Inspiration¶

Fruit leather Rotterdam (Material development from fruit waste in the Netherlands)

3D-printing with living organisms "could transform the food industry"

Maybe I could apply this to the additions of the garment: buttons etc...

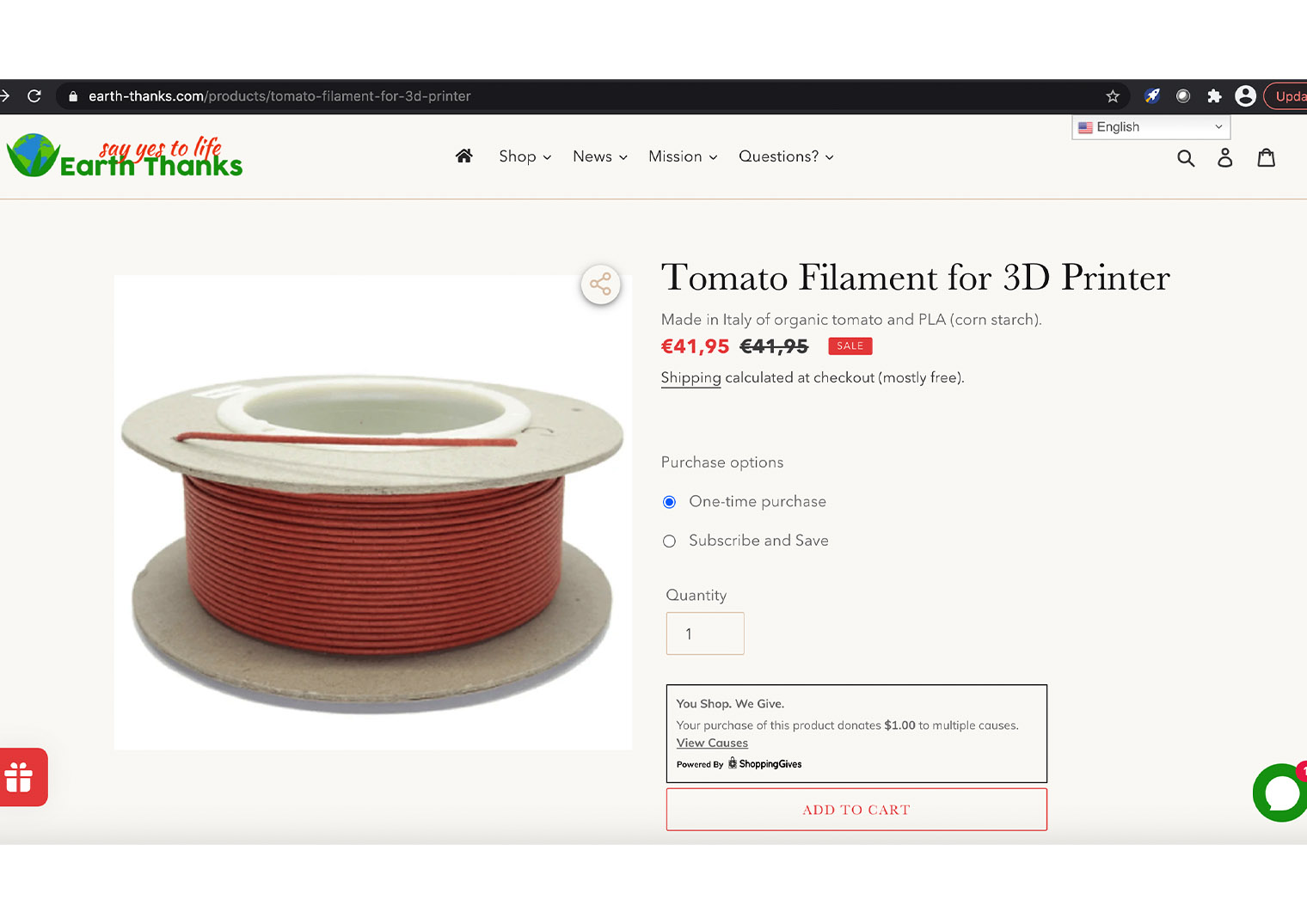

3D-printing tomato filament:

Fashioning the future: Tomorrow's wardrobe. written by: Suzanne Lee.

