12. Soft robotics¶

Research¶

Soft Robotics is one of the interesting field that have a direct impact on the medical sector and many application can improve the life of others such the people with disable movements, also some educational proposes.

Inspirations:

I like the project of Beatriz Sandini TextileLab Amsterdam 2019-20) & Vicky Luan from previous Fabricademy years.

Recently a new suit project come to live and have a direct impact on the disabled people: New Suit Project.

After watching the class of Lily Chambers and Adriana Cabrera during soft robotics week I started to experiment with:

Thermo Adhesive Vinyl¶

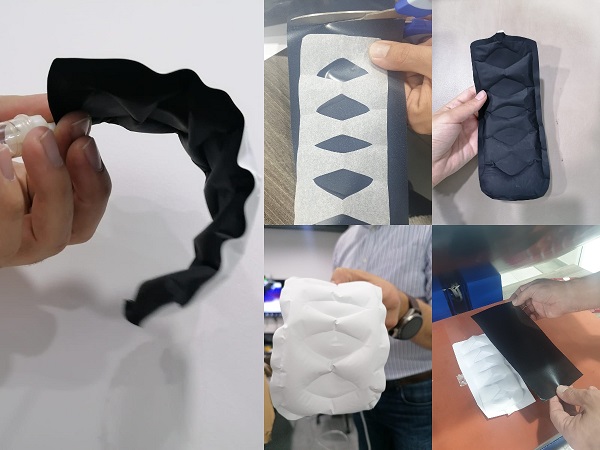

- First Experiment:

Below is the result.

Work process steps:¶

-

1st step: design the shape on the baking paper we put it on sandwich method. This will not stick to the vinyl and will be where air will pass through for inflation.

-

2nd step: Turn on the heat press.

-

3rd step: putting the vinyl material with the baking paper in between to make sure to let the shiny surface face should be up.

-

4th step: change the heat press settings temp to : 90 C for 30 second.

-

5th step: press down the handle and wait till it stick together.

-

6th step: Peel the shiny protection sheet off then cut the extra parts so we can have the exact shape .

Second Experiment also on Thermal Adhesive Vinyl :

The work process here as above, just here ** put hinges to allow the air goes in different shape as appear from the pictures above.

Note that I used two different colors of Vinyl sheet and hand pump to blow the air . in the second experiment the air flow can be controlled by hand or Arduino .

Video¶

First Experiment :

Tools¶

- Scissor

- Heat machine press

- Backing Paper

- Hand Pump

- Motor pump DC 3V

- Cables

3D Modelling with Fusion 360¶

- Silicon Mold:

Firstly Design on the fusion 360, as we need to design a mold either for Laser cut machine or 3D printer it to cast silicon in it.

Design note: we will make 2 layers with note that it should have flexibility and note too heavy

the design should have a pattern shape and avoid sharp angle so it can flow by hand or by electronic pump the pattern should be connected with a panel

