Experiment 03; 3D Printed Feather¶

For this week, i made some experiments with 3D printing. I have mixed feelings with this experimentation because to made this feather, i have to use plastic filament, in this case i used FILAFLEX, that is a flexible TPU (thermoplastic polyurethane) material.

Here's the material specifications:

| Filament | Colour | Filament Diameter | Temperature | File Size | Printing Time | Flexibilidad | Bed Temperature |

|---|---|---|---|---|---|---|---|

| Filaflex | White | 1,75 mm | 190°C - 210°C | 22 cms | 20 min | 82A | No need |

Models¶

EXP03-PT01¶

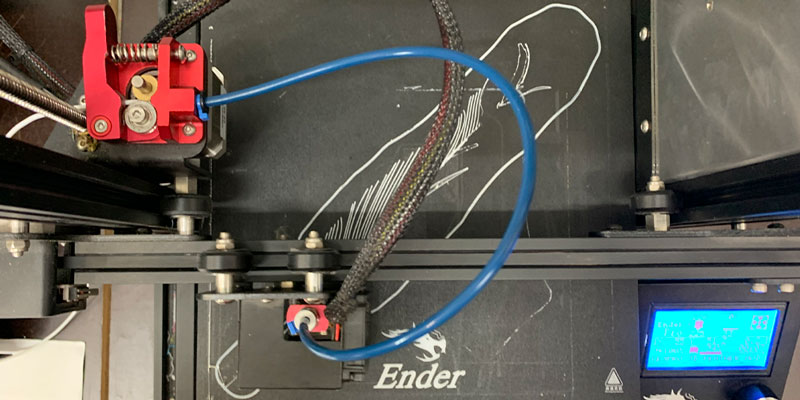

First of all, we need to make our 3D Model, to test thickness, elasticity, see how the model is printed and if there are problems when printing.

