IV. | BIOCHROMES¶

NATURAL DYEING¶

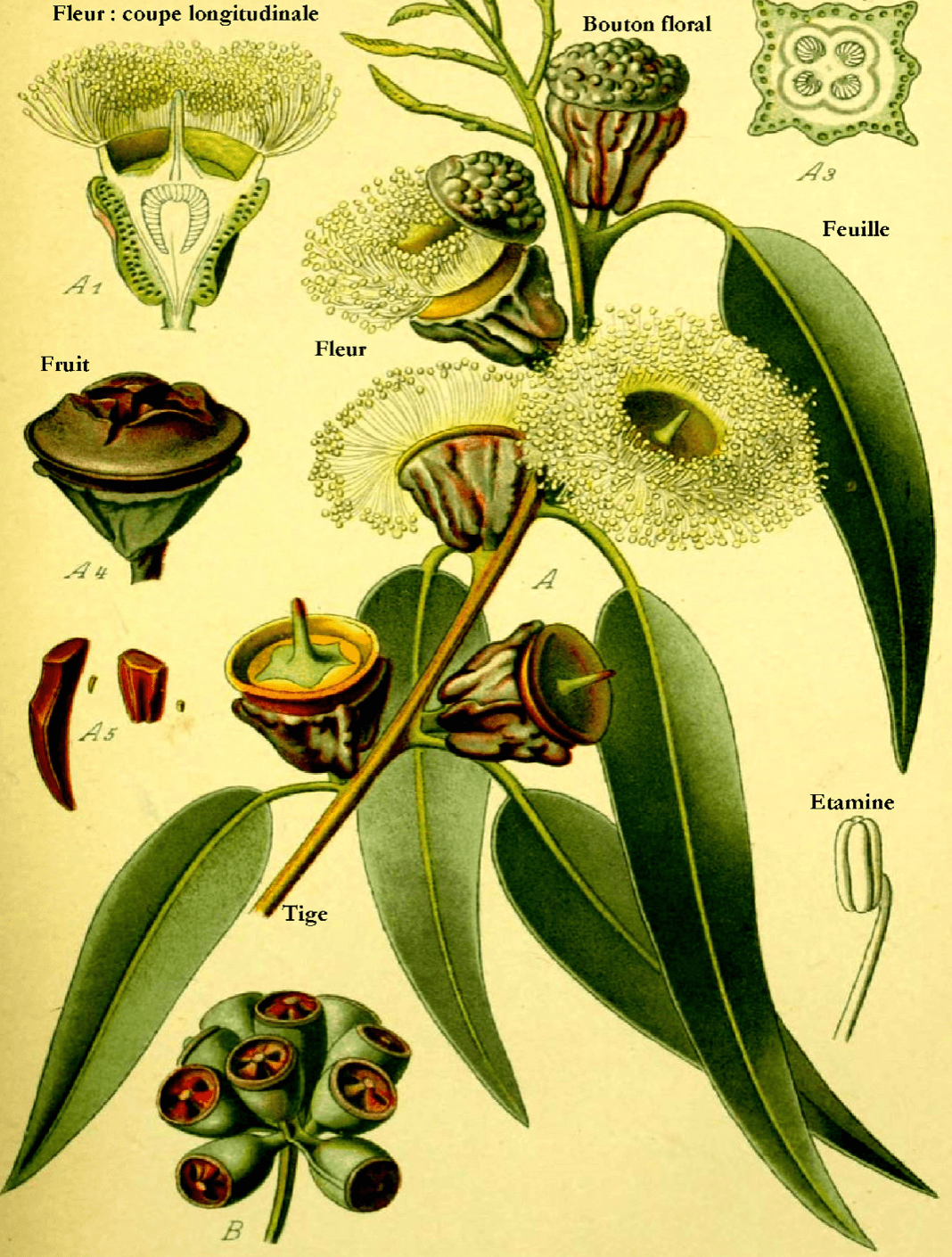

EUCALIPTUS¶

Eucalyptus Globulus

ABOUT¶

- Protein fibres such as wool and silk take up eucalyptus dye very well.

Iron and copper were used at 2% of the dry weight of the fabric to be mordanted. So for every 100 grams of fabric I used 2 grams of iron or copper.

* Alum was used at 15% of the dry weight of the fabric. Alum brightens the colours.

TOOLS¶

- cooking pots (2 pieces), stirring spoon, weight, mesh strainer, cooking stove, glass jar

INGREDIENTES¶

- eucalyptus (leaves) - 81 g

- water

- textile (not synthetic)

1. SILK + MORDANTS¶

| a. | b. | c. |

|---|---|---|

| Silk | Alum | Iron sulphate |

| 53 g | 6.36 g | 0.53 g |

2. VISCOSE + MORDANTS¶

| a. | b. | c. |

|---|---|---|

| Viscose | Alum | Iron sulphate |

| 125 g | 6.3 g | 1.25 g |

3. COTTON + MORDANTS¶

| a. | b. | c. |

|---|---|---|

| Cotton | Alum | Iron sulphate |

| 238 g | 28.56 g | 2.38 g |

RATIO¶

- Scouring - 2 % - soda ash of the total weight of the textile

- Iron sulphate (mordant) - 1 % of the total weight of the textile (use gloves)

- Alum (mordant) - 12 % of the total weight of the textile

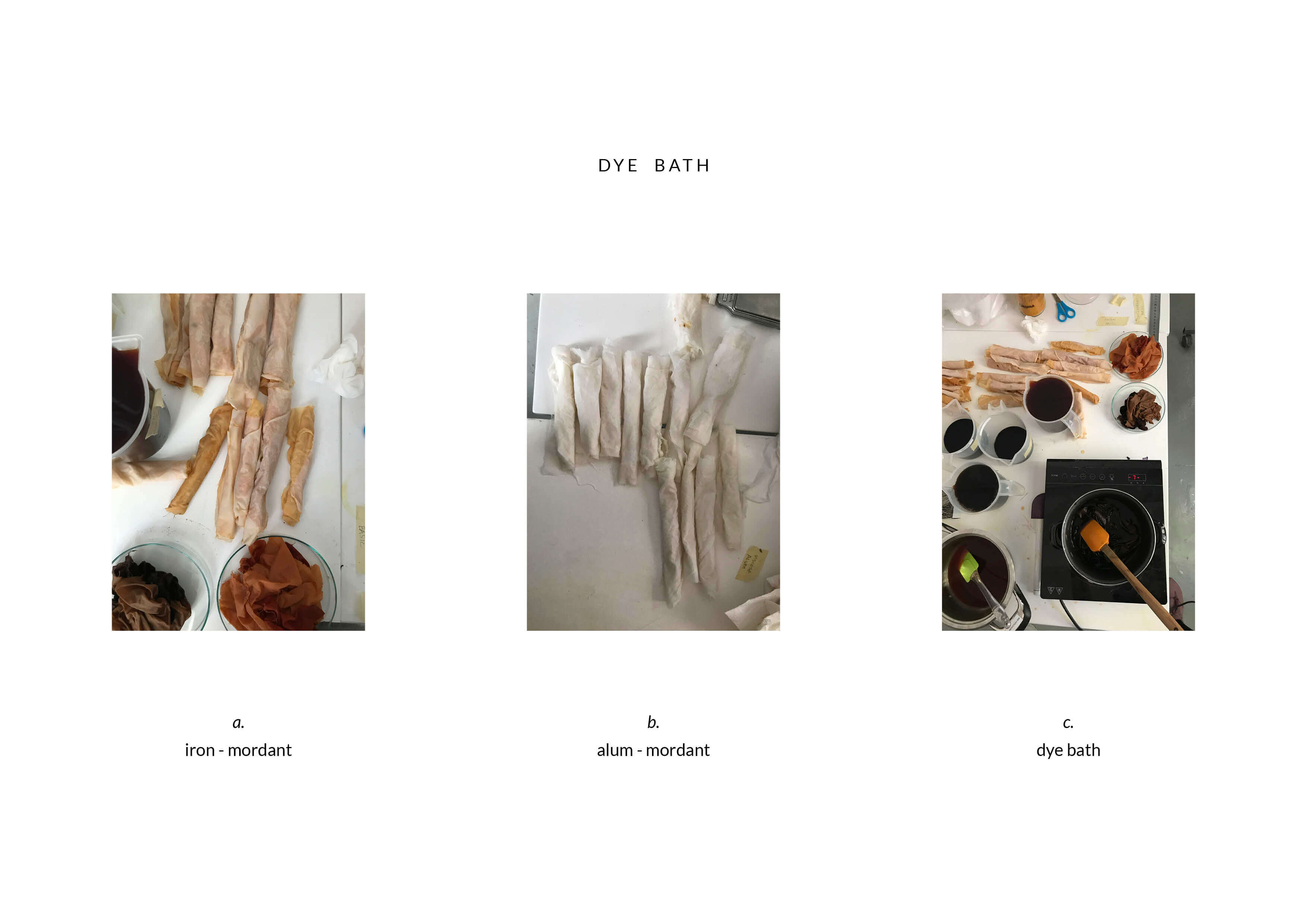

PROCESS¶

- Scouring: Place your textile in a larger pot (around 10l) and add 2% of soda ash. Let it simmer for 1 hour. After 1 hour drain out the water and refill the pot with clean water. Simmer it again for another hour.

- Colour extraction: Fill the pot with eucalyptus leaves and with enough water to cover all the leaves. Place the pot on the stove and heat for at least an hour. and a half (low heat) to extract the colour. The longer you leave it, the stronger the colour will be. (This is the colour I achieved after two and a half houres on the stove.)

- Put the leaves out of your dye bath. Pour the water through a mesh strainer into your second container or a glass jar. * Pour the colored water back into the pot and keep it on low heat. Then put your textile in the pot. Do not mix alum fabrics with iron ones. * After 15 minutes add another piece of fabric to the pot.

- The whole dyeing process took 30-40 minutes, then you can see the differences between the fabrics and the time they spent in the dyeing bath.