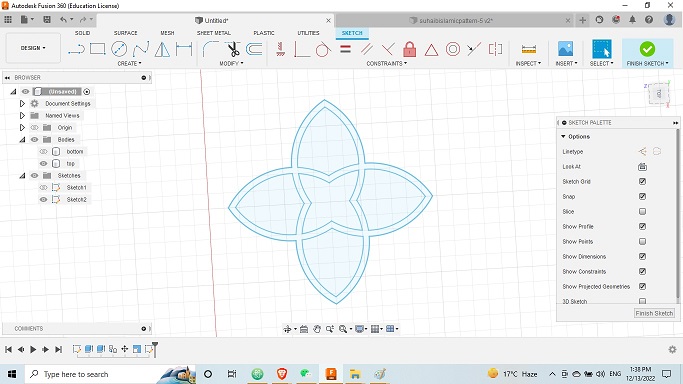

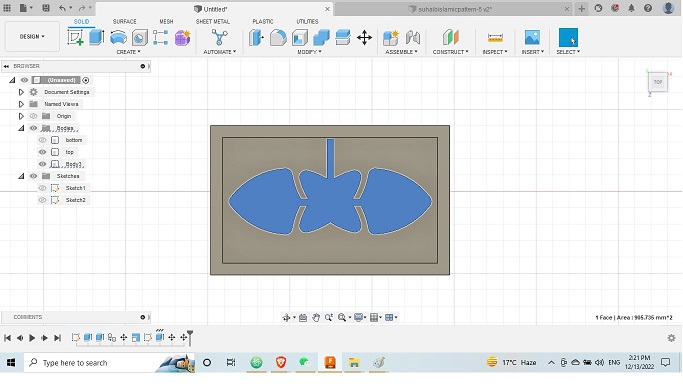

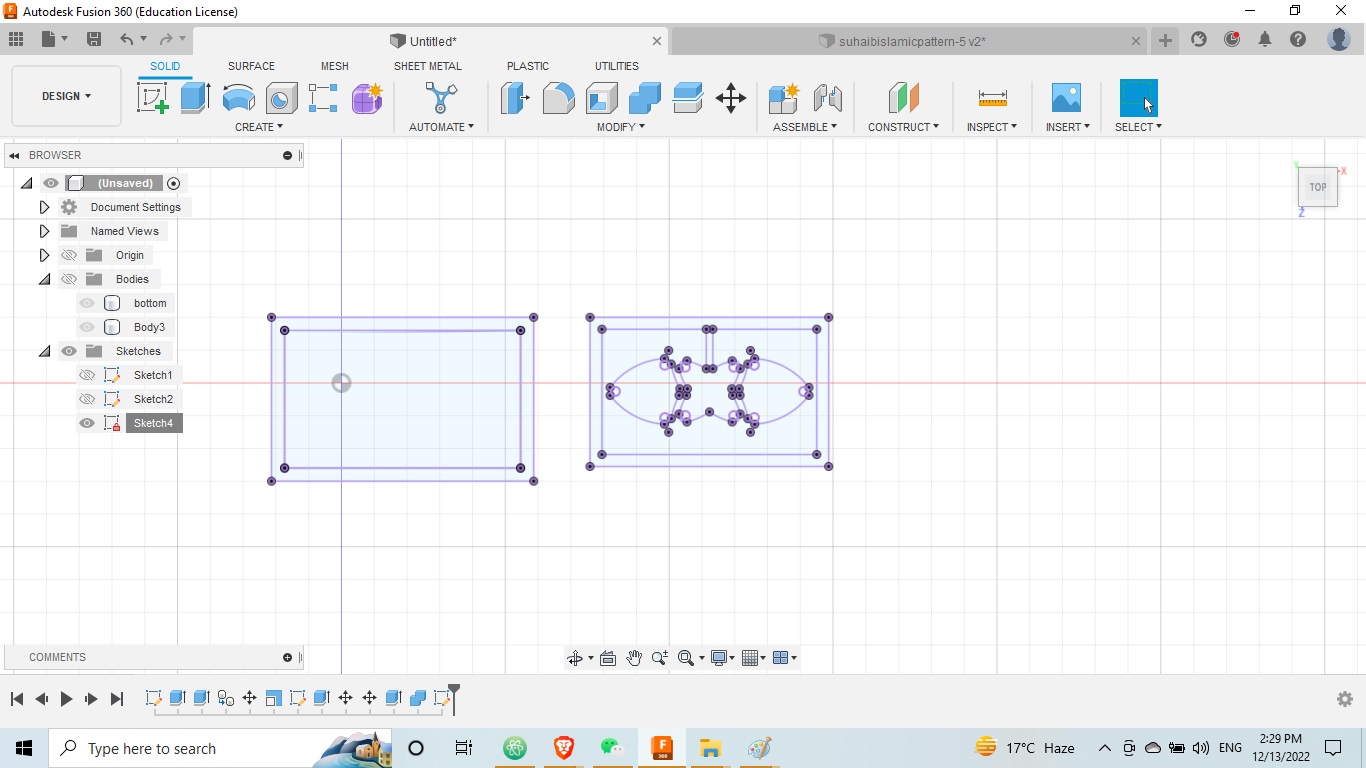

I started modelling my mold in Fusion starting from a sketch.

i used my previous model form week no7 and I try to use as base for inflatable design .

i double check the thickness of the available acrylic sheet that will be used in the first mold .