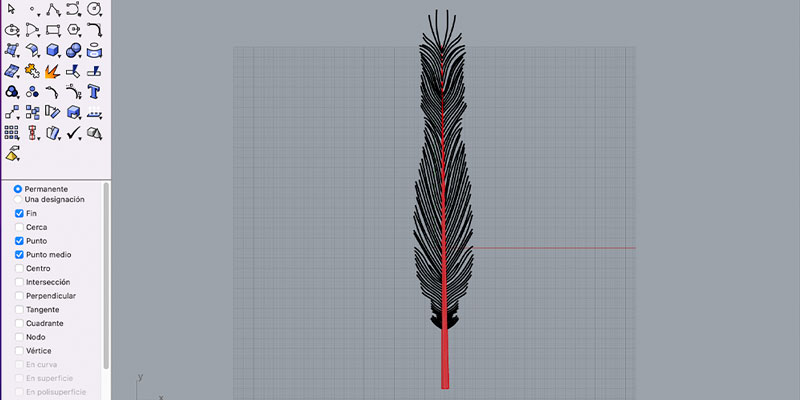

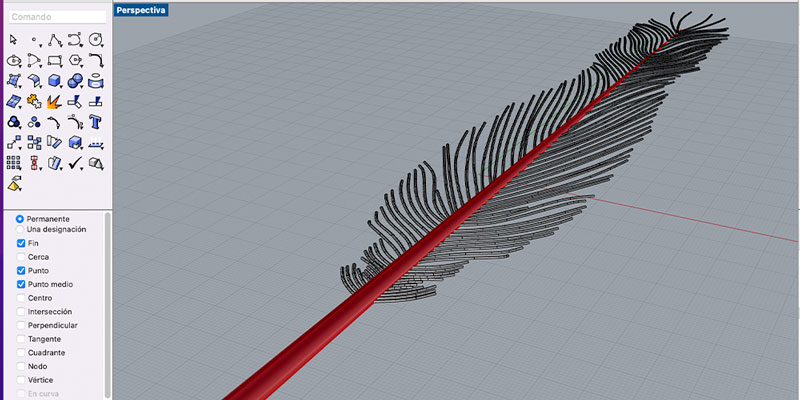

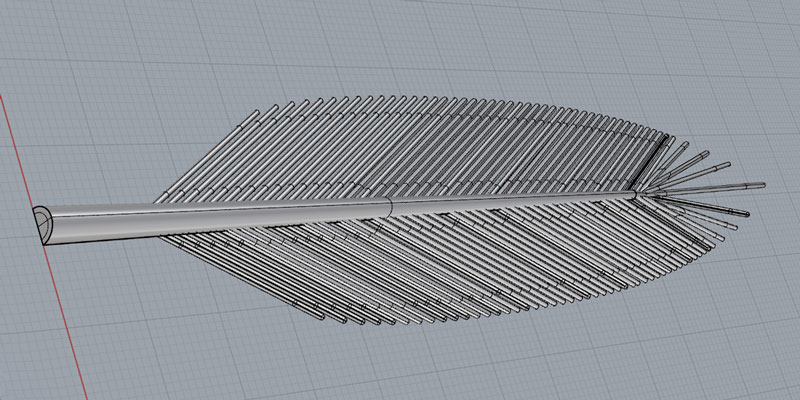

For the Rachis, i made a 22 cms curve line and revolve it, then for the Vexils I draw it in Ilustrator and then export them into Rhino.

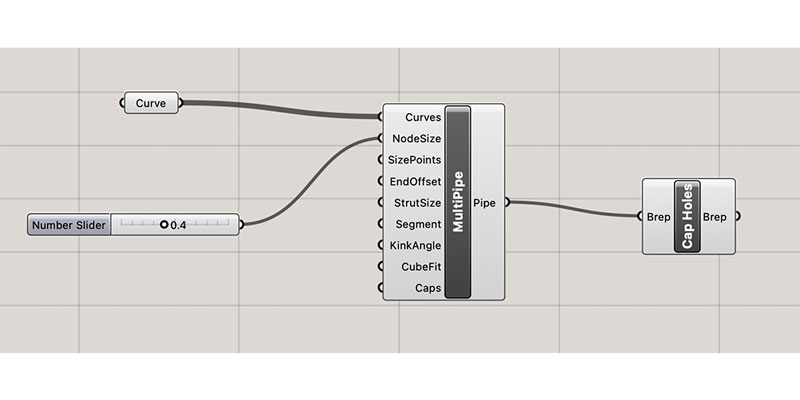

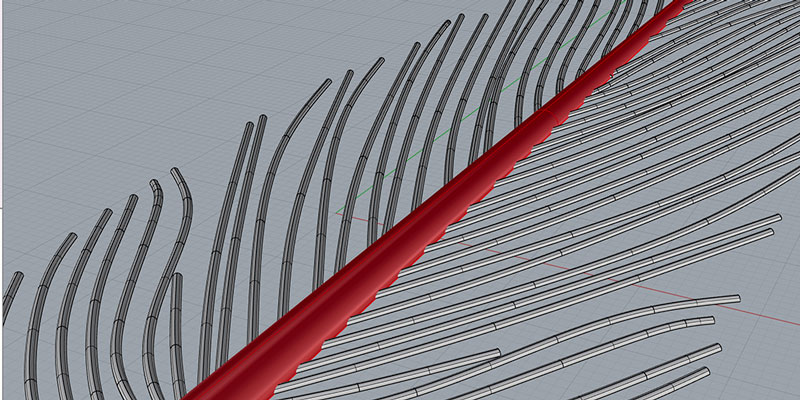

To make the lines "thick" (cause it's the only way that the 3D printer can read it) I use Grasshopper where I put Multiple Pipes to be able to generate a thickness of 0.4 mm from the lines.

