VII. | COMPUTATIONAL COUTURE¶

| MOODBOARD |¶

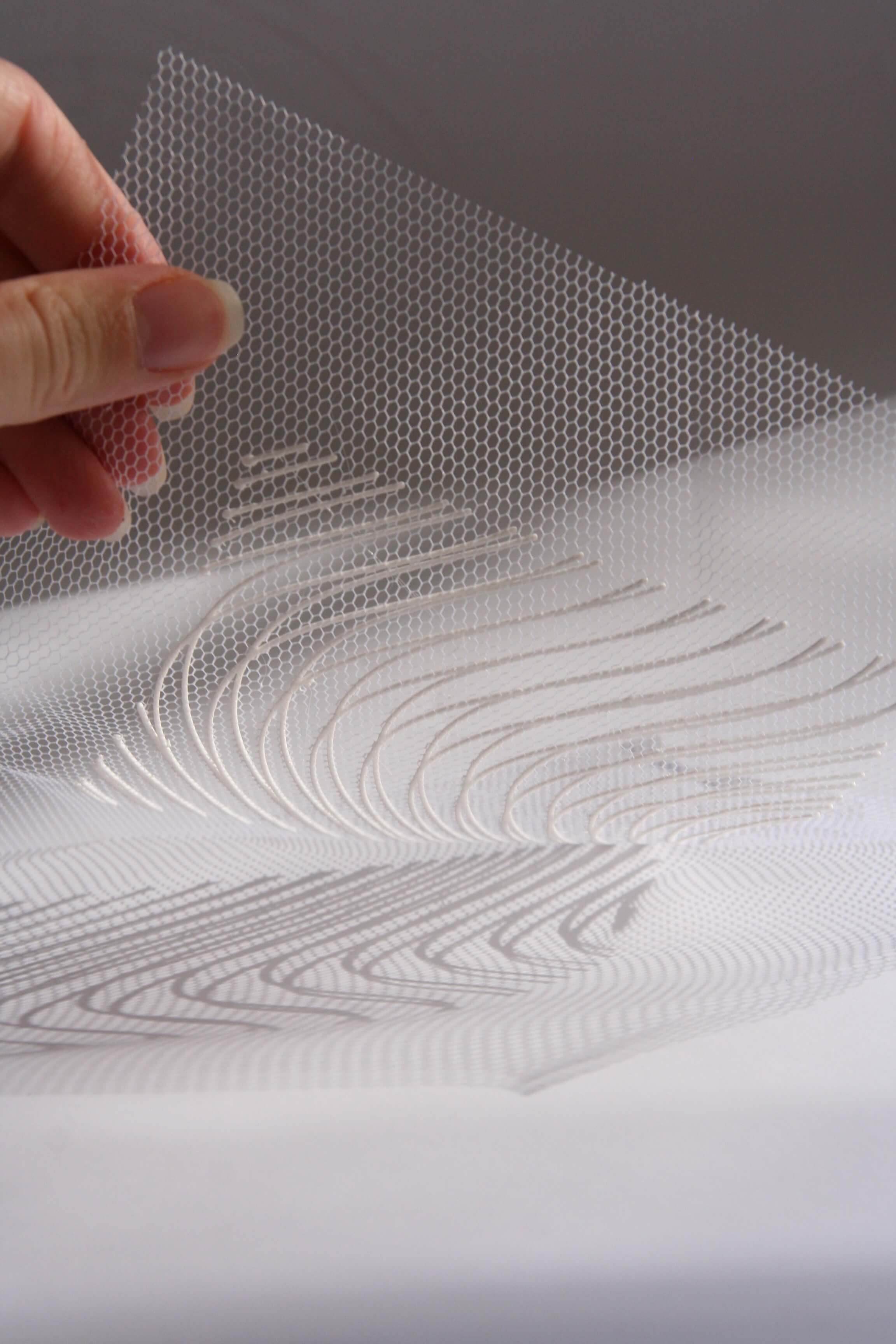

How to socialize technology? How we can define intimacy using digital tools? We use digital fabrication to create inovative textiles, computational design to optimize utilization of material, or pattern developement and custamization. However, we are only talking about physical parametres. On the other hand, we can think about the creation itself. It is not a typical fabric or pattern, it gives us a completely different feeling or visual of the garment than we know them. We consider them as wearable objects with different properties and interpretations. We are not able to look at them according to known fashion rules. intimacy a close association with or detailed knowledge or deep understanding of a place, subject or period intimacy an act or expression serving as a token of familiarity, affection

