Recipes

Material development¶

Fruit leather Recipes:

- tomato stalks:

Experimentation: Test 1 Tomato stalk Bioleather try out 1 - Do it yourself friendly¶

21.01.21

First test with the tomato stalks:

I was able to collect 240 grams of tomato waste from my friend Bloeme on the 18th of January 2021. She works in a restaurant called Europa and so kindly saved me the rest of the stalks from her tomato sauce. The first test that I made I was sure to use the tomato stalk which had a little white mould on there already. They had been concealed in a vacuumed bag but due to bacteria the stalks had already started to rot. I wanted to see whether the stems are still useful even after they have rotted a little bit.

For the recipe:

Recipe 1: 21.01.21

-

60 gr tomato waste (stems)

-

60ml water

-

20 ml apple cider vinegar

-

10ml glycerine

-

10g beeswax

Equipment:

-

Pot

-

Wooden spoon

-

Gloves

-

Oven tray 20 x 30 cm

-

Mask

-

Blender

-

Oven: 60 degrees

-

Weighing scale

Method: 1. Firstly, wash all the stalks because they are covered in some mold. Place in a large pot and place under very hot water. Rinse the stalks and rid them of the mold.

-

Once cleaned, place back in pot and place on the weighing scale to measure units (240 grams). Then fill the pot with hot water so that the stems are covered entirely.

-

Place the pot on your furnace (mine is an inductive one) and put the furnace on low heat (in my case I put this on 2 on the induction). This process is meant to soak the stems so that they become softer before we blend in the blender later on. This will avoid breaking the blender and also make the pulping process a lot easier.

-

Place water on furnace for 120 minutes and time this! Make sure to check on your stems every 10 minutes or so making sure they aren’t boiling completely. Like a hot bath. Once a they are a little softer, remove the stalks from the water bath and let leak through a sieve.

-

Place 120 grams of stalks to one side. This is for recipe 1. When grinding your stems make sure to add little by little into your blender seeing as the blender will clog up because the stems are still strong in structure. Problem with the blender: it would jam because of the thicker stalks. Problem blending it bit by bit: you’re blended stems will never all be the same structure in thinness or thickness. Blend till it reaches a little thicker than small wood chips.

-

Add the stalks + 60 ml water + 20 gr beeswax + 10 ml glyceron +20 ml apple cider vinegar to a pan. Let is cook on low heat until beeswax is melted. I ended up running out of glycerine and beeswax.The next experiment will be the other 60 gr tomato stem waste with more binders.

- Place the compost onto an oven tray cook on 60 degrees for two hours first to see if anything happens.

Results: The fibres didn’t hold together at all. Applying a mango bioleather recipe to the tomato waste is therefore trickier than I thought it would be. The tomato pulp dries out quicker and it seems that it must be combined with something in order for it to hold together like leather. Perhaps the stalks were already too dry also, the water content therefore was low. In the second experiment I will add more glycerine and perhaps another binding to see whether the pulp will hold without another agent (alginate for example).

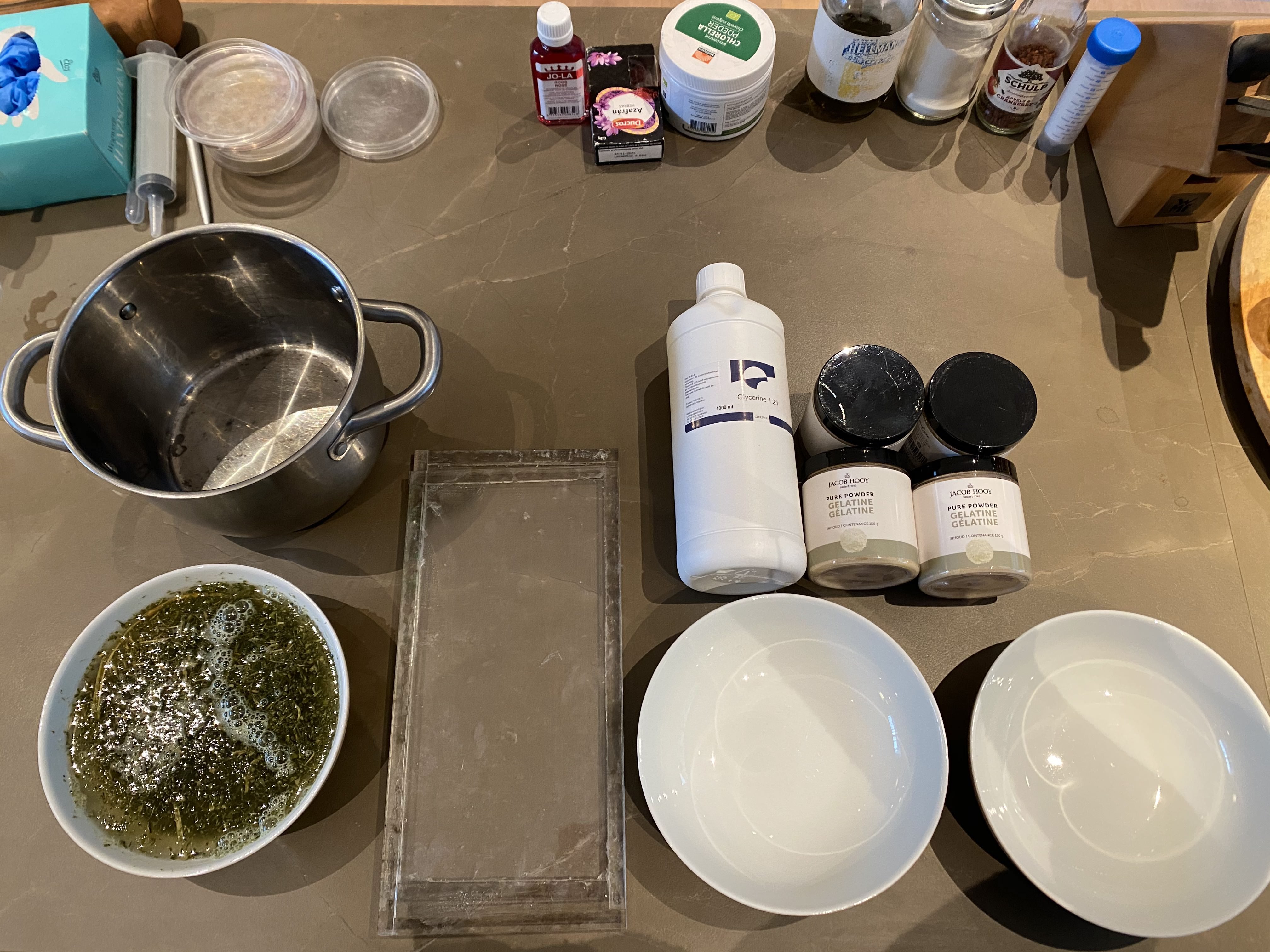

Gelatine Recipes: Test 2 Tomato Biojelly¶

Ingredients:

Glycerin based experiment with the help of BeasBeatriz Sandini's previous documentation:

Sample 1 - Tomato waste pulp:

More information is coming soon...

Result:

Sample 2 - Filtered tomato pulp:

More information is coming soon...

Result:

Sample 3 - Filtered tomato pulp + concentrated Rose (Red) dye:

More information is coming soon...

Comments:

Gelatine Recipes: Test 3 Dassemus grape biojelly¶

Process:

To be continued...

On the day that it was casted:

To be continued...

Results:

7 Days after drying:

Potential placement/positioning for this biojelly? - Design.