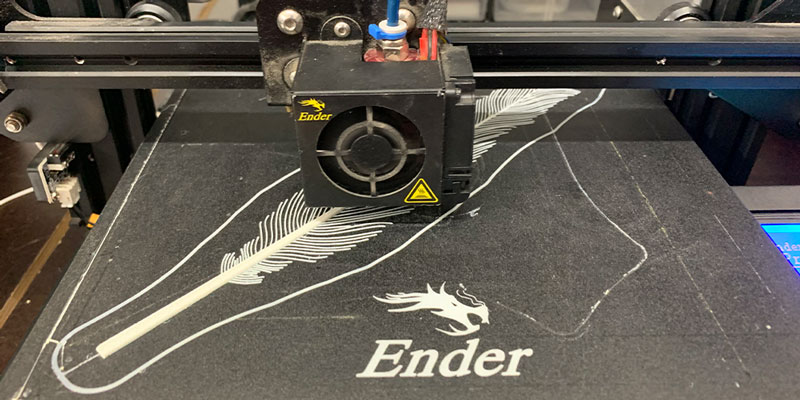

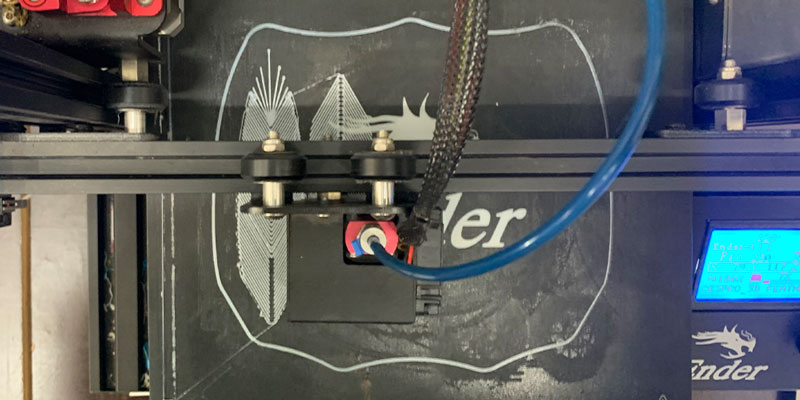

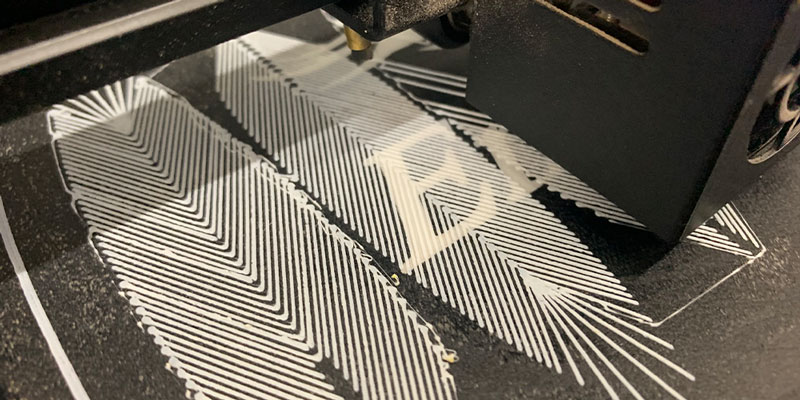

Once we export the file on STL and upload the material into the 3D printer, it's time to see the magic happen!

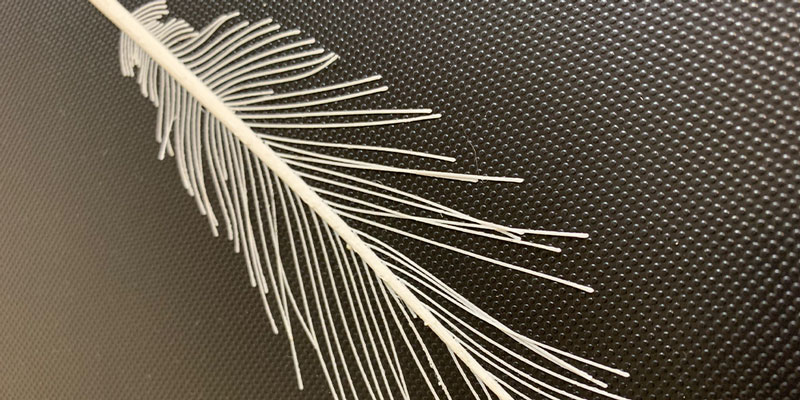

EXP03-PT01; First Final Result¶

EXP03-PT02¶

For the next part, i will try another Feather model, one that has a more concentrated line drawings and that the pen is of a smaller size, trying to "take to the limit" of what the 3D printer allows me to do.

