XI. | IMPLICATIONS AND APPLICATIONS¶

| MATERIAL SCIENCE & RESEARCH |¶

| ANIMAL PROTEIN FIBERS |¶

FEATHERS, HAIR, WOOL

| LIFE CYCLE OF MATERIALS |¶

- TEXTILE INDUSTRY

- CONSTRUCTION MATERIALS

- FOOD MASS PRODUCTION

| MATERIAL SCIENCE |¶

IDEAS¶

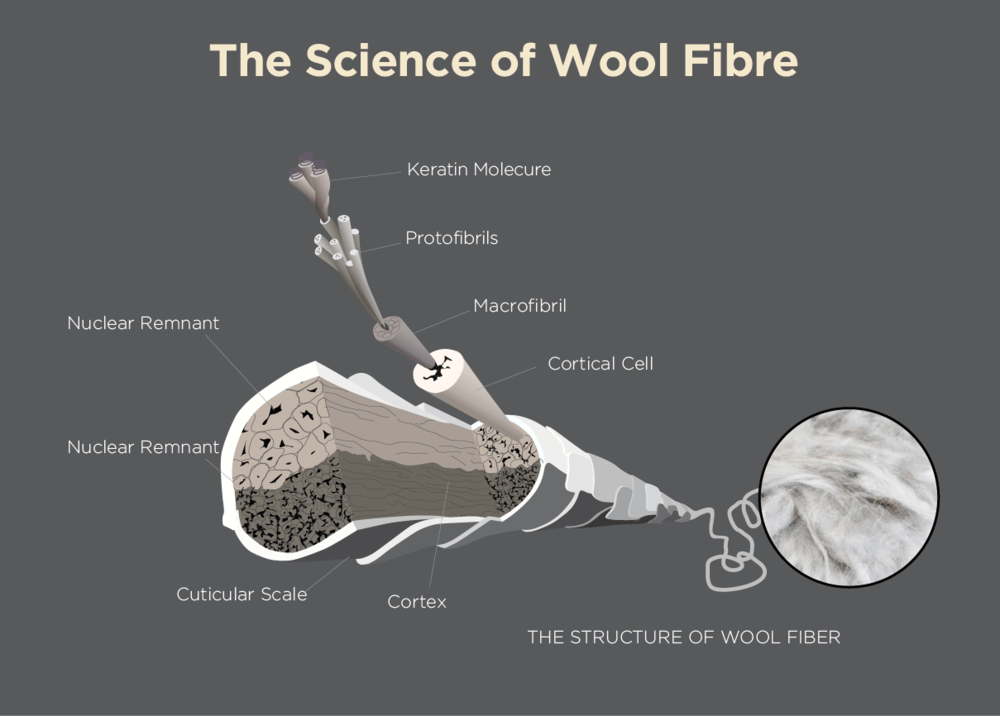

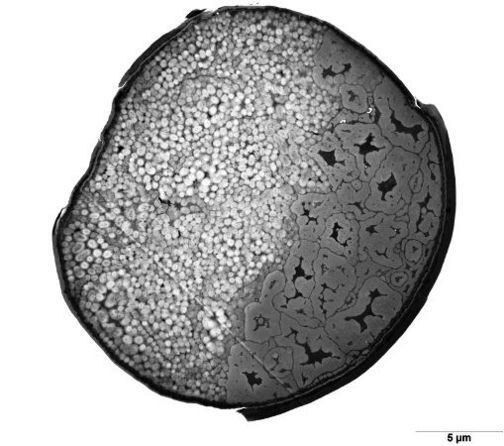

KERATIN¶

Extraction for biopolymer application - ionic liquids.

LIVING materials¶

MOTH¶

Moths need a source of keratin, which is a protein that’s present in organic fibers, and – you guessed it – human hair. Clothes moths are unique, because few species in the animal kingdom are able to digest keratin. Any substance containing keratin in your home will be a target for the clothes moth’s next meal.