Comments:

Alginate Recipes:¶

- Solo: (On it's own)

Process:

To be continued... - Extruder (syringe is also fine to do tests)

Results:

Comments:

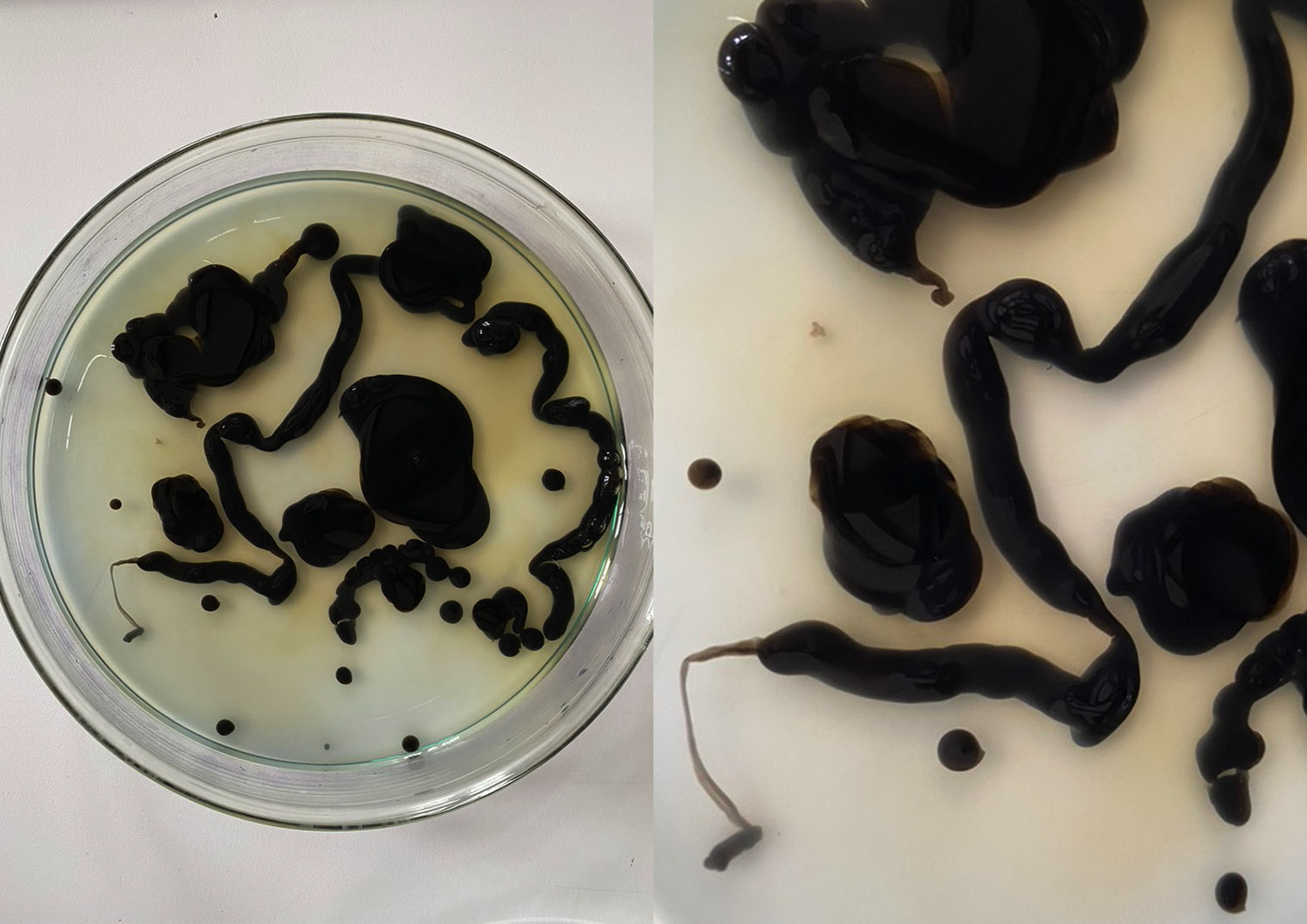

This experiment failed a little seeing as the extruder wasn't giving a constant amount of alginate. The blobs are a result of the uncontrolled alginate that would touch the sodium chloride bath.

3 Recipes:

- Flexible Bio plastic Aginate:

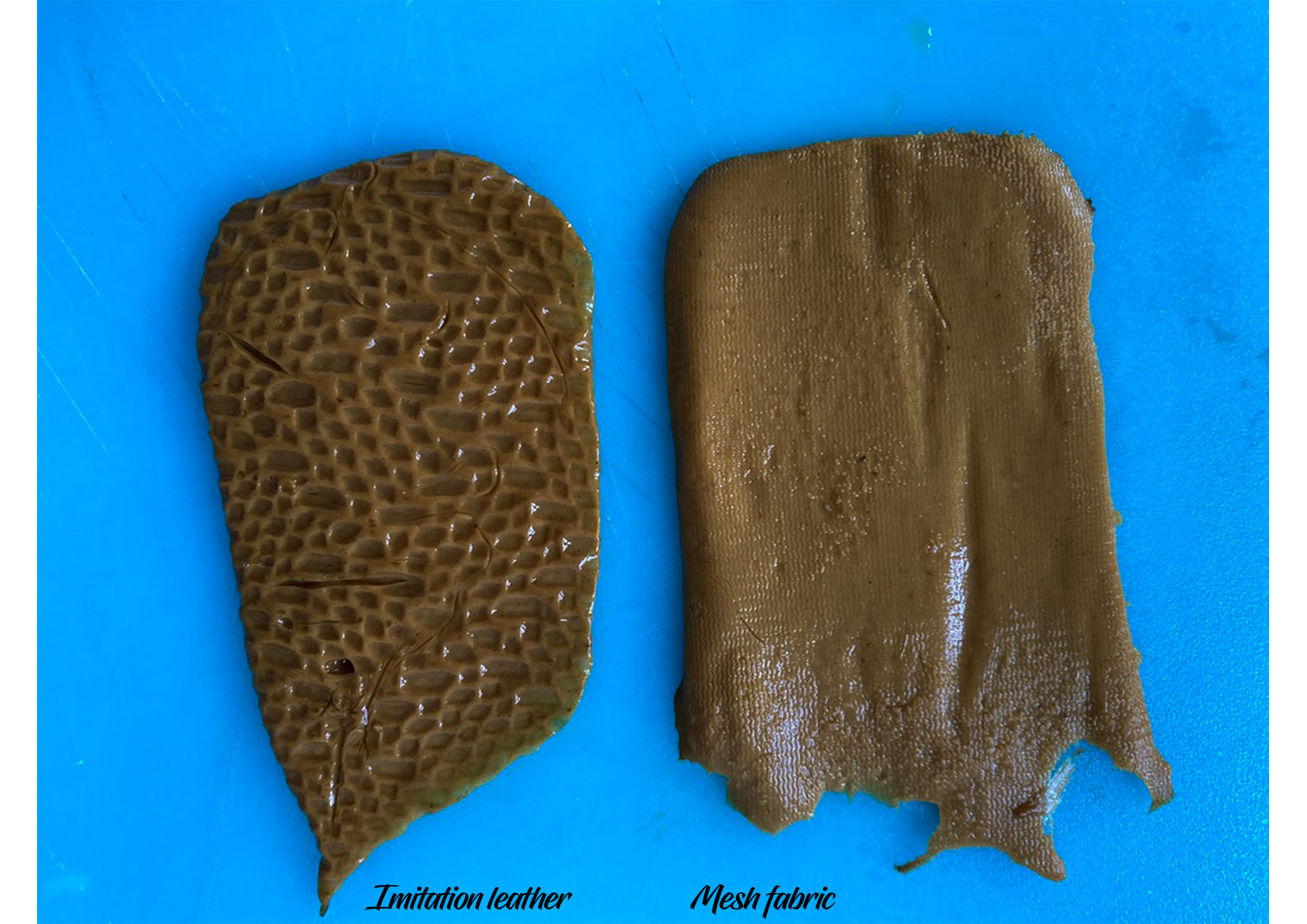

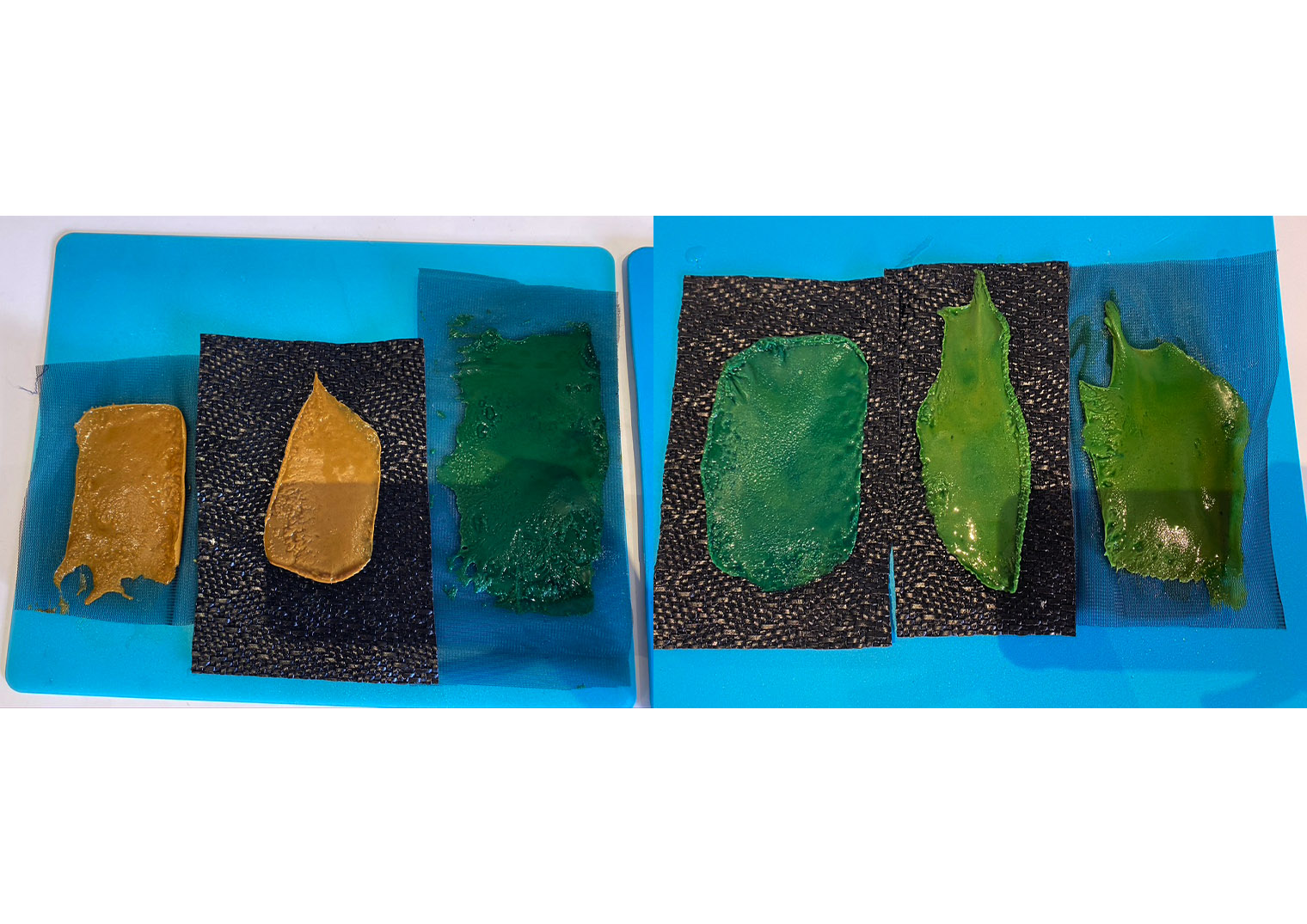

Casted: (leave the colour as is) - 1 on top of mesh - 1 Imitation leather - 1 Acrylic cast.

results:

with a print:

- Flexible Bio plastic Aginate:

Different colour (Green)

Results:

-

Flexible Bio plastic Aginate: Different colour: (Blue)

-

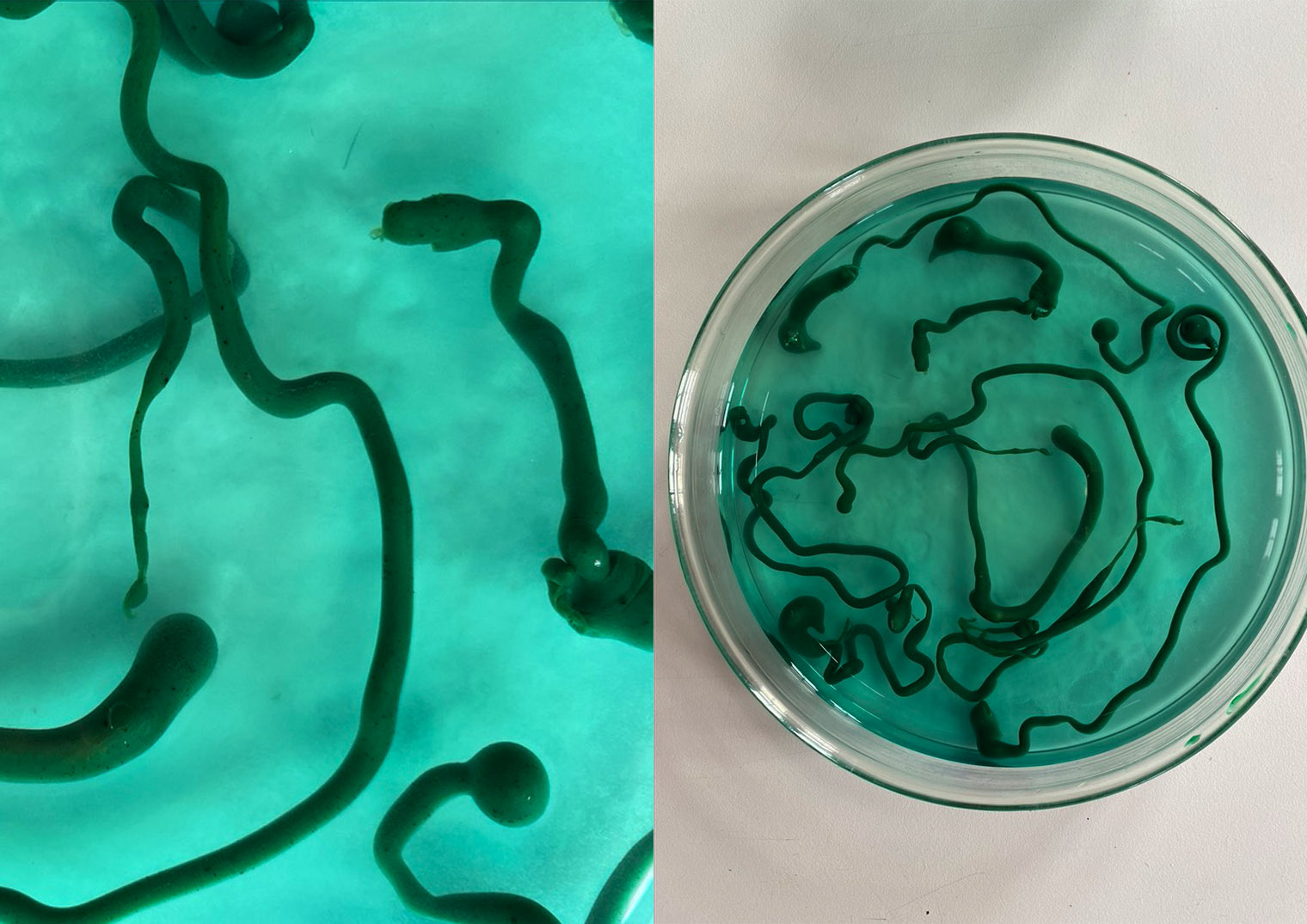

Alginate strings:

The alginate strings are pressed into a Sodium chloride bath. The mixture for the concentration of the sodium chloride in the water is a 10%. Meaning 10 grams of Sodium chloride per 100 ml. In this experiment 47 grams of Sodium chloride was used with 470 ml of water so that more strings could be floating in the liquid.

The reason for my experimentation with different materials and colour is to see what kind of texture I can achieve with Alginate. The alginate will schrink eventually giving it a natural feel. The shape cannot be controlled and therefore this makes the design of the material playful and unpredictable.