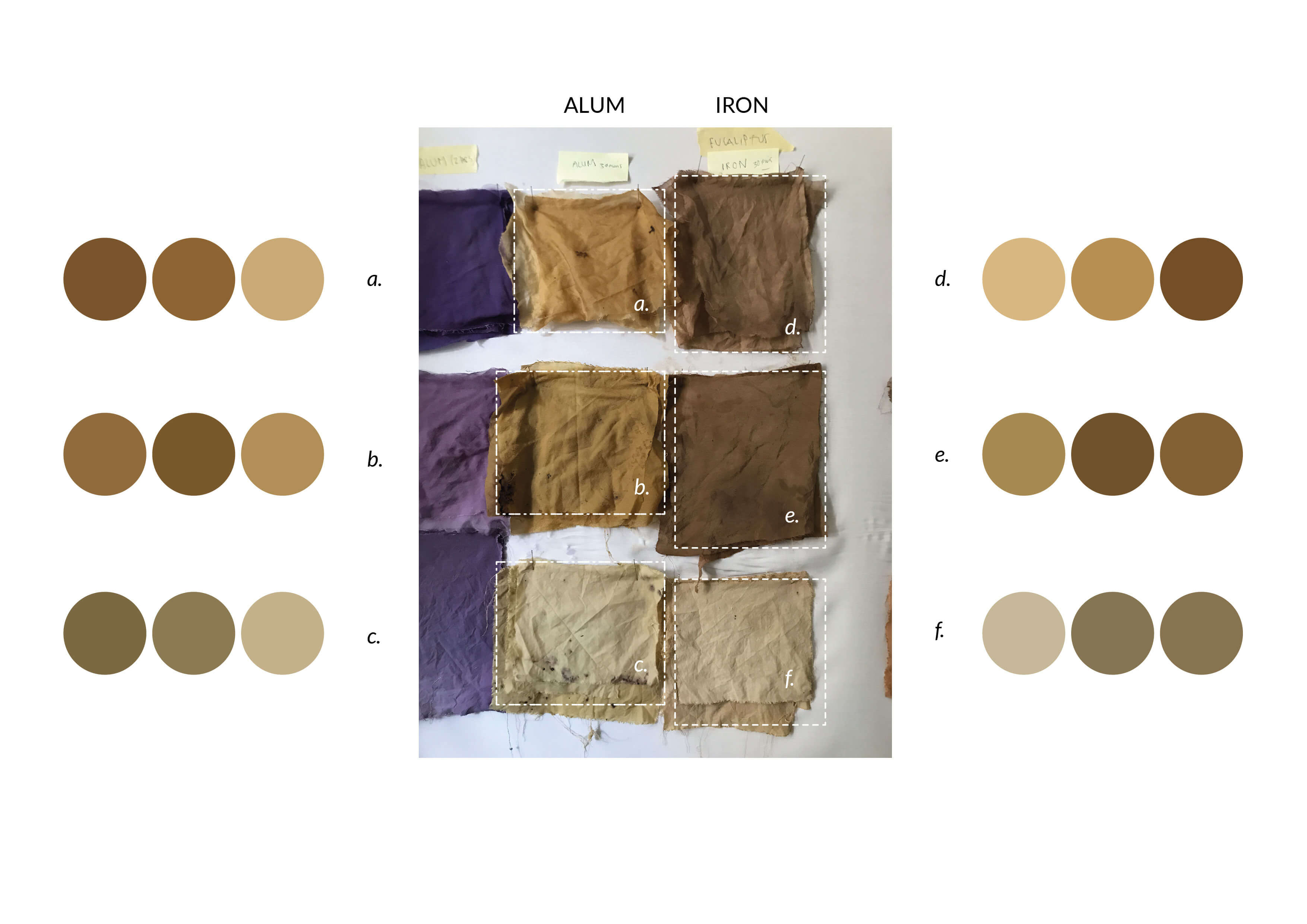

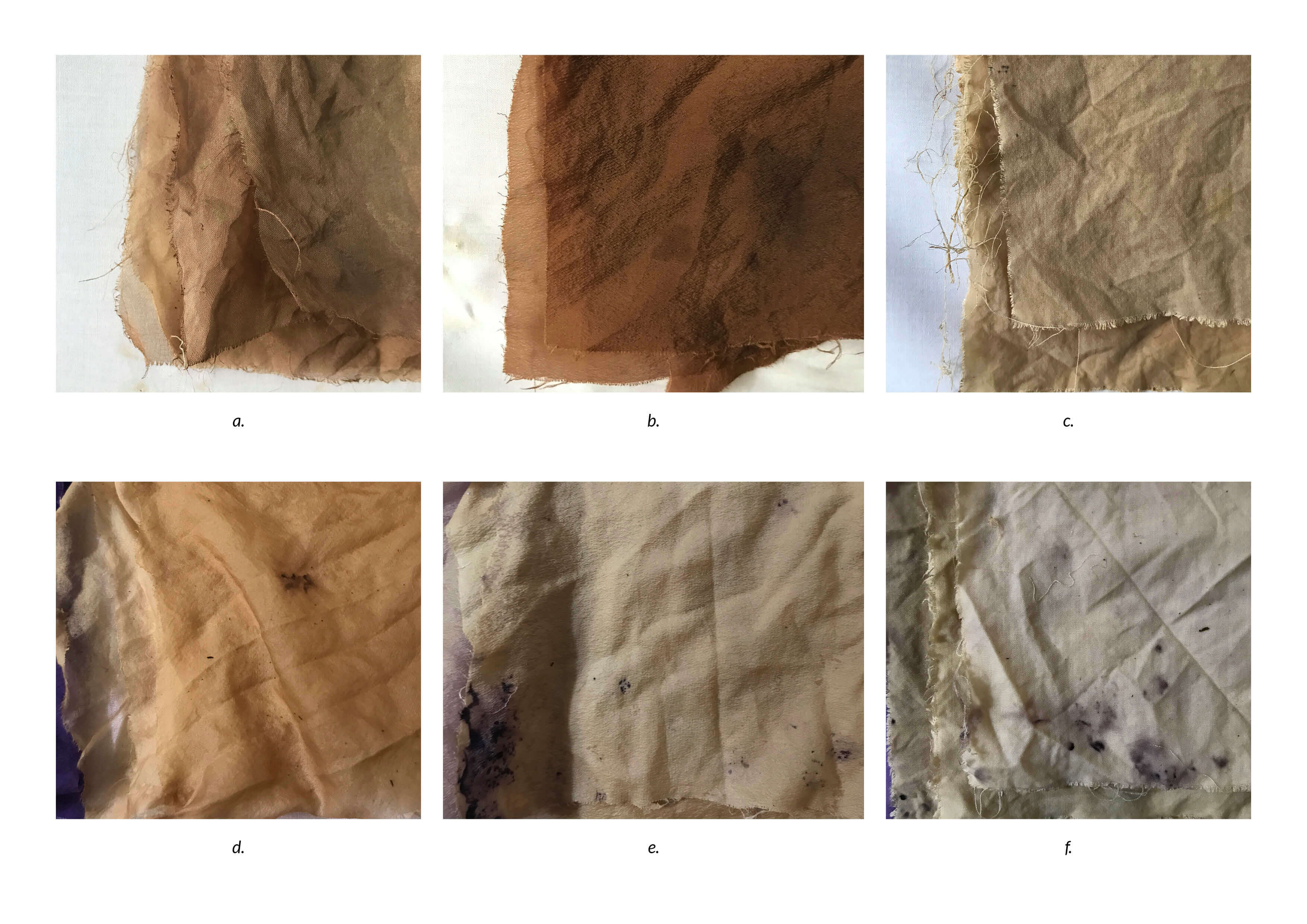

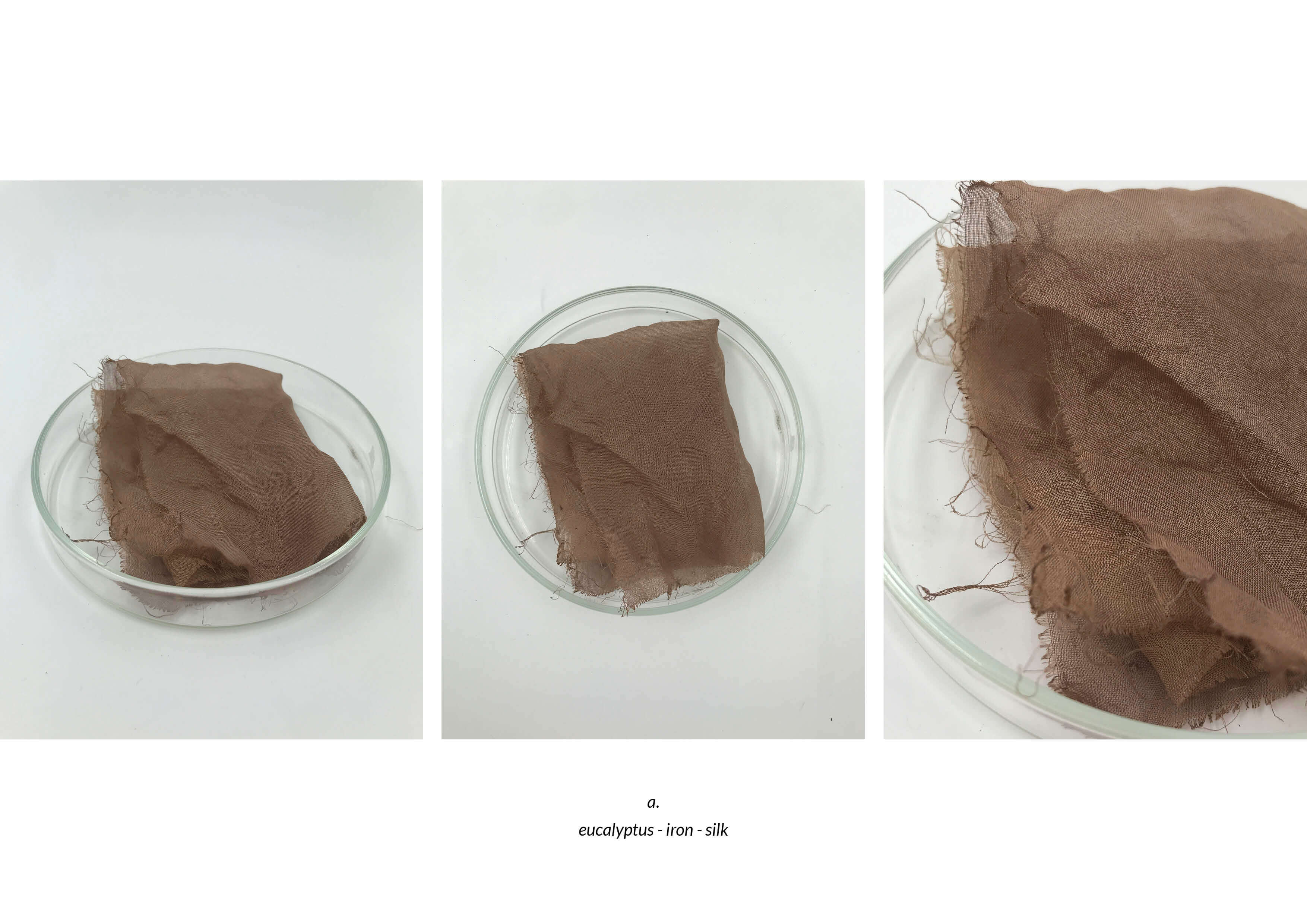

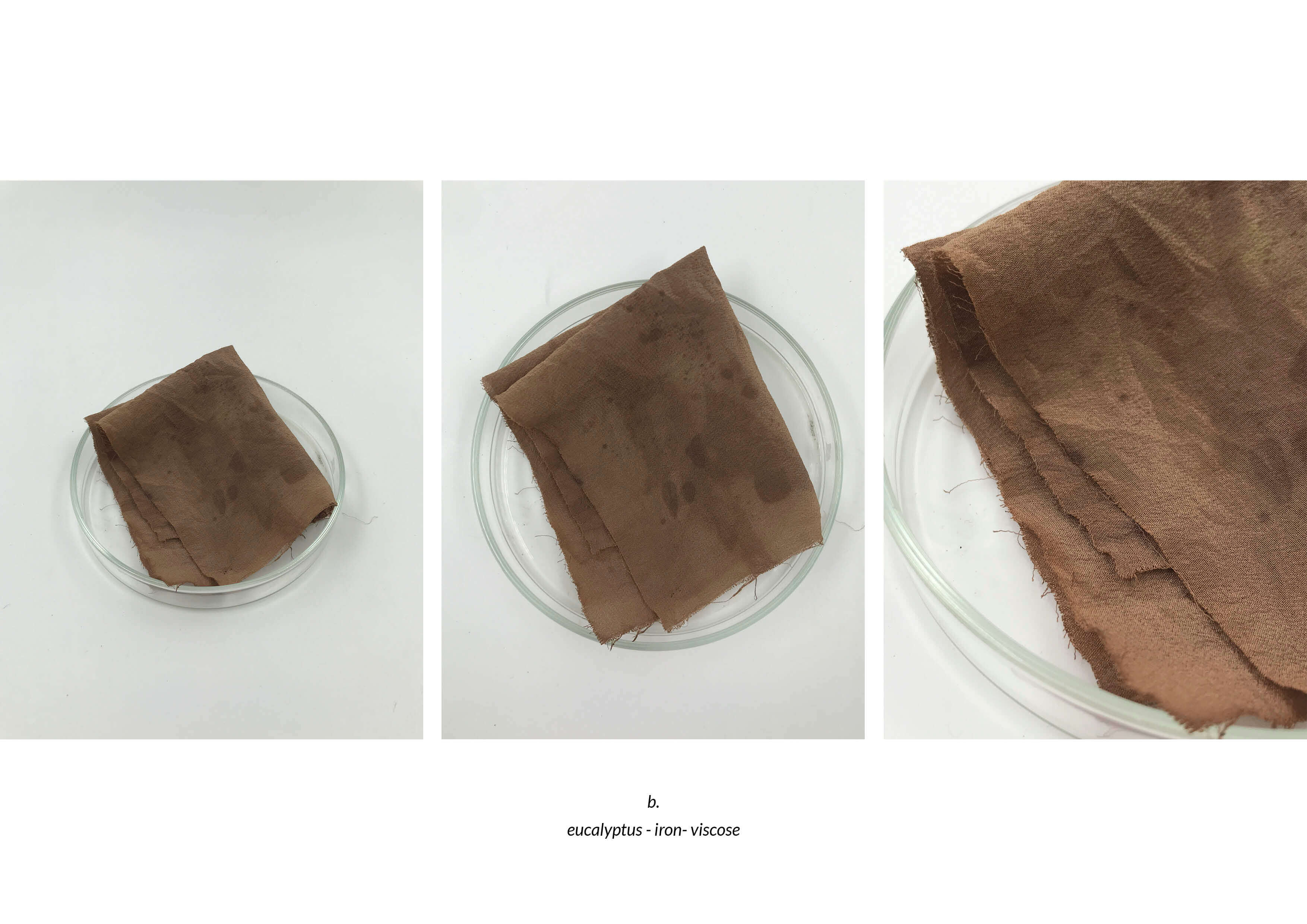

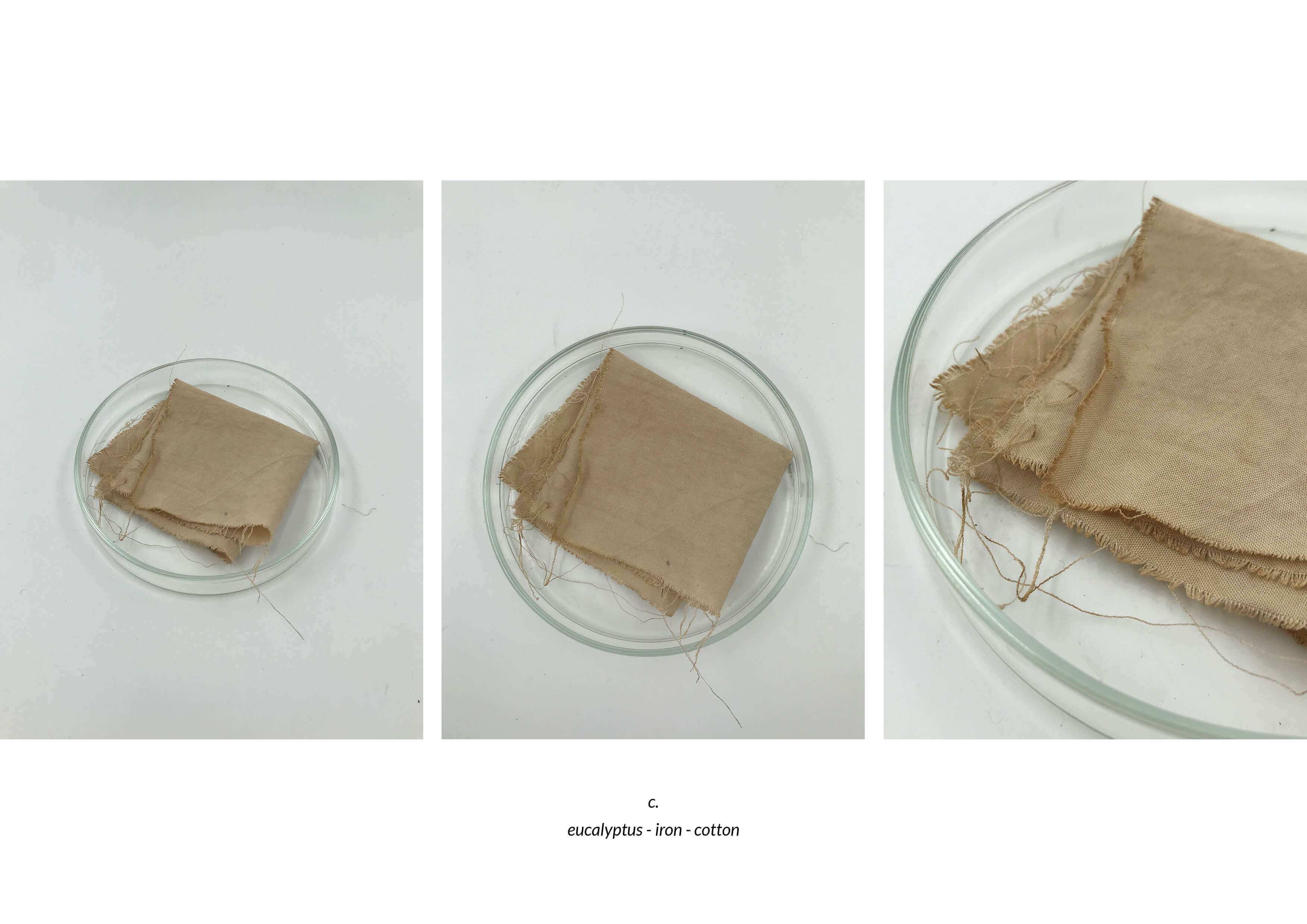

| TEST | TEXTILE | MORDANT | COLOUR |

|---|---|---|---|

| (a.) | silk | iron | light brown |

| (b.) | viscose | iron | brown |

| (c.) | cotton | iron | beige |

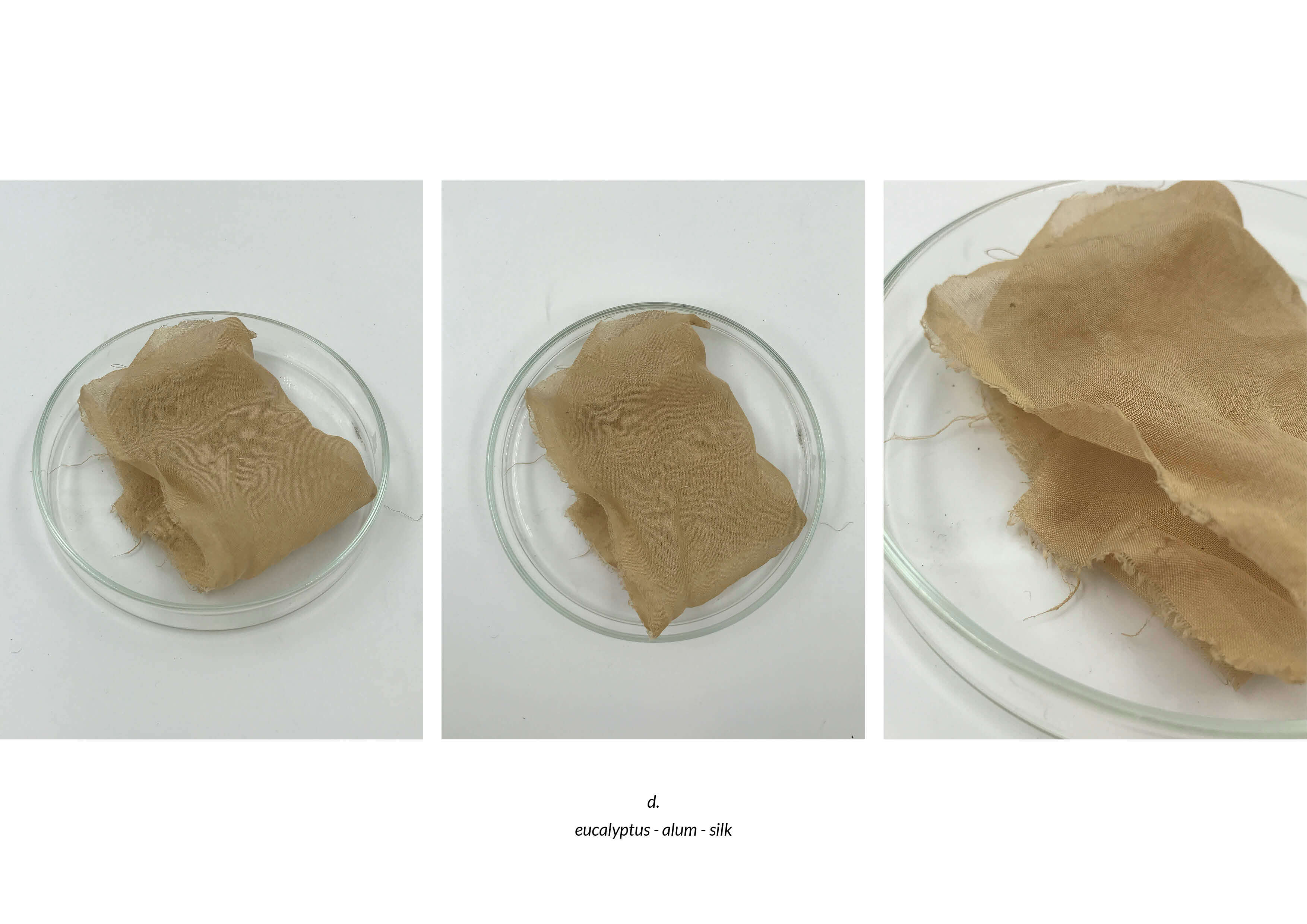

| (d.) | silk | alum | light orange / brown |

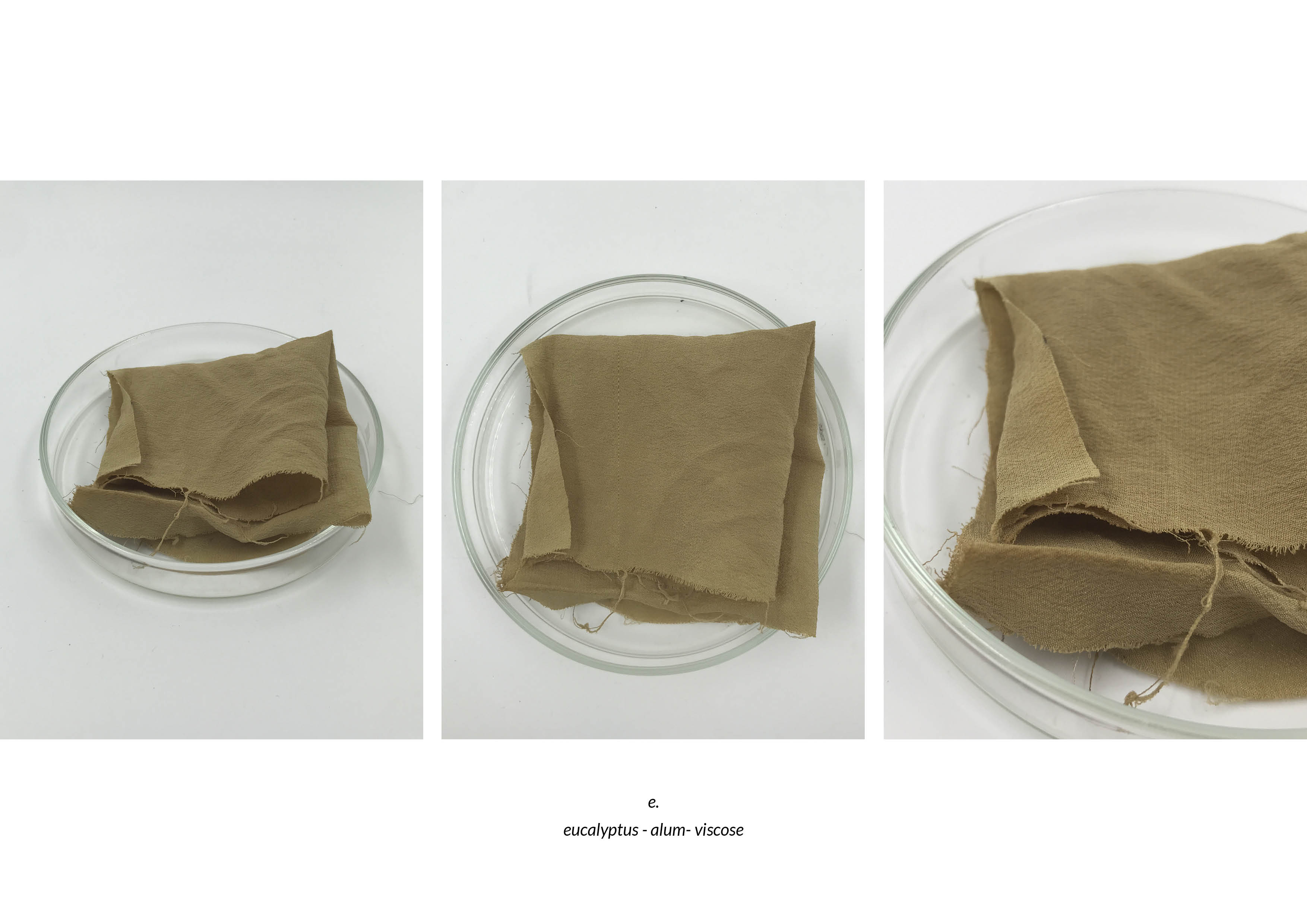

| (e.) | viscose | alum | orange / brown |

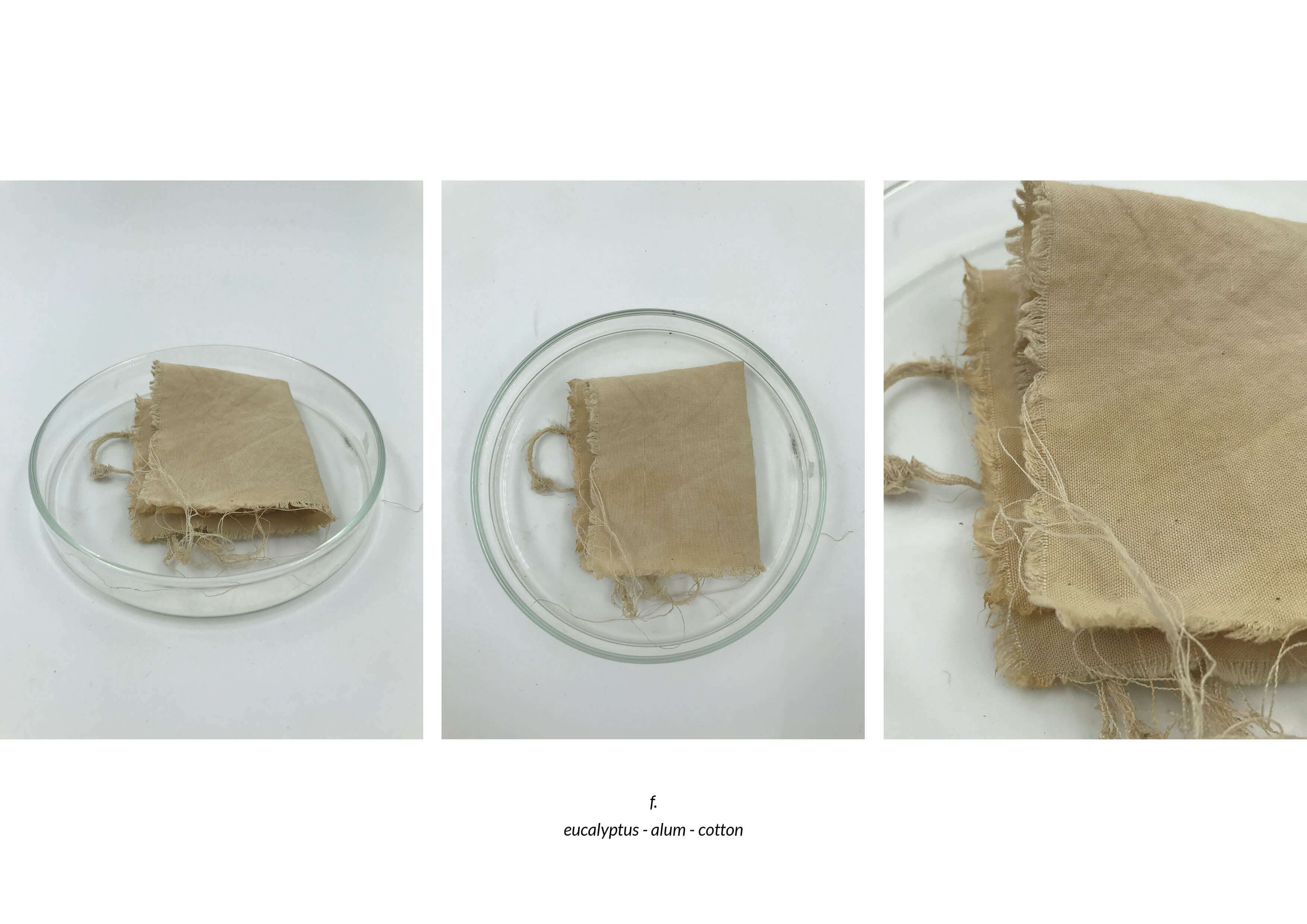

| (f.) | cotton | alum | light beige |