WOOL YARN coated witth alginate¶

| KERATIN |¶

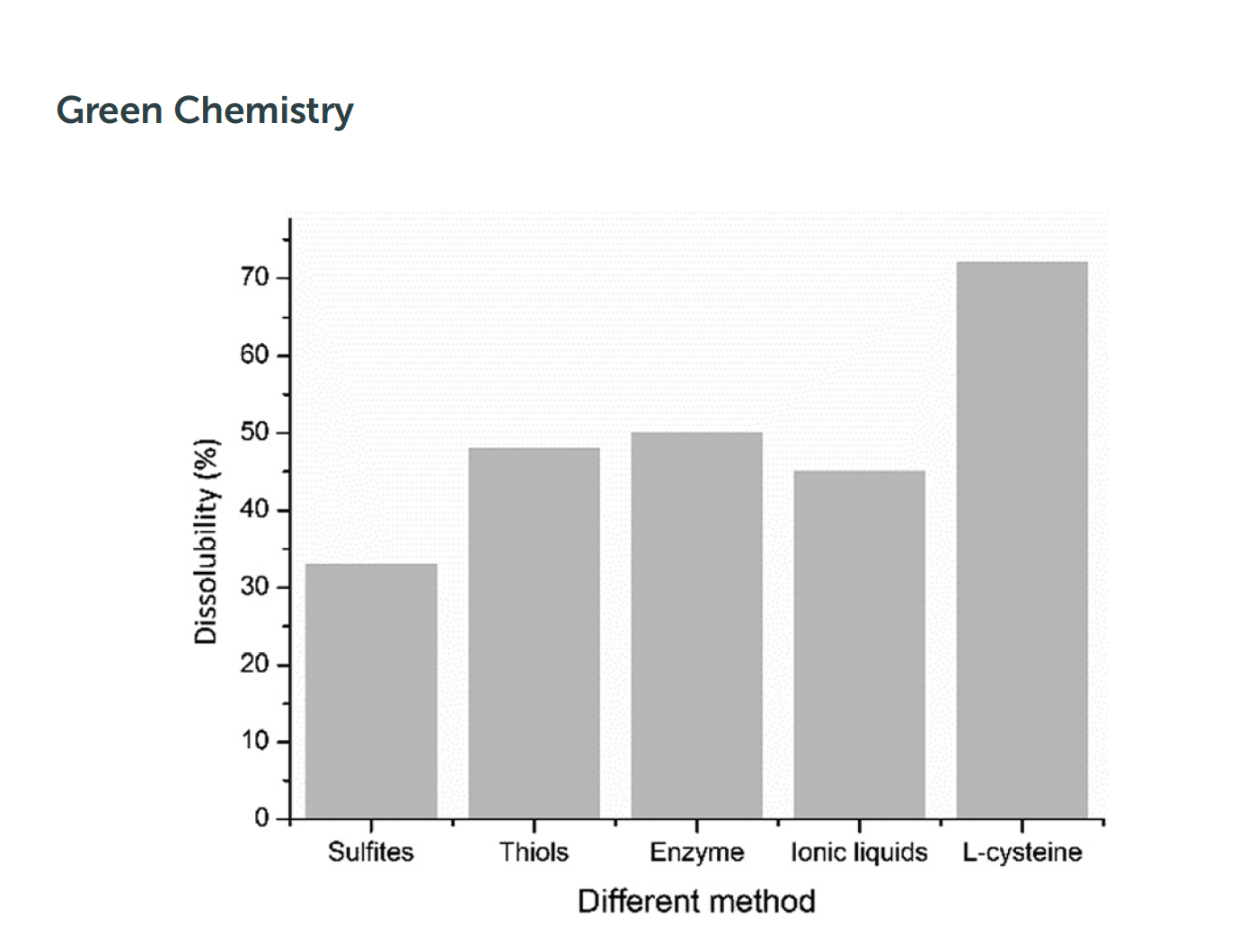

KERATIN EXTRACTION METHODS¶

- METHODS

- 1. CHEMICAL

- 1.1. REDUCTION

- 1.1.1. thiol containing chemicals (_a._ L-Cysteine)

- 1.1.2. sulfitolysis (_a._ sodium sulphite, _b._ bisulfite, _c._ disulfite)

- 1.2. OXIDINATION

- 1.2.1. Paracetic acid

- 1.2.2. Performic acid

- 1.3. HYDROLYSIS

- 1.3.1. Sodium hydroxide

- 1.4. IONIC LIQUIDS

- 2. MICROBIAL & ENZYMATIC

- 2.1. Gram negative bacteria (_a._ Stenorophmonas SP, _b._ Chryseobacterium SP, _c._ Vibrio SP)

- 2.2. Gram positive bacteria (_a._ Bacillus SP, _b._ Kocuria rosea)

- 2.3. Saprohytic and parasitic fungi

- 3. SUPERCRITICAL WATER AND STEAM EXPLOSION

- 4. MICROWAVE IRRADIATION

- SOURCE: Keratin: dissolution, extraction and biomedical application, Amin Shavandi, Tiago H. Silva, Adnan A. Bekhit and Alaa El-Din A. Bekhit, 2017, DOI: 10.1039/c7bm00411g, rsc.li/biomaterials-science

REDUCTION¶

- is using reducing agents as thiols

- has been the most reported technique to break the cystine disulfide bonds

- disadvantages of being expensive and can be toxic and harmful

- Sulfitolysis - sodium sulfide - 1. sulfitolysis step, 2. cysteine-sulfonate - both require the use of large amounts of urea as a protein denaturant, which can change the physicochemical properties of the final keratin.

