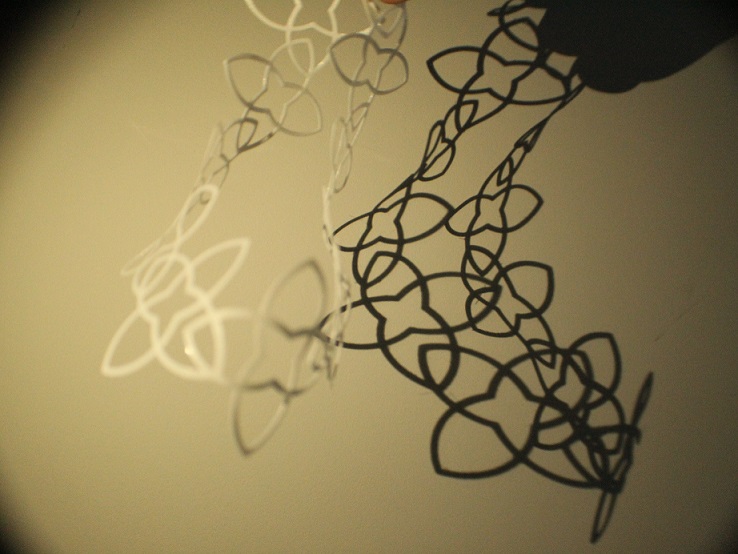

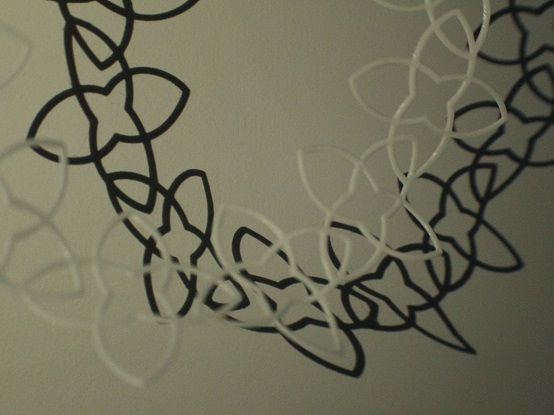

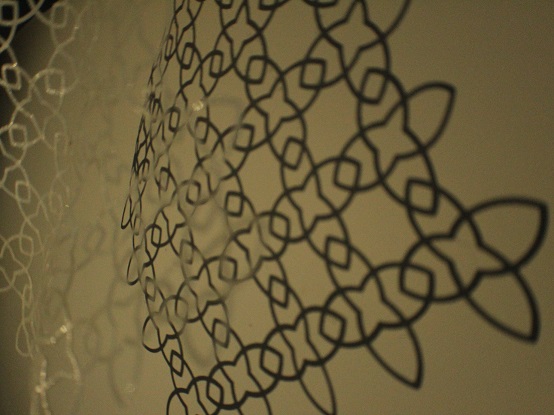

Light projections

Oher possible Applications:

Videos¶

check below Videos on vimeo :