Experiment 06; Parametric Feather¶

To keep experimenting with new filaments and shapes, i found a flexible filament made out of recycled materials.

| Filament | Colour | Size | Temperature | Printing speed | z off | Bed Temperature |

|---|---|---|---|---|---|---|

| Reciflex | Black | S (750g) | 225°C | 150 mm/sec | 0.3 mm | 0°C |

The material is carefully selected and magnetically screened for its production, in order to avoid metal residues and thus ensure its correct operation during printing.

Its hardness ranges between 96A and 98A SHORE A', due to variations attributable to its origin as recycled material, practically imperceptible in printed parts. Despite being a recycled material, it has excellent mechanical properties and good resistance to solvents, surprising for its quality.

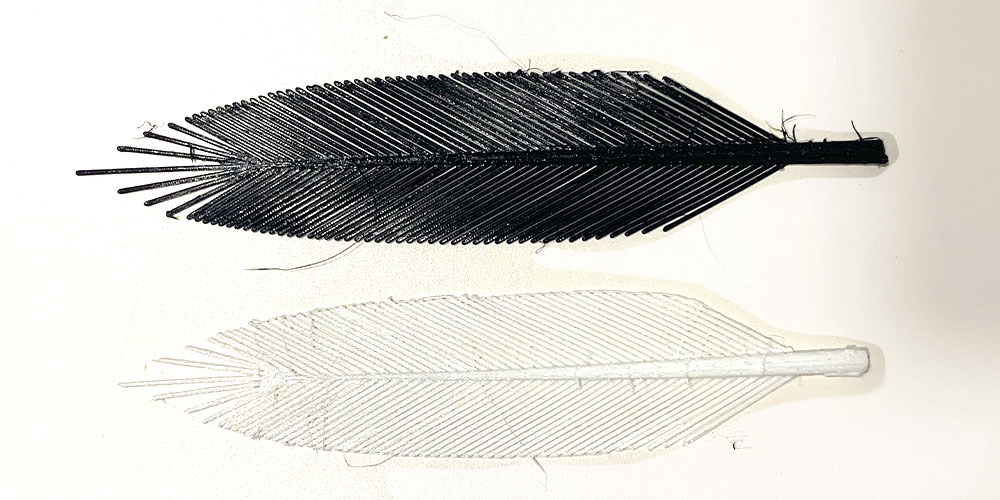

Small Feather Prototype¶

In order to be able to see the quality of the printing with this material, I decided to make the same feather model that I did earlier, so with that I could have a comparison parameter in terms of texture, strength, quality and flexibility.

compared to the first filament used, the RECIFLEX turned out to be,

- More resistant

- Less flexible

- Same resolution

- Much rougher texture

With all of this in mind, i decided to use Reciflex for another kind of feather, one that need more resistance in the rachis and longer vexils, maybe emulating some movement.