REFERENCES - Inspiration¶

| COMPUTATIONAL DESIGN |¶

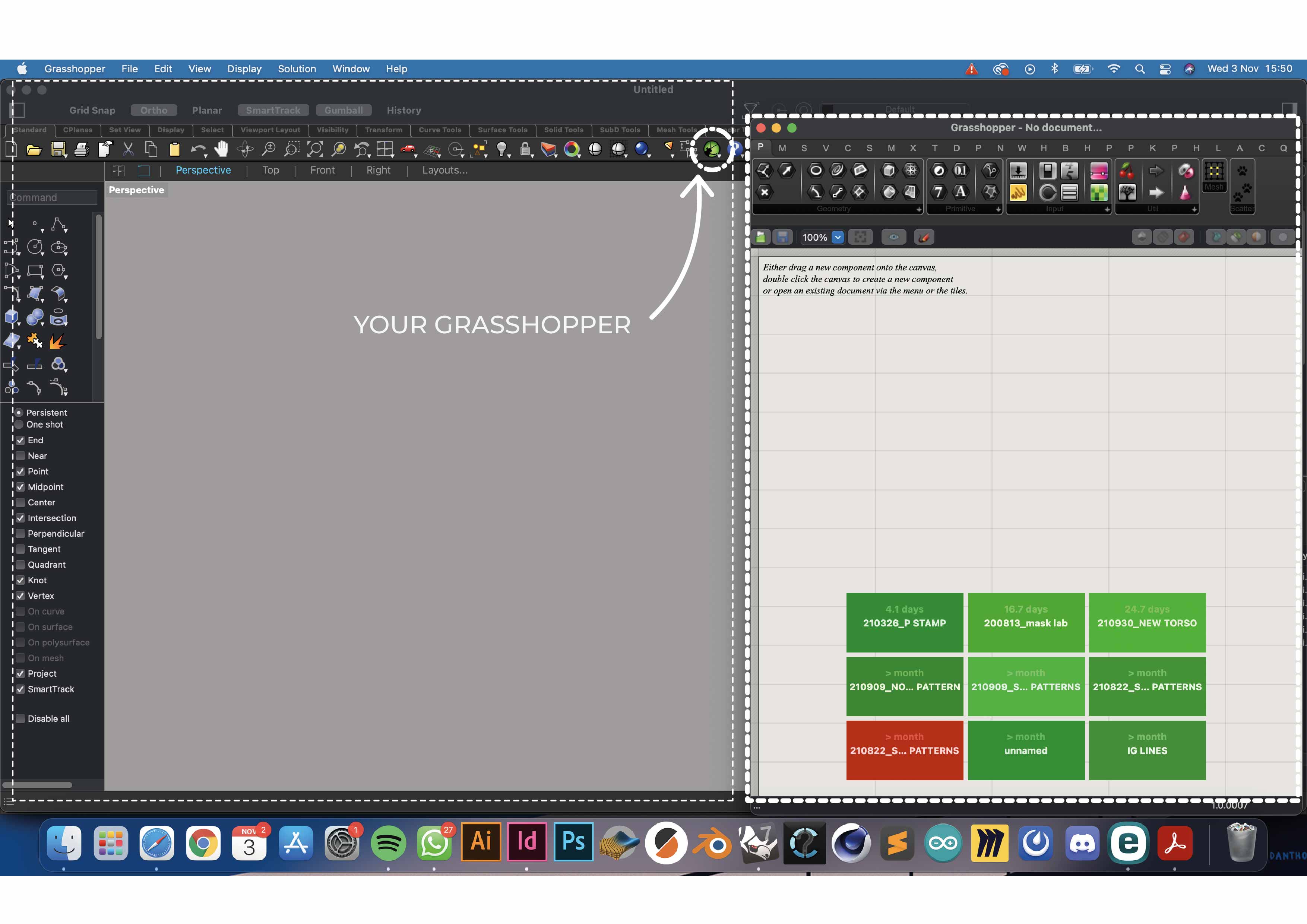

Language of Grasshopper¶

- algorithmic modeling for Rhino

-

Grasshopper is primarily used to build generative algorithms, such as for generative art. Many of Grasshopper's components create 3D geometry. Advanced uses of Grasshopper include parametric modelling for structural engineering, parametric modelling for architecture and fabrication, lighting performance analysis and building energy consumption.

-

Your grasshopper is already hidden in Rhino 07. You can open it through the green icon (pic. below) or you can just write it down in the command line of Rhino (Grasshopper - press Enter).