Results:

Comments:

Alginate + Hemp:¶

- Alginate strings Hemp:

Ingredients:

- 200 - 250ml alginate mixture

- 20g Hemp

- Scale

- 470 - 500ml water Sodium chloride mixture.

Process:

Results:

Added colour: Comments:

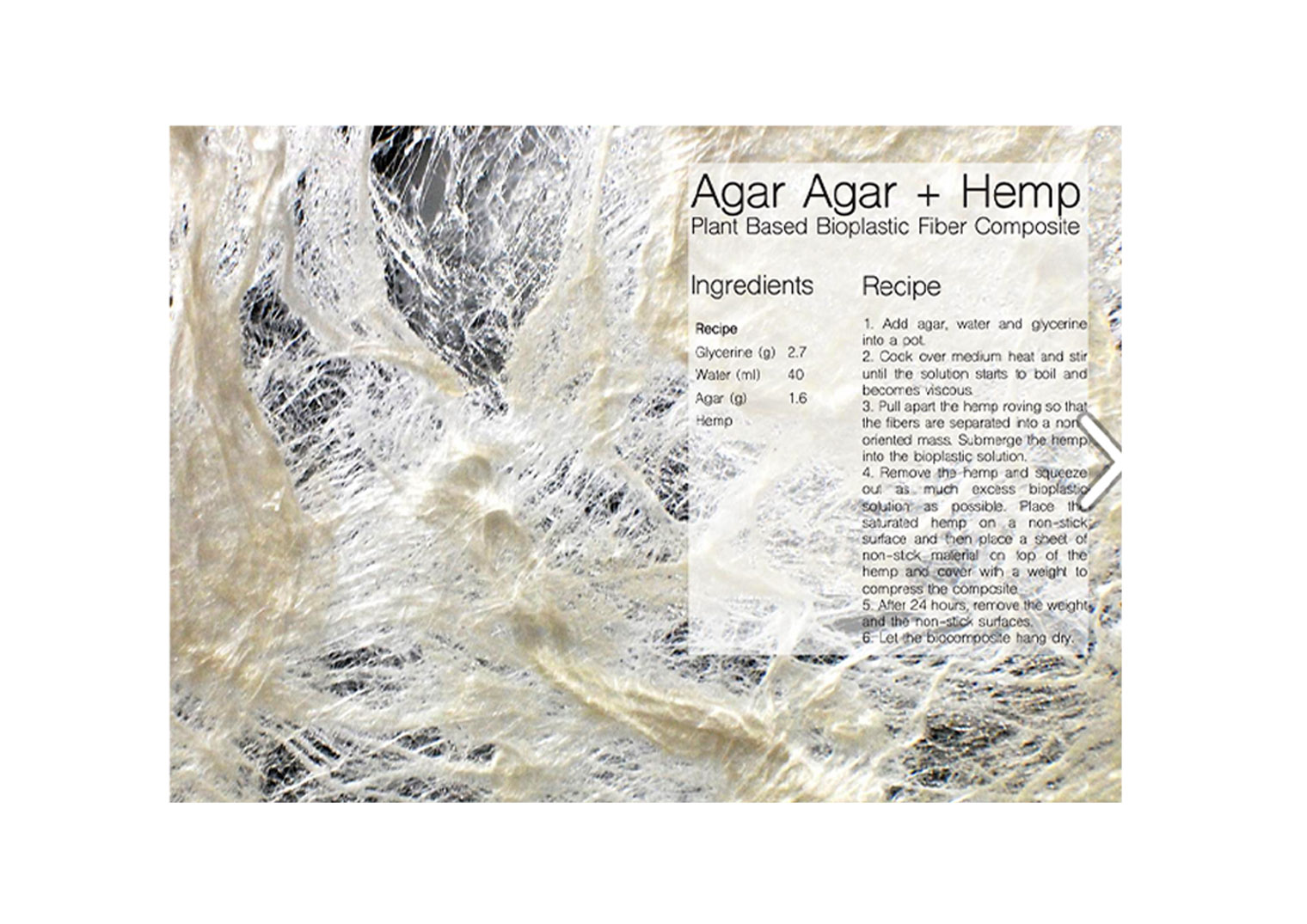

Agar recipes:¶

Process:

- With hemp:

Thanks to Anastasia Pistofiou's Bio plastic cookbook: Agar agar + Hemp recipe

In process:

Comments:

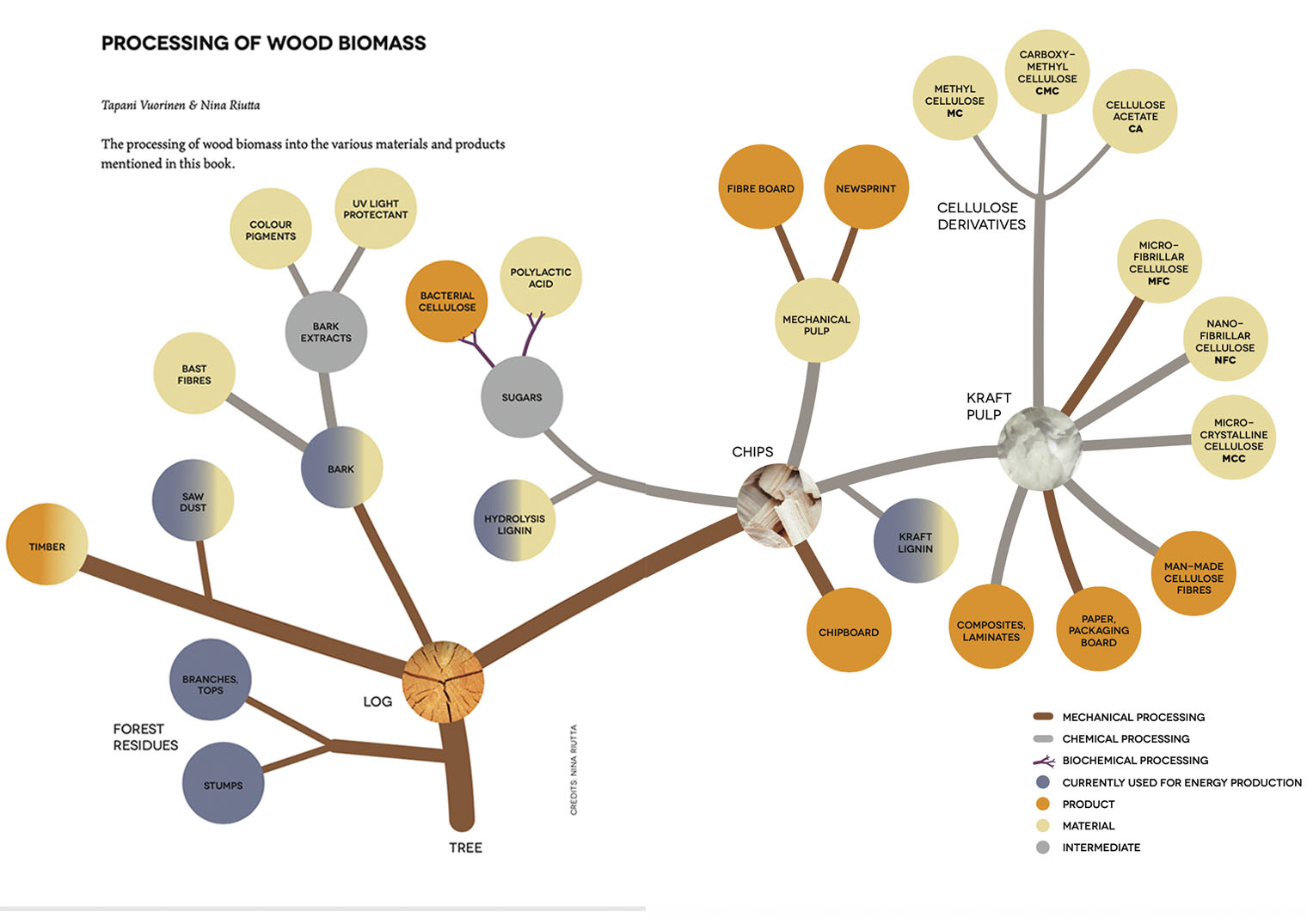

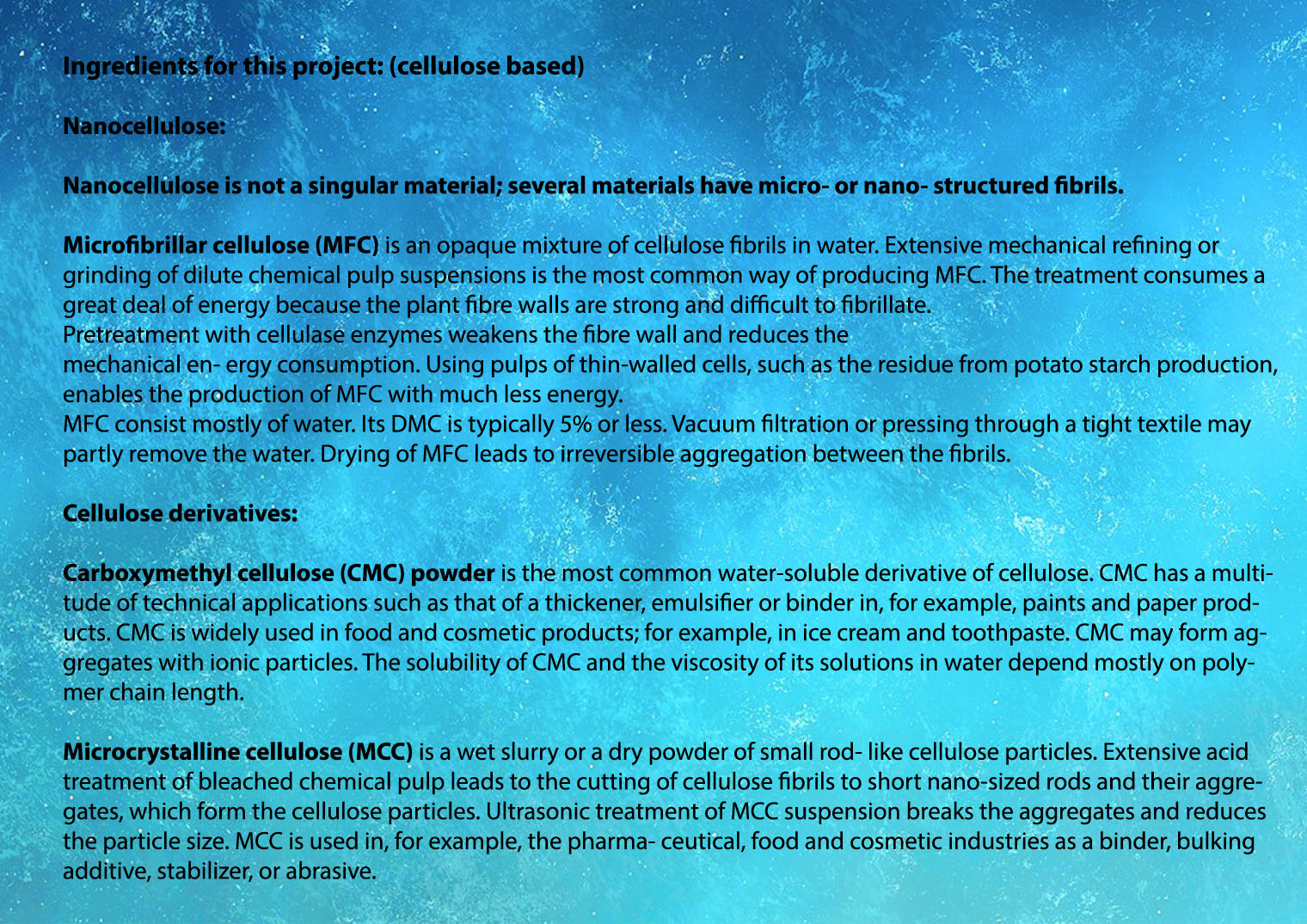

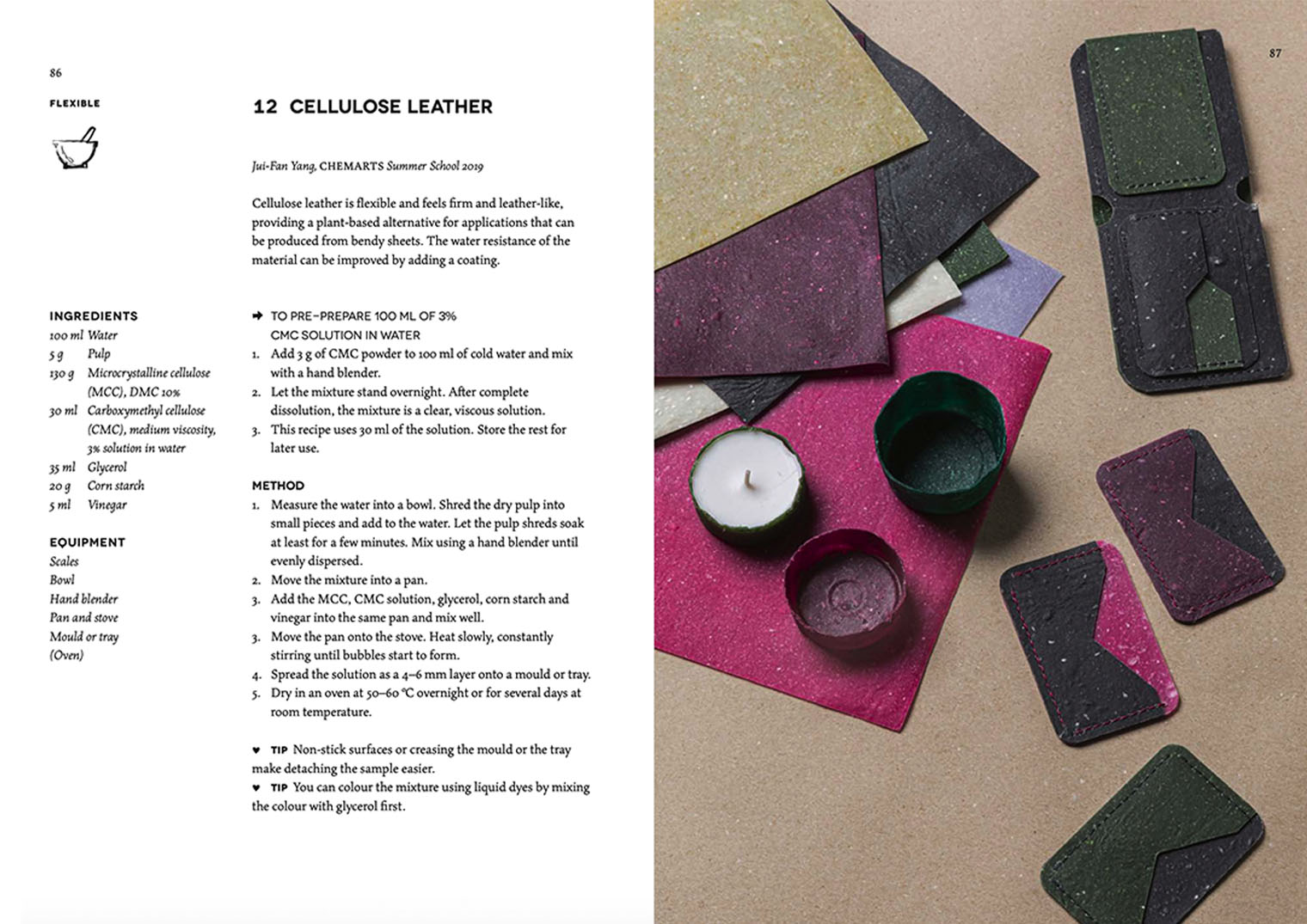

Cellulose recipes chemarts:¶

source: chemarts cookbook. The processing of wood biomass into the various materials and products mentioned in this book.

source: chemarts cookbook. The processing of wood biomass into the various materials and products mentioned in this book.

