6| BioFabricating Materials¶

Research¶

TEXT

Designer/other

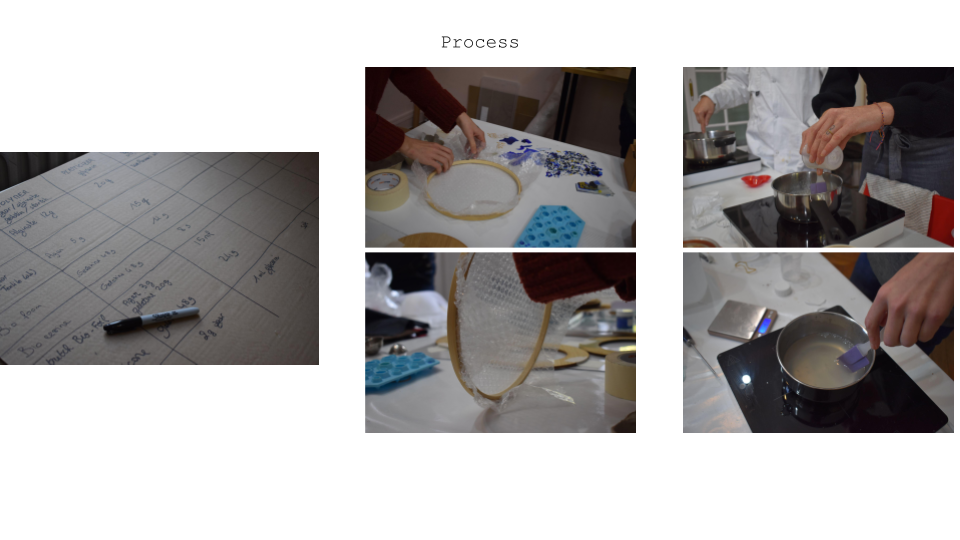

Process¶

Recipes¶

CONDUCTIVE BIOPLASTICS¶

| Conductive Bioplastic * | |

|---|---|

| Ingredients | Quantities |

| Agar | 2gr |

| Glycerol | 1mL |

| Salt | 5gr |

| Water | 240mL |

| *Recipe from Conductive Agar Ag03 by Elisabeth Lorenzi, Materiom |

| Conductive Bioplastic 2 | |

|---|---|

| Ingredients | Quantities |

| Agar | 4gr |

| Glycerin | 12gr |

| Salt | 10gr |

| Water | 800mL* |

| *misread the cardboard and put 800mL instead of 200mL but it is drying well so far |

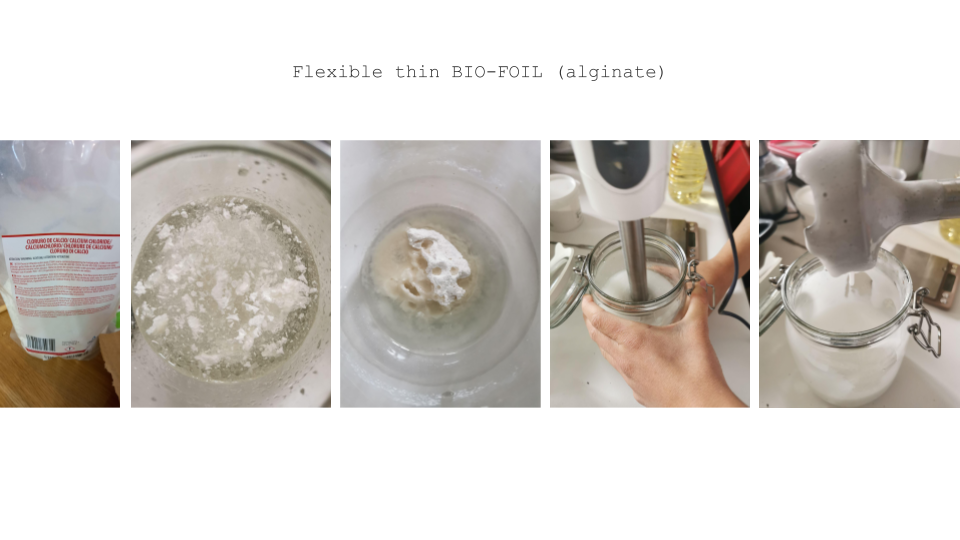

ALGINATE¶

Flexible thin BIO-FOIL

| Flexible thin BIO-FOIL | |

|---|---|

| Ingredients | Quantities |

| Alginate | 12gr |

| Glycerol | 20gr |

| Sunflower oil | 10gr |

| Water | 200ml |

| Spread solution for curing | |

|---|---|

| Ingredients | Quantities |

| Sodium chloride hydrate/ Calcium Chlorure | 10ml |

| Water | 100mL |

- let the mixture rest for a few hour, (to eliminate the bubbles created during mixing) then pour it into your mold, or other