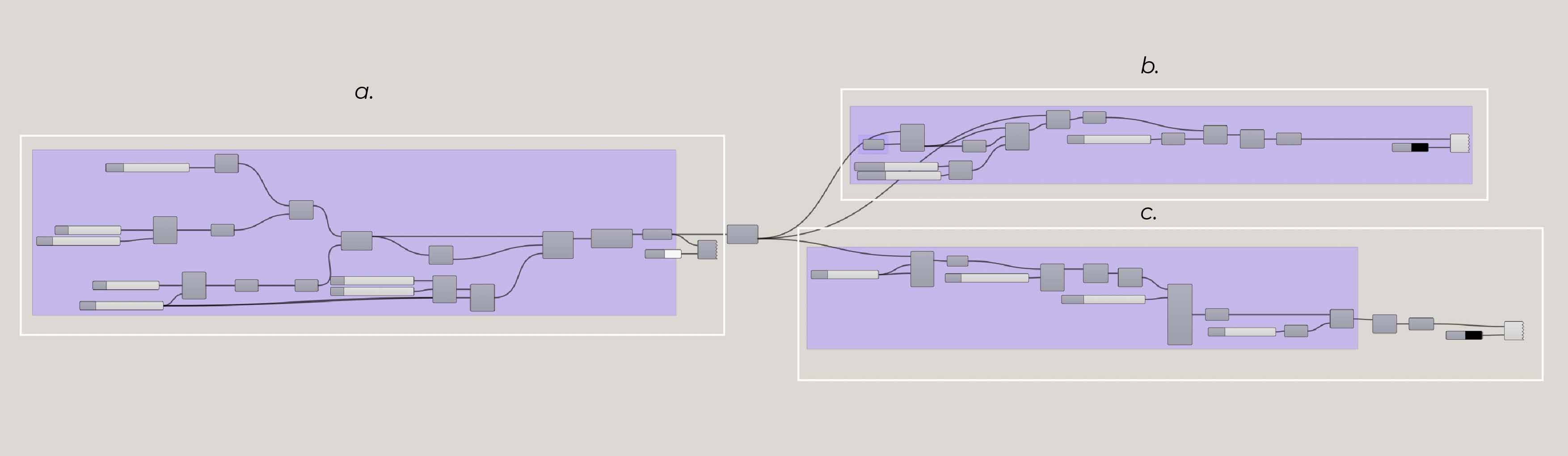

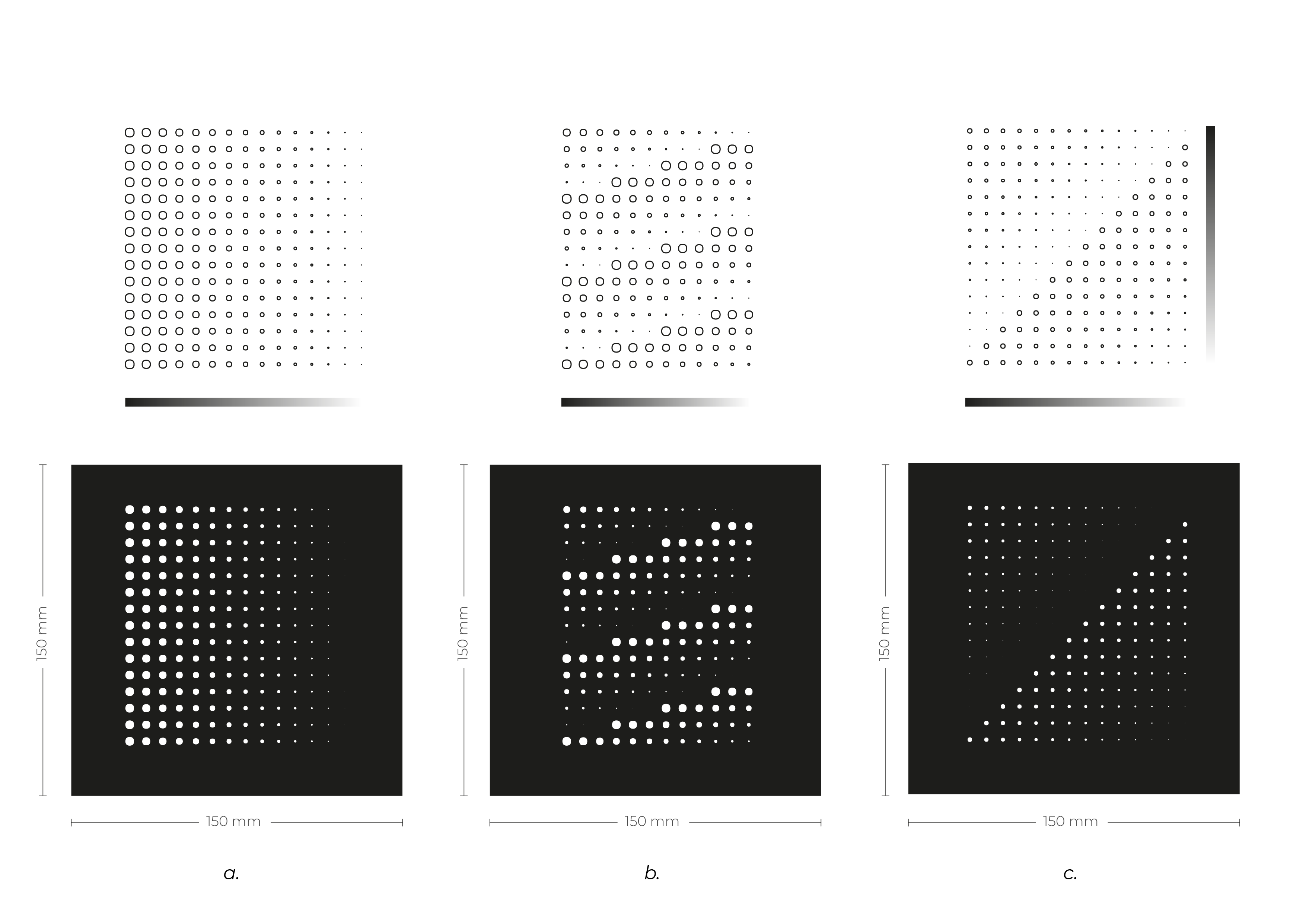

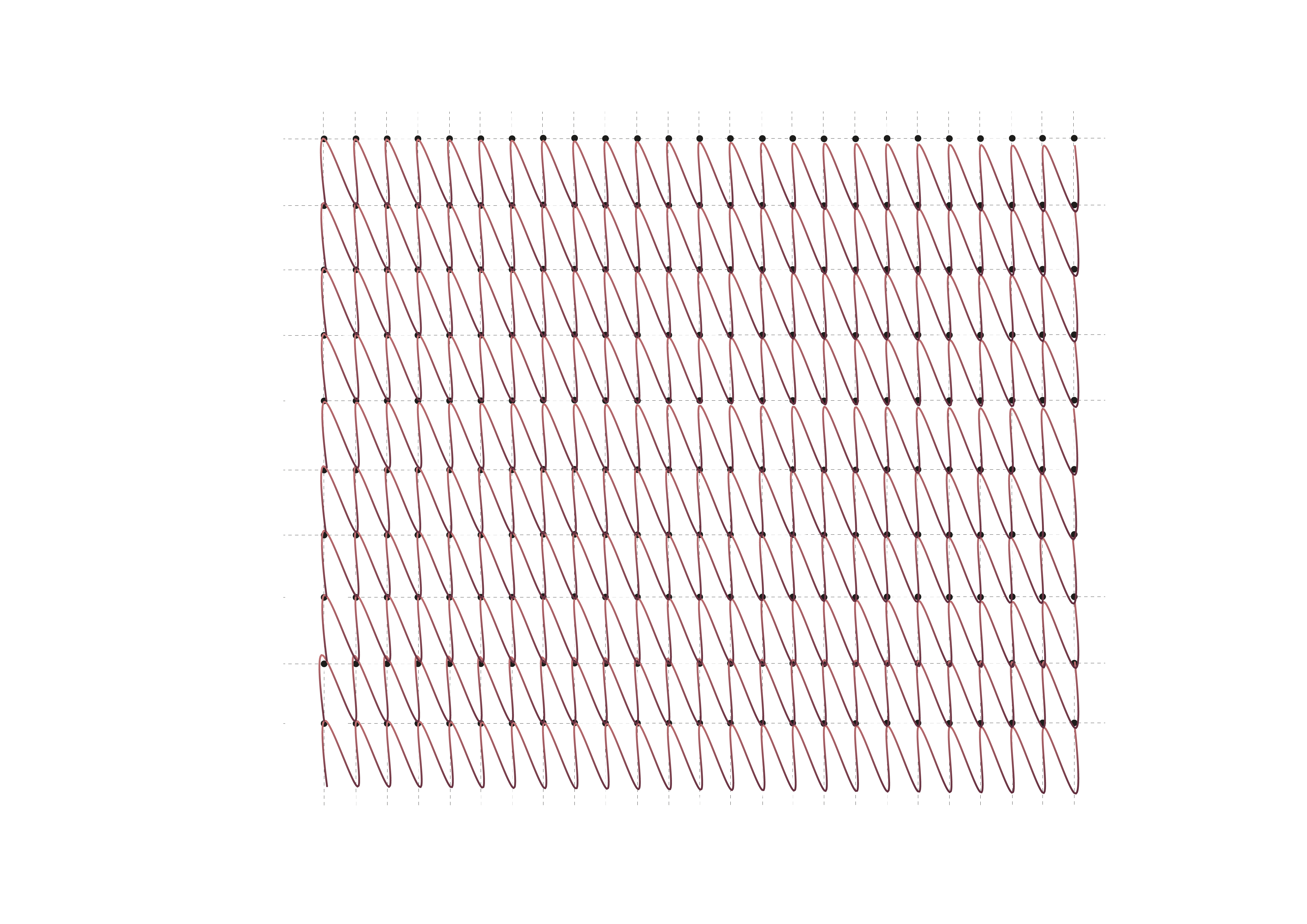

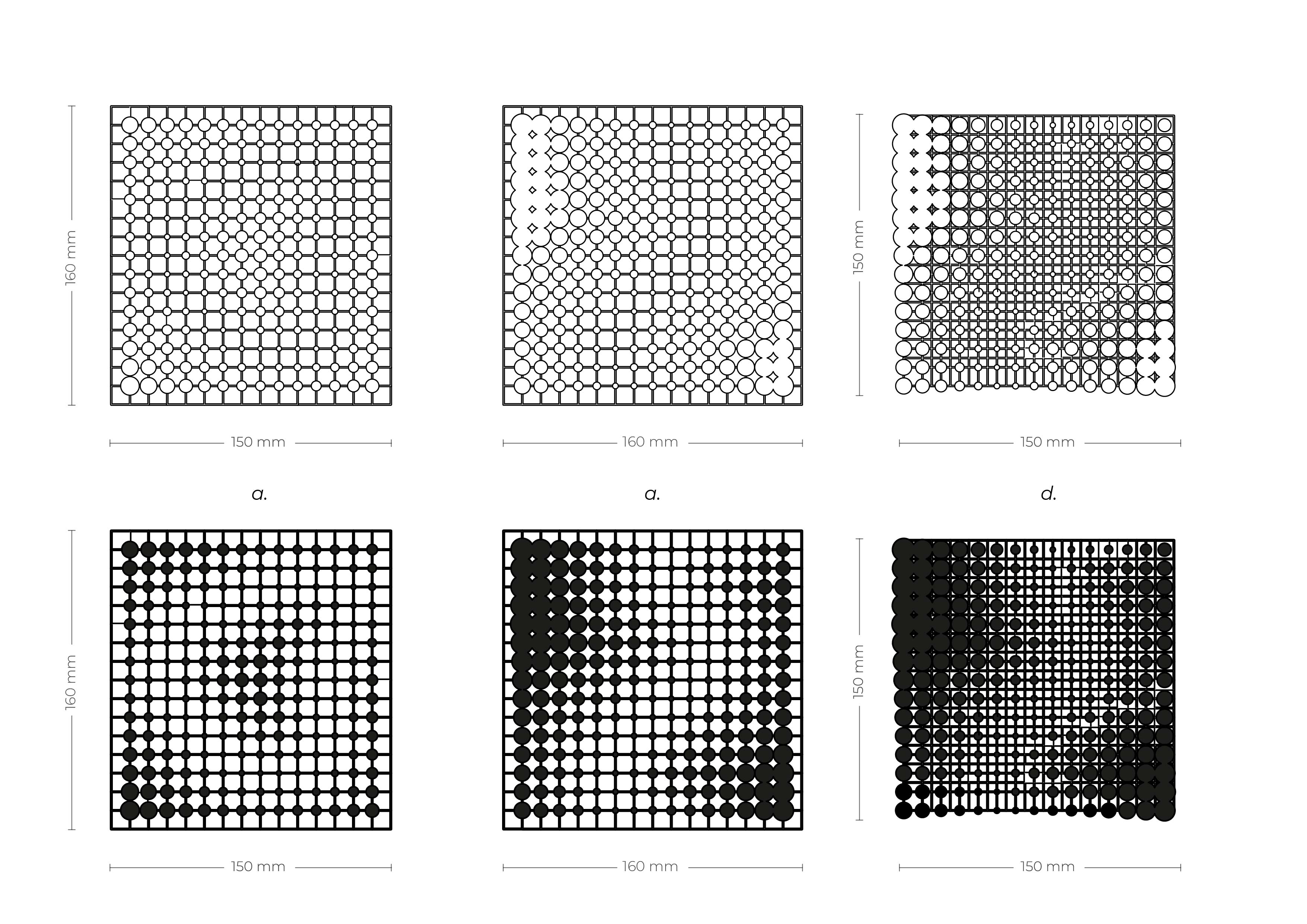

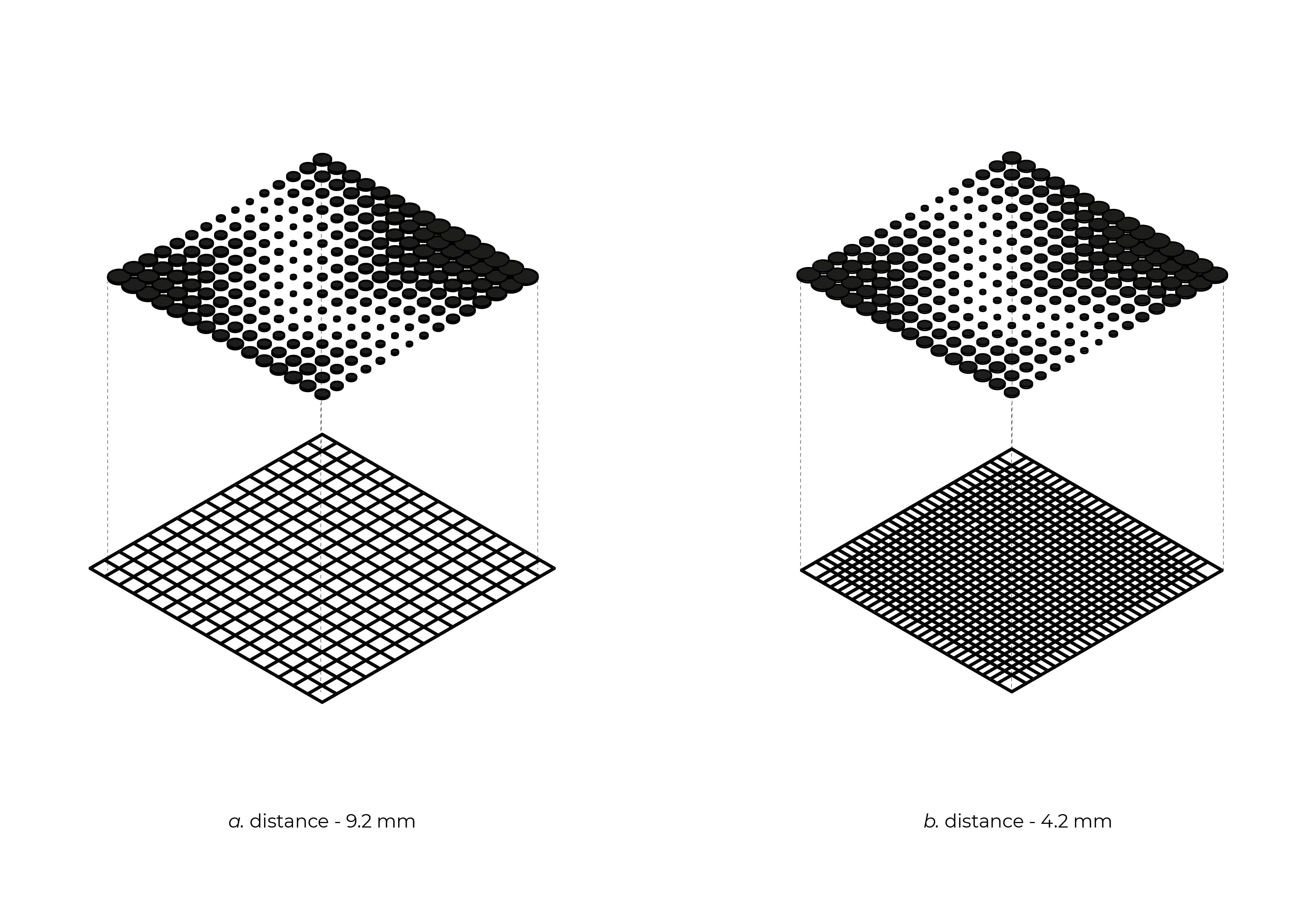

- a. - a series of points created a grid where each point is the center of a circle. Then each area of the circle is predefined with new data numbers and modified - scaled.

