Diary

Week 1: (18-24th January 2021) Research¶

In the first introduction week of the FMP, I felt that it was important to start researching the idea behind my concept.

As well as the sourcing of the fruit and vegetable waste: tomato waste (restaurant Europa) & grape waste (Dassemus vineyard). This waste was sourced locally in the Netherlands.

In the beginning I thought that it would be an interesting idea to set up a system where I could create a circular project: "Boertex". This would mean taking the rests of food waste streams (from farmers or greenhouses) in The Netherlands and transforming them into some kind of textile that could be used in an industry such as fashion or other Design areas.

Though, due to the unfortunate situation at this moment (covid pandemic '20 - '21), the project is going to take on another role with a different outcome. The focus still lies on material research, design and gaining a network but it will only be remaining in phase 1 where a garment will be developed using the biomaterial. The focus will lie on the design of the bionmaterial rather than creating a system between different sectors: Farmers - designers - customers. The different stakeholders partaking in this project.

Areas of research: - Material realisation: What can I do with the food waste that I have received and how far can I push this material so that I can form a textile?

-

Design:

-

How is the prototype designed so that it can catch the idea behind this project.

-

Textile manipulation methods.

-

Zero-waste design methods.

-

Networking:

-

Collaborations with universities and labs: i.e. Waageningen University.

-

Collaborations with previous designers in the same field: Biomaterials.

In order to create a textile that could 'mimic' the idea of a cotton or linen:

Cecilia advised to have a look at the following paper: (more chemistry based)

"Isolation and Characterization of Cellulose from Different Fruit and Vegetable Pomaces."

The necessary items were ordered in this week. The only question was , is it safe enough to test this recipe without having a chemist near by? This is were a network with chemists could come in handy.

This week I started collecting my materials:

The first tests were done using Beas' Fruit leather recipes.

You can find the images on the recipes page.

Week 2: (25-31 January 2021) Material research continuation...¶

This week was about contonuing the research for the polymer paper: Was I able to practise this experiment? Who was going to help me to obtain the knowledge on the process?

The Chemarts cookbook:

"CHEMARTS is the long-term collaboration project of two Aalto University schools: the School of Chemical Engineering (CHEM) and the School of Arts, Design and Architecture (ARTS). These schools combined forces in 2011 with the aim of re- searching bio-based materials in an innovative way and creating new concepts for their advanced use. The core values of CHEMARTS are the sustainable use of natu- ral resources, experimental working methods, and the respectful cross-pollination of design and material research."

sourced: from the chemarts cookbook by: chemarts.aalto.fi

This book was a great starting point for the research of the tomato stalks and grape waste that I had collected. Some of the recipes are based on cellulose, these process seem useful for the biomaterial development of my tomato stalk material.

As some of the ingredients had to be shipped from other countries, this week was about prepping everything and the start of understanding the foundations of the recipes for material innvation.

Week 3: (1-7 February 2021) Material research continuation...¶

This week all of the ingredients were arriving from overseas. The material experimentation with alginates and gelatine was continued. This information is documented on the reciped page.

Week 4: (8-14 February 2021) Material research continuation...¶

Contact with professionals:

Waageningen: Anouk Mesch feedback:

- Waageningen has tested the idea of using tomato waste from greenhouses.

- Agricultural residues.

- Paper making : virgin wood fibres supplied in big sheets.

- The use a stitching blender to use the pulp.

- The use of the pulp and mix it with other things to create a new mix.

- Extraction of fibres from tomato waste, you need a large scale

- Sodium hydroxide , to dissolve the liquids and to keep the glue.

To do this you need several permits to work with these projects. This is why WUR hasn’t followed through with this project. Their developed tomato paper however can exist because it is a blend of this other pulp, not just make 100% from tomato waste.

Optimising the chemical process. 2000 tonnes is not worth while. Feasibility from an economical perspective. This is why WUR hasn’t followed through with this project.

There are a few plants in Europe: Spain that focus on hemp and straw.