- and spray some sodium chloride solution on top of it (repeat if necessary)

To make the threads : - prepare a pot with the solution for curing - put the flexible thin bio foil mixture into a syringe - the poor it into the solution to produce fine lines of material "threads"

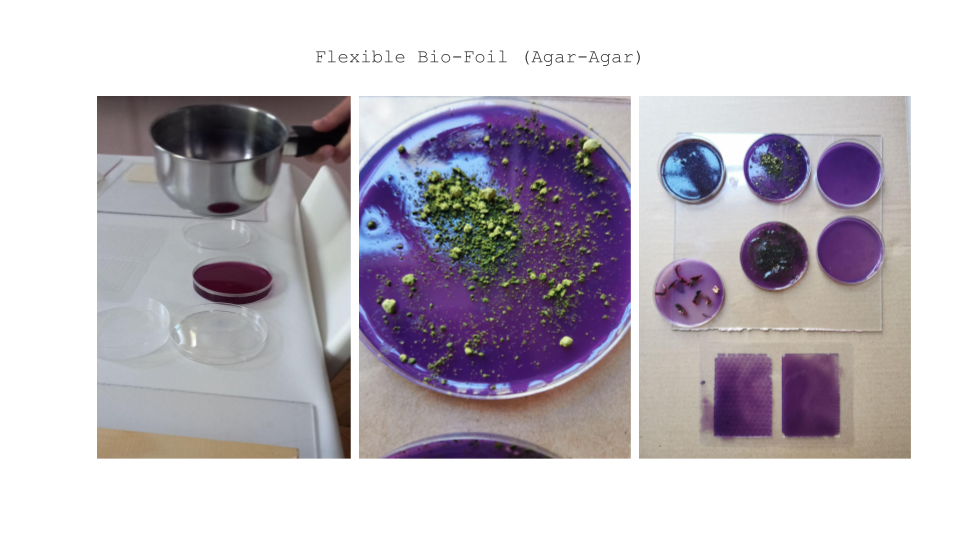

AGAR AGAR¶

Flexible Bio-Foil

| Flexible Bio-Foil | |

|---|---|

| Ingredients | Quantities |

| Agar | 5g |

| Glycerine | 15g |

| Water | 250mL |

Cook +/- 25 minutes at 80°C gives the best results

Stretch Bio-Foil

| Stretch Bio-Foil | |

|---|---|

| Ingredients | Quantities |

| Agar | 3g |

| Gelatine | 20g |

| Glycerine | 15mL |

| Water | 400mL |

Cook +/- 45minutes at 80°C gives the best results

Bio-Plastic 1

| Bio-Plastic 1 | |

|---|---|

| Ingredients | Quantities |

| Agar | 4g |

| Glycerine | 25g |

| Water | 400ml |

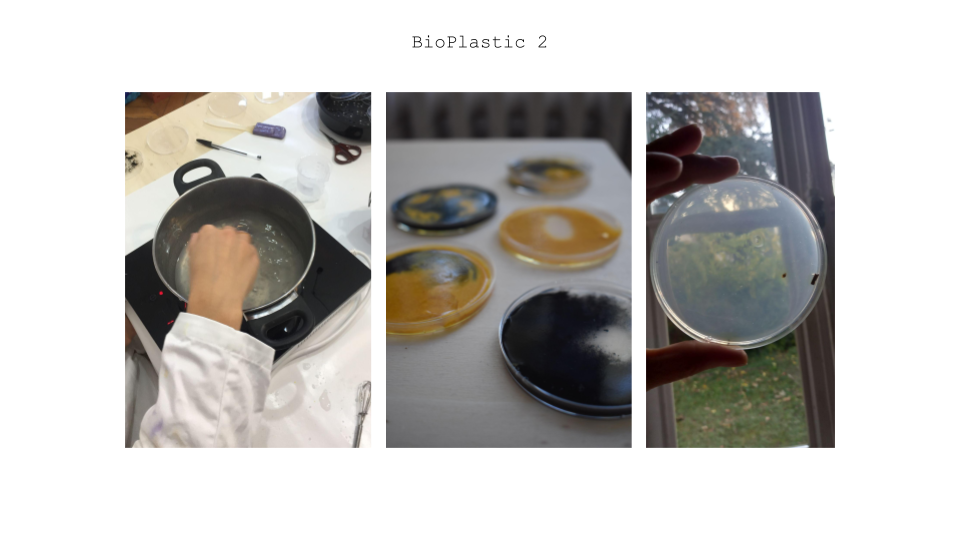

Bio-Plastic 2

| Bio-Plastic 2 | |

|---|---|

| Ingredients | Quantities |

| Agar | 4g |

| Glycerine | 17mL |

| Water | 200mL |

- Add the agar in the warm water quantity, on low heat

- Stir a bit

- Then add the Glycerine,

- cook for approximetly 15 or more minutes until it gets a little bit less transparent and slightly thicker

- Pour it into the molds

Kuzu

| KUZU | |

|---|---|

| Ingredients | Quantities |

| Kuzu | 60 mg |

| Water | 120 ml |

| Glycerine | 10 mL |

| Vinegar | 10 mL |

| The recipe we followed was taken on materiom (https://materiom.org/recipe/592) | |

| from a tapioca starch recipe |

KUZU BIO PLASTIC

The recipe we followed was taken on « materiom », from a tapioca starch recipe. You can find it here : https://materiom.org/recipe/592 What is KUZU ??

Kuzu (Pueraria montana var. lobata) is the Japanese name for the kudzu plant and the starch derived from the kudzu root.