- b. - the offset of the cicles is modified by the attractor points of the curve and extruted into the mesh (0.9 mm high)

- c. - creating a square grid as a basis for 3D printing (0.6 mm high)

- All GH plugins and libraries you can find here Food for Rhino

REFERENCES - Tutorials¶

| DIGITAL FABRICATION |¶

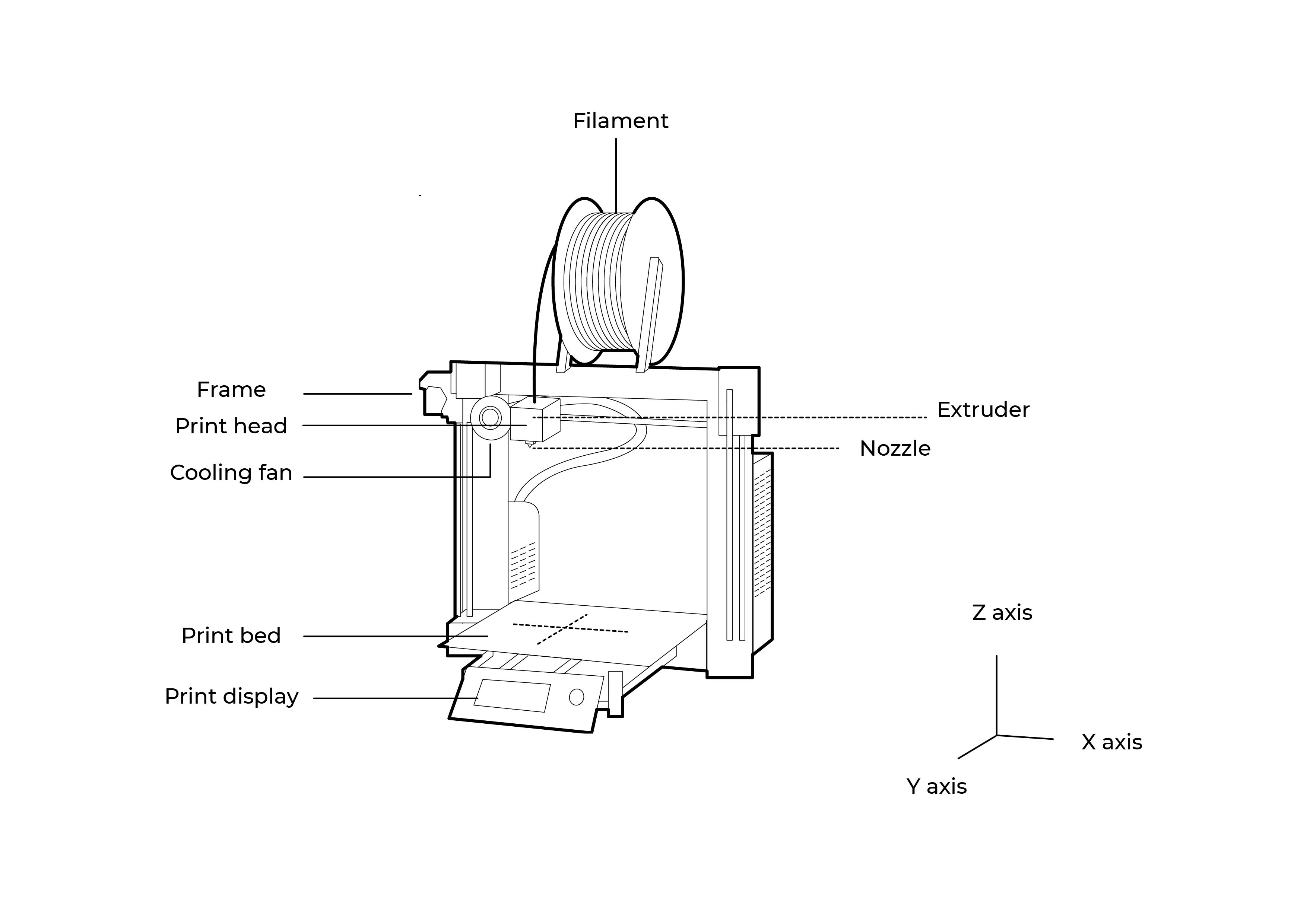

3D PRINTING¶

3D PRINTER DIAGRAM¶

3D PRINTERS¶

-

Desktop 3D printing

Home users with small, affordable and easy-to-use 3D printers.

-

Industrial 3D printing

Professional 3D printing is the industrial-grade counterpart to consumer 3D printing.

MATERIAL - FILAMENTS¶

3D PRINTERS - BRANDS¶

SOFTWARES¶

3D PRINTING ONTO TEXTILES¶

TEXTILES¶

Polyester mesh fabrics¶

- Common uses: Athletic jerseys, athletic shorts, lingerie, shapewear, workout apparel, screens for screen printing, net

It is commonly used for inserting side panels in athletic outfits. This kind of clothing is found to be breathable and can dry away moisture easily from the skin while the athlete is carrying different sports activities. This kind of fabric is also used by the clothing designers in the form cover to add dimension and texture to tricot and other flat weave materials. The delicate part of the body can be camouflaged by making use of two layers of this fabric of mesh.

| Material name | Fabric composition | Breathability | Moisture-wicking abilities | Heat retention abilities | Stretchability | Washing temperatures |

|---|---|---|---|---|---|---|

| Power mesh, tulle, powernet | Different synthetic fiber types | Very breathable | Medium | Low | High | Cold or hand wash |

-

Mesh netting fabrics

It is chiefly useful for the outfits that needs the body to be air dried quickly. This way it can protect the body and the material from bites of the insects. Also for the camping materials, equipment and gears this fabric is of use. Anything like totes and backpacks which require breathable material it can be used effectively.