Fibre feedstocks that are still processing this. Spain and Eastern Europe. In Spain: Philesa or flies, several options and a few other.

In Hungary: Mill that produces straw. - check it out.

Pulp wood procedure. Cellulose bioleather. Rotterdam. Fruit leather. Contact them. 03.02.21

Call general Wageningen research facility if there are more questions.

Week 5: (15 - 21 February 2021) Material research continuation...¶

Contact with professionals:

Fruitleather Rotterdam: Are not capable to collaborate at the moment because of their agenda.

Results: Alginate shrinkage. Check the recipes page for the results.

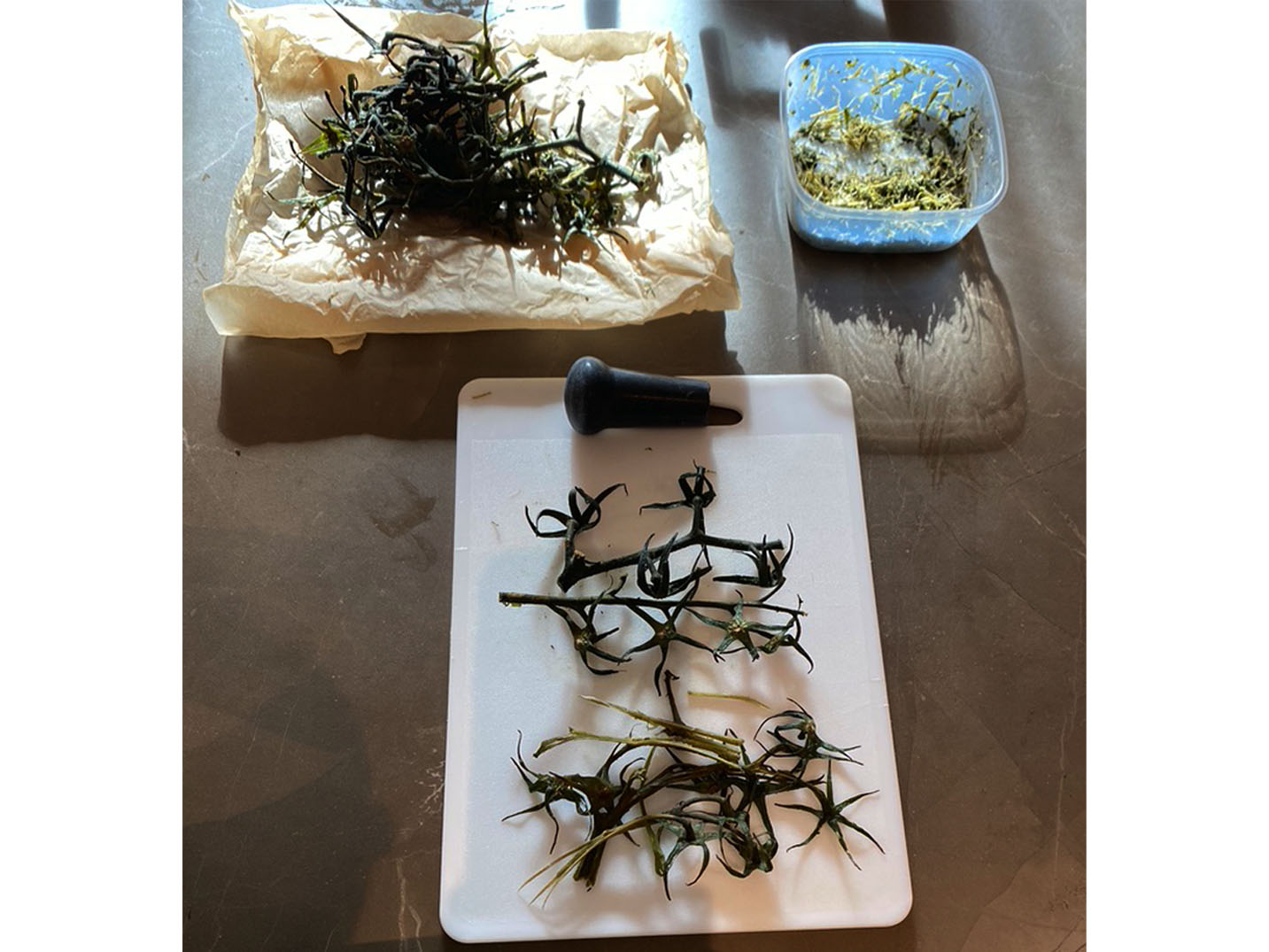

19.02.21: (Results were super anticlimatic) Bashing of the tomato stalks to see whether they contain fibres for cording like in the Rhubarb and horseradish technique.

This was a fustrating experiment seeing as the cellulose within the tomato stalks was at a minimum.

Week 6: (22 - 28 February 2021) Heading towards the finalisation of the material experimentation¶

Contact with professionals:

Ward groutars: 1 hour conversation about the possibilities of this project and to put the idea into perspective regarding time. Waageningen: Waageningen has tested the idea of using tomato waste from greenhouses.