04.02.21

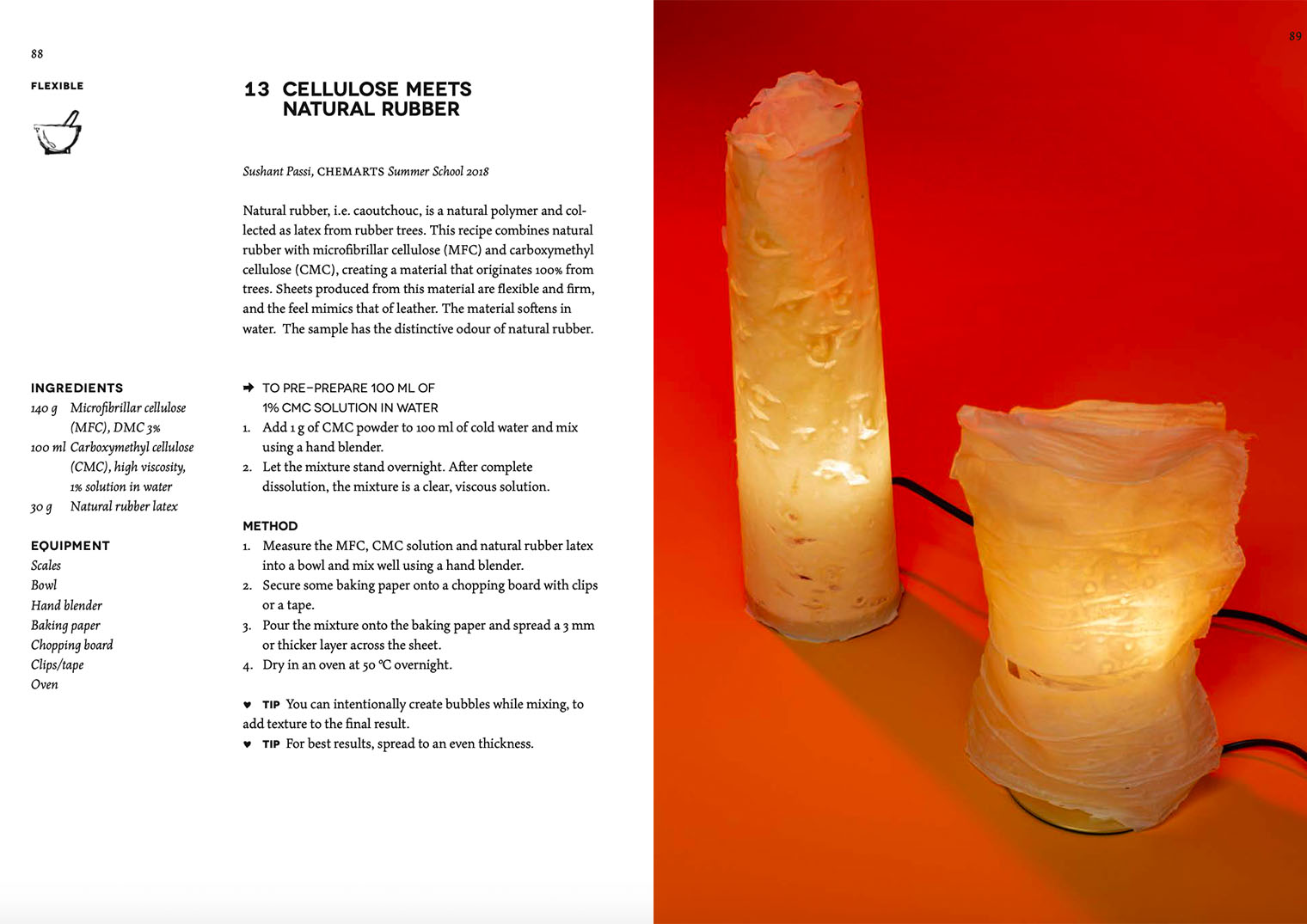

The idea was to start with this recipe that shows how flexible the cellulose recipe could become by adding the latex element to the composition.

- Cellulose rubber with natural latex:

Natural rubber, i.e. caoutchouc, is a natural polymer and col- lected as latex from rubber trees. This recipe combines natural rubber with microfibrillar cellulose (MFC) and carboxymethyl cellulose (CMC), creating a material that originates 100% from trees. Sheets produced from this material are flexible and firm, and the feel mimics that of leather. The material softens in water. The sample has the distinctive odour of natural rubber.

source: Chemarts cookbook.

Cellulose explained:

Process:

The base of the first recipe is sourced from the Chemarts cookbook. The idea is to test different variations from this cookbook to see whether the material can become thicker in weight or more stretchy.

Results:

Comments:

So far the Cellulose natural rubber recipe is testing just fine.

Week 1 drying:

-

Thickness: 0.1mm

-

Tactility: Matt on one side, this is the rough/soft side of the material. A similar stucture to that of a cats tongue. On the other side the material is glossy.

-

Colour: White

-

Translucency: Quite see through.

-

Properties: The material softens in water.

Week 3 drying:

-

Thickness: 0.1mm

-

Tactility: Matt on one side, this is the rough/soft side of the material. A similar stucture to that of a cats tongue. On the other side the material is glossy.

-

Colour: Creme, a slight discoloration. Perhaps the material can be dyed using natural dyes to cover the discoloration over time.

-

Translucency: Quite see through.

-

Properties: The material softens in water.

Show video of testing: .......

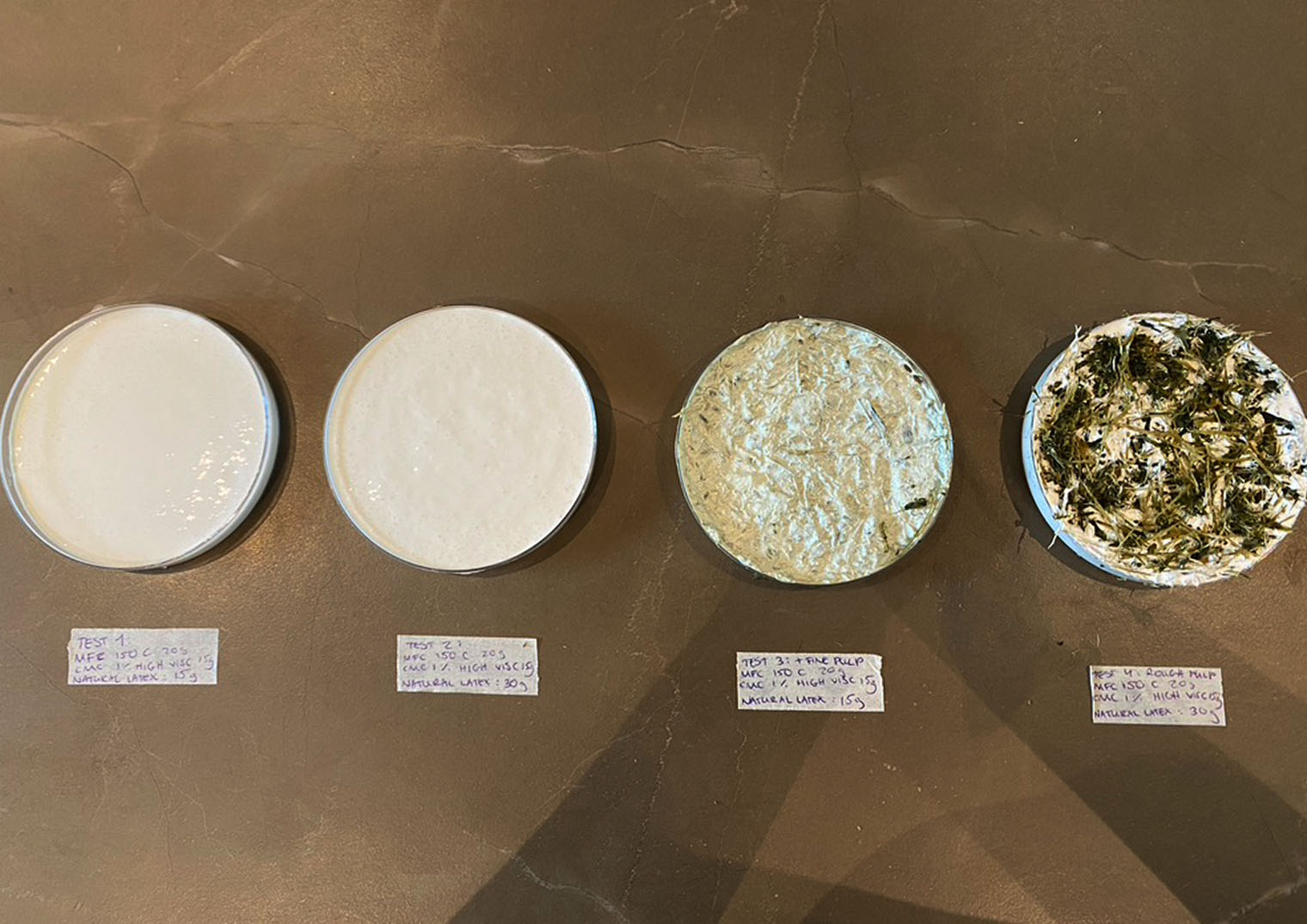

Variations of the CMC experiment:

Material development process: Cellulose Natural rubber variations:

From left to right:

- Name: Cellulose w/ celova 150 + Medium LATEX (to increase flexiblity?)

Ingredients:

-

CMC mixture high visc: 15g

-

Natural rubber latex 15g (SPECIAL ABOUT THIS RECPIE)

-

MFC 150 celova 20g

-

Cast petri dish 10 cm diameter

-

Name: Cellulose w/ celova 150 + Maxi LATEX (to increase flexiblity?)

Ingredients:

-

CMC mixture high visc: 15g

-

Natural rubber latex 30g (Increased by 6 x to see the flxibility of textile)

-

MFC 150 celova 20g

-

Cast petri dish 10 cm diameter

-

Name: Cellulose w/ celova 150 + MaxiLATEX (to increase flexiblity?) + fine pulped tomato

Ingredients:

-

CMC high visc: 15g

-

Natural rubber latex 15g

-

MFC 150 celova 20g

-

Cast petri dish 10 cm diameter

-

Tomato stems pulp fine 20g (SPECIAL ABOUT THIS RECPIE)

-

Name: Cellulose w/ celova 150 + MaxiLATEX (to increase flexiblity?) + fibre placed tomato

Ingredients:

-

CMC high visc: 15g

-

Natural rubber latex 30g

-

MFC 150 celova 20g

-

Petri dish 10 cm diameter

-

Tomato stems pulp - extract the fibres and place tacticly 05g (SPECIALstructurre THIS RECPIE)

Bigger swatches to test the durability of the material:

Progress 03.03.21

This weeks aim was to create a material that would satisfy this project aesthetically. The material experimentation should be done by the 7th of March 2021.

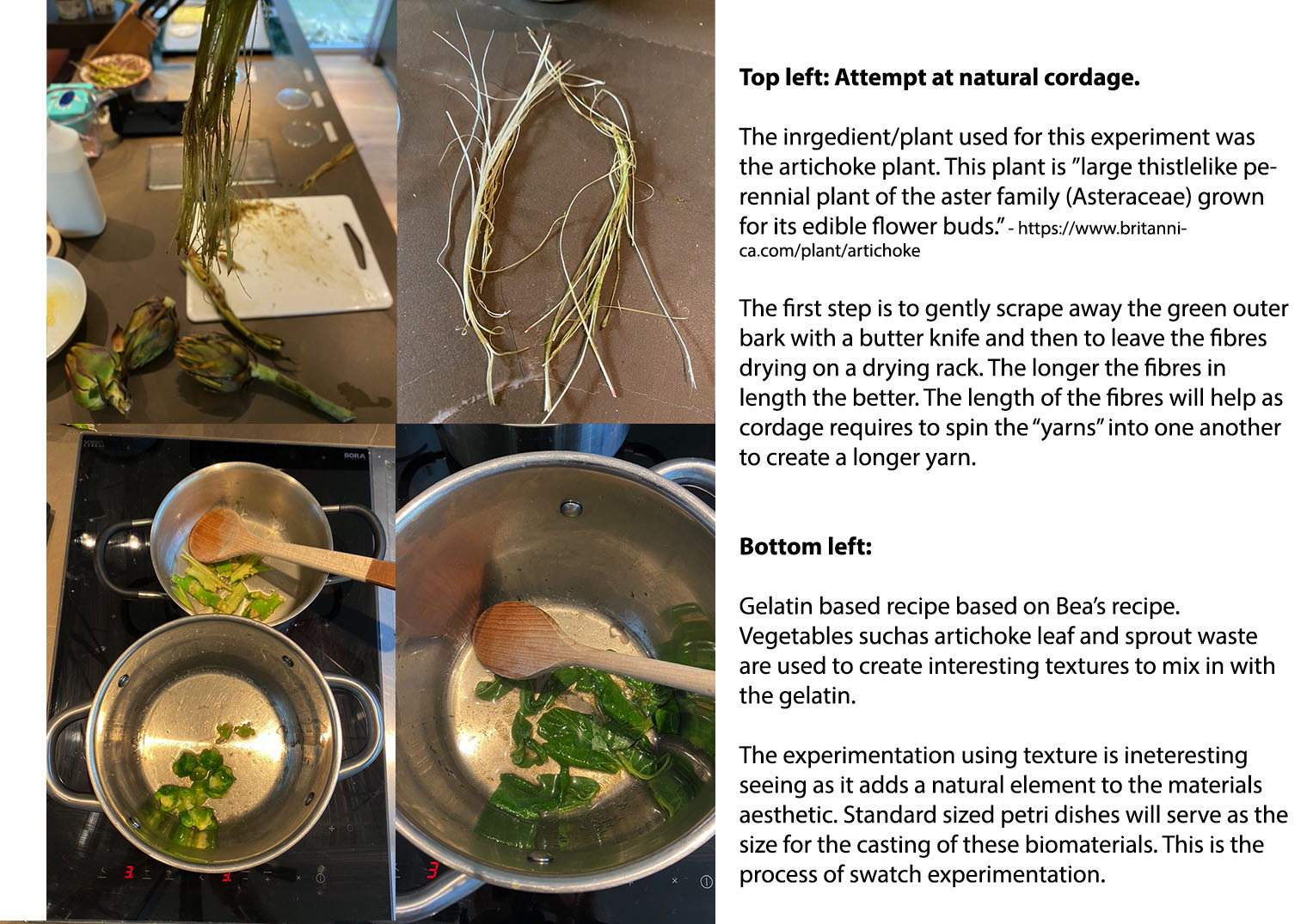

After visiting Lindenhoff, it was clear that not all vegetables are grown throughout the whole year. Many vegetables grow seasonally if the production is done my a (organic) farm. Having spoken to Olaf (the vegetable chef) I realised that this project would have to look at other vegetables as well as tomato. Vegetables that look like behave like horse radish and rhubarb would be great for the experiment form Sally pointer: Extracting fibres from begetables and spinning this into natural cordage.