-

Power mesh

This technology is helpful in making outfits designed to smoothen the body, such as long-line panties, long-line bras, control slips and control top panty hose. These are more often used for making undergarments for women, although shape-wear and abdomen reducing undershirt for men are also made up of this fabric. The main advantage of the fabric is that it allows the skin to breathe and helps body to preserve its shape. It offers more comfort compared to the fabric like spandex and other stretchable fabric. Also it comes in various vibrant colors like red, cream, black, white and pink.

-

Tulle

It is commonly used for manufacturing wedding veils. It is also used for wedding gowns, hats, evening gowns, lingerie’s and gifts as being a versatile fabric.

-

Nylon mesh

This is porous in nature hence used for making birdcage covers, laundry bas, camper’s camp and tents. Its long lasting even its worn and torn out a nylon mesh patch can be used to repair it.

Lycra¶

- Common uses: Underwear, socks, bras, sports bras, bike shorts, yoga pants, hiking apparel, motion capture suits

Lycra is a brand name for elastane, which is a highly elastic synthetic fabric. Despite having different names, Lycra, spandex, and elastane are all the same material, and these fabrics can stretch to 5-8 times their usual size. Lycra fabric is a polymer, which means that it is composed of long chains of monomers that are connected with a special type of acid. Unlike many other types of synthetic fabrics, Lycra is highly resistant to heat, and it was quickly recognized as an excellent addition to heat-sensitive synthetics like polyester and nylon.

| Material name | Fabric composition | Breathability | Moisture-wicking abilities | Heat retention abilities | Stretchability | Washing temperatures |

|---|---|---|---|---|---|---|

| Spandex, elastane | Polyether-polyurea copolymer | High | High | Low | Extraordinarily high | Cold or hand wash |

FILAMENTS¶

TPU Filament¶

- Size: 1.75 mm or 2.85 mm

Thermoplastic Polyurethane (TPU) is one of the most popular flexible filaments on the market. Just like TPE, this is durable, flexible and strong like rubber.This is also resistant to abrasion, oil, greases, chemical, and wearing. It’s also resistant to low temperatures so it does not brittle and is not prone to warping

| Special properties | Impact strength | Durability | Flexibility | Chemical resistance | Water resistance | Nozzle/extruder | Heated bed |

|---|---|---|---|---|---|---|---|

| Extremely flexible, rubber-like | High | High | Very high | Medium high | High | Medium | 220-250º C |

PLA Filament¶

- Size: 1.75 mm or 2.85 mm

Polylactic Acid, commonly known as PLA, is one of the most popular materials used in desktop 3D printing. It is the default filament of choice for most extrusion-based 3D printers because it can be printed at a low temperature and does not require a heated bed.

| Special properties | Impact strength | Durability | Flexibility | Chemical resistance | Water resistance | Nozzle/extruder | Heated bed |

|---|---|---|---|---|---|---|---|

| Biodegradable | Medium | Medium | Low | Medium high | Low | High | 180-230º C |