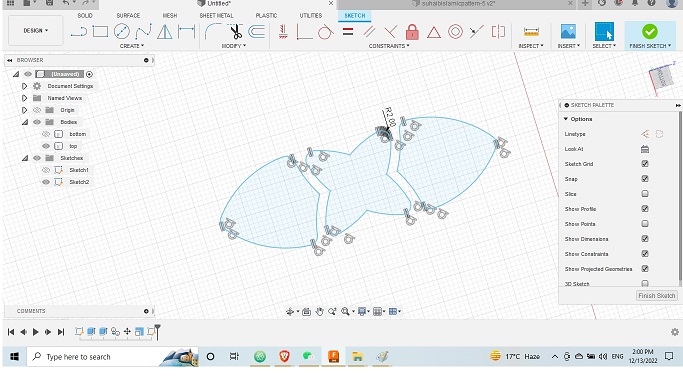

inside the skitch in fusion 360 I kept the shape I want to include and round the edge so it is not sharp when I cast the silicon mixture

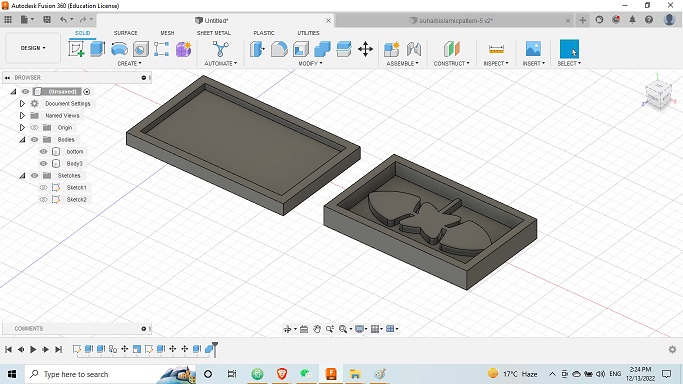

so I extruded the shape and create a box for the first mold as rectangle shape .

then I combine the chamber of the desired design with the box mold .

I design the second mold which is a little bigger than the first mold .

In the picture above I used fillet feature to reduce the edge degree from sharp to smooth edge .

Finally I export the design for leaser cutting machine as DXF file extension.

Leaser Cut:¶

![]()

I move to "Inkscape" software to nest the DXF file and assign the RGB color for the "Trotec 400 " leaser cut machine

![]()

I double check the shape that I want to cut according to the acrylic board setting .