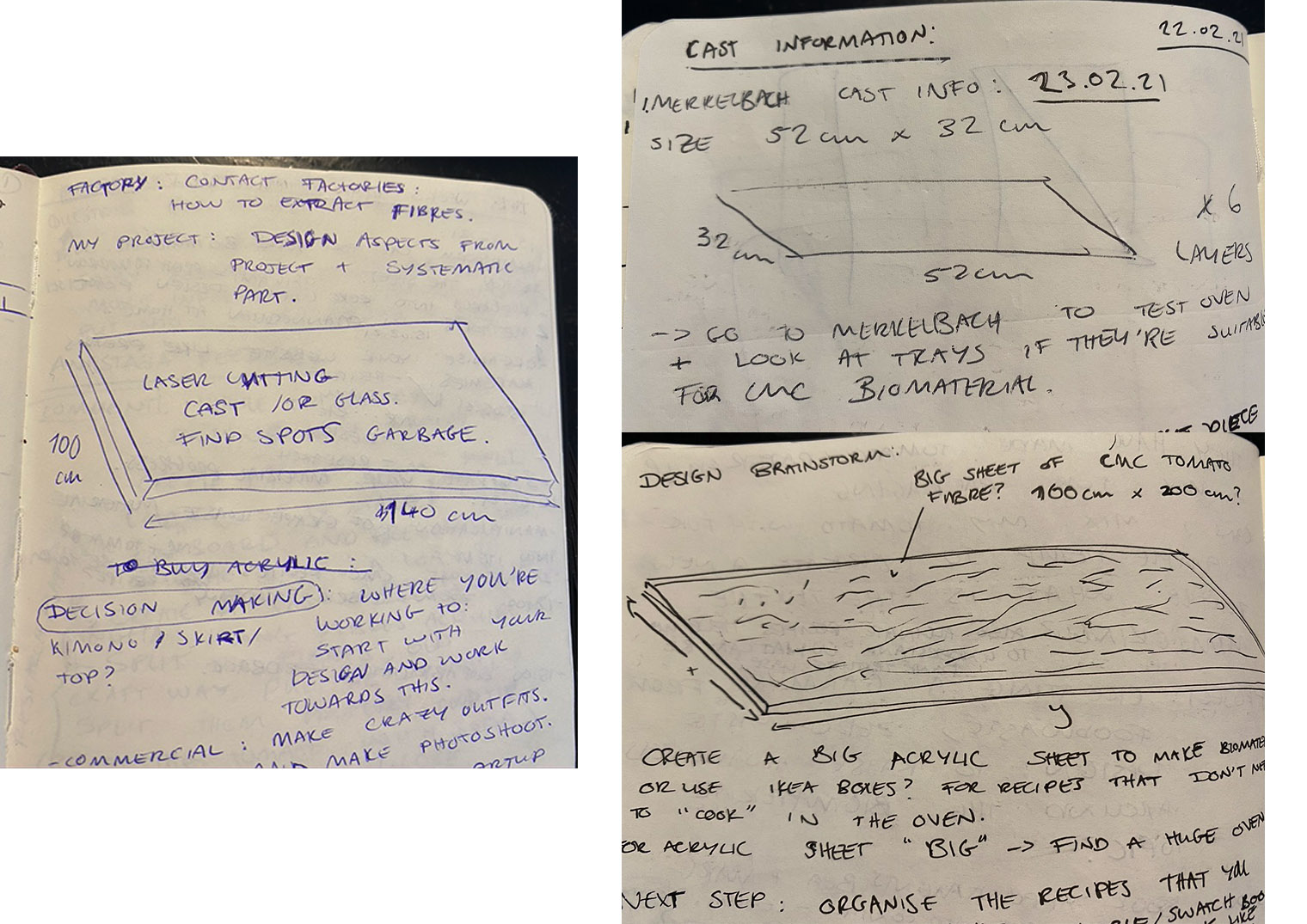

Storytelling:

Image of my sketch so far:

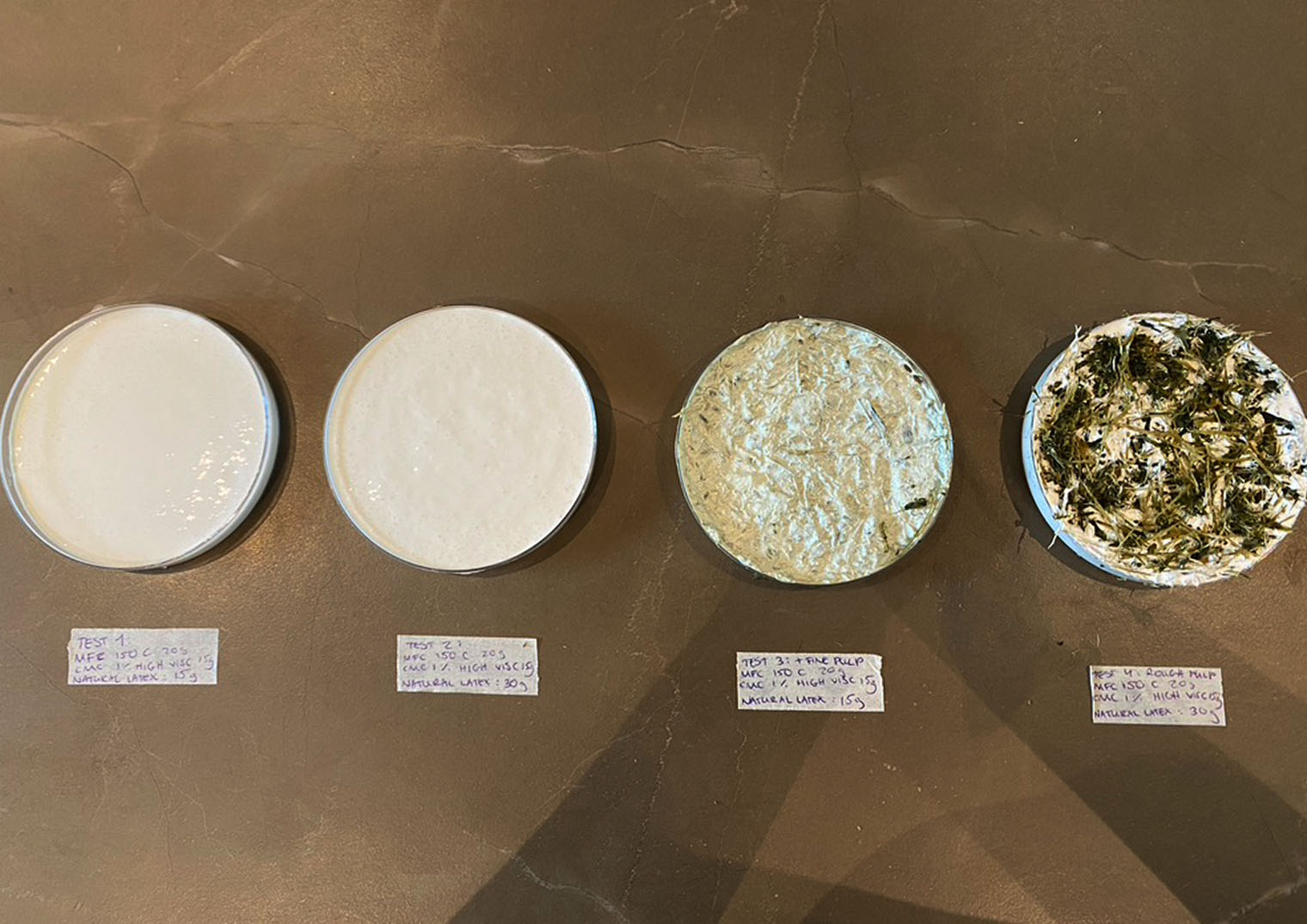

Material development process: Cellulose Natural rubber variations:

From left to right:

- Name: Cellulose w/ celova 150 + Medium LATEX (to increase flexiblity?)

Ingredients:

- CMC mixture high visc: 15g

- Natural rubber latex 15g (SPECIAL ABOUT THIS RECPIE)

- MFC 150 celova 20g

- Cast petri dish 10 cm diameter

- Name: Cellulose w/ celova 150 + Maxi LATEX (to increase flexiblity?)

Ingredients:

- CMC mixture high visc: 15g

- Natural rubber latex 30g (Increased by 6 x to see the flxibility of textile)

- MFC 150 celova 20g

- Cast petri dish 10 cm diameter

- Name: Cellulose w/ celova 150 + MaxiLATEX (to increase flexiblity?) + fine pulped tomato

Ingredients: - CMC high visc: 15g - Natural rubber latex 15g - MFC 150 celova 20g - Cast petri dish 10 cm diameter - Tomato stems pulp fine 20g (SPECIAL ABOUT THIS RECPIE)

- Name: Cellulose w/ celova 150 + MaxiLATEX (to increase flexiblity?) + fibre placed tomato

Ingredients - CMC high visc: 15g - Natural rubber latex 30g - MFC 150 celova 20g - petri dish 10 cm diameter - Tomato stems pulp - extract the fibres and place tacticly 05g (SPECIALstructurre THIS RECPIE)

Week 7: (1 - 7 March 2021) Testing parametric design with a substitute material/Finalisation of the material experimentation¶

Results drying of Celova variation: Drying since 26.02.21

Progress 03.03.21

This week the aim was to create a mterial that would satisfy this project aesthetically. The material experimentation is thereby finished by the 7th of March 2021.

After visiting Lindenhoff, it was clear that not all vegetables are girwn throughout the whole year. Many vegetables grow seasonally if the production is done my a (organic) farm. Where: Utrecht.

Having spoken to Olaf (the vegetable chef) I realised that this project would have to look at other vegetables as well as tomato. Vegetables that look like/ behave like horse radish and rhubarb would be great for the experiment form Sally pointer: Extracting fibres from begetables and spinning this into natural cordage.

This is the final week for all material experimentation! The idea is to ustilise just one final recipe that serves as useful and also looks great for the garment that is constructed in the next phase.

The results so far: Material innovation x vegetable waste"