REFERENCE¶

HERBAL EXPERIMENTS¶

| HERBS | COLOUR (ORIGINAL) | COLOUR (ACHIEVED) | TEXTILE | MORDANT |

|---|---|---|---|---|

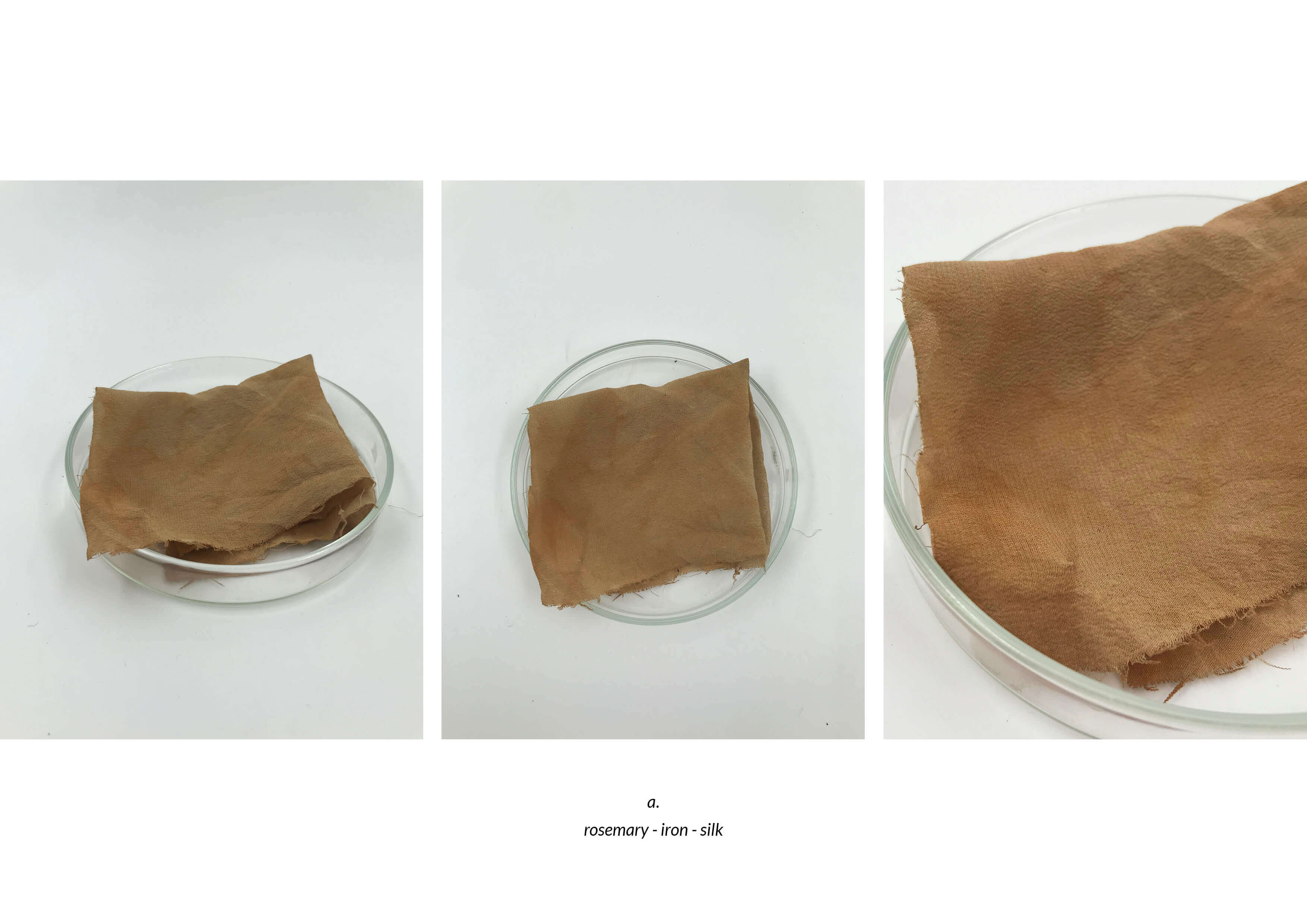

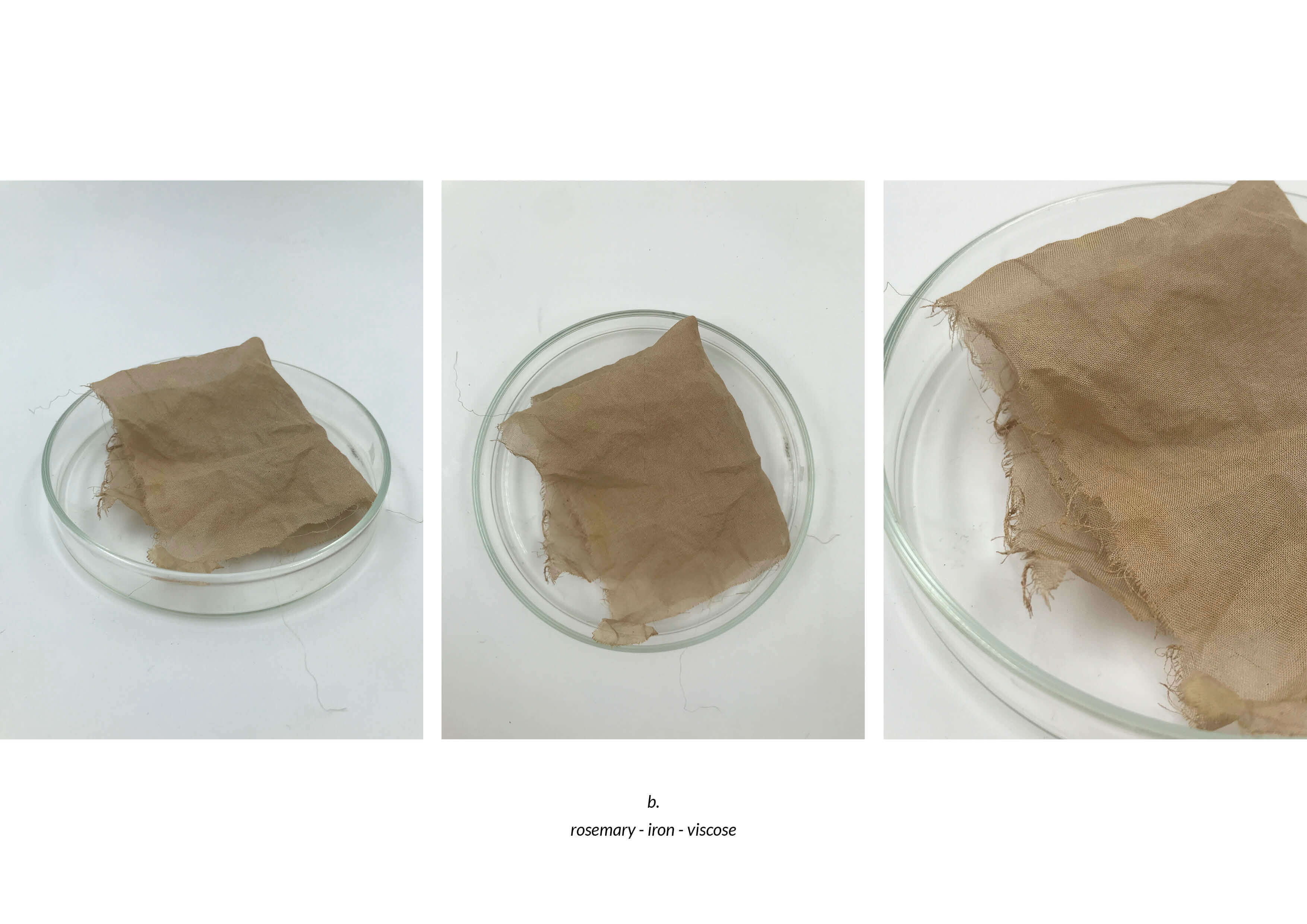

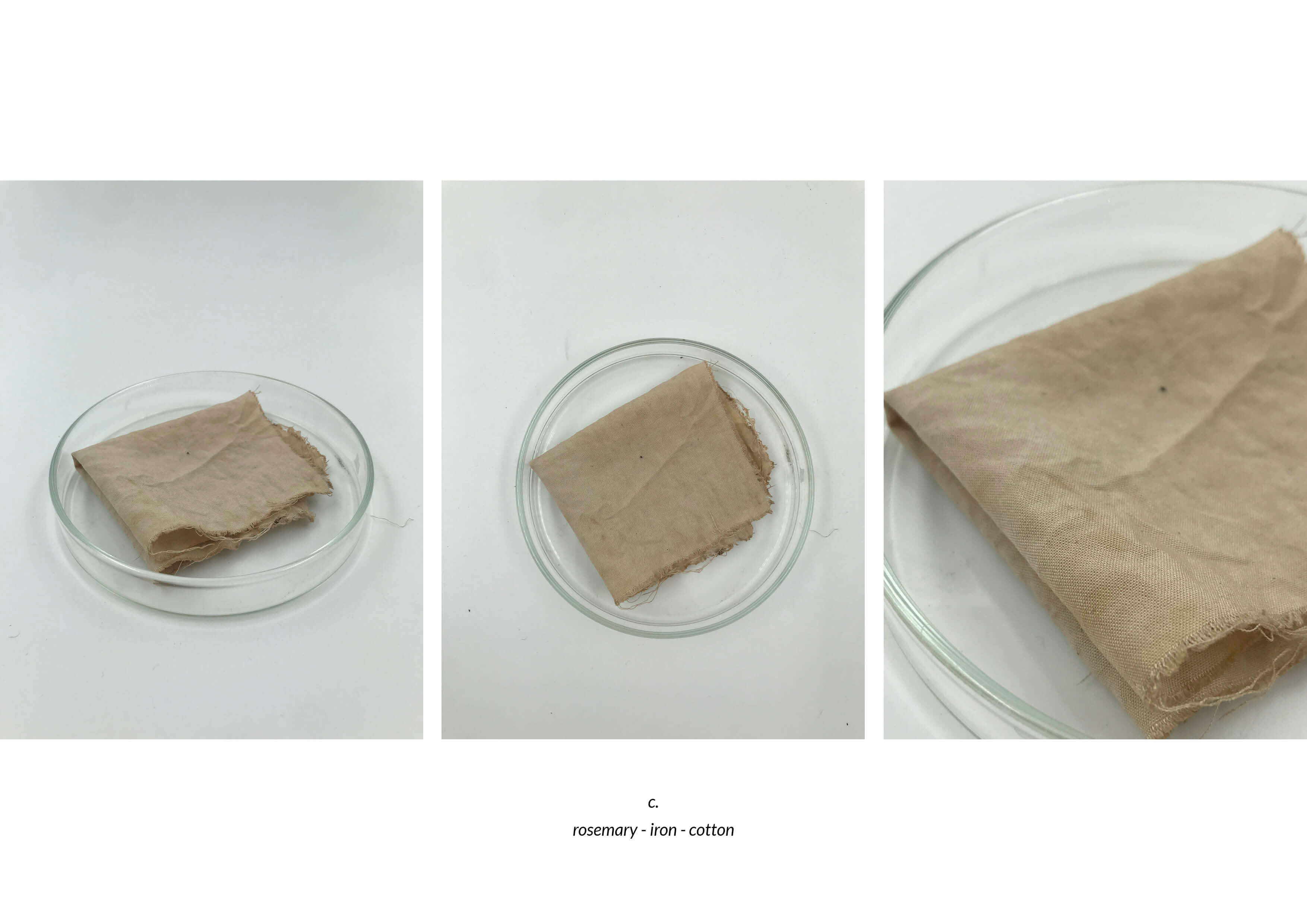

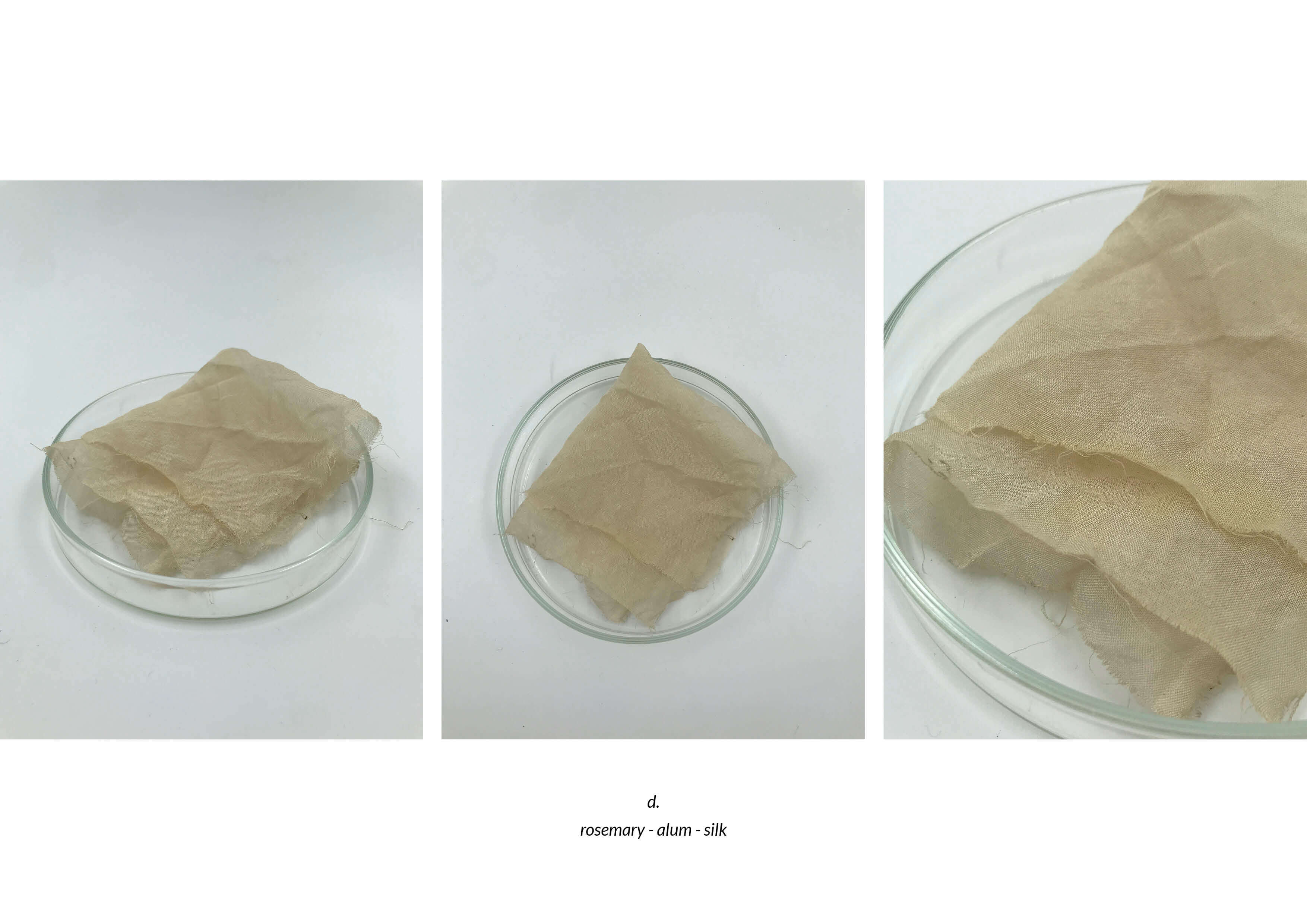

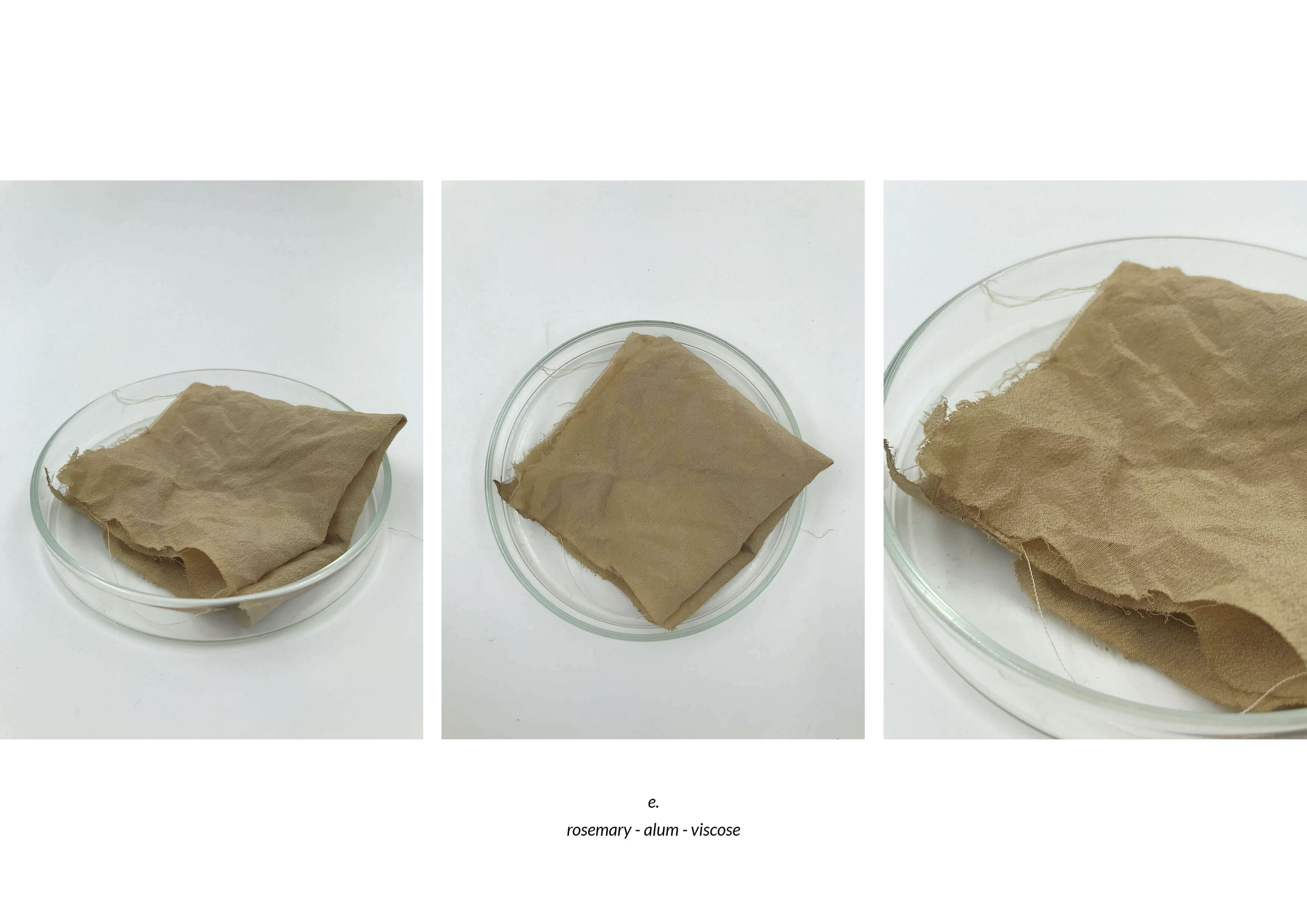

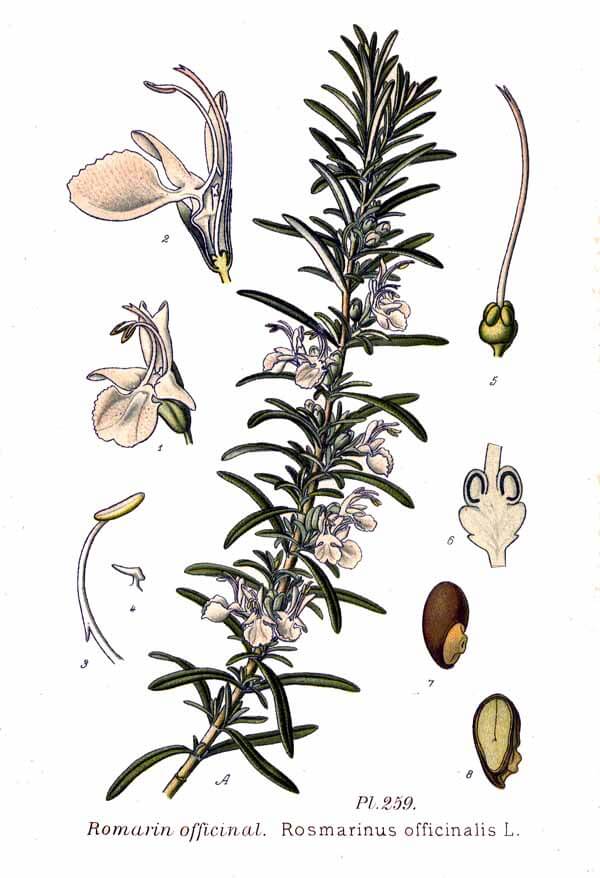

| rosemary | yellow, brown, grey, purple | green | silk (a.) / viscose (b.) / cotton (c.) | iron |

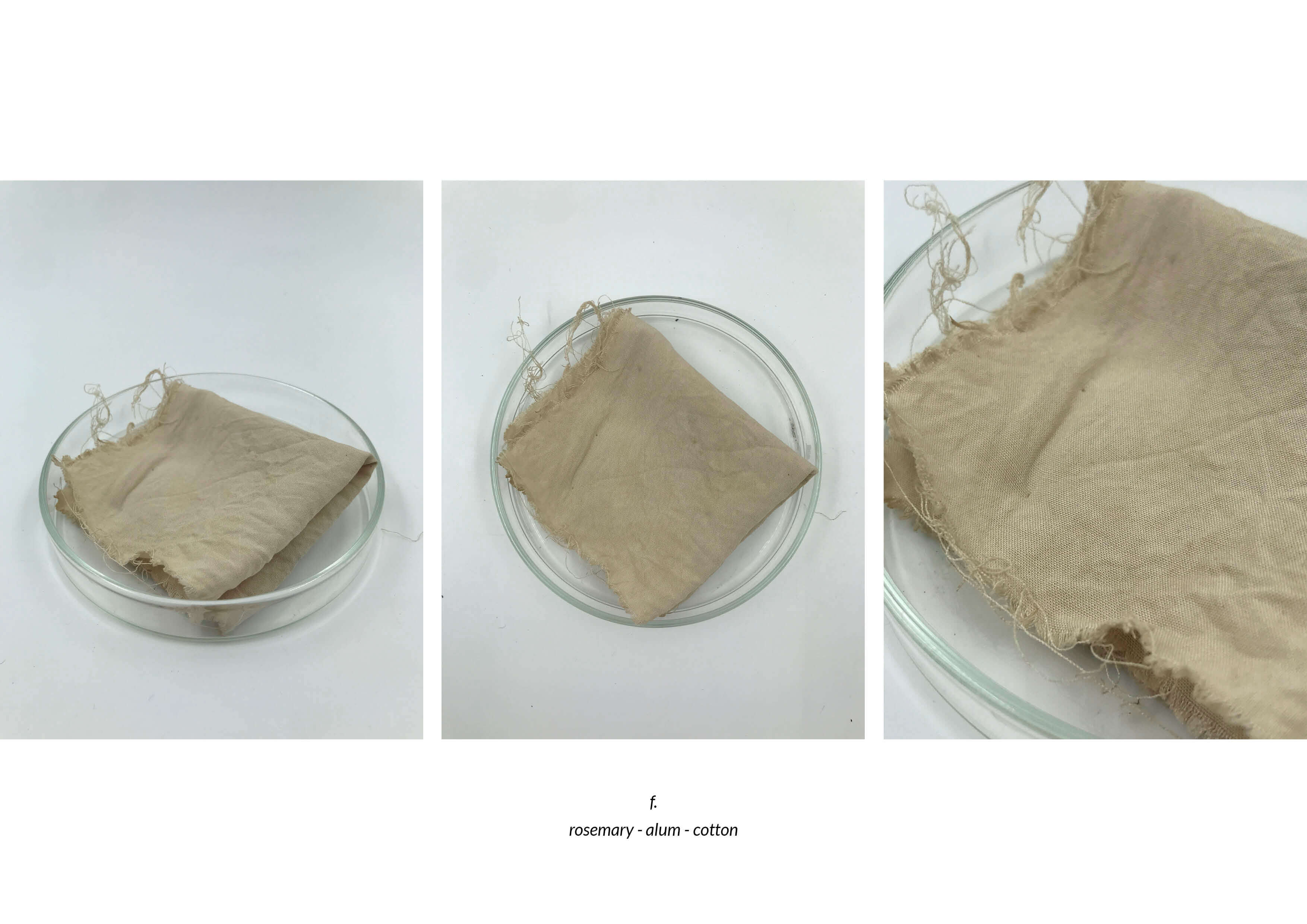

| rosemary | yellow, brown, grey, purple | yellow / green | silk (d.) / viscose (e.) / cotton (f.) | alum |