TEXTILE CUSTOMIZATION¶

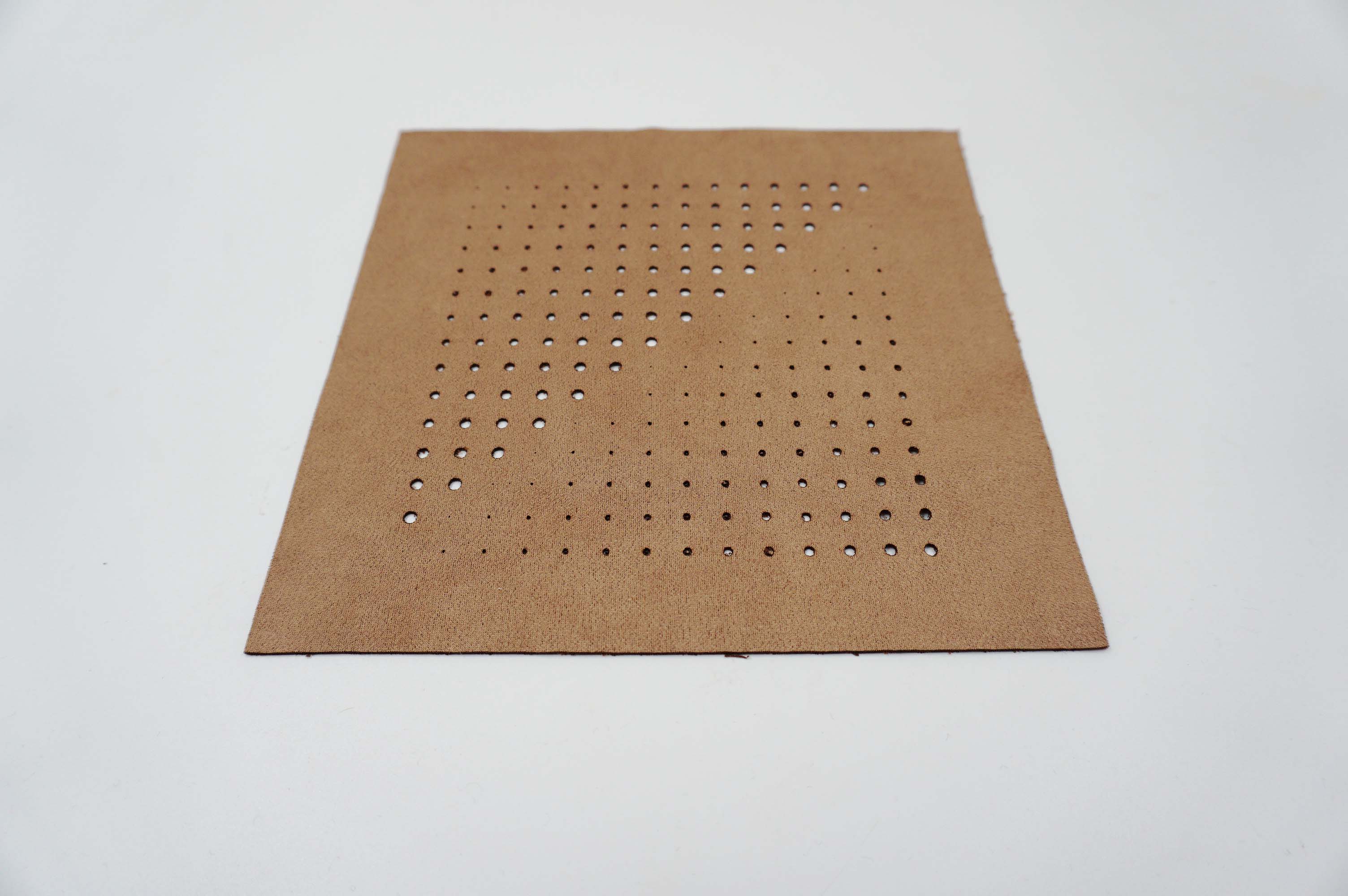

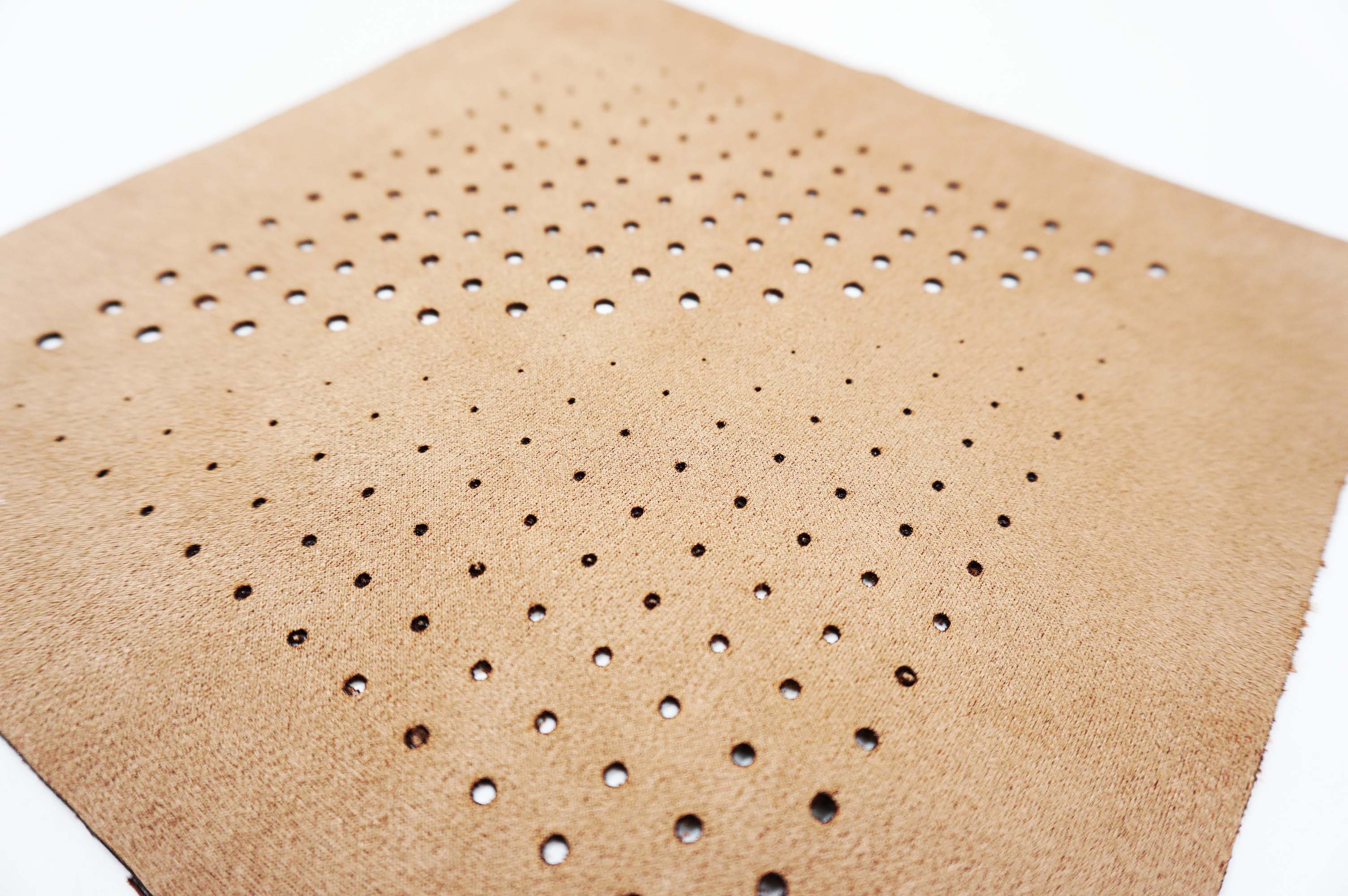

- Textile parameters - Scuba ante

- Common uses: Scuba gear, dresses, skirts, blouses, leggings, swim suits, laptop sleeves, seat covers, camera cases

Scuba fabric is a term that is commonly used to refer to Neoprene, which is a type of synthetic textile. This fabric was originally developed by the DuPont Corporation. Neoprene makes a total water barrier between the skin and the environment surrounding it. Neoprene isn't breathable at all.

PROPERTIES AND SETTINGS¶

Textile properties¶

| Material name | Fabric composition | Breathability | Moisture-wicking abilities | Heat retention abilities | Stretchability | Washing temperatures |

|---|---|---|---|---|---|---|

| Neoprene, polychloroprene, chloroprene rubber | Polyether-polyurea copolymer | Zero | None | High | High | Cold |

Material Parametres¶

| Material | Size | Thickness | Structural properties | Visual | Structure | Texture | Strengh | Weight |

|---|---|---|---|---|---|---|---|---|

| 5% Spandex, 95% Polyester | 150 x 150 mm | 1 mm | Flexible | Matt | Woven | Soft (top), Flexible (bottom) | High | 30 g |