Results¶

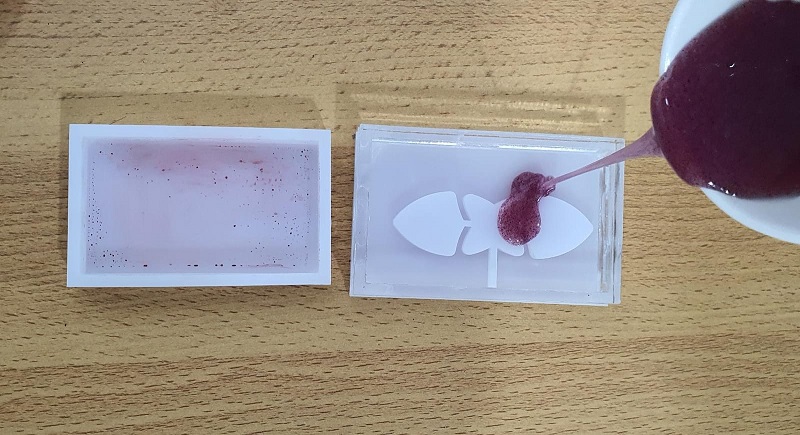

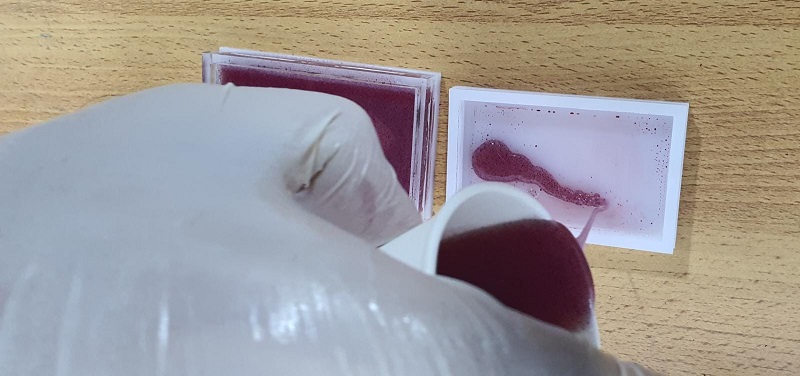

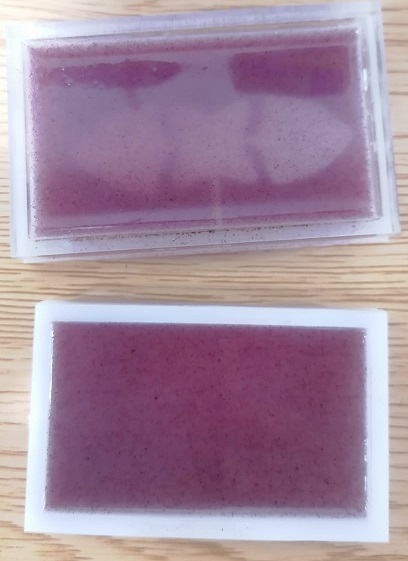

Casting silicon mold :¶

Materials:

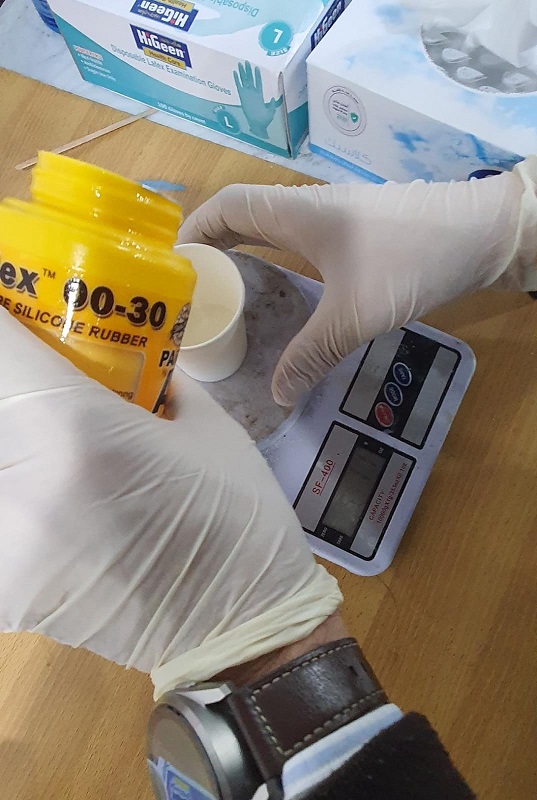

We use Smooth-on Ecoflex silicon to cast the mold, which is made of two components A & B, the ratio is 1:1. and i used 15 gm approximately for each mold

1: Measure you components

add A to B and mix gently for 2 minutes try to get rid of the bubbles and leave it for 4 hours to cure before gluing the two side together in a sandwich using extra silicone.

I add food coloring to the mixer before casting and start stirring .

recommendation while stir process in case have any bubble it is recommended to smash it in before casting in the molds .if have inside the mold use sharp needle to blow it .

Video¶

Second Experiment on "Silicon Mold"

- First Try :

- Second Try :

Fabrication files¶

First File:Islamic Pattern

Second File:silicon mold