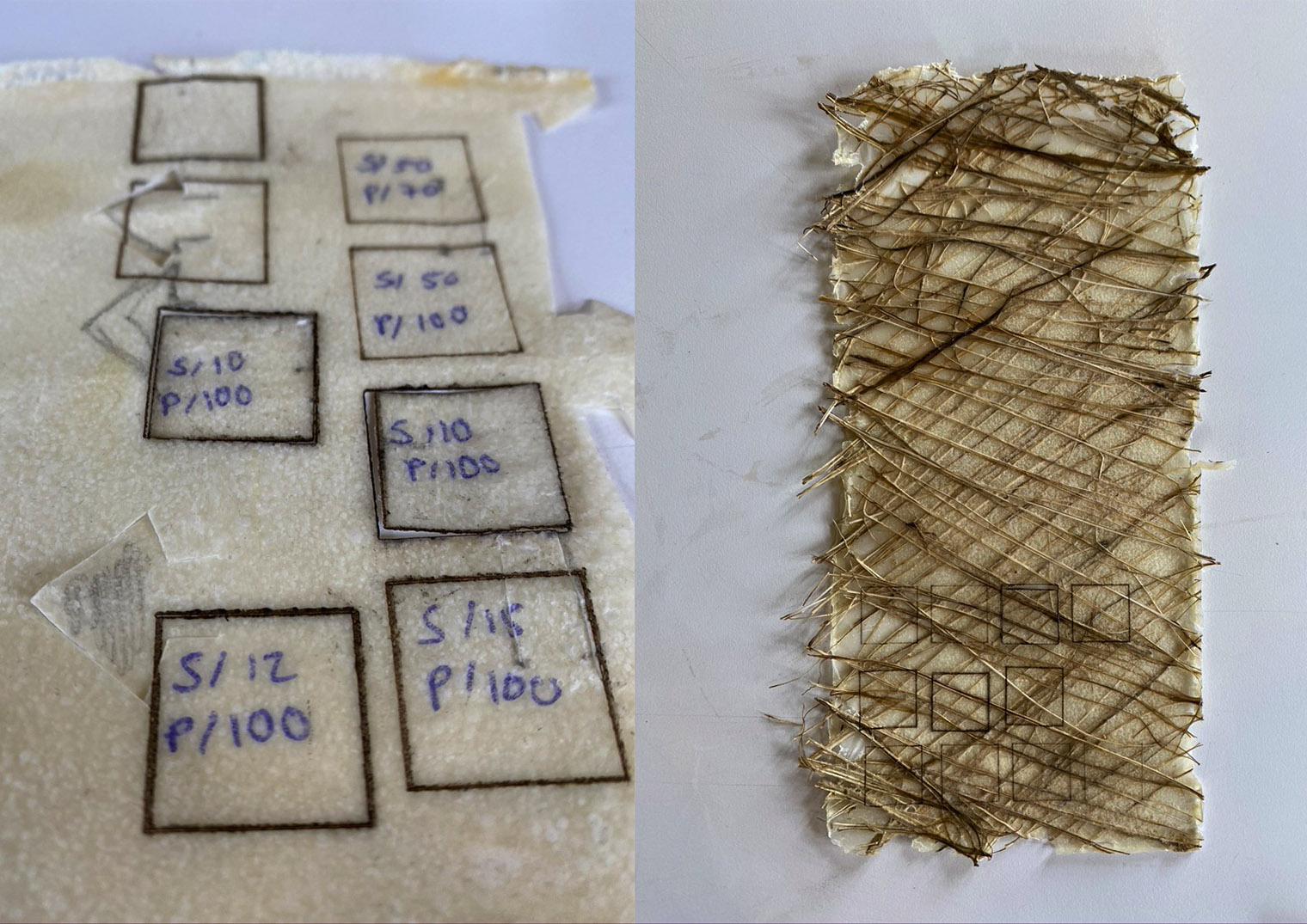

Week 8: (8 - 14 March 2021) Testing laser cutter with biomaterial/week to prepare the teaser¶

After testing this week the final laser cutter settings were as follows:

For the engraving on the cellulose (guidelines) on pattern: Speed: 100 Power: 10

For the cutting of the outside edges: Speed: 30 Power:40

Week 9: (15 - 21 March 2021) Mid review time: Collecting all of the ingredients for the final.¶

Week 10: (22 - 28 March 2021) prepping big sheets of biomaterial : Restaurant merkelbach¶

Week 11: (29 March 2021 - 04 April 2021) Laser cutting garments¶

This week was tricky, any slots that were open in De Waag were holy.