Laser cutting settings¶

| Textile | Thickness | Speed | Power | Cutting time |

|---|---|---|---|---|

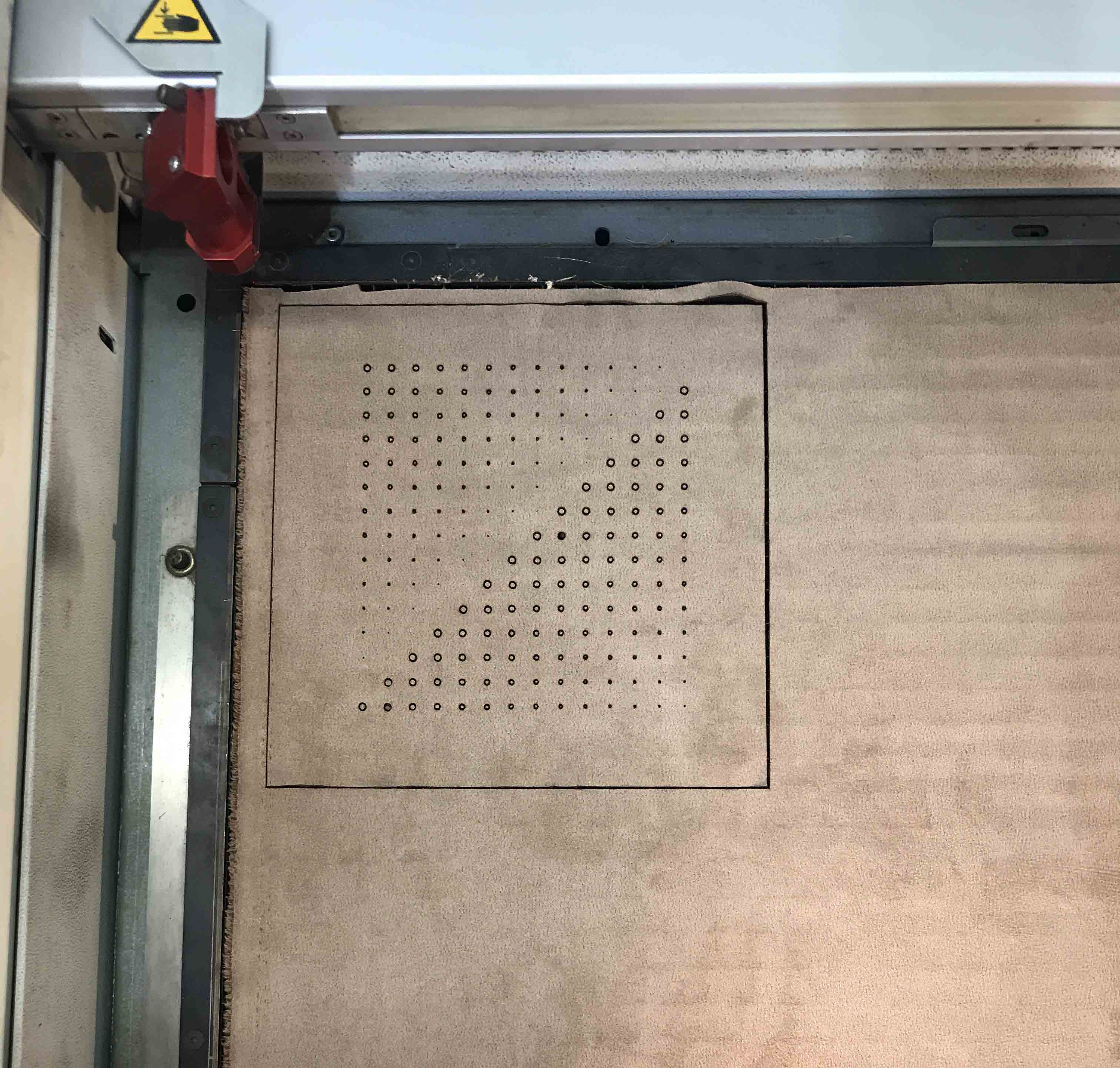

| Scuba ante | 1 mm | 1 | 20 | 4 min 10 s |

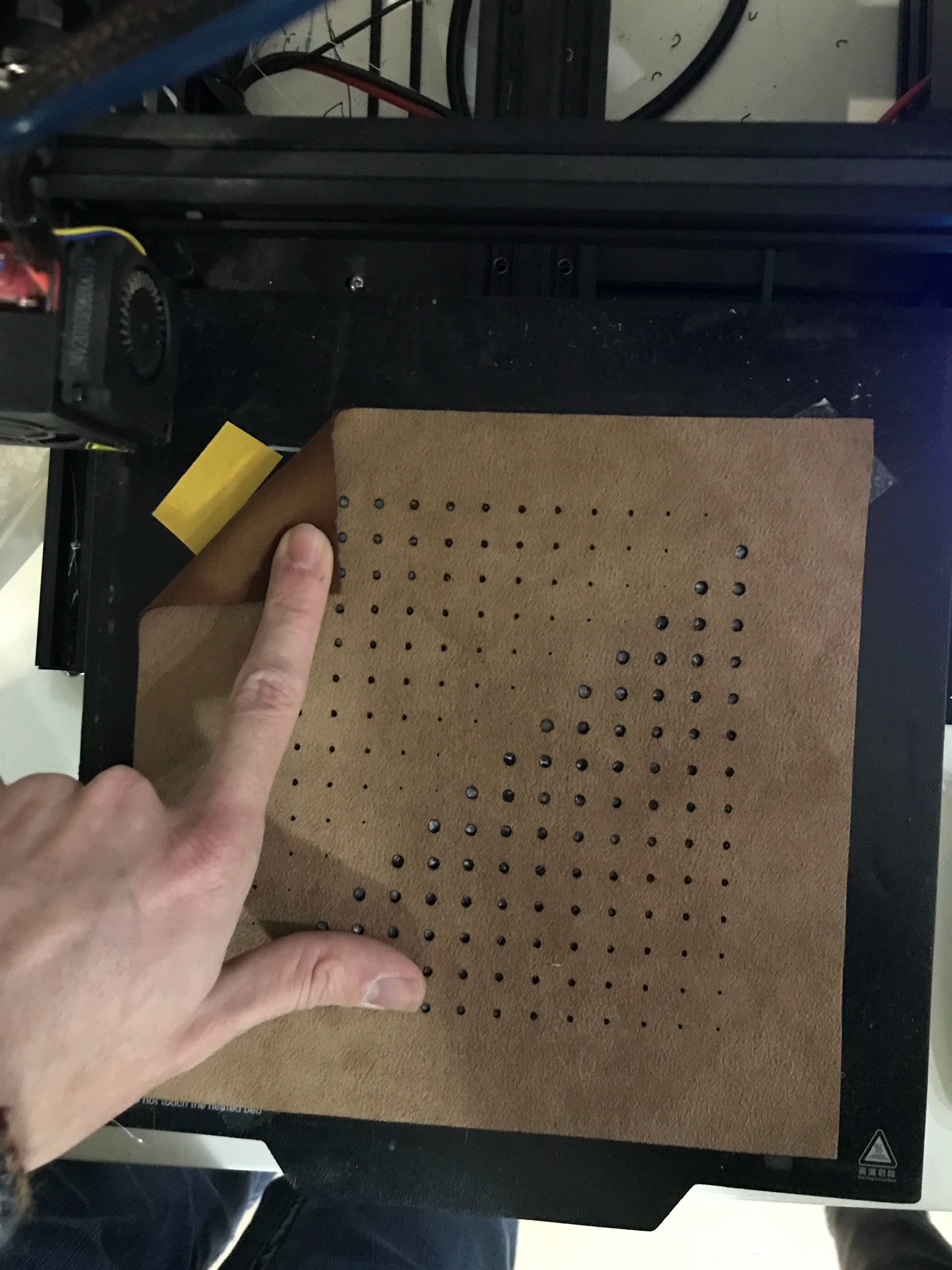

- c. textile prototype

