10. Open Source Hardware - From Fibers to Fabric¶

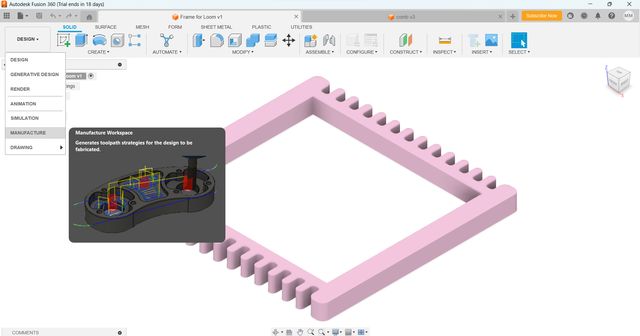

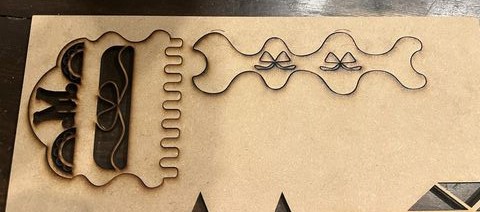

This week was one of the weeks I spent the least amount of time in the lab, therefore I decided to create the simplest of machines: an analog one. Due to the inspiration I gathered from some fellow students in the program as well as from my classmate in Japan, Kae Nagano, I decided to enter the realm of weaving. I had some fun on fusion360 designing the frame, comb, and shuttle. While some of the DIY loom designs that I researched online had some very cool interaction with technology, the design of the loom was very minimalist and a bit boring. I decided I wanted to create a very simple manual loom, but to add some details and embellishments to the design. After finishing the design, I laser cut the intricate comb design and the shuttle on a 6mm MDF board and CnC'd the frame - allowing me to try out the "Manufacture" desktop on fusion360 for the first time after completing my design in the "Design" desktop.

weekly assignment

Learning outcomes

- Research skills: the participant has acquired knowledge through references and Concept development

- Design skills: the participant has learnt through sketches, 3D modeling, use of electronics, etc

- Fabrication skills: the participant is capable of executing from file to production workflow, from 3D modelling to digital fabrication, electronics, materials

- Process skills: Anyone can go through the process, understand it and reproduce it

- Final outcome: The assignment is assembled and either complete or tested

- Originality: Has the design been thought through and elaborated?

Student checklist

- Research and document existing fabrication methods, machines and industries, add references, tutorials and sketches of the hardware you will make

- Document the process of designing the files for your machine/machine-hack/tool and its fabrication including the assembly process

- Document the schematic and the software source code (if any)

- Document the parts and how to make your tool or machine

- Document your BOM (Bill of materials): electronics, materials, their amount, etcetera (with references of the components)

- Upload your 3D model and CAM files (if any)

- Design, create and document a final outcome, a sample project of your process

- Make a small video of the machine

- Create an interface for controling your machine (extra credit)

get inspired!

Check out and research alumni pages to betetr understand how to document and get inspired

- Amsterdam lab group project 2023 Hacking Cnc machine to make a paint machine

- Kae Nagano Interactive Loom machine

- Ala Janbek Print Making Machine

- Pauline Gamore Drawing Arduino

- Berenice Coutin Weaving Loom

references & inspiration¶

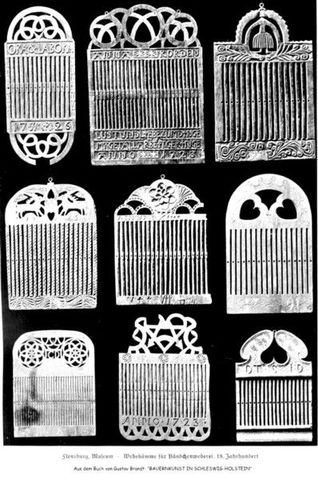

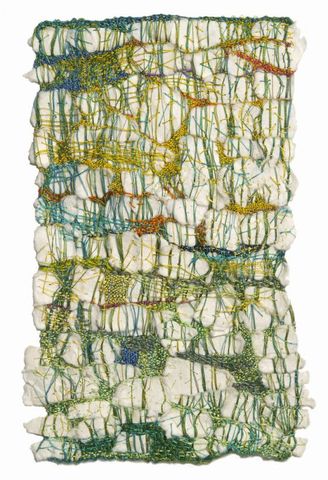

Some of my classmate Riley Cox' work. Weaving.

research¶

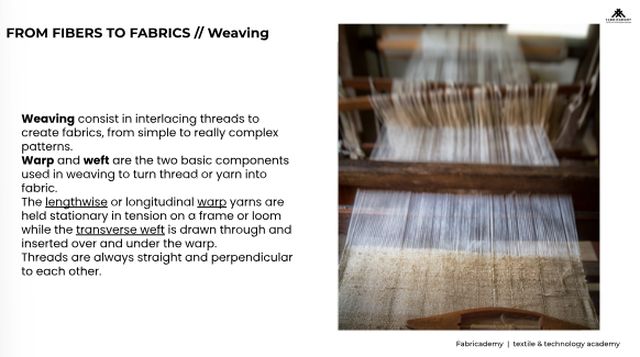

i've never weaved before. so the first thing i had to do was educate myself on the basics. here is a great overview on weaving

the most simple way of creating a loom, is out of cardboard.