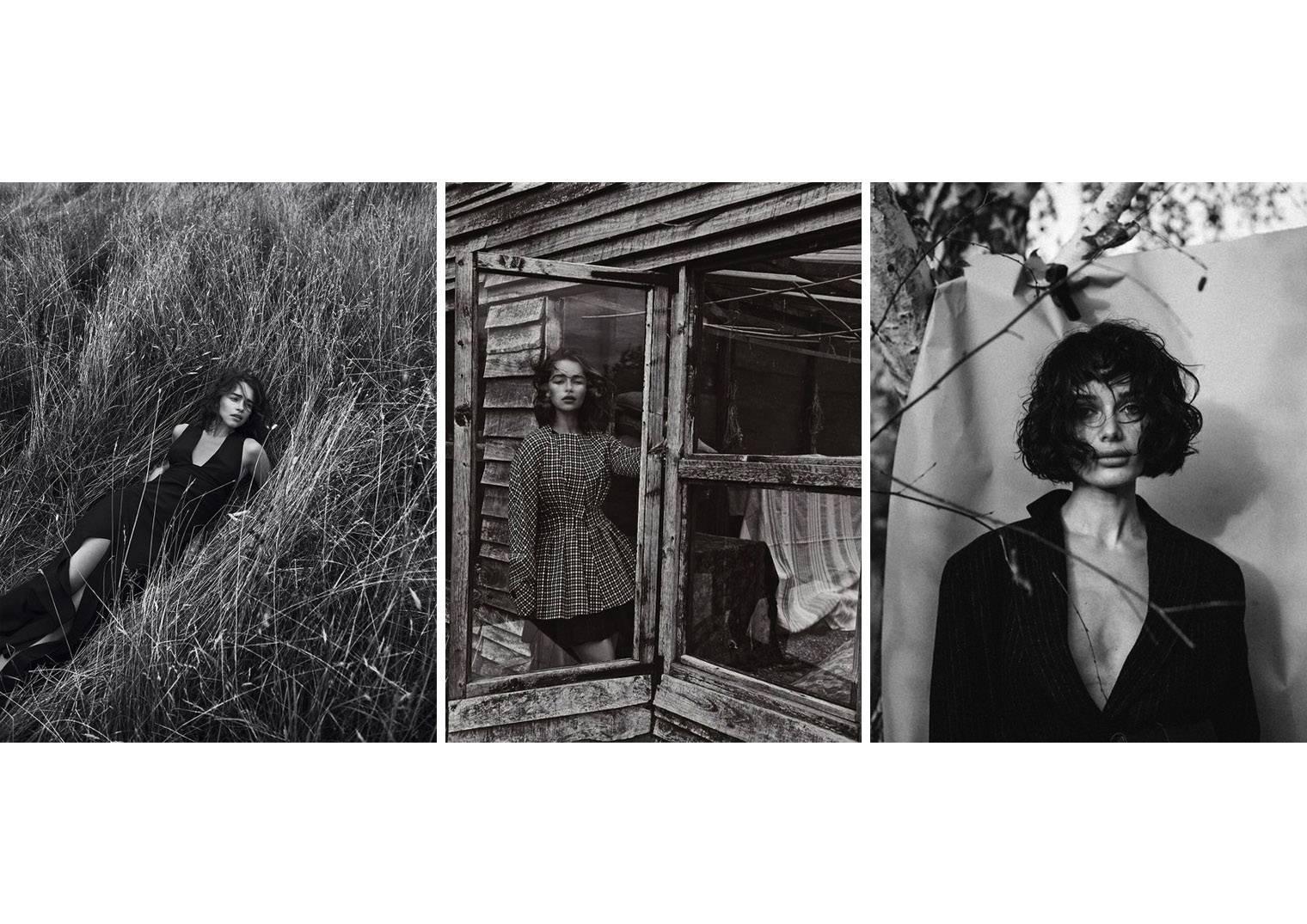

Week 12: (5 - 11 April 2021) Photoshoot!¶

Photoshoot inspiration:

We spent the whole day shooting on location in Amsterdam. Due to the weather conditions we chose a venue that was set inside just to be safe.