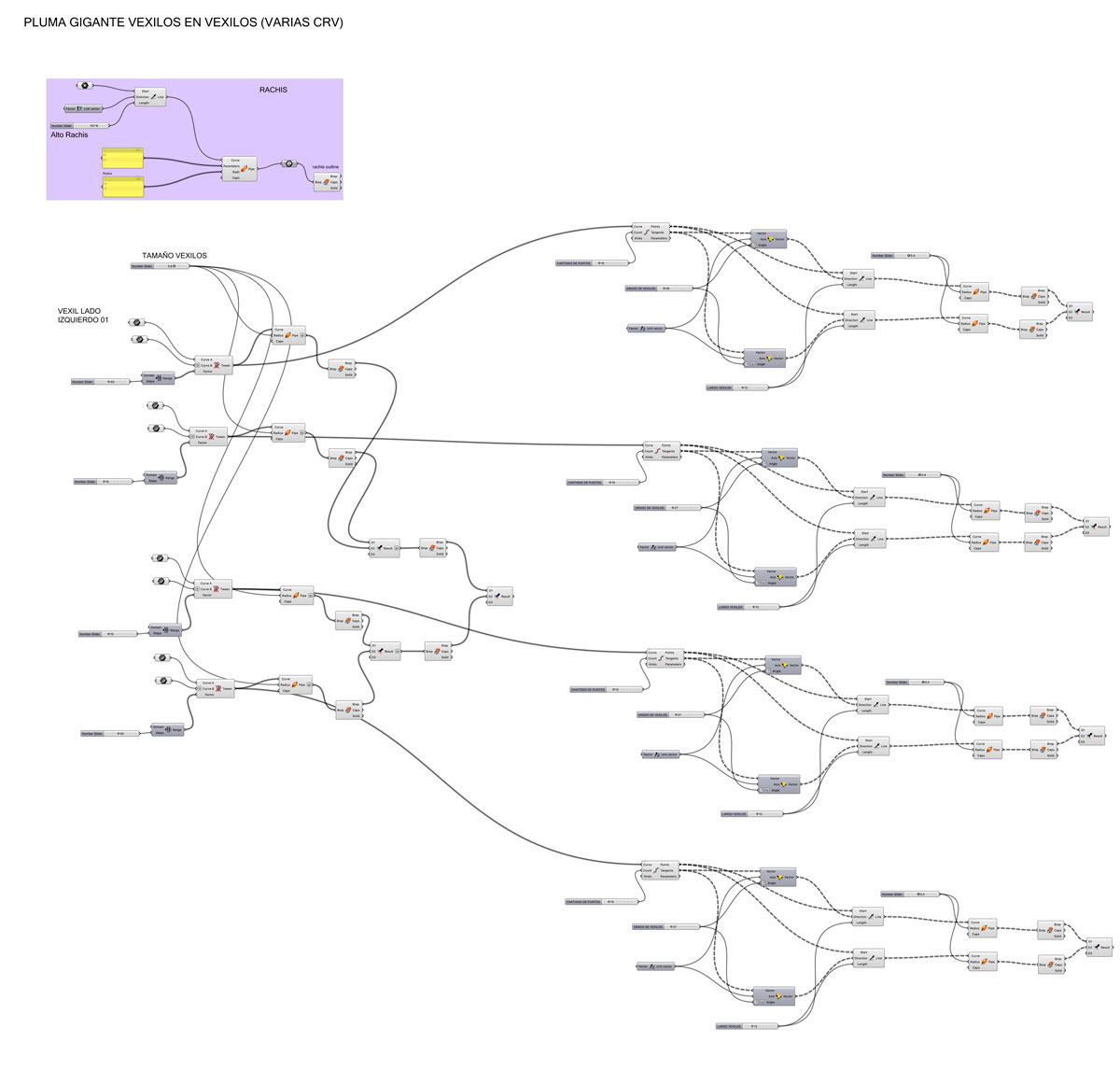

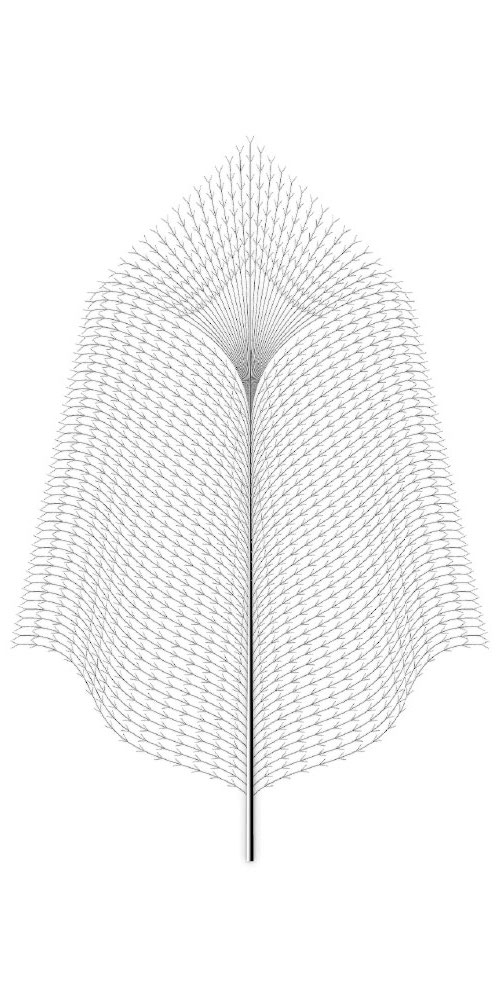

Parametric Feather File¶

The idea of this file is to develope a system where with a dot and 2 lines you can shape any type of feather that you want. With the control points, you can design different shapes, sizes, textures and movements.

This is the sample that came out of this file,

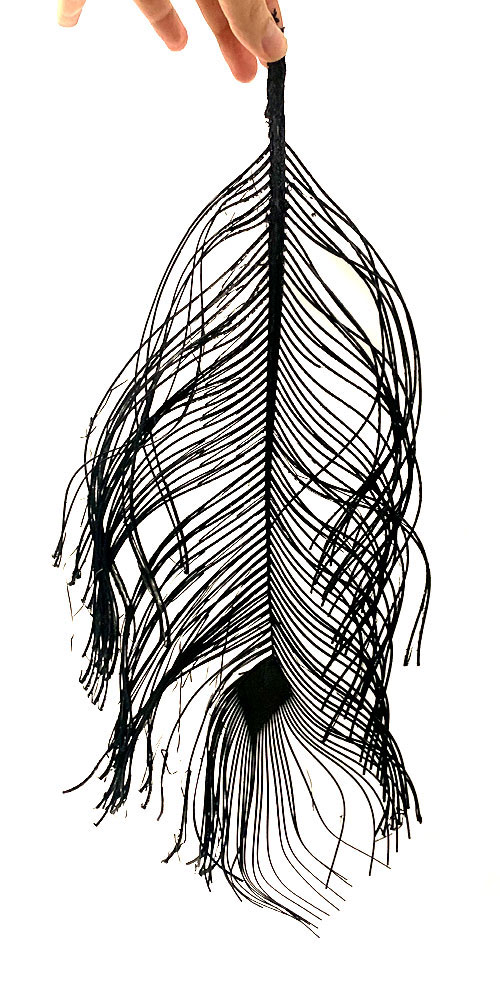

Final Results¶

The experiment went well, but there's a lot of things to fix, the printer can't shape the little vexils into the base vexils, and the rachis rose halfway through the impression.

Thanks for reading! :)