The extraction of fibres (old technique) from vegetable stems and leaves: First attempt

Result:

On 03.03.21:

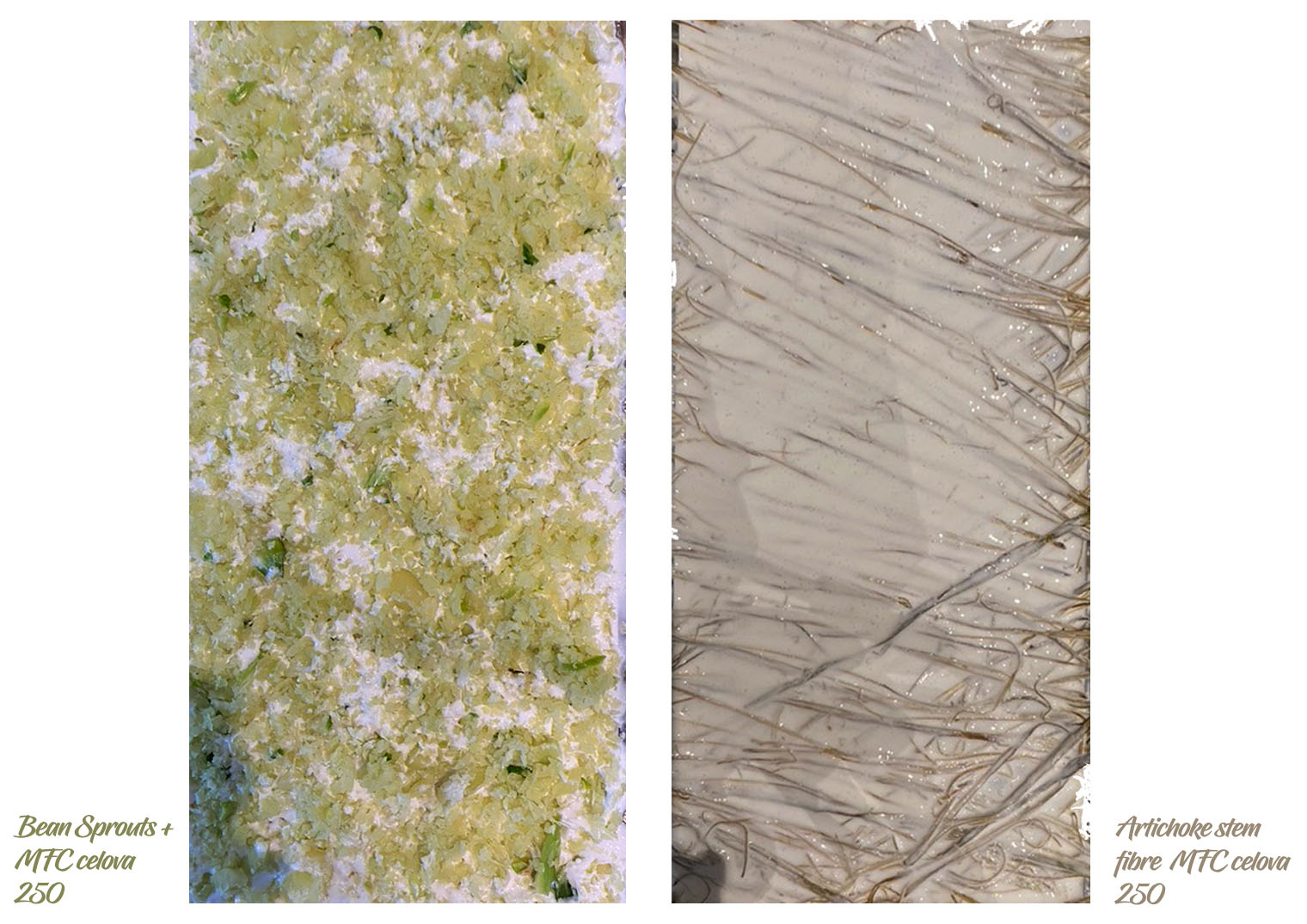

New vegetables were experimented with:

- Gelatin based:

Process:

Results so far:

- MFC + CMC based:

Cellulose leather: The CMC (Carboxymethyll cellulose) for this project is on its way. :(¶

The package is En Route, Sat, February 27, 2021 at 9:50 AM ET, Avenel, NJ, US

Process:

source: Aalto University publication series C 1/2020 . The chemarts cookbook.

Before:

After:

Comments:

Once cooked in the oven for 10 hours at 50 degrees celcius, the bioleather cellulose results in a matt texture. The materials is flexible, breathable and boidegradable. This plant based leather/plastic can be labelled as biodegradable as all of the materials could break down easily when the right environmental factors are present in the environment.

The natural dyes are added to see whether dyieng is possible with the CMC, MCC and pulp mixture. So far the Hibiscus dye is strong in colour and the powder pink allows for a soft look. The minty green Mixture also does the trick. Minty green colurs are known for their unisex qualities. This colour could be a great addition to the product as it can appeal to all genders.

This format for the recipes is only temporary until I find a nice format for a table. The information regarding the different material compositions will be structured inside this table.

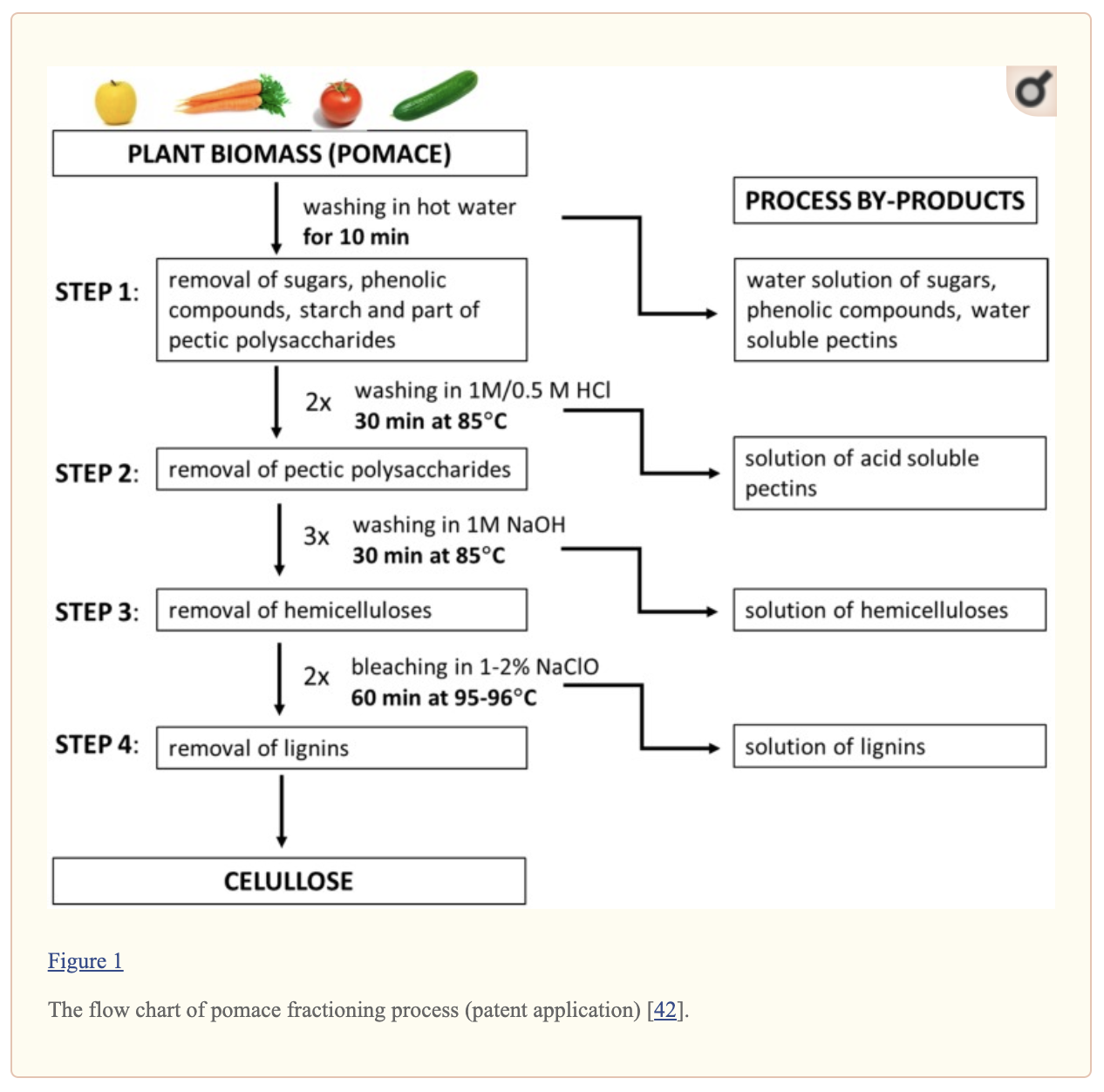

Experimentation: Isolation and characterization of cellulose from different fruit and vegetable Pomaces:¶

This experiment should be discussed with a professional chemist before I attempt to try this extraction on my own.

The ingredients:

The recipe:

TO be continued...