Rhino Model

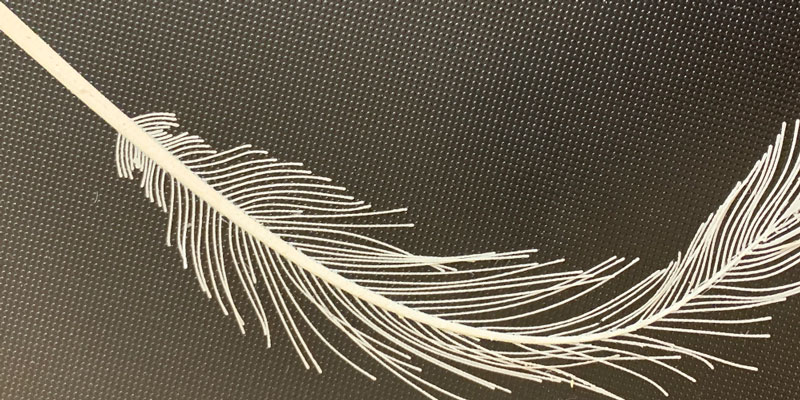

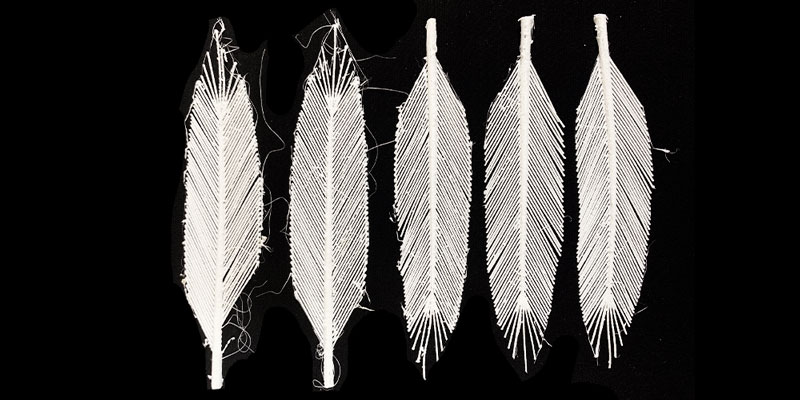

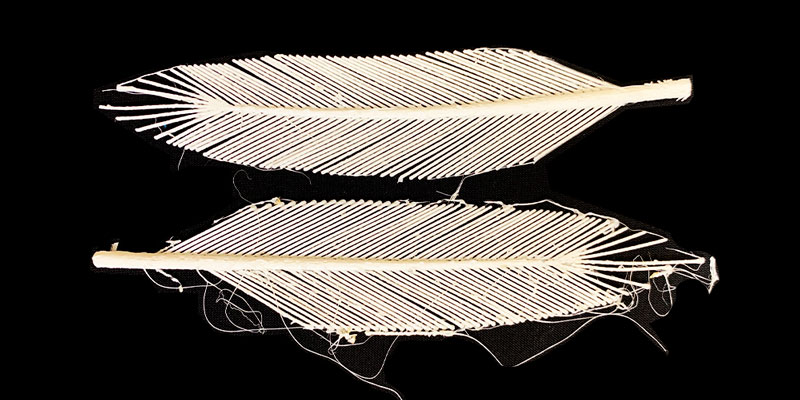

EXP03-PT02; Second Final Result¶

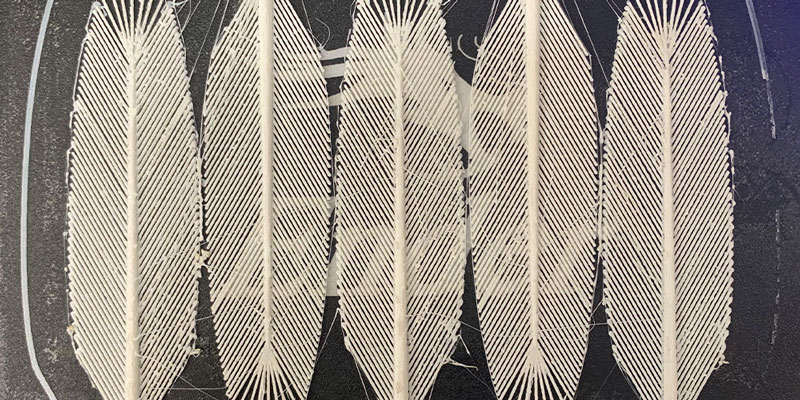

Final Feather, 2 of them are pretty messy, 3 of them are fine.