Technique: Fibre extraction methods¶

Fibre chords/ strings from plants:

https://www.youtube.com/watch?v=X3I_ele6Ums

Nettles fibre extraction:

A more upgraded version of what I am seeking:

Splitting and processing:

Vegetable waste: Horseradish

In holland horseradish grows throughout the whole year.

Vegetable waste: Rhubarb

Papers:¶

Designers:¶

Emma van Der Leest: Growing the next generation of Biodesigners

https://class.textile-academy.org/2021/rebecca.caem/

Anastasia Pistofidou: Fabric Academy mentor.

The overall inspiration for the garment idea is a little like Fablabs project with El Barrio. The orange peel recipe – Trenchcoat showpiece.

youtube:

Stella mcCartney x Mylo (Bolt threads):

https://fashionunited.com/news/fashion/stella-mccartney-unveils-first-garments-made-from-mylo-a-fungi-based-fabric/2021031838996

Issey Miyake folding art:

Fabric folding technicalities:

Material research: biodegradability of the cellulose natural rubber. How Eco is it really?¶

Discarding latex natural rubber:

https://www.linkedin.com/pulse/20140501222120-11496812-advancements-in-rubber-disposal-biodegradation-and-the-environment/

What is natural rubber?

Natural rubber is extracted from rubber producing plants, most notably the tree Hevea brasiliensis, which originates from South America. Nowadays, more than 90% of all natural rubber comes from these trees in the rubber plantations of Indonesia, the Malay Peninsula and Sri Lanka. The common name for this type of rubber is Para rubber.

Most commonly-used natural polymers and fibers (e.g. natural rubber, starches, gelatin, wood and cotton) are inherently biodegradable under proper conditions although the extent of degradation decreases with increasing molecular weights of the polymers. Natural rubber is often considered an environmentally degradable material, however, in nature is expected to degrade very slowly in comparison with other natural polymers. Natural rubber degrading bacteria are widely distributed in soil, water and sewage.

Studies on the Biodegradation of Natural Rubber Over the years, there have been concerted efforts to investigate microbial rubber degradation. It became obvious that bacteria as well as fungi are capable of degrading rubber. It is assumed that degradation of the rubber backbone is initiated by oxidative cleavage of the double bond.

Most studies have been performed using isolated strains of bacterium. Early studies showed that pure strains of some bacteria caused up to a 55% loss in weight of thin rubber sheets in 70 days. Thin films from a latex glove were rapidly degraded and weight losses reached 75% after a two-week cultivation period. Pure isolated strains of bacteria in batch cultures, using laboratory fermenters, completely degraded latex glove films after 45 days. After eight weeks, about 28% of a tire strip disintegrated into very small particles with a 51% loss of initial weight.

More recent research has found that a crude enzyme from a bacterium is able to biodegrade natural rubber in the latex state. This work has uncovered evidence for the existence of an extracellular enzyme capable of degrading natural rubber.

Research has also shown that overall biodegradation rate is influenced by environmental factors. Biodegradation rate was studied by burying natural rubber latex gloves in tropical soils amended with nitrogen and phosphorus, and in a composting environment created from dried grass clippings, cattle manure and soil. The test involved manipulating soils to favor microbial growth enhanced biodegradation compared to natural attenuation processes in un-amended soils.

The degradation rate of natural rubber glove pieces in a high soil nutrient treatment was three times higher than in the un-amended controls.

In a composting environment, biodegradation rates over 24 weeks were twice that compared to the fertilized treatment in soils. Degradation of natural rubber condoms in soil was slower compared to gloves with 42% of the initial weights remaining after 48 weeks. In contrast, the manufactured polyurethane condoms were hardly biodegradable.

source: https://www.linkedin.com/pulse/20140501222120-11496812-advancements-in-rubber-disposal-biodegradation-and-the-environment/