Kuzu is native to both China and Japan and is a member of the pea family. Though the vine itself is quite invasive and survives by covering other plants and thus robbing them of a light source, the starch contained in its large roots is valued throughout parts of Asia for its culinary and medicinal properties.

Kuzu is unsurpassed as a thickening agent and can produce sparkling sauces, gloss soups, and provide a smooth texture to a wide variety of foods. Kuzu can even be dusted on vegetables or fish prior to frying to provide a light and crisp coating.

What's more, kuzu is most often utilized for its ability to help balance the acidity of sweets, and is commonly an ingredient in desserts such as puddings, pies, icing, and atop a variety of cakes. Kuzu’s superior jelling strength, taste, texture and healing attributes make it a great alternative to other natural starches such as arrowroot, and is healthier than processed corn and potato starches.

Experimenting the recipe : Since the quantity of water for one recipe seemed really tiny, we doubled the quantity. Made the the 28th of October (The recipe advise to wait 7 days before taking it off the surface.)

- Take a cooking pot (preferably steel container). Add kuzu and coldwater and stir thoroughly until no lumps are present and kuzu is completely dissolved.

- Add glycerine and vinegar to the kuzu solution and mix well.

- Now, cook the solution under a low flame for five minutes, don't forget to keep stirring (the whisk was a good toll for this step) the solution until it becomes a thick white paste.

- Transfer the compound from the cooking pot and spread it over a butter/ oil coated flat surface.

…Coming soon for the 2 last steps ! Keep it for air-drying for at least 7 days.

Once it's completely dried, carefully peel it off from the surface and dip it in water for few minutes and dry it.

This recipe is as fast as easy to execute. Just be careful to stir enough when it gets thicker to avoid lumps ! No awful smells to deal with ☺ When the texture is ready to be spread, you’ve got to do it quite quickly before it becomes to solid to be spread !

GELATINE¶

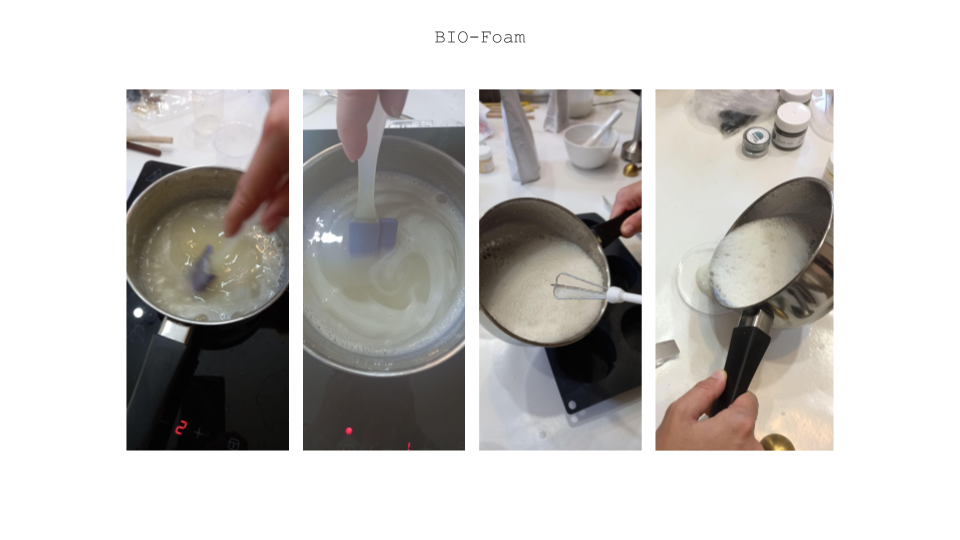

Bio-Foam

| Bio-Foam | |

|---|---|

| Ingredients | Quantities |

| Gelatine | 48g |

| Glycerin | 12g |

| Water | 240mL |

| Soap | 10mL |

Bio-Resin

| Bio-Resin | |

|---|---|

| Ingredients | Quantities |

| Gelatine | 48g |

| Glycerin | 8g |

| Water | 240mL |

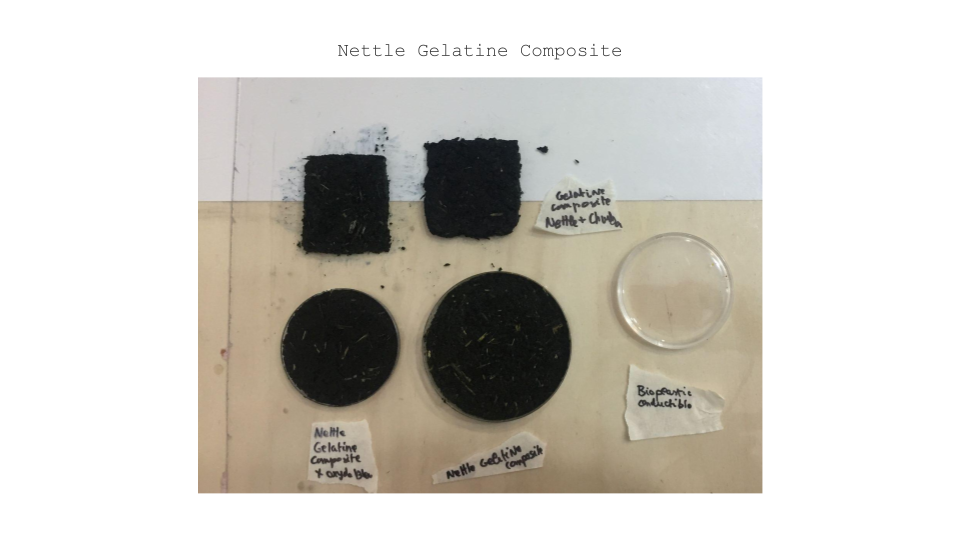

Neetle Gelatine Composite

The recipe I used was found on "Matriom" website: Page on Materiom for the Neetle Gelatine composite recipe But I guess the quantities are not good ones, as there is too much neetle for too many liquid ingredients. I tried this quantities: 20grams nettle leaf intead of 100gr in the recipe

| Neetle Gelatine Composite | |

|---|---|

| Ingredients | Quantities |

| Gelatine | 10gr |

| Glycerol | 10ml (appr 14gr) |

| Water | 100mL |

| Dried Neetle leaves | 20gr |

-

- Remove the leaves from the Nettle Plants and place in the oven on a low heat to dry out

-

- Put the dried nettle leaves in a grinder until a fine powder has formed

-

- Pour 100ml of cold water into a pan

-

- Dissolve the gelatine and glycerol into the cold water

-

- Heat the gelatine and glycerol mixture until it begins to thicken

-

- Mix in the nettle powder to the pan

- 7.Pour the mixture into a mould or flat tray and leave to harden

NOTE : for the a better result the nettle leafs needs to be in almost very fine powder - avoid branches. Be carreful in converting "ml" in "gr"

Steel waiting the dried result to then adjust the recipe

Mushroom¶

Other resources¶

Useful links¶

Lecture

Tutorials

- Biomaterials tutorials Part 1 – Beatriz

- Biàmaterials tutorials Part 2 – Beatriz

- Tutorial Mycocomposite Workshop by Jessica Dias