OXIDATION¶

- with oxidizing materials such as formic or peracetic acids being the most frequently used acids to form a sulfonic acid

- a time-consuming process with more than 24 h

HYDROLYSIS¶

- Alkali extraction - requires amounts of alkaline chemicals for hydrolysis and acids for neutralization

- the primary chain of keratin is damaged

IONIC LIQUIDS¶

-

New green solvents - this process needs to be carried out under nitrogen, requires a precise temperature control, the raw material needs to be added in small portions to the hot liquid, and the obtained keratin is not water soluble.

-

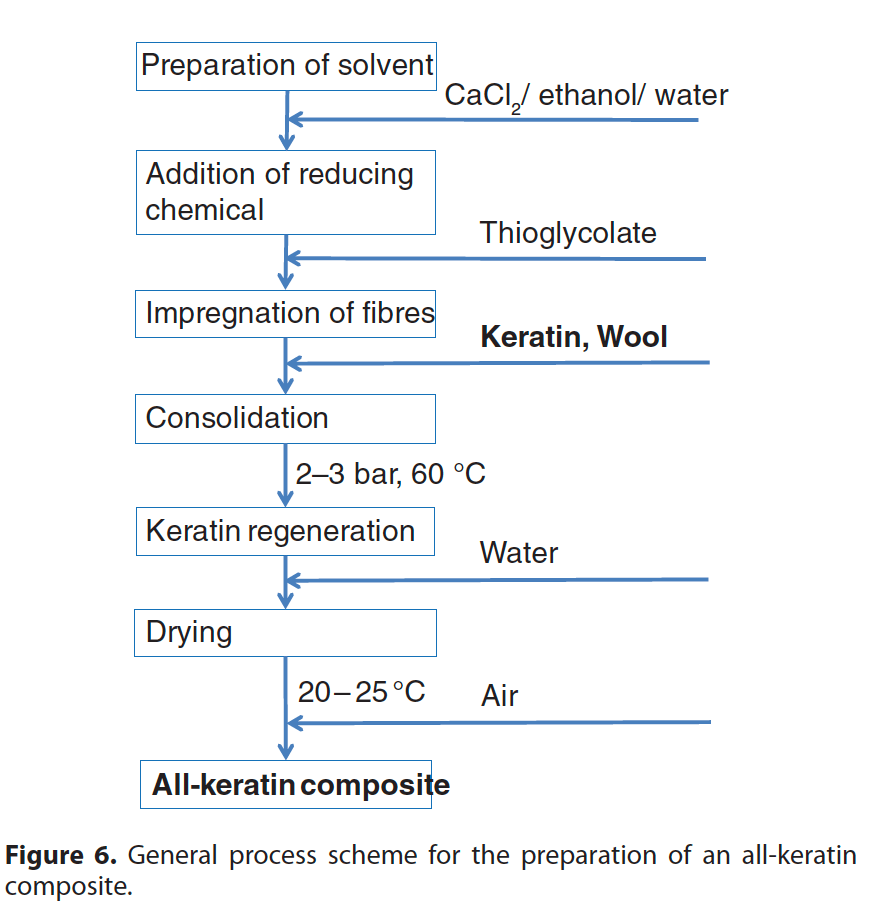

Process:

-

SOURCE: A second life for low-grade wool through formation of all-keratin composites in cystine reducing calcium chloride–water–ethanol solution, Christa Fitz-Binder, Tung Pham and Thomas Bechtold, 2019, DOI 10.1002/jctb.6151, wileyonlinelibrary.com

L-CYSTEINE¶

- L-Cysteine is an α-amino acid with the chemical formula HOOCCH(NH2)CH2SH. Due to the ability of thiols to undergo redox reactions, we used L-cysteine as a substitute for 2-mercaptoethanol which is a benchmark for extracting keratin because of good yield and undamaged keratin, but causes environmental harmfulness.