I made my own cardboard loom to start giving weaving a go:

Here is a tutorial on how to weave on a cardboard loom:

TheInterlaceProject offers open-source intructions on how to create your own loom. I followed this tutorial to help me design mine.

This was another very useful tutorial I followed to create my loom.

tools¶

- Fusion360

- LaserCut Machine

- CnC Machine

- Yarn

- PLywood

- MDF

BoM example¶

materials¶

| Qty | Description | Price |

|---|---|---|

| 1 | MDF 6mm | |

| 1 | Plywood (650x450mm) | 450 Yen |

process¶

Design¶

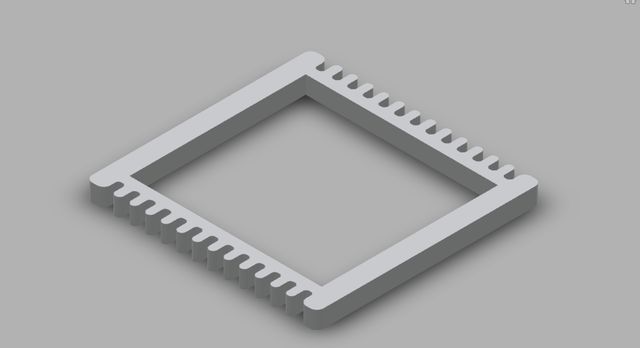

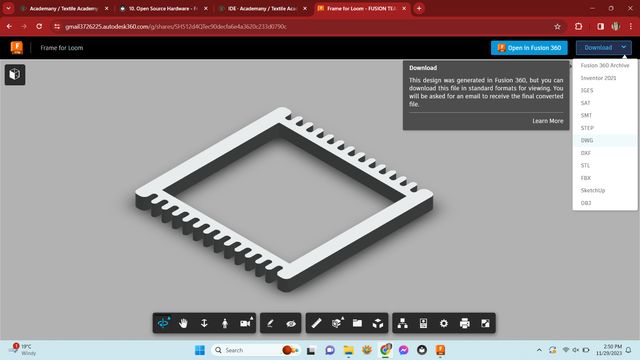

See this link for my Frame design on fusion360 and to Download the file.

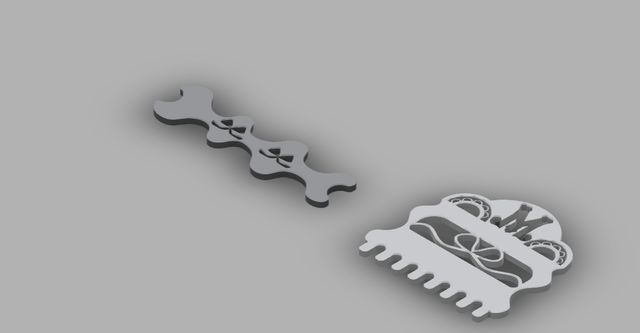

See this link for my Comb and Shuttle design on fusion360 and to Download the file for laser cutting.

Cnc¶

rico helped me out a lot this week to learn how to use the cnc machine. it involves entering the Manufactuer desktop of fusion360.

we used plywood (450mmx650mmx12mm)

and this drill

the cnc machine took about 40 minutes to cut out the frame.

it is also possible to laser cut the frame if the cnc machine is something you are not used to working with

Laser Cut¶

power: 20 speed: 60 6mm mdf

results¶

go further¶

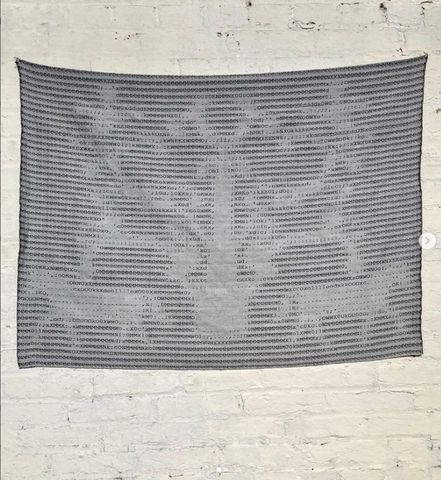

i highly reccomend looking at Nagano Kae San's documentation of her machine loom which involves human and machine interaction. She uses code to create an interaction between human and machine. Whenever she is done shuttling a line of yarn to one side, she speaks to the machine (recorded by the mic connected to the arduino) and the machine calls back out (played out by the DF Player) and then turns the Heddle bar of the loom (with the help of a motor). Her intention to make weaving (a solo activity) less lonely really shines through and it impressed everyone in the program.