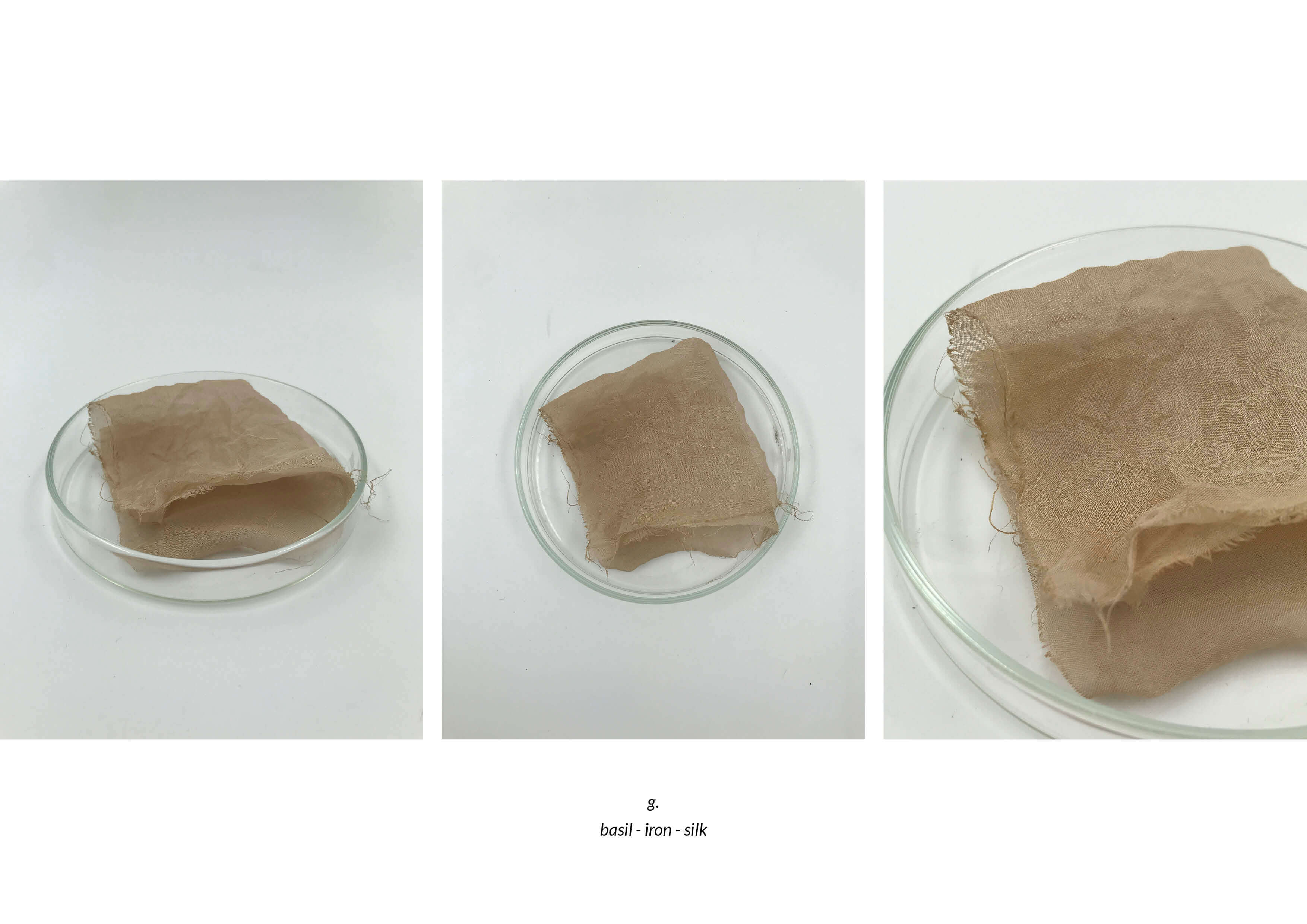

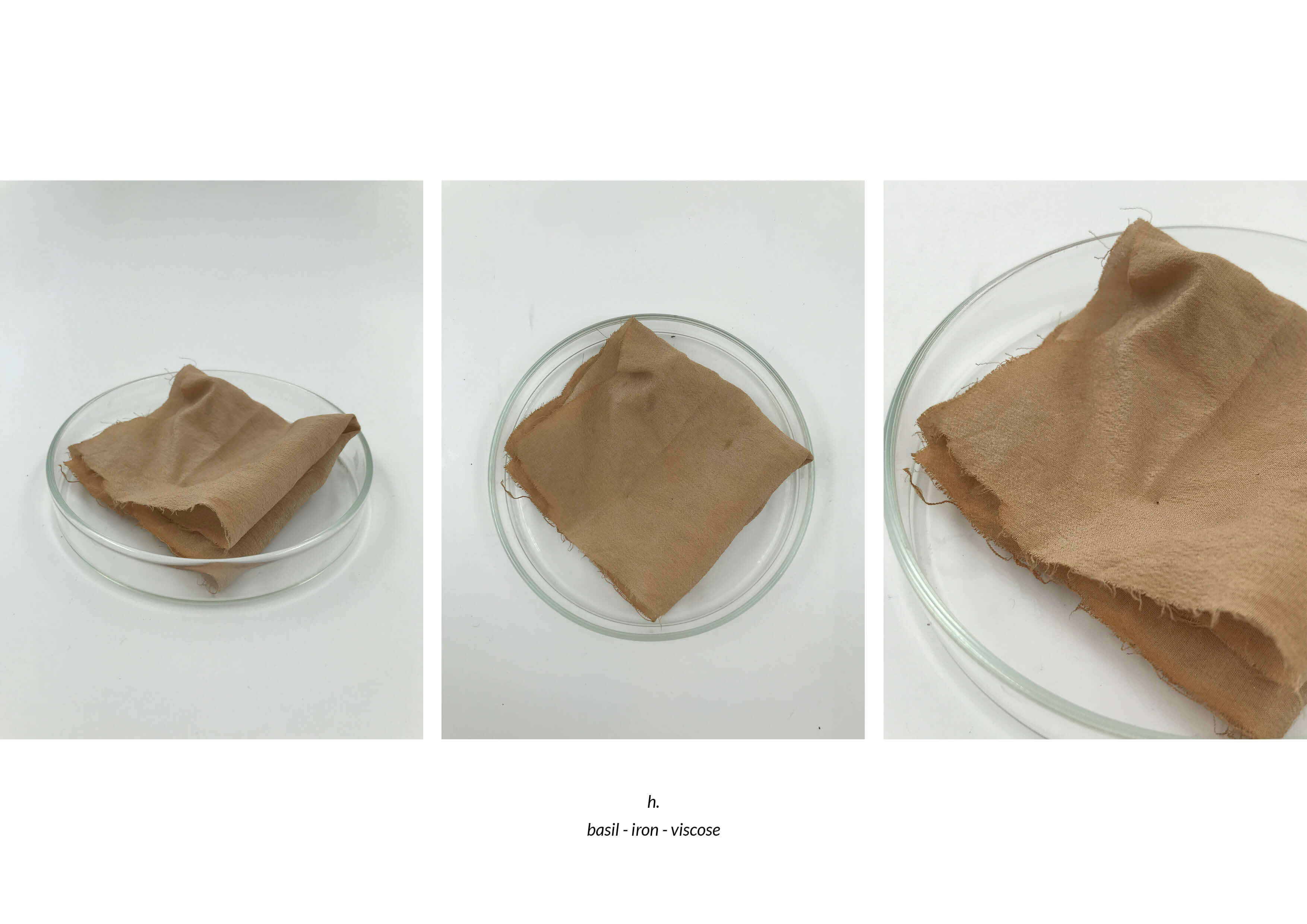

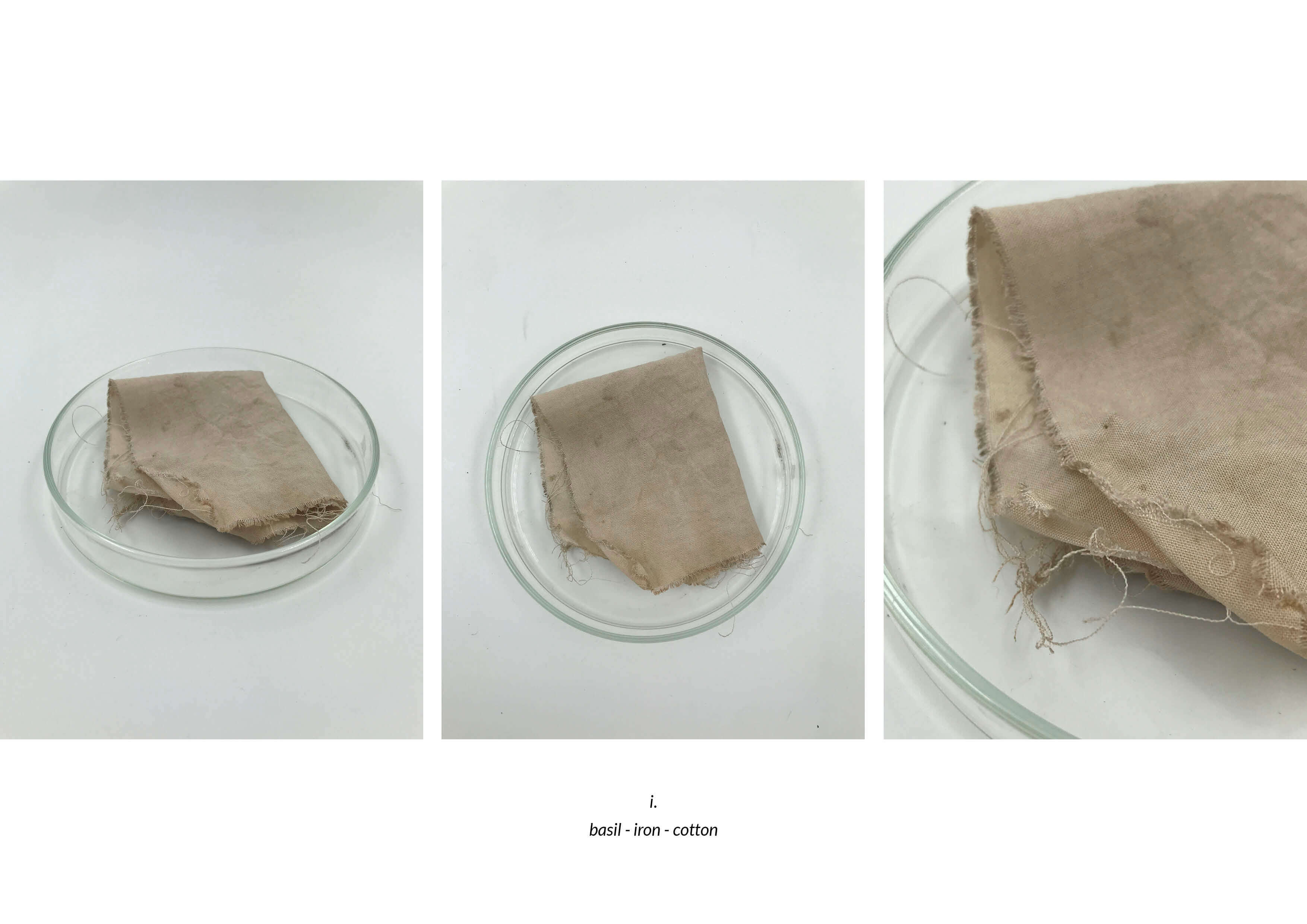

| basil | purplish-grey | brown | silk (g.) / viscose (h.) / cotton (i.) | iron |

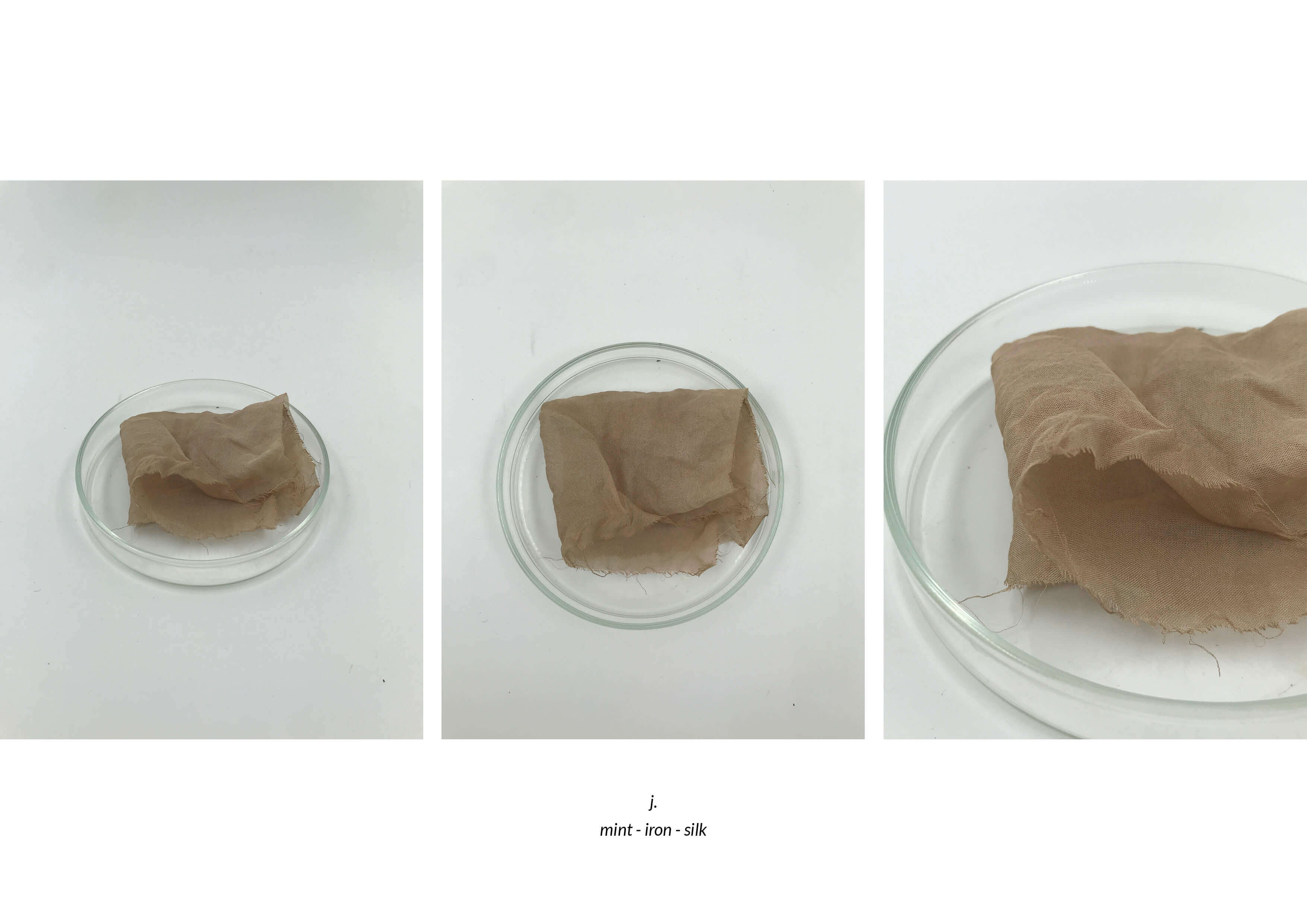

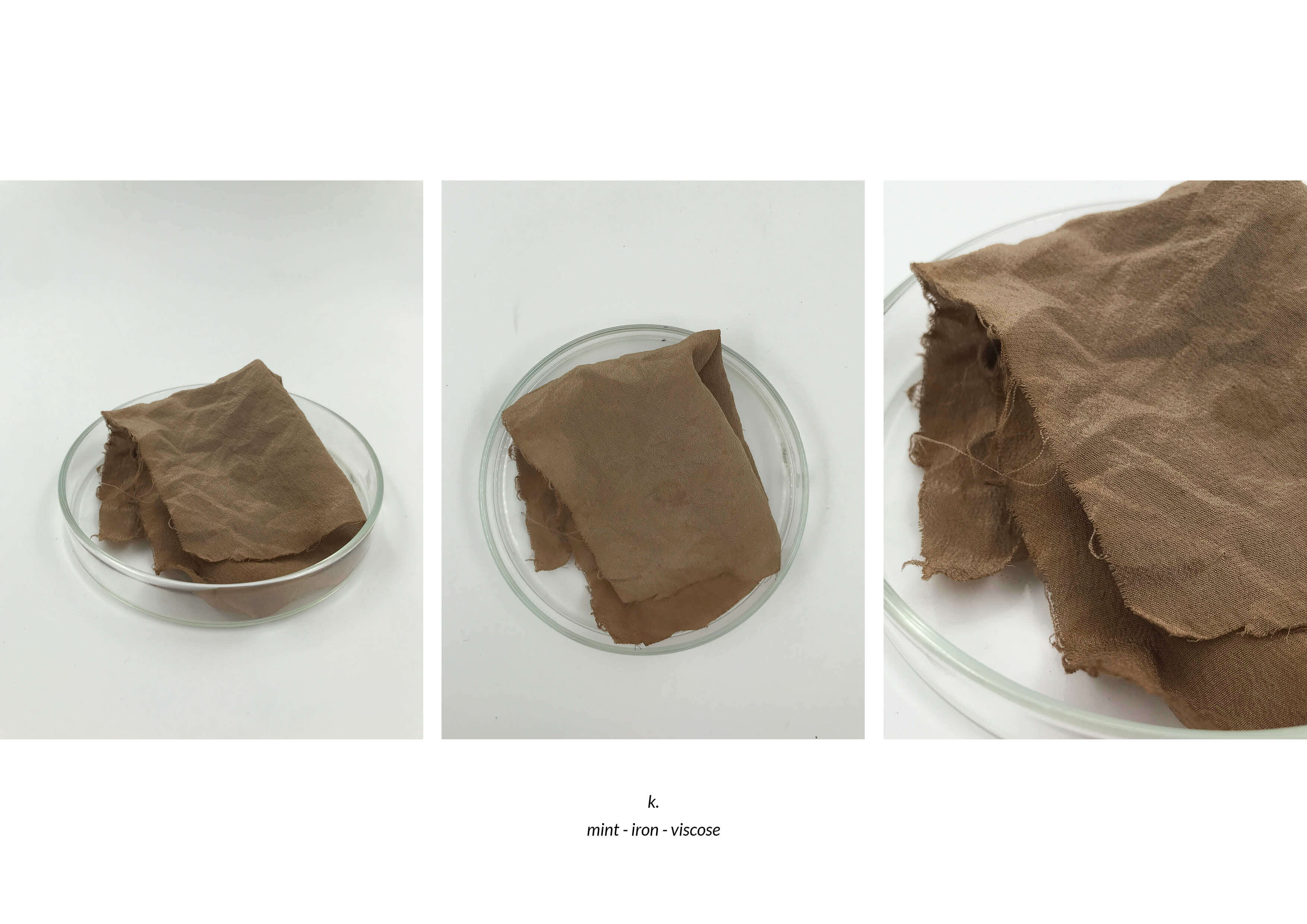

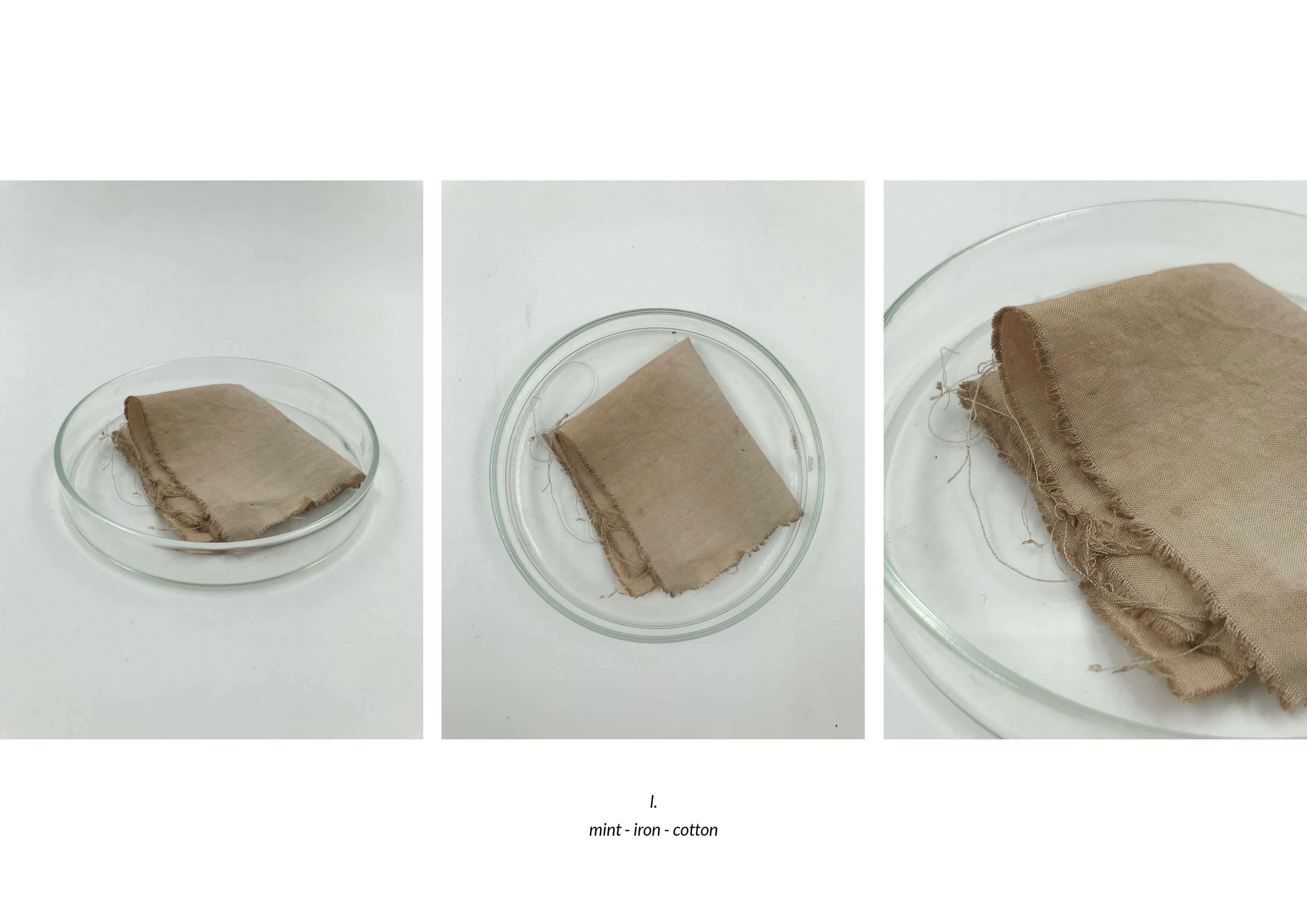

| mint | green | brown | silk (j.) / viscose (k.) / cotton (l.) | iron |

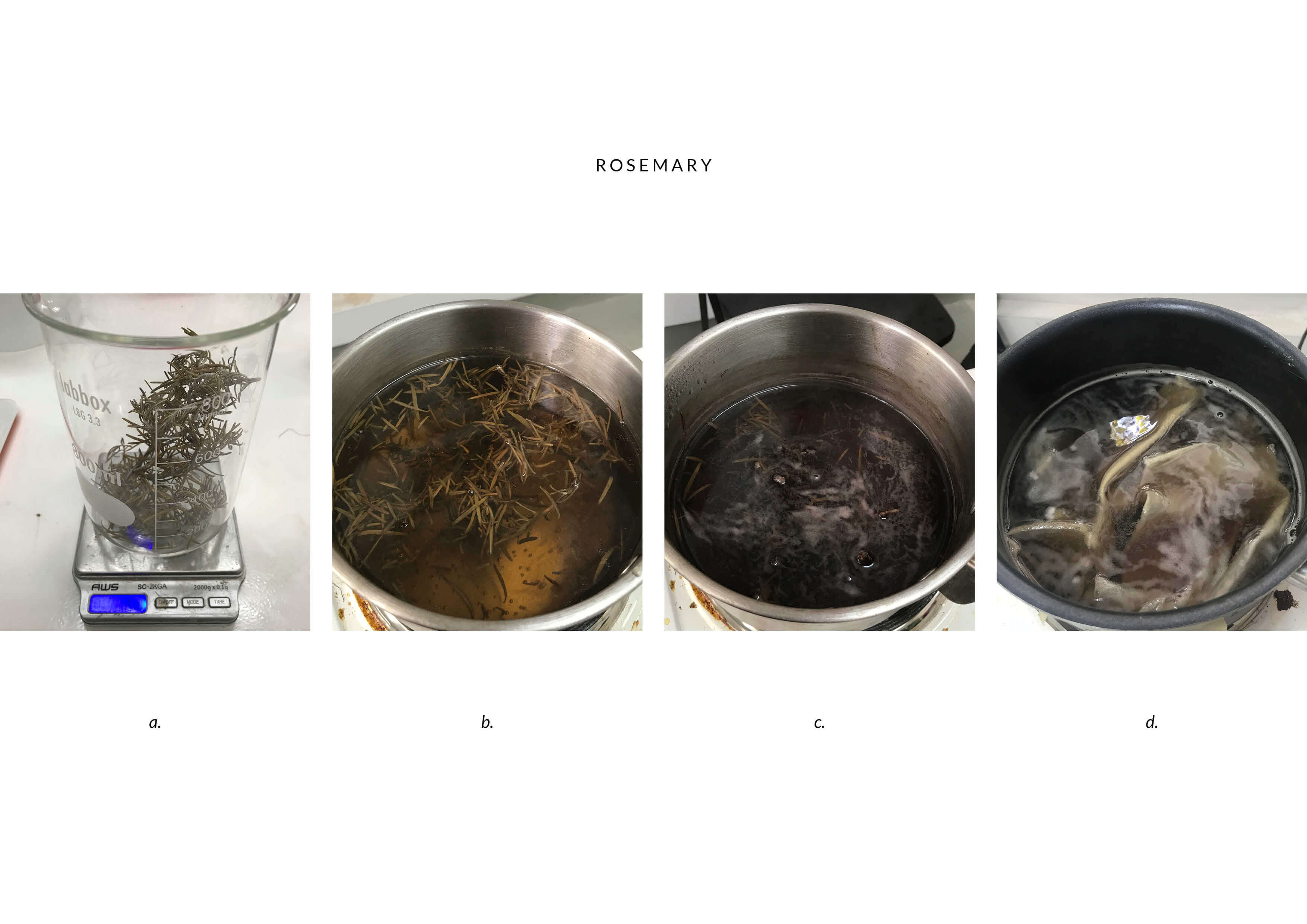

ROSEMARY¶

Rosmarinus officinalis

TOOLS¶

- cooking pot, stirring spoon, weight, mesh strainer, cooking stove

INGREDIENTES¶

- rosemary - 32 g

- water

| a. | b. |

|---|---|

| Rosemary | Water |

| 32 g | - |

PROCESS¶

- a. / Weigh the amount of your rosemary - (32 g in my case)

- b. / Fill the pot with rosemary and with enough water to cover all the herbs. Place the pot on the stove and heat for at least an hour. The longer you leave it, the stronger the colour will be.

