Experiment 04; Extruded Biomaterials¶

For this week, i made some recepies based in Cellulose.

Cellulose is a homopolysaccharide biopolymer that is also the most abundant existing organic biomolecule since it forms the majority of the terrestrial biomass. Cellulose is a structural polysaccharide in plants, since it is part of the structural tissues. The wall of a young plant cell contains about 40% cellulose; wood 50%, while the purest example of cellulose is cotton, with a percentage greater than 90%.

For the experiments, I'll try to make some Biomaterials based on Cellulose, the base ingredients are:

- 4 grs of CMC Cellulose

- 8 grs of Glycerine

- 4 drops of Collagen

- Water

EXP04 - PT00, Base¶

First of all, we have to see if the base of our biomaterial is gonna work by itself and see how it looks without any additives.

For the preparation of the biomaterial it is only necessary to follow the order of,

- Polymer, in this case the CMC Cellulose

- Plasticizer, in this case Glycerine

- Color or Pigments, in this case I put Collagen

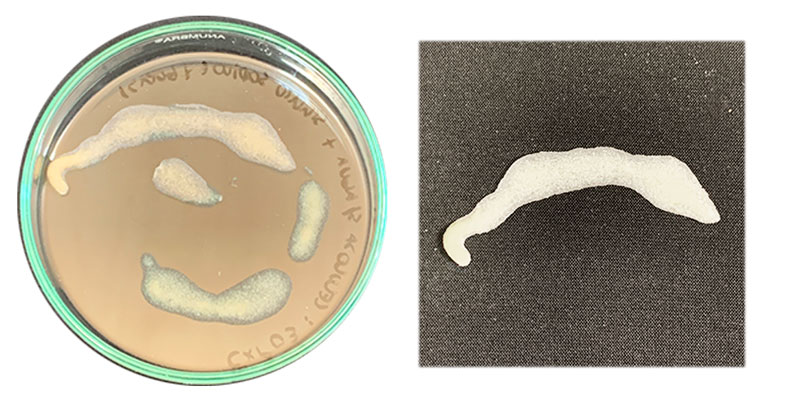

For this sample, I try to extrude it with a syringe and made this filament, then I left it in a petri dish for overnight and then put it in the dehydrator for 4 hrs.

This base went better than I expected, even when it's "totally" dry it stays elastic and with good form, it sticks with each other so it works as 3D printing material.

EXP04 - PT01, Base + Chitin¶

For the first experiment I try adding Chitin or Chitosan to the Base of the Cellulose Filament. For this experimentation I need,

- 1 grs of CMC Cellulose

- 4 grs of Glycerine

- 0,4 grs of Chitosan (1 pill)

- 2 drops of Collagen

- Water

For this sample, I try to extrude it with a syringe and made this filament, then I left it in a petri dish for overnight and then put it in the dehydrator for 4 hrs.

The Experiment 01 went well at the begging, it's more malleable than the base. It can be extruded with a thinner syringe but it started well and then it started to break, maybe the amount of water isn't enough for the additive.

EXP04 - PT02, Base + Sodium Silicate¶

For the second experiment I try adding Sodium Silicate to the Base of the Cellulose Filament. For this experimentation I need,

- 4 grs of CMC Cellulose

- 8 grs of Glycerine

- 4 drops of Collagen

- 4 drops of Sodium Silicate

- Water (18 drops)

For this sample, I try to extrude it with a syringe, the mix was so liquid that the extrusion lose the form at the moment that it touch the petri dish. Then I left it in a petri dish for overnight and then put it in the dehydrator for 4 hrs.

The final result was this big and thick circle of Cellulose paste, when it gets completely dry, it keeps the elasticity of the base, maybe it could work for the making of the Rachis with some negative mold, but this mix it doesn't work for 3D printing.

EXP04 - PT03. Base + Sodium Silicate (Part 2)¶

For the third experiment I try again with Sodium Silicate mixed with the Base of the Cellulose Filament. For this experimentation i added a little bit more of Cellulose to the base.

- 8 grs of CMC Cellulose

- 8 grs of Glycerine

- 4 drops of Collagen

- 4 drops of Sodium Silicate

- Water (18 drops)

For this sample, I try to extrude it with a syringe. In this case, the mix was less liquid than the EXP02, so we need to add more Cellullose to the mix if we want to work with Sodium Silicate. Then I left it in a petri dish for overnight and then put it in the dehydrator for 4 hrs.

The Sodium Silicate helps for the hemulsification of the mixes, that's why the base gets more liquid when you add some drops.

Final Results¶

For the FINAL CONCLUSIONS,

EXP00: It works pretty well, next expetimentation will be to 3D print with it in a Feather's Shape.

EXP01: Works really well too. So maybe a mix of EXP00 and EXP01 for the 3D printed Feather.

EXP02: Doesn't work.

EXP03: Maybe it could work for the making of the Rachis with some negative mold, but this mix it doesn't work for 3D printing.