- SOURCE: Extracting keratin from wool by using L-cysteine, K. Wang,a R. Li, J. H. Ma, Y. K. Jiana and J. N. Cheb, 2015, DOI: 10.1039/c5gc01254f, www.rsc.org/greenchem

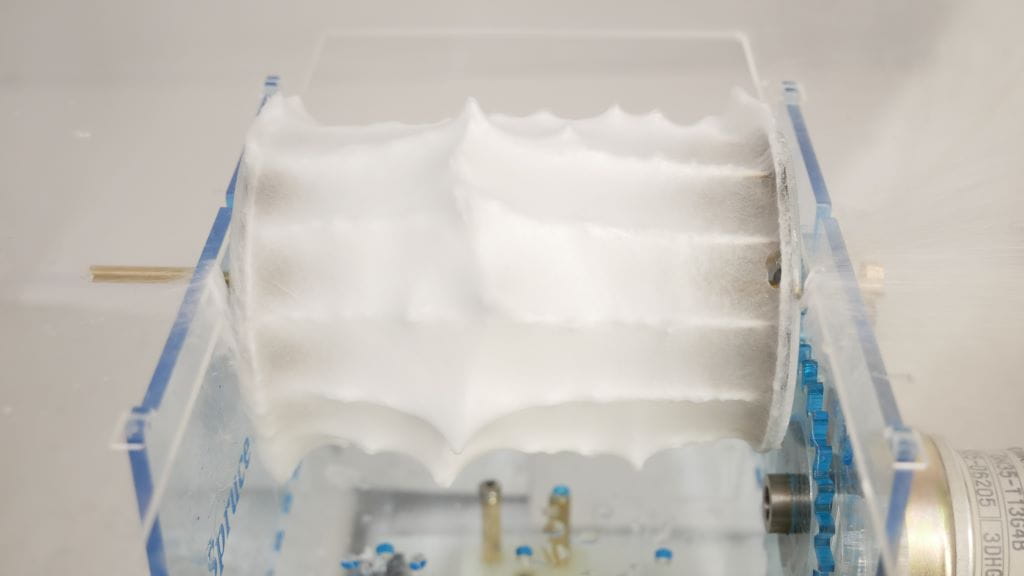

| TECHNOLOGIES |¶

- Digital fabrication

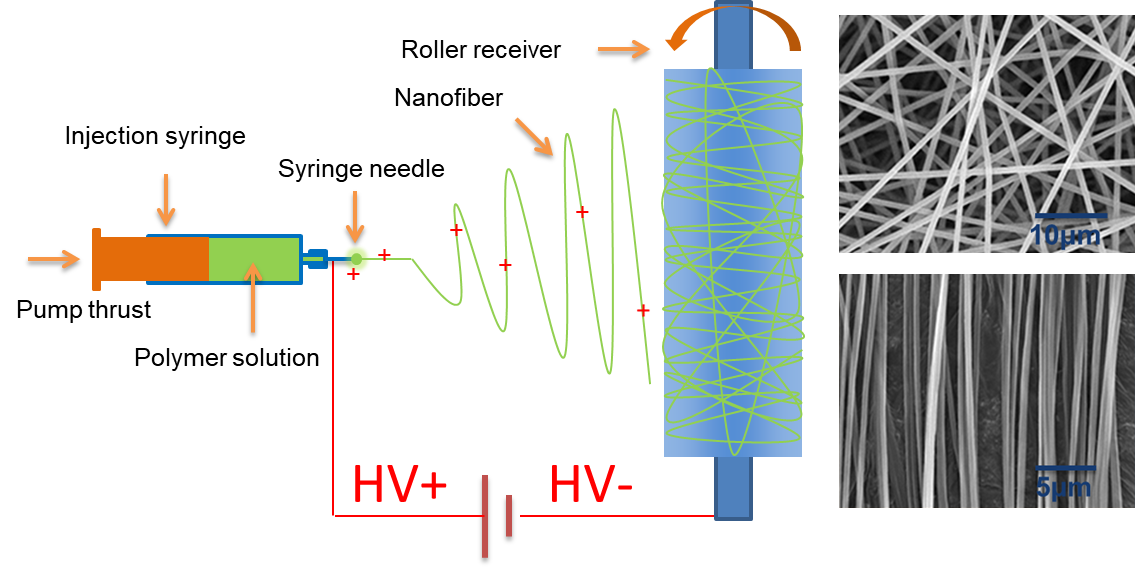

- Electro-spinning machine

Bio-3D printing¶

REFERENCE¶

Electro-spinning machine¶

REFERENCE¶

- Electrospinning Machine 30kV

- Electrospinning for nanofibers production, 2016

- DIY Polymer Melt Electrospinning with Hot Glue

| APPLICATIONS OF KERATIN |¶

- Hydrogels

- ... add more Petra

| TARGET |¶

- Local farmers

- Research centers

- Biotechnology