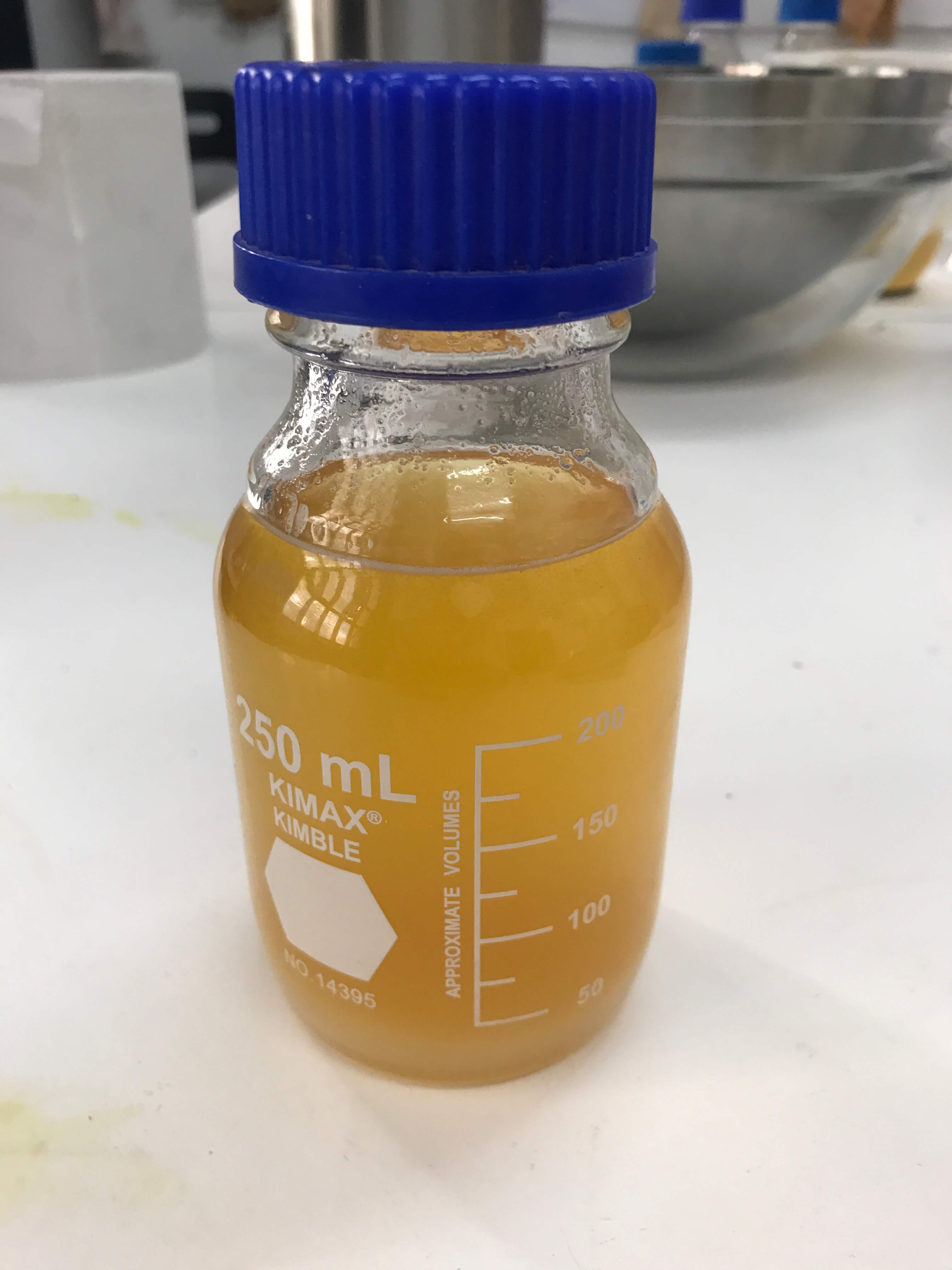

- c. / You will achieve this color after two and a half hours of cooking. You will probably need to add more water, after some time the water will evaporate.

- d. / Put the rosemary out of your dye bath. Pour the water through a mesh strainer into your second container or a glass jar. Pour the colored water back into the pot and keep it on low heat. Then put your textile in the pot. Do not mix alum fabrics with iron ones. After 15 minutes add another piece of fabric to the pot. The whole dyeing process took 30-40 minutes, then you can see the differences between the fabrics and the time they spent in the dyeing bath.

REFERENCE¶

BASIL¶

Ocimum Basilicum

TOOLS¶

- cooking pot, stirring spoon, weight, mesh strainer, cooking stove

INGREDIENTES¶

| a. | b. |

|---|---|

| Basil | Water |

| 21.3 g | - |

PROCESS¶

- Scouring: Place your textile in a larger pot (around 10l) and add 2% of soda ash. Let it simmer for 1 hour. After 1 hour drain out the water and refill the pot with clean water. Simmer it again for another hour (picture b.).

- Colour extraction: Fill the pot with basil leaves and with enough water to cover all the leaves. Place the pot on the stove and heat for at least an hour. and a half (low heat) to extract the colour. The longer you leave it, the stronger the colour will be. (This is the colour I achieved after two and a half houres on the stove.)

- Put the leaves out of your dye bath. Pour the water through a mesh strainer into your second container or a glass jar. * Pour the colored water back into the pot and keep it on low heat (picture c.). Then put your textile in the pot. Do not mix alum fabrics with iron ones. * After 15 minutes add another piece of fabric to the pot.

- The whole dyeing process took 30-40 minutes, then you can see the differences between the fabrics and the time they spent in the dyeing bath.

REFERENCE¶

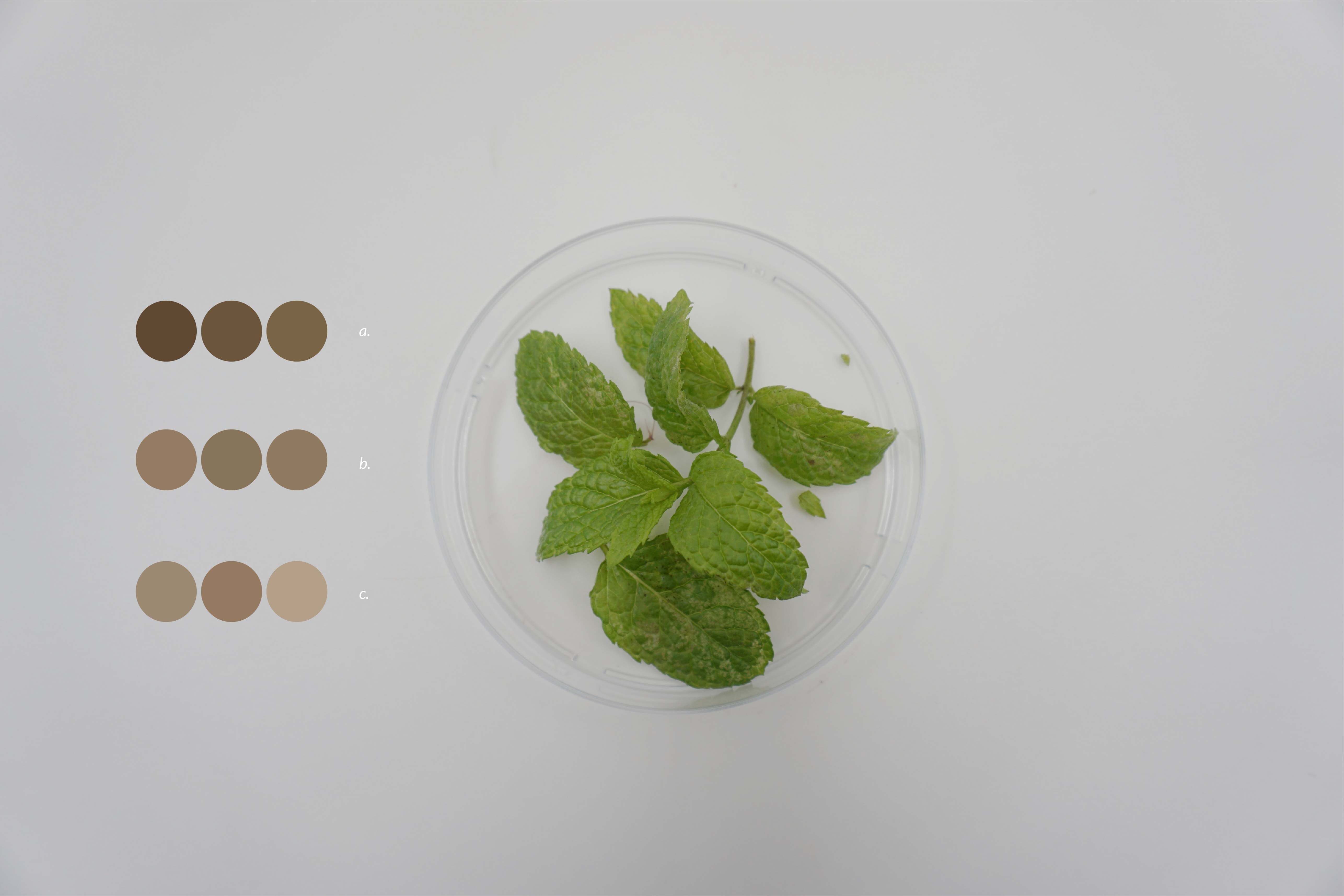

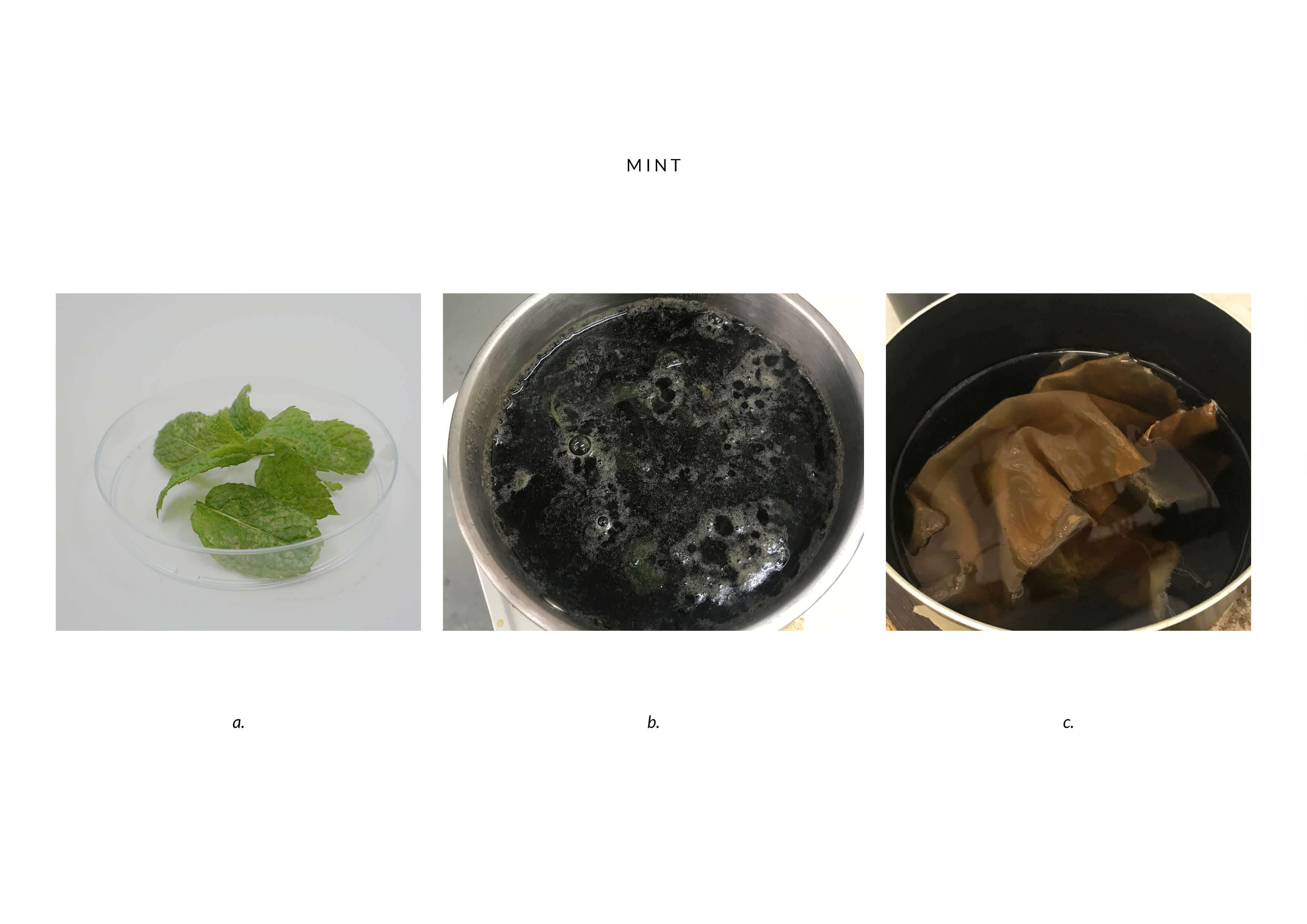

MINT¶

Mentha piperita

TOOLS¶

- cooking pot, stirring spoon, weight, mesh strainer, cooking stove

INGREDIENTES¶

| a. | b. |

|---|---|

| Mint | Water |

| 20.1 g | - |

PROCESS¶

- Scouring: Place your textile in a larger pot (around 10l) and add 2% of soda ash. Let it simmer for 1 hour. After 1 hour drain out the water and refill the pot with clean water. Simmer it again for another hour (picture a.).

- Colour extraction: Fill the pot with mint leaves and with enough water to cover all the leaves. Place the pot on the stove and heat for at least an hour. and a half (low heat) to extract the colour. The longer you leave it, the stronger the colour will be. (This is the colour I achieved after two and a half houres on the stove.)

- Put the leaves out of your dye bath. Pour the water through a mesh strainer into your second container or a glass jar. * Pour the colored water back into the pot and keep it on low heat (picture c.). Then put your textile in the pot. Do not mix alum fabrics with iron ones. * After 15 minutes add another piece of fabric to the pot.

- The whole dyeing process took 30-40 minutes, then you can see the differences between the fabrics and the time they spent in the dyeing bath.

REFERENCE¶

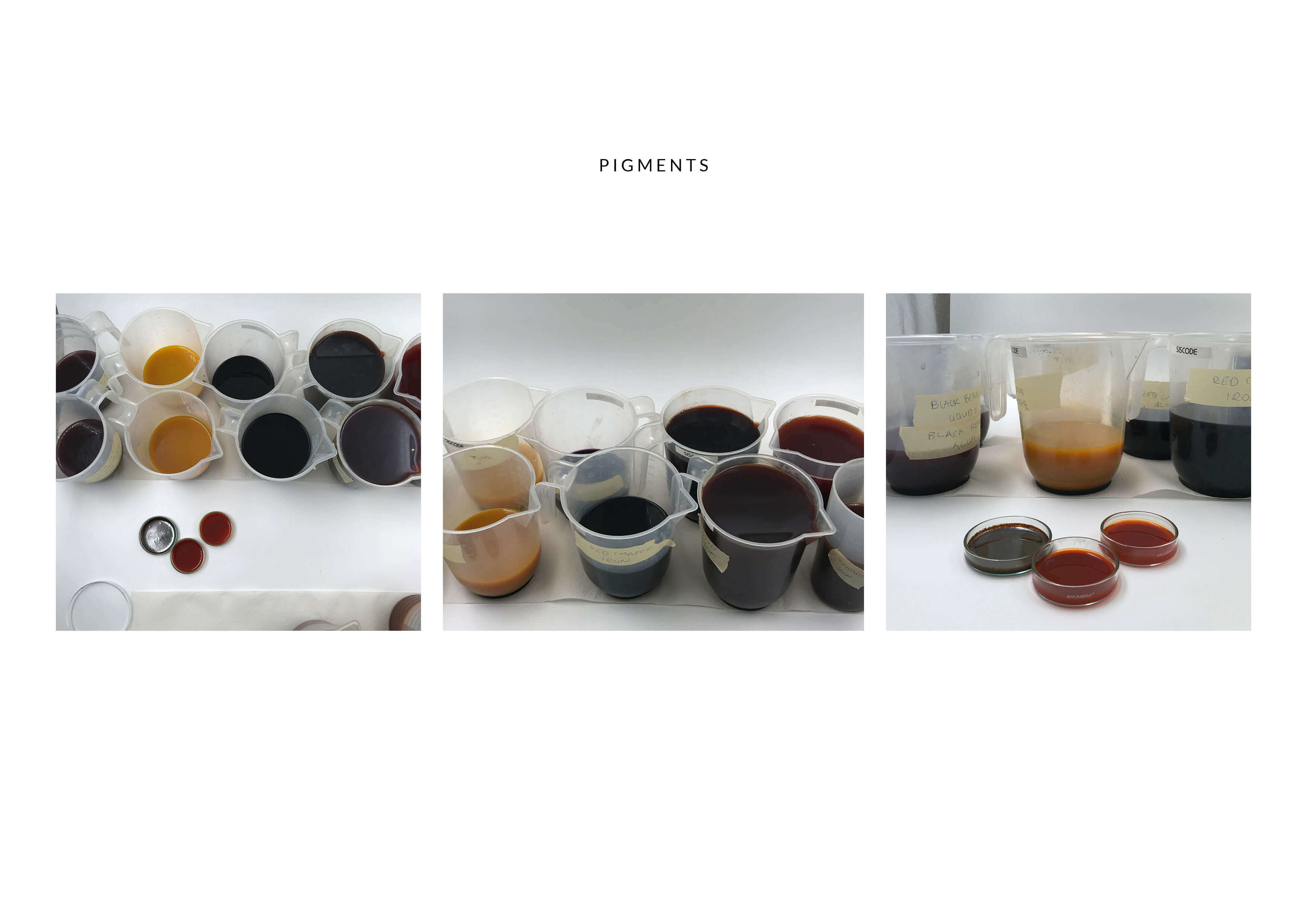

PIGMENTS¶

TOOLS¶

- plastic cup, bowl, stirring spoon, weight, cooking pot, cooking stove, coffee filters, mesh strainer

INGREDIENTES¶

- dye bath - leftovers

- baking soda - 6 g

- alum - 18 g

- hot water

PROCESS¶

- Alum solution: Weight 18 g of alum and mix it with 100 ml of hot water. Add the alum into the water and mix them together, till the alum will disolve in the hot water completely. Keep stirring all the time.

- Add the alum solution into the plastic cup with the dye leftovers. Keep stirring all the time.

- Baking soda solution: Mix 6 g of baking soda with 100 ml of hot water. A reaction will appear, for that reason you need to place your plastic cup into another bigger bowl (picture a.). While you stirring the dye bath with alum solution add very slowly baking soda medium and wait for the reaction. A foam will start rising, try to push foam back to the cup and keep stirring the mixture (picture b.).

- We left the mixture settle down overnight. You will see 2-3 cm layer of clear water under the water surface. * Place a coffee filter into the mesh strainer and pour the mixture inside to filtrate piecies of pigment from the water. * The pigment sediments will stay on the surface of coffee filter which you can place into a dehydrator for 2h.

AVOCADO¶

CABBAGE¶

BIOCHROMES WEEK 04 from PETRA GARAJOVÁ on Vimeo.

RESULT¶

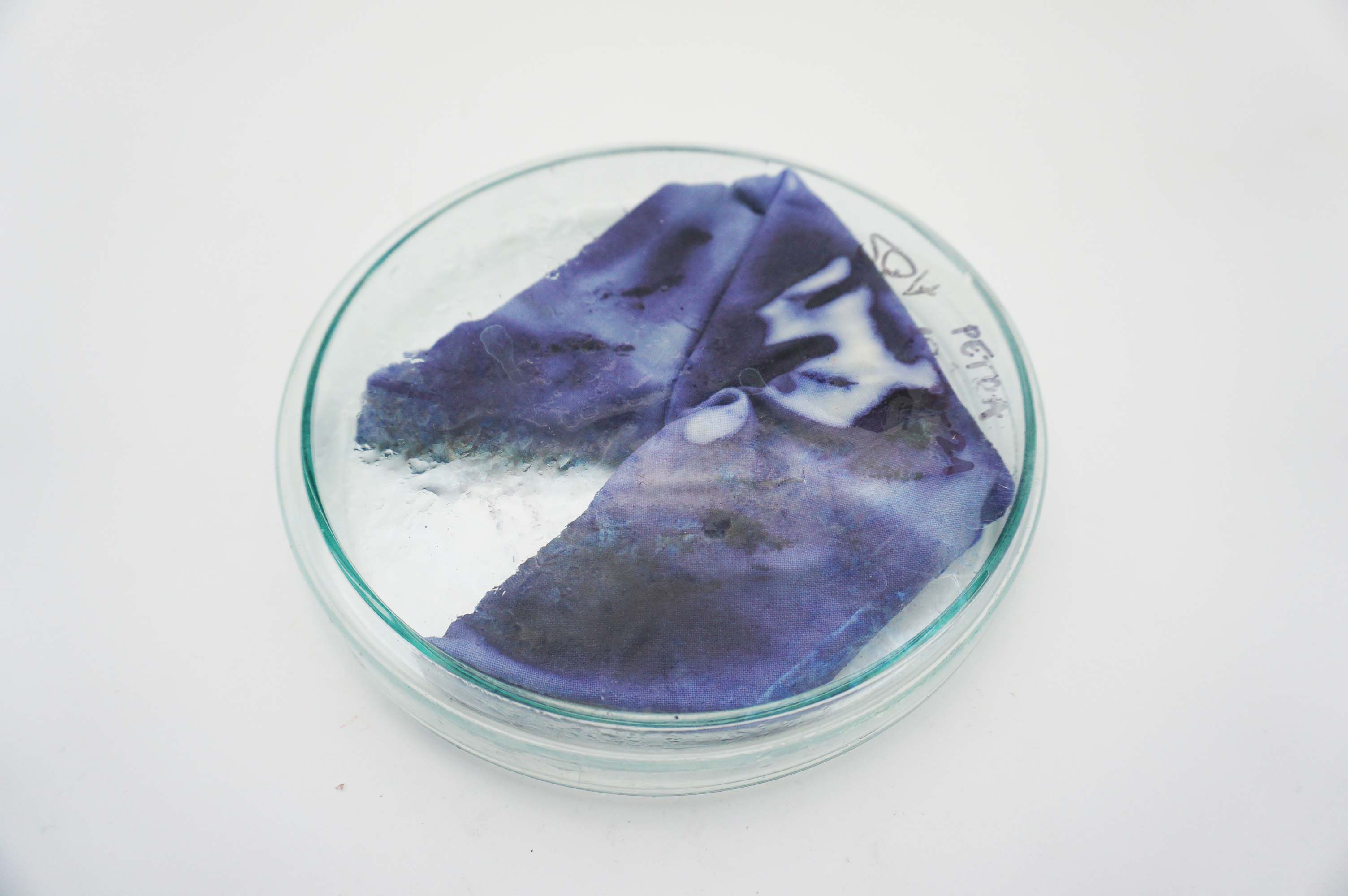

BACTERIAL DYEING¶

ABOUT¶

- Bacteria are single-celled organisms, dwelling nearly everywhere on Earth, from the bottom of the sea to the skin of animals, from our houses to our own bodies.

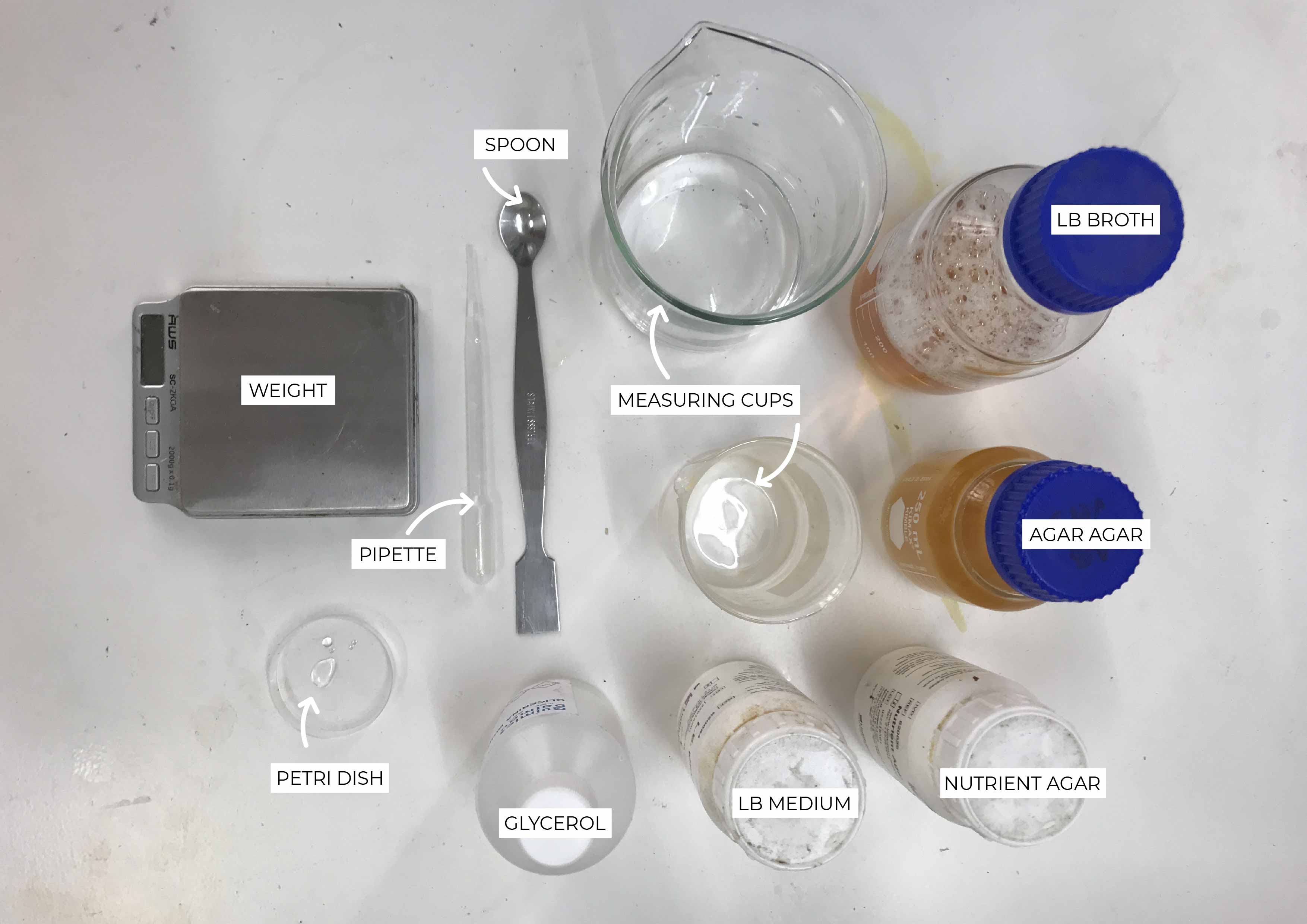

TOOLS¶

- incubator, measuring cups, weight, cooker / sterilizator, petri dishes, alcohol, pipet, inoculation loop

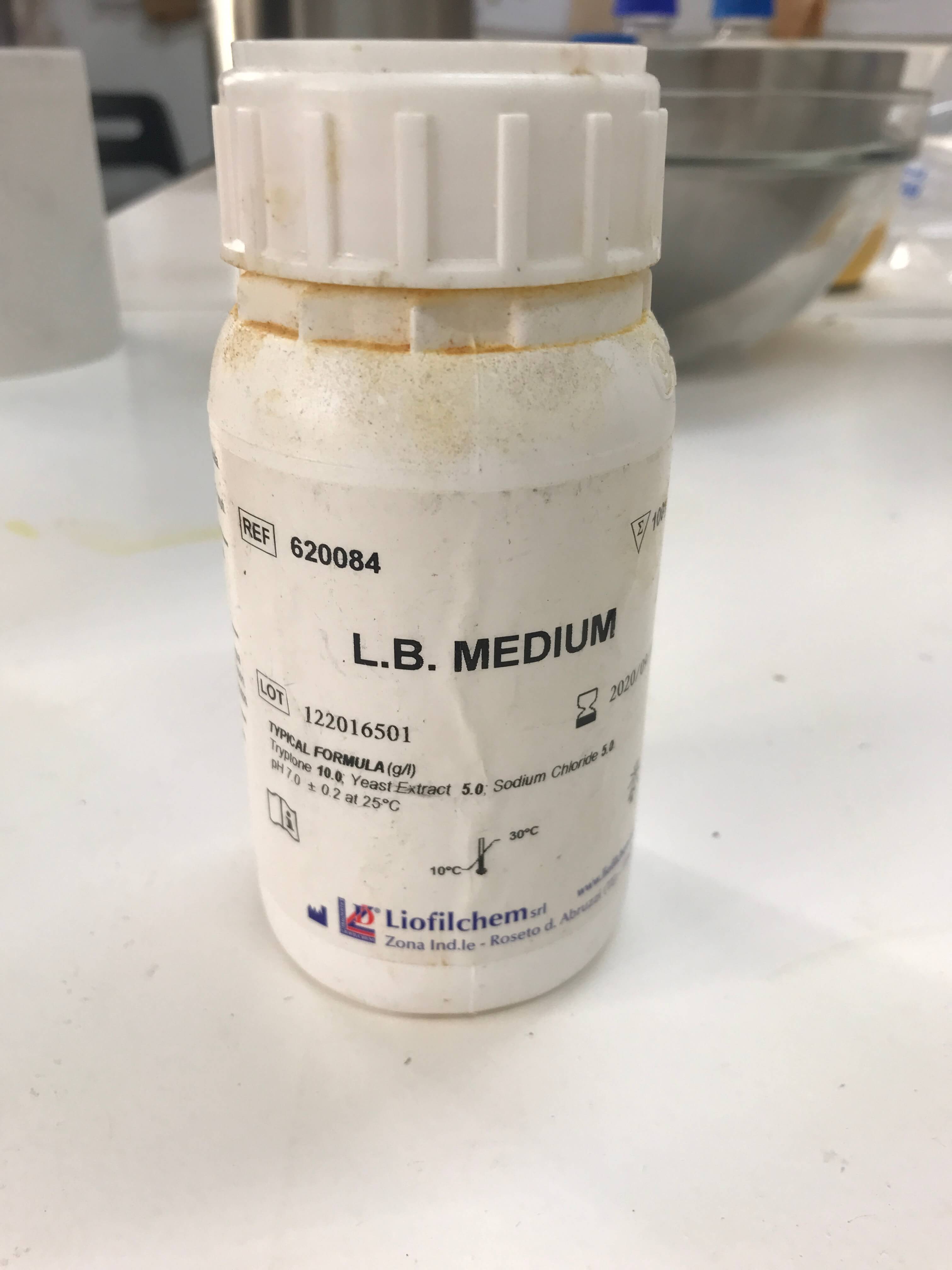

FOOD - MEDIUM¶

-

- LB BROTH (4 plates)

| a. | b. | c. |

|---|---|---|

| LB Broth | Glycerol | Water |

| 6.75 g | 1 ml | 250 ml |

-

- AGAR AGAR (4 plates)

| a. | b. | c. |

|---|---|---|

| Agar Agar | Glycerol | Water |

| 4 g | 1 ml | 200 ml |

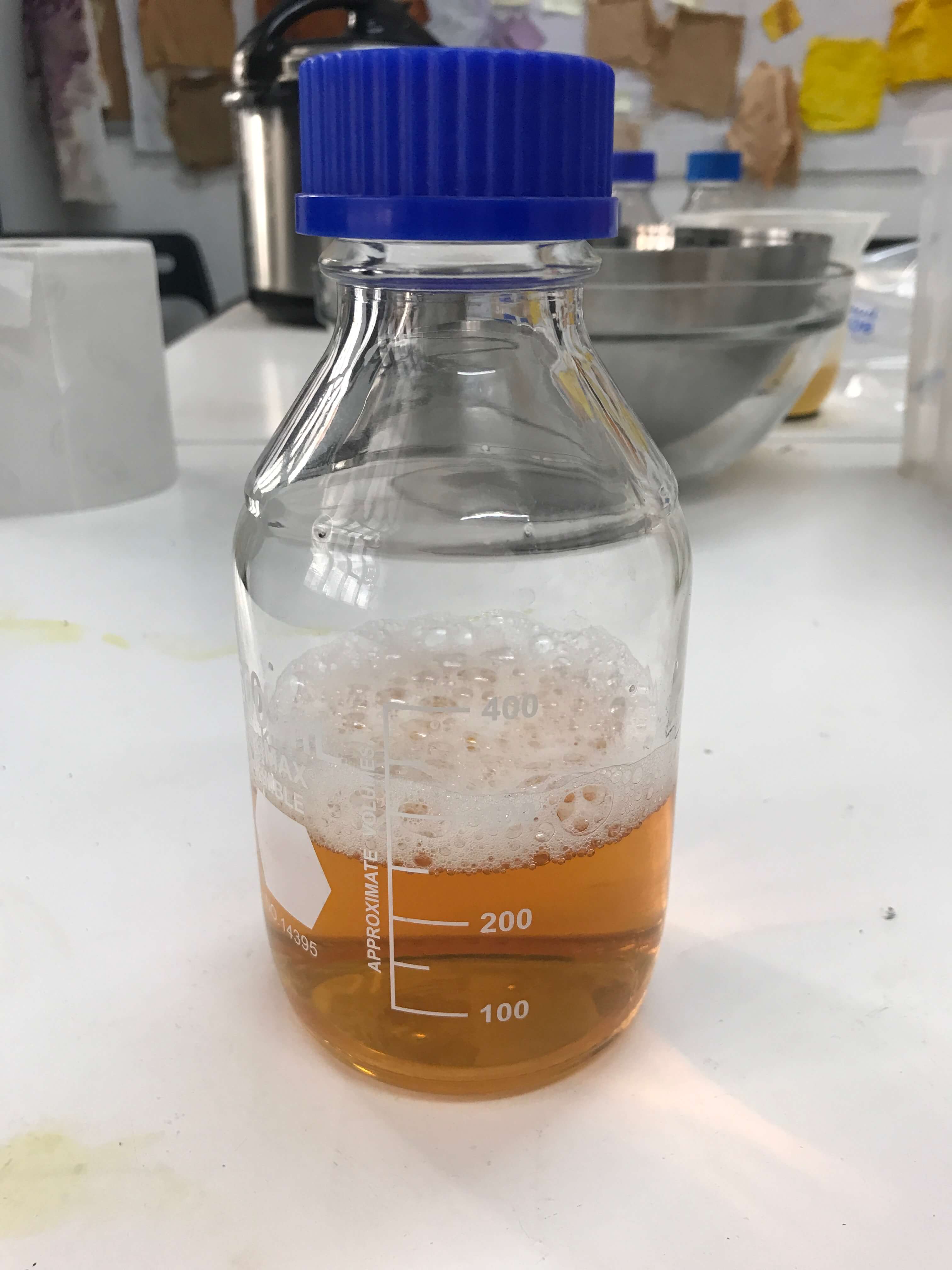

PROCESS¶

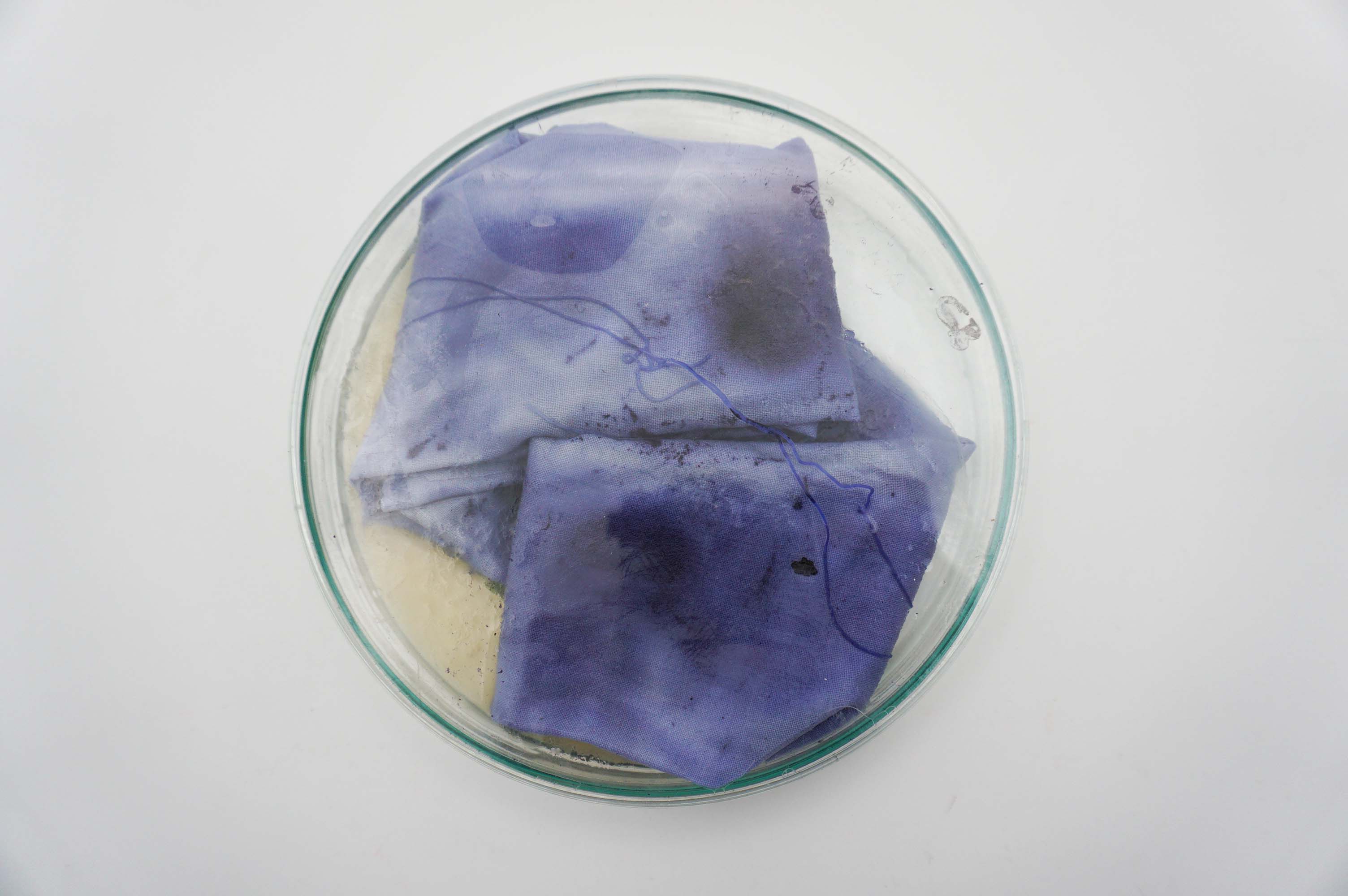

- Scouring: Place your textile in a larger pot (around 10 l) and add 2% of soda ash. Let it simmer for 1 hour. After 1 hour drain out the water and refill the pot with clean water. Simmer it again for another hour. If you want to use animal fibers you do not have to do this step. * Prepare LB Broth in a lab glass. Let the lid loose - do not close it completely otherwise it will explode in the pressure cooker. Before the pressure cooking put the fabric in a glass petri dish. Put LB Broth, petri dishes and all tthe tools you will use into a special plastic bag and then to the pressure cooker to sterilize them. (In Fabtextile's pressure cooker select option - CARNE and set the time to 2O min).

- Double check if there is enough water at the bottom of the pressure cooker. To do not melt your plastic bag.

- Prepare your working place. You have to put the mini stove in the middle and light it. Pour alcohol in a circle around it and wait 10-15 minutes for a "safe bubble" to form around your workplace.

- When your pressure cooker is finished put it out. Keep everything it in the plastic bag until it will cool down.

- Put everything close to the mini stove and put the gloves on. Then disinfect your hands.

- Take the glass with LB Broth. Always use one hand to hold the glass with LB Broth and with other the cover of your petri dish with the fabric. * Open it only close and with the throat leaning towards the fire. Let the fire breathe for about 3 seconds. * After you can pour it onto the fabric in the petri dish. Lifts the cap of the petri dish only enough to pour the liquid into it. You have to do everything quickly to avoid the risk of contamination. * Take the inoculation loop and hold it under the fire till will get hot and red. With other hand open the petri dish with the bacteria. Touch the yellow part around the bacteria (medium) to cool down the inoculation loop. And then you can use it for bacteria inoculation. Do it gently with less pressure as you can and ttouch only the purple parts (no medium). * Transfer it to the petri dish with fabric with the inoculation loop. Try to do not open the cap of the petri dish too much.

- After the transfer put the inoculation loop back on the top of the fire. To kill all bacteria on it.

- Place your dyied fabric in the petri dish in to the fridge (around 25°C for 48 h).

- In two days you will see your result. If the bacteria did grow properly, maybe yoou put too much LB Broth. It is not necessary to put too much liquid. * You have to pressure cook everything again to kill the bacteria. Rinse the cloth in water.

- If you are not satisfied with your colours you can repeat all tthe process once again.

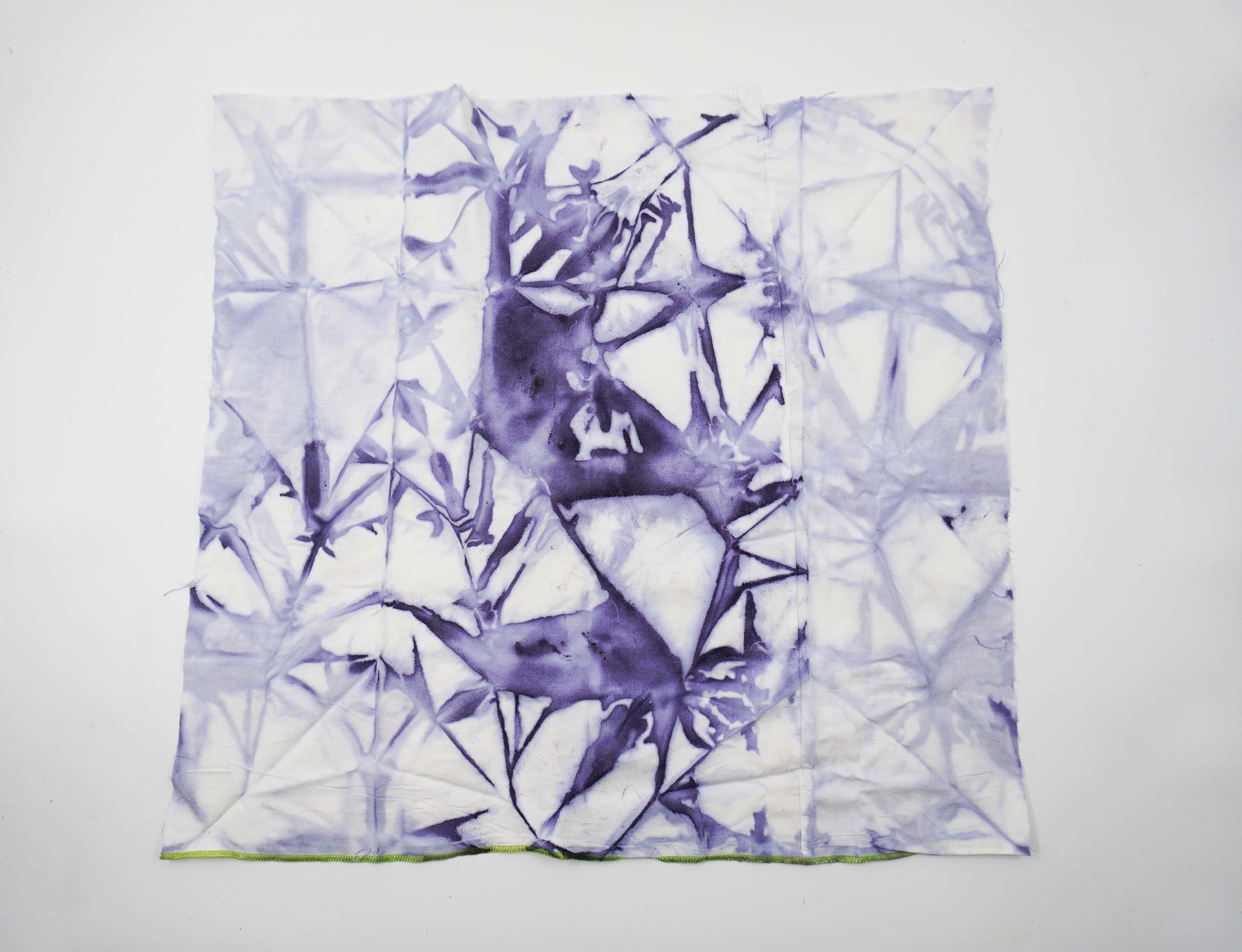

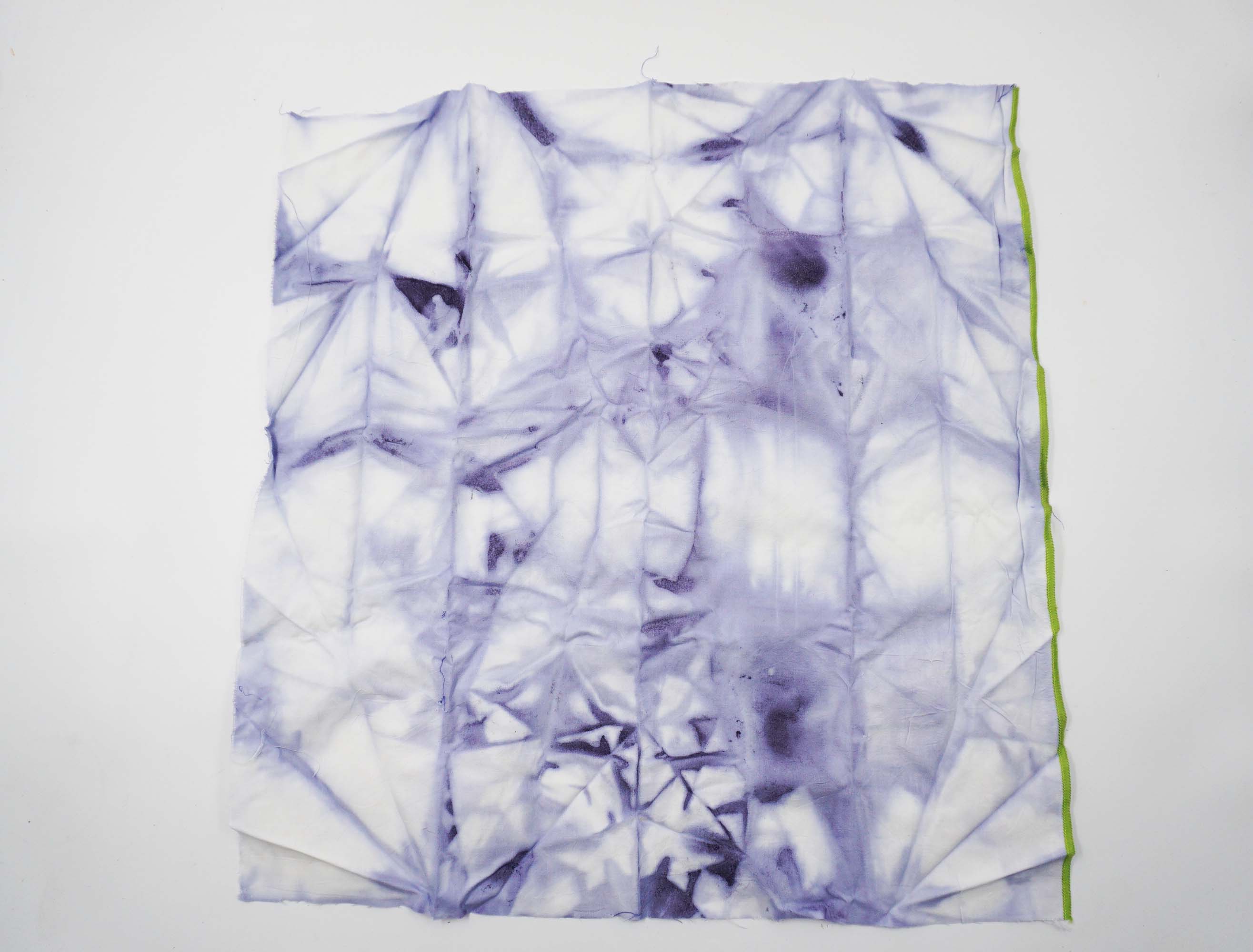

TEST 01 - COTTON¶

| Material name | Fabric composition | Breathability | Moisture-wicking abilities | Heat retention abilities | Stretchability | Washing temperatures |

|---|---|---|---|---|---|---|

| Cotton | Polyether-polyurea copolymer | Zero | None | High | High | Cold |

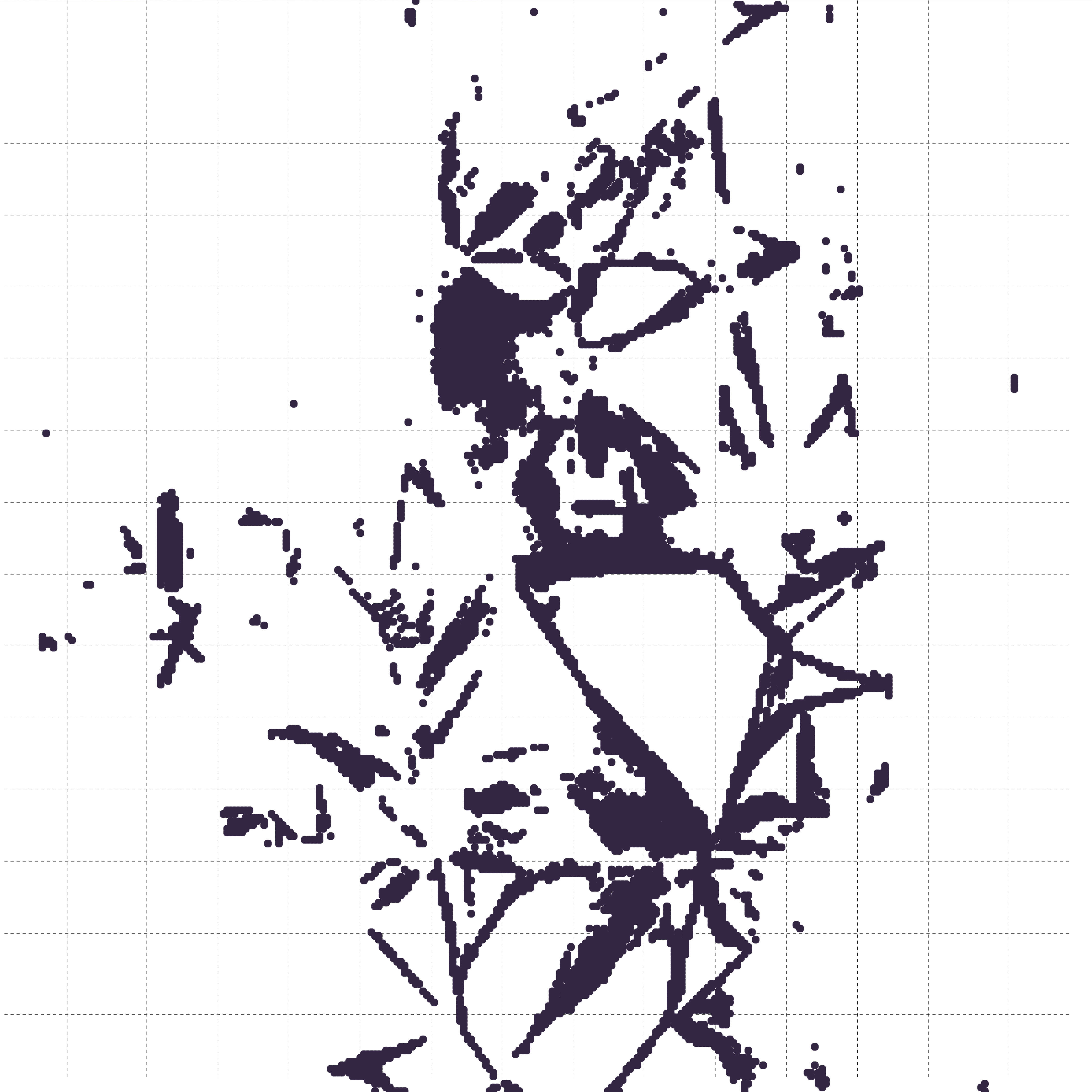

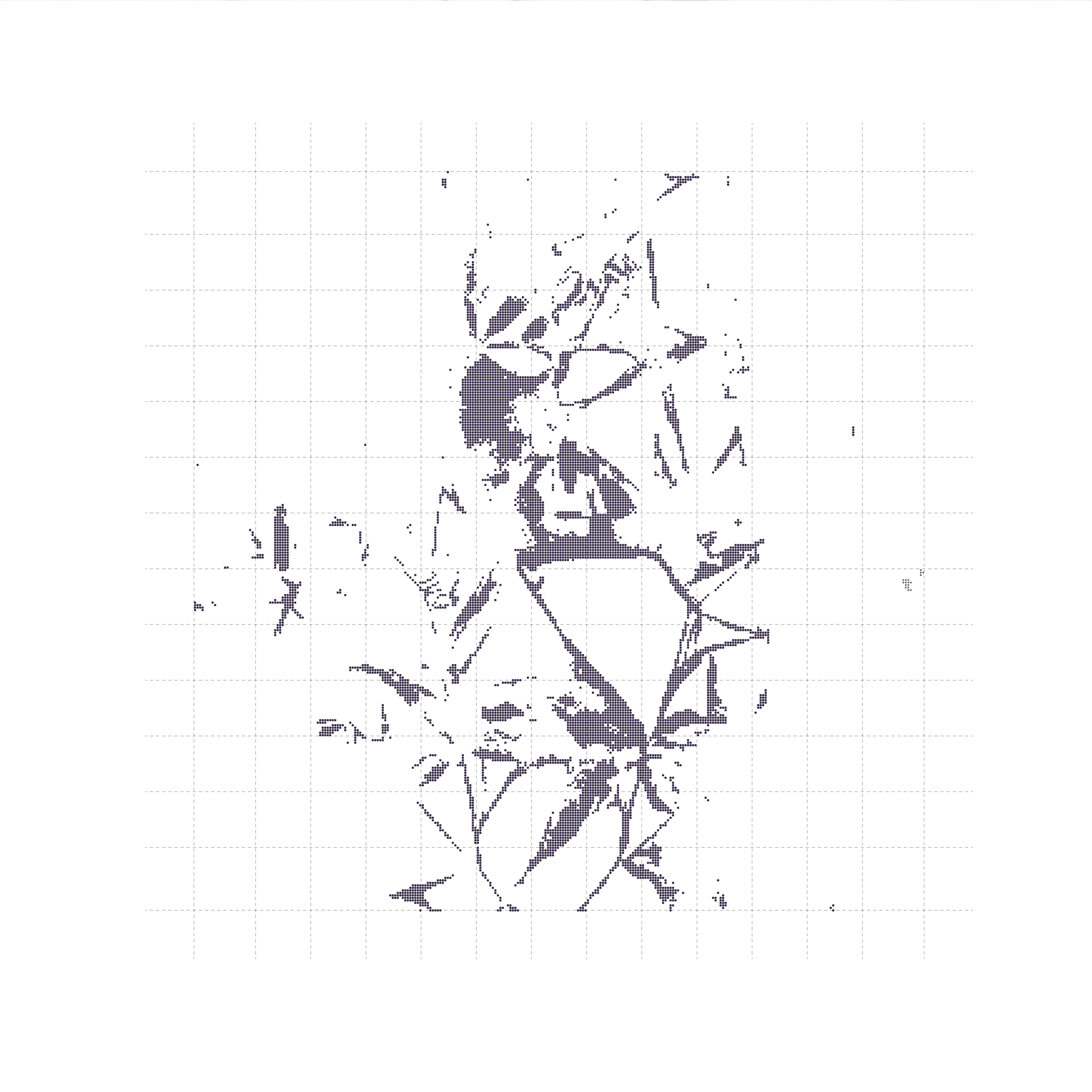

COLOR INTENSITY DIAGRAM¶

RESULTS¶

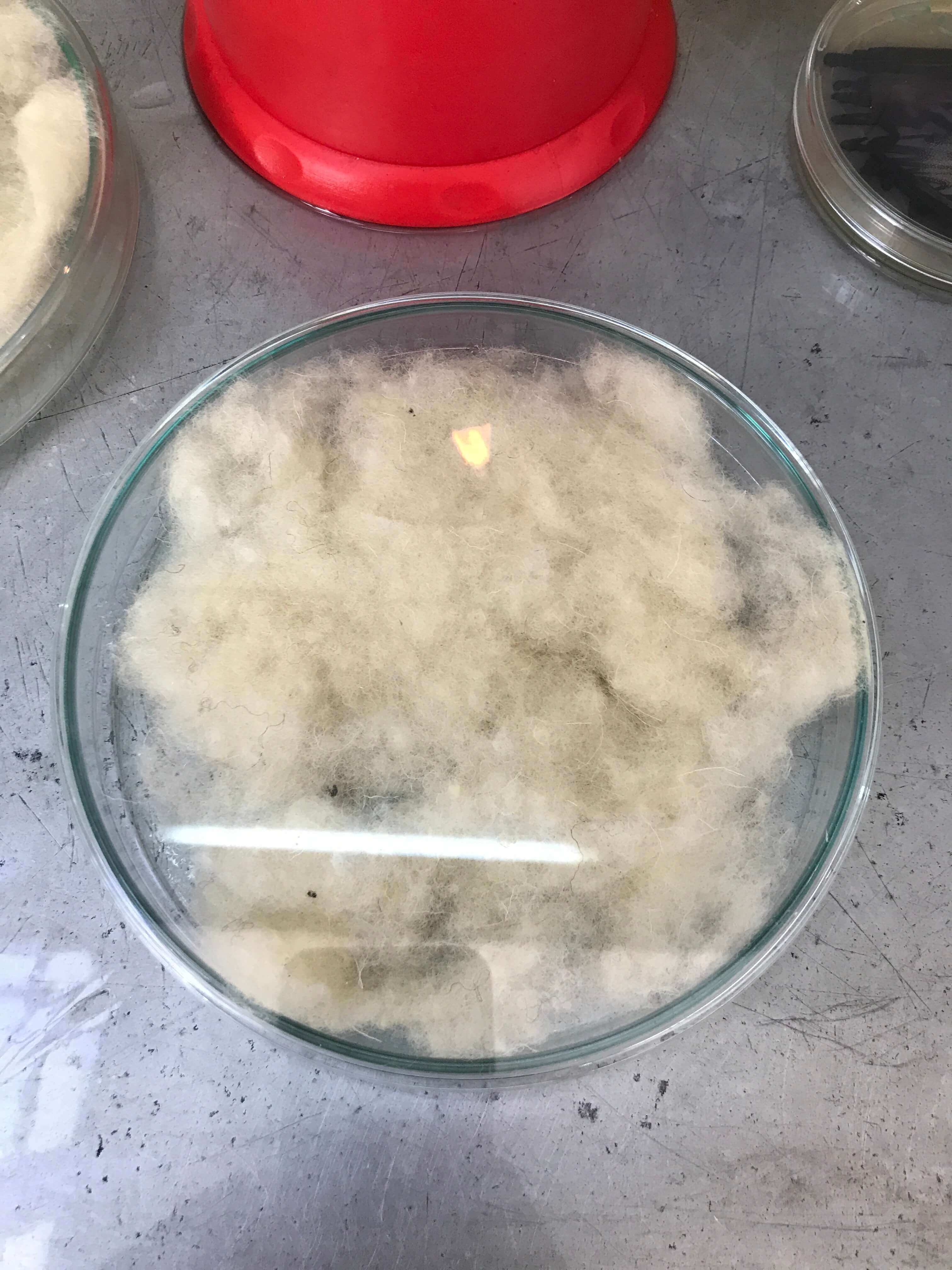

TEST 02 - COTTON¶

RESULTS¶

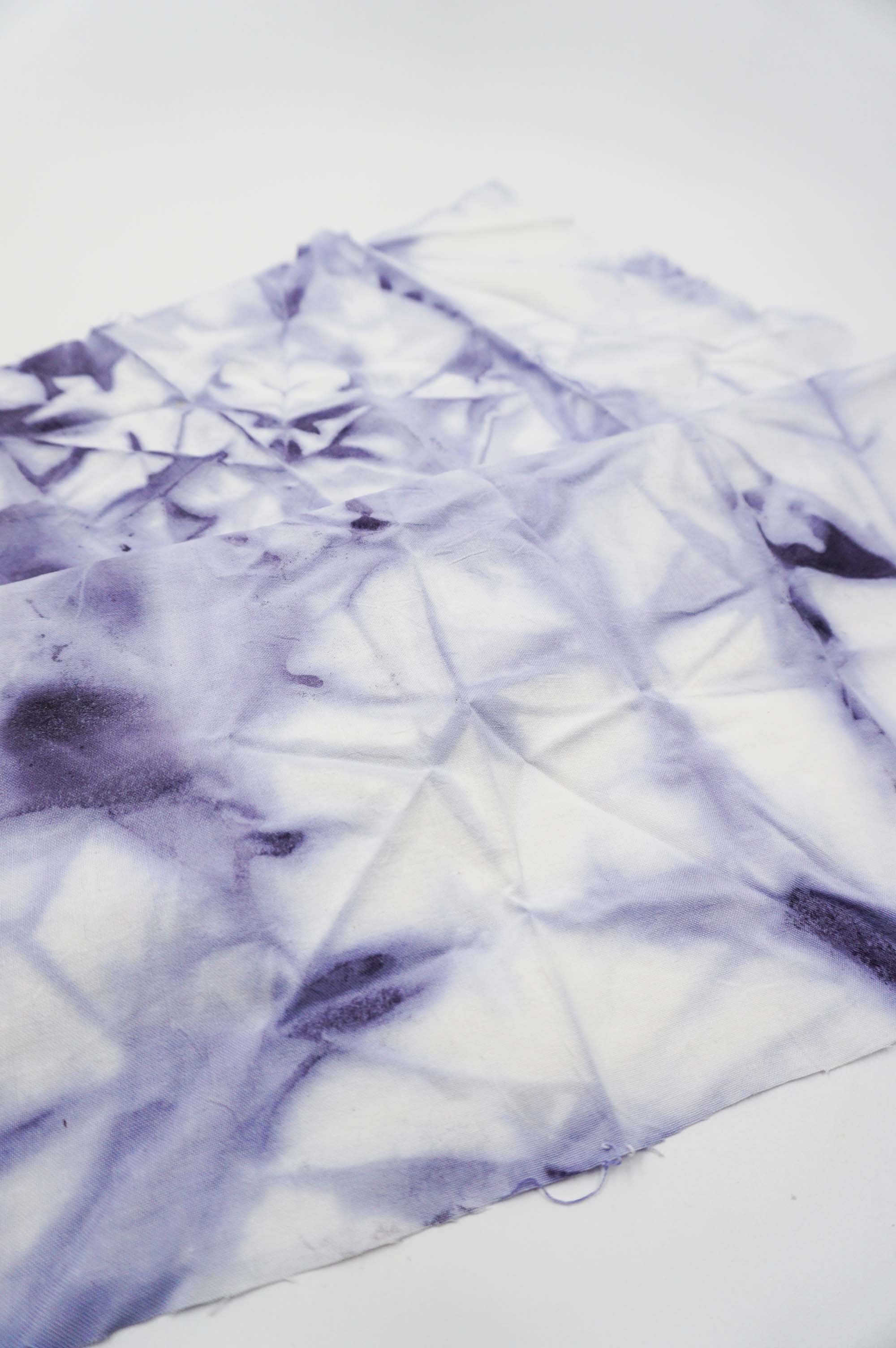

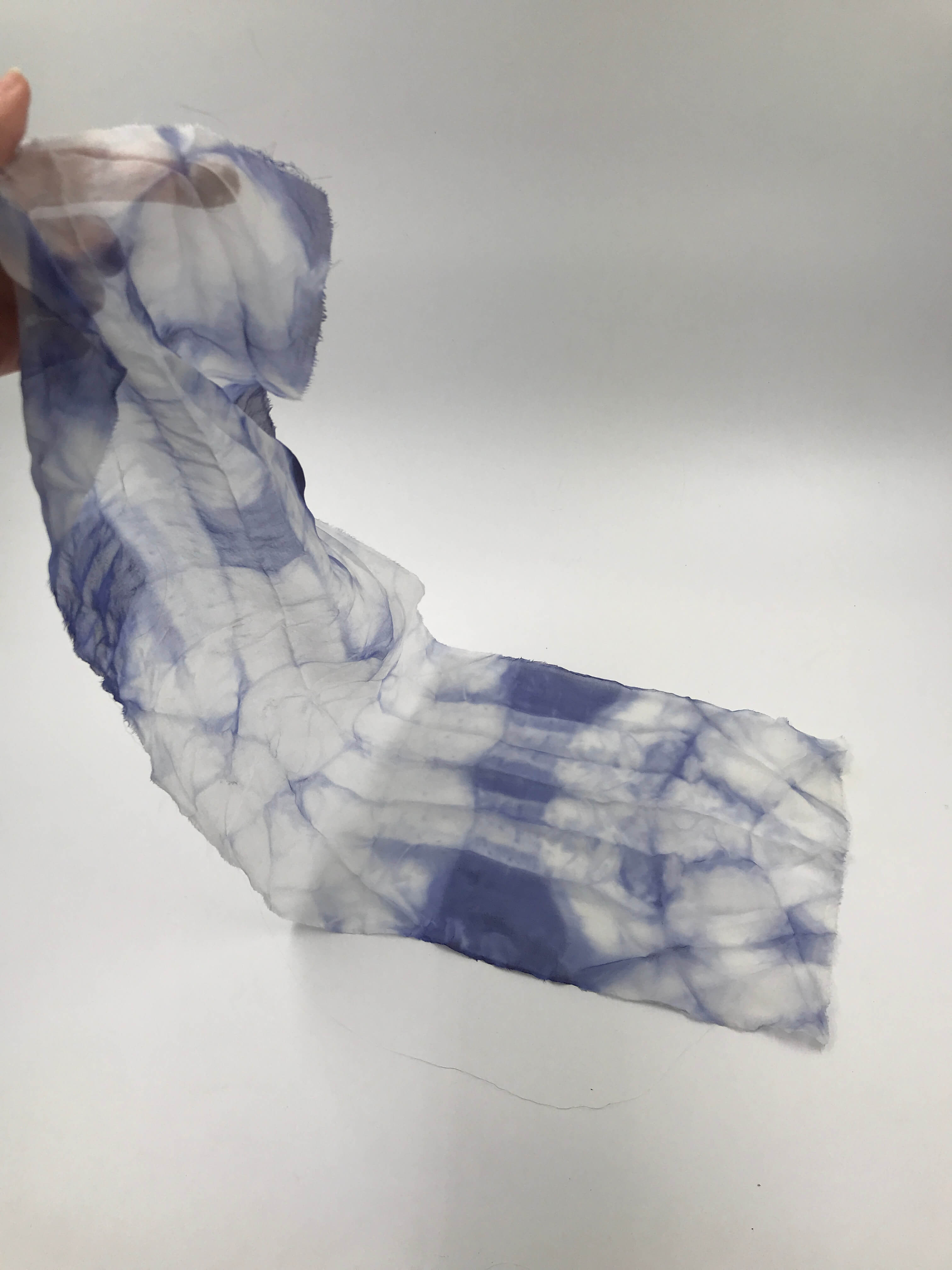

TEST 01 - SILK¶

| Material name | Fabric composition | Breathability | Moisture-wicking abilities | Heat retention abilities | Stretchability | Washing temperatures |

|---|---|---|---|---|---|---|

| Silk | Animal fibers - silkworm insect | Highly breathable | High | Low | Low | Cool or warm |

RESULTS¶

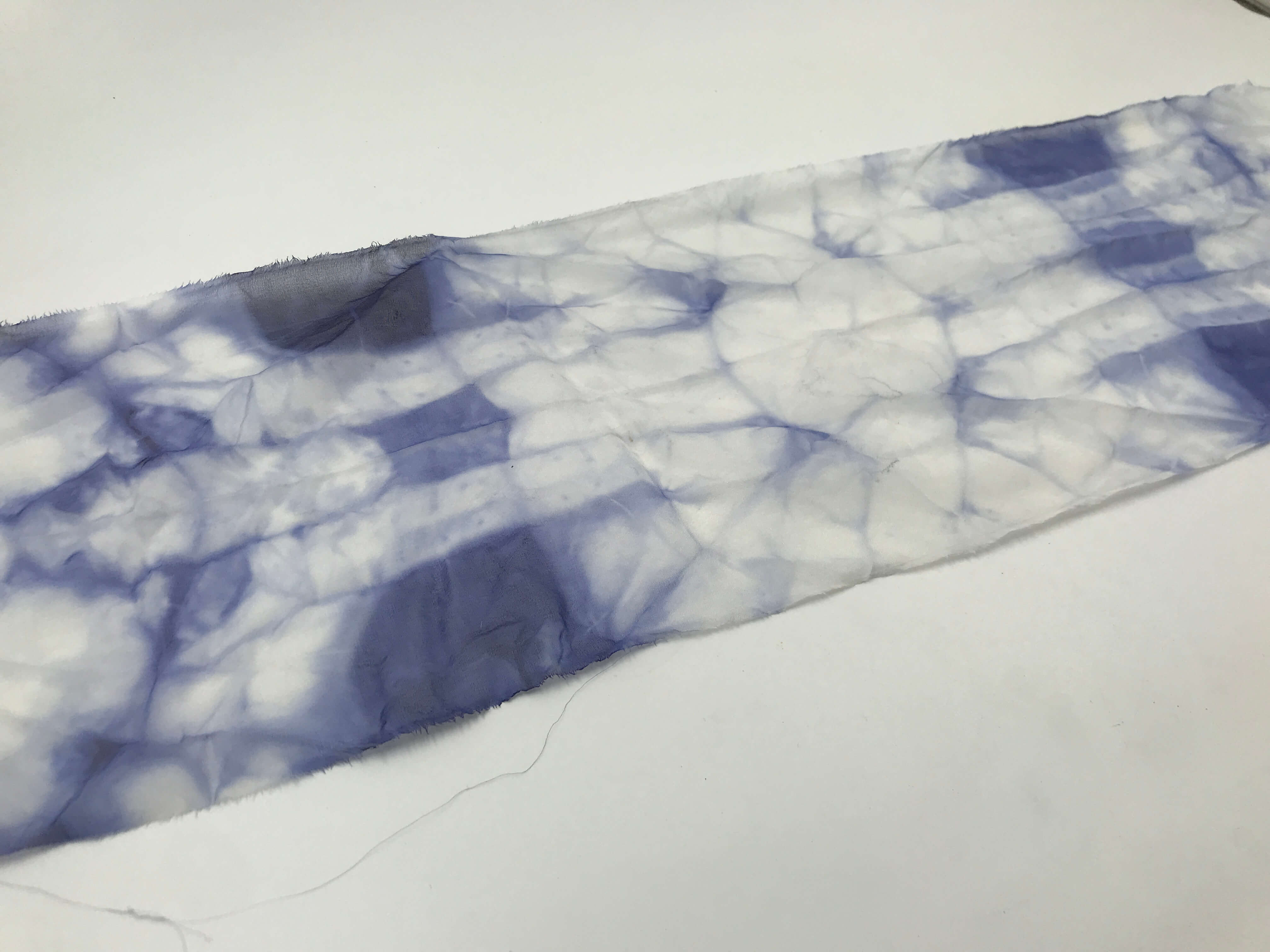

TEST 01 - WOOL¶

| Material name | Fabric composition | Breathability | Moisture-wicking abilities | Heat retention abilities | Stretchability | Washing temperatures |

|---|---|---|---|---|---|---|

| Felted wool | Hair animmal fibers | Moderately breathable | High | High | Medium | Cool or warm |

RESULTS¶

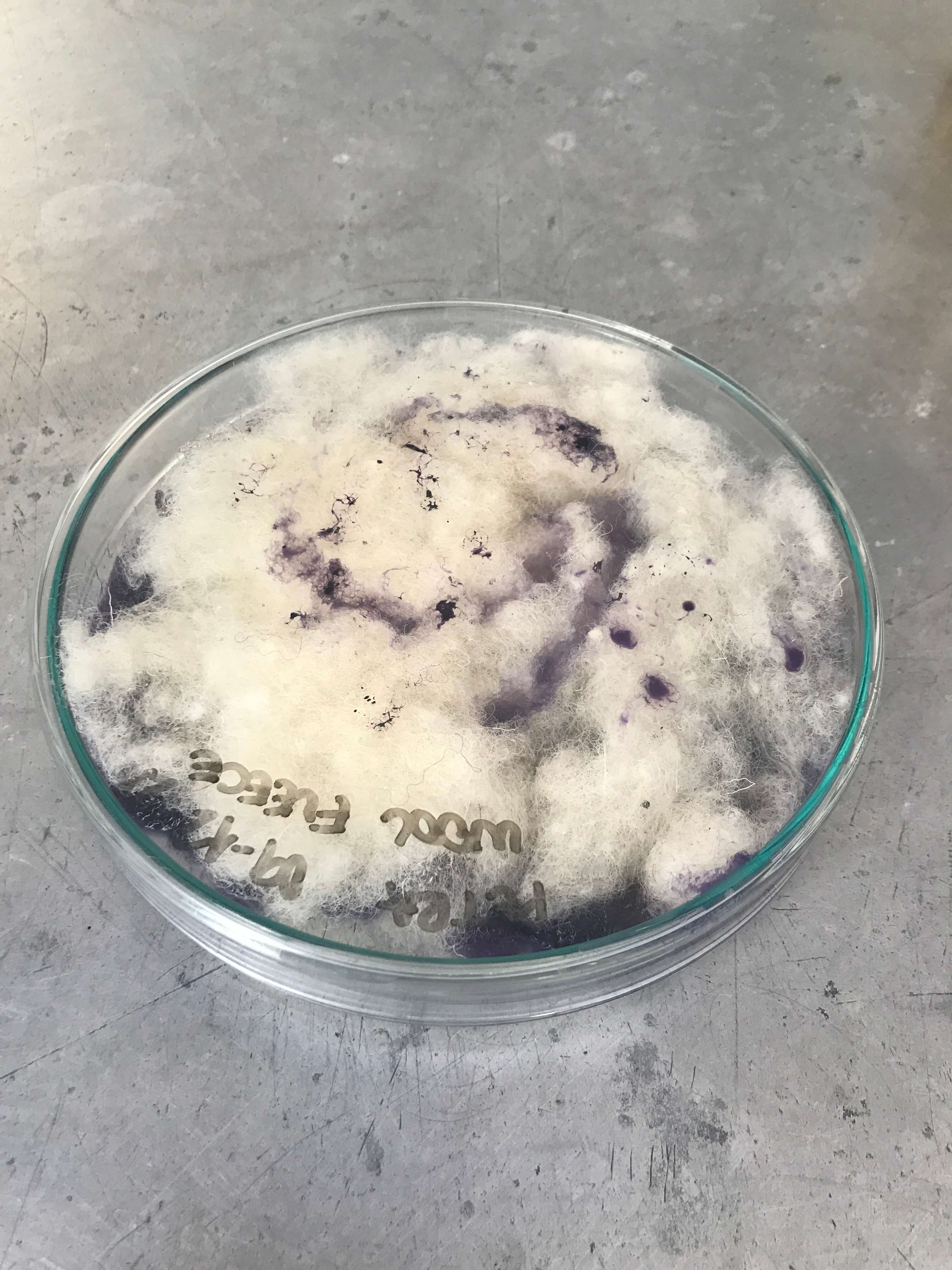

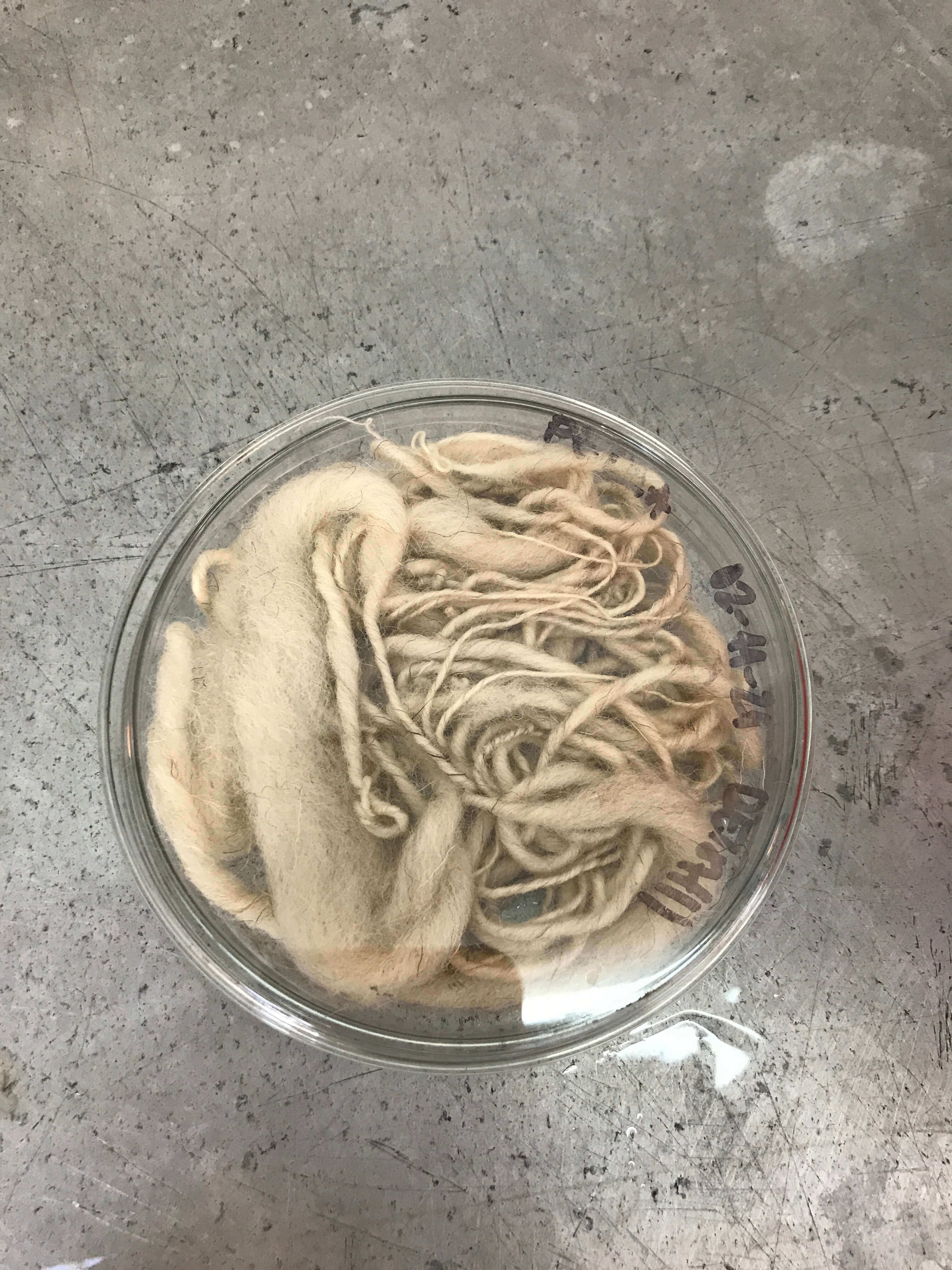

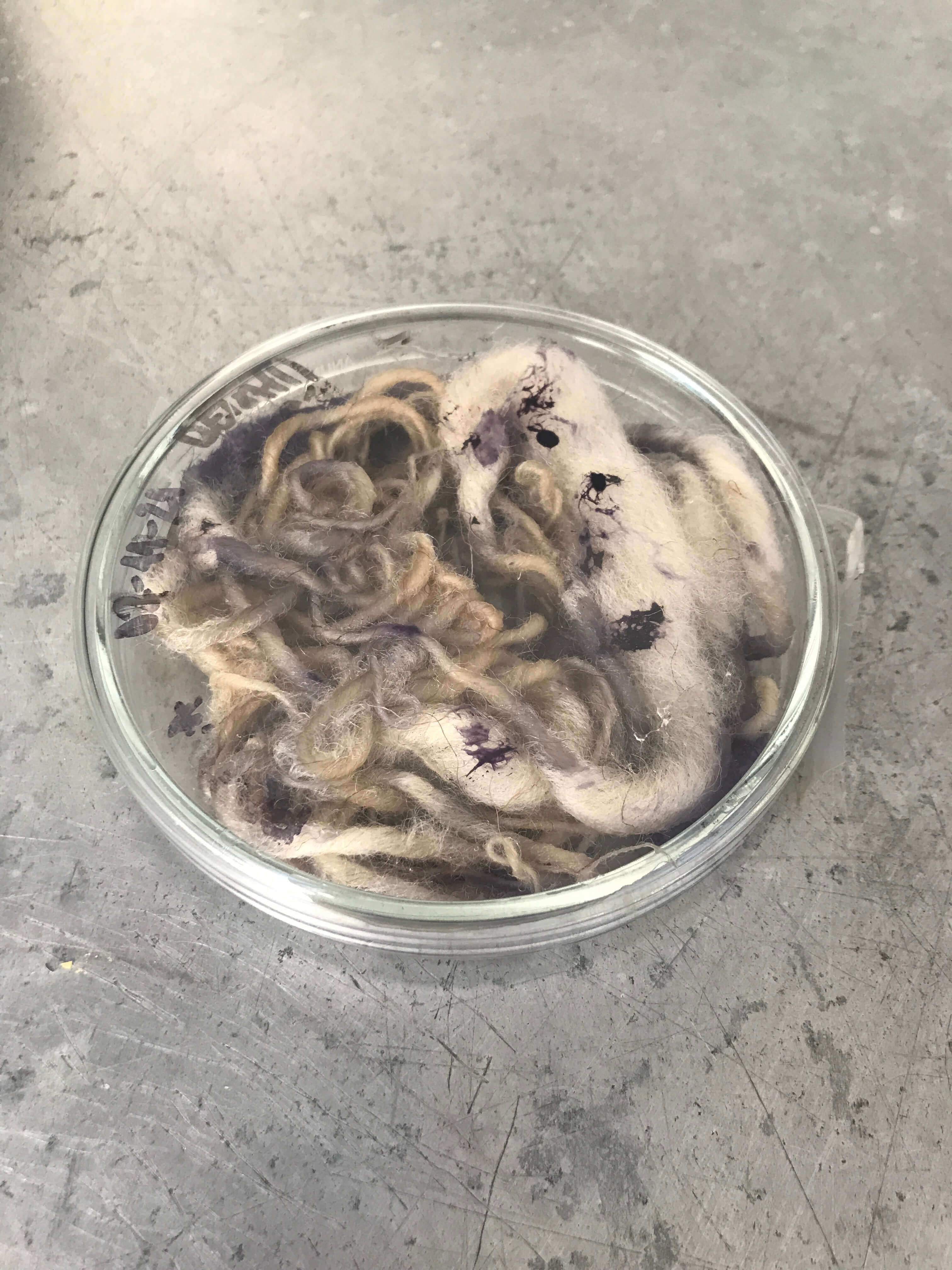

TEST 02 - WOOL¶

| Material name | Fabric composition | Breathability | Moisture-wicking abilities | Heat retention abilities | Stretchability | Washing temperatures |

|---|---|---|---|---|---|---|

| Wool fleece | Hair animmal fibers | Moderately breathable | High | High | Medium | Cool or warm |

PROCESS¶

RESULT¶

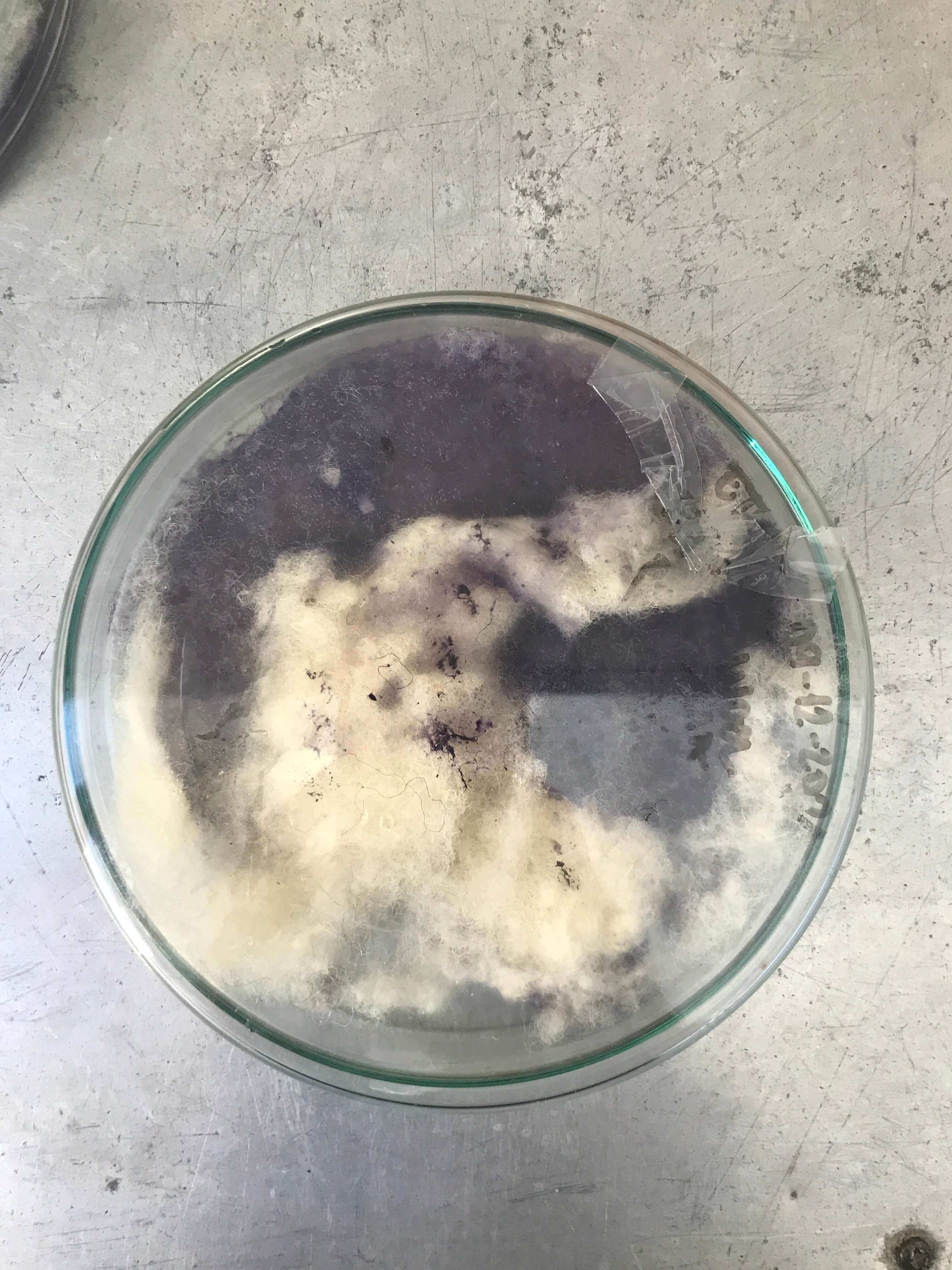

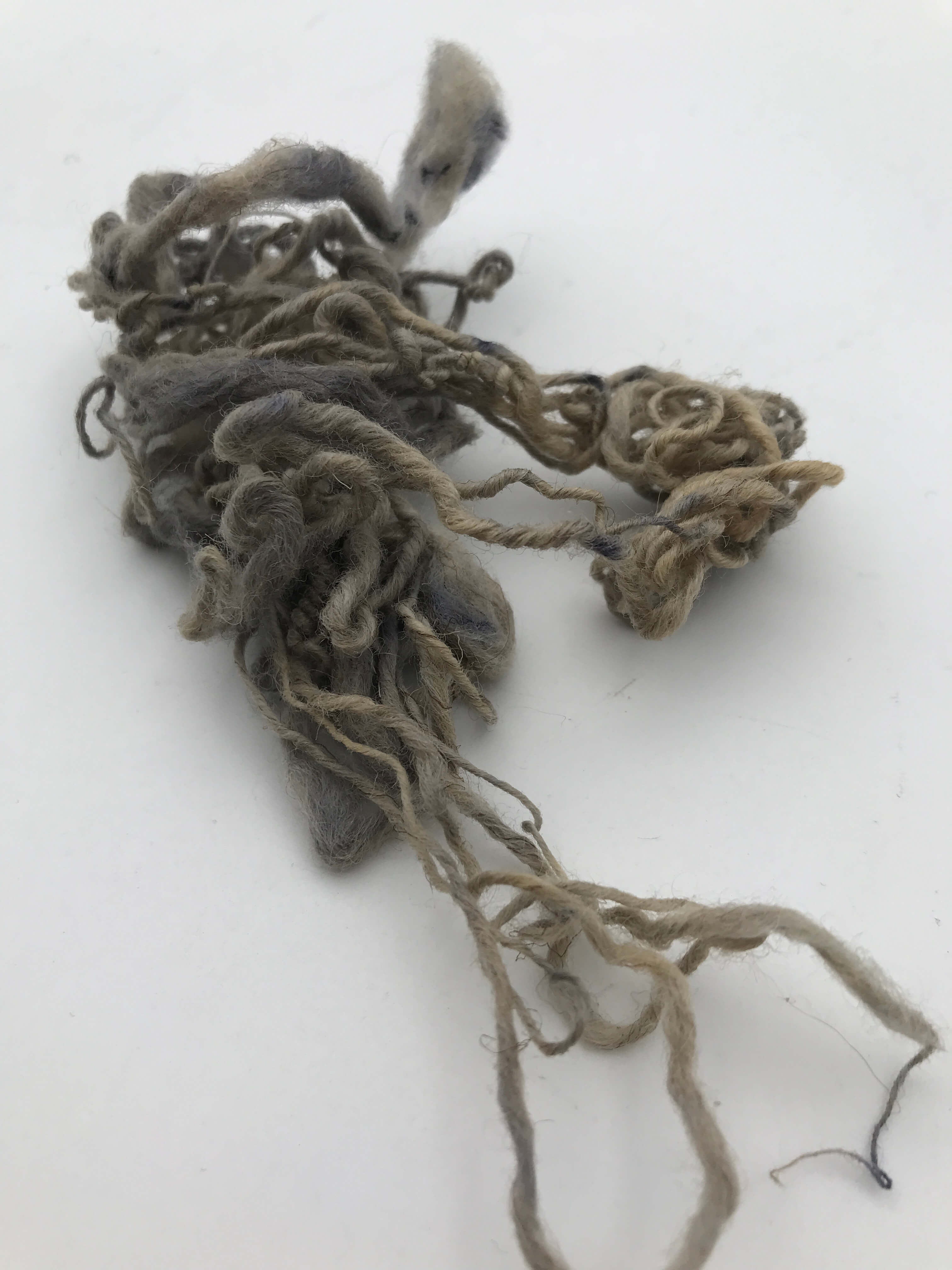

TEST 03 - WOOL¶

| Material name | Fabric composition | Breathability | Moisture-wicking abilities | Heat retention abilities | Stretchability | Washing temperatures |

|---|---|---|---|---|---|---|

| Wool threads | Hair animmal fibers | Moderately breathable | High | High | Medium | Cool or warm |

PROCESS¶

RESULTS¶

REFERENCES¶

Last update: 2022-01-10