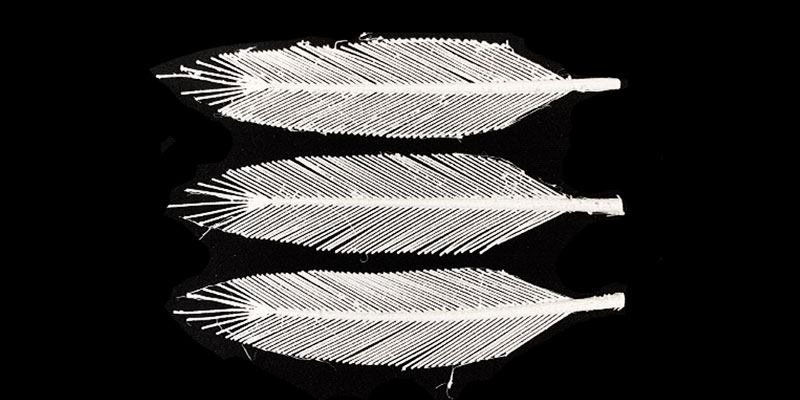

3 Final good Feathers

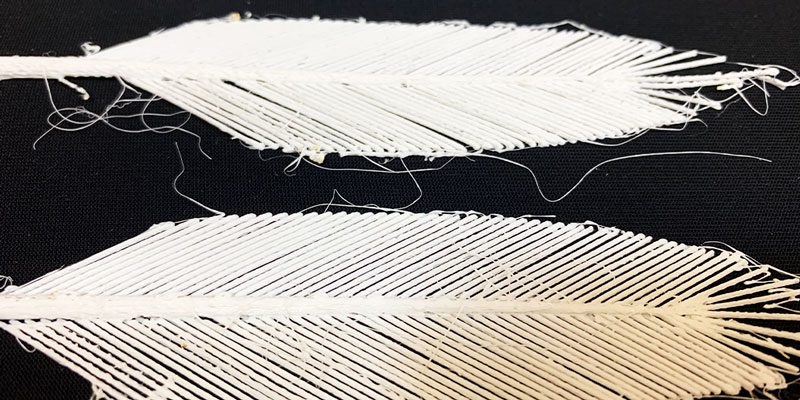

2 messy Feathers

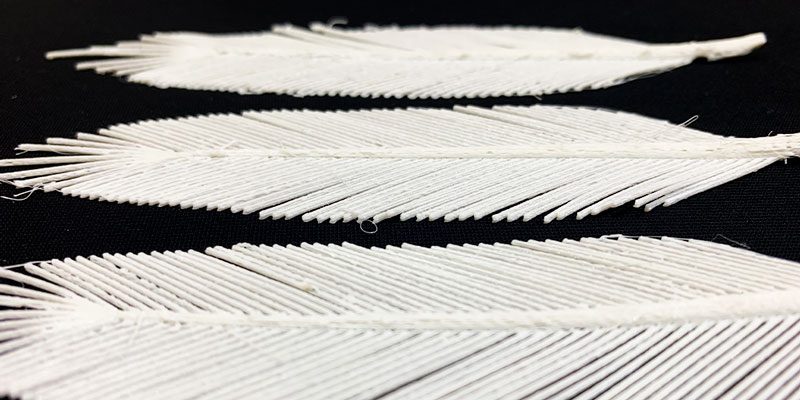

Comparation between the most good looking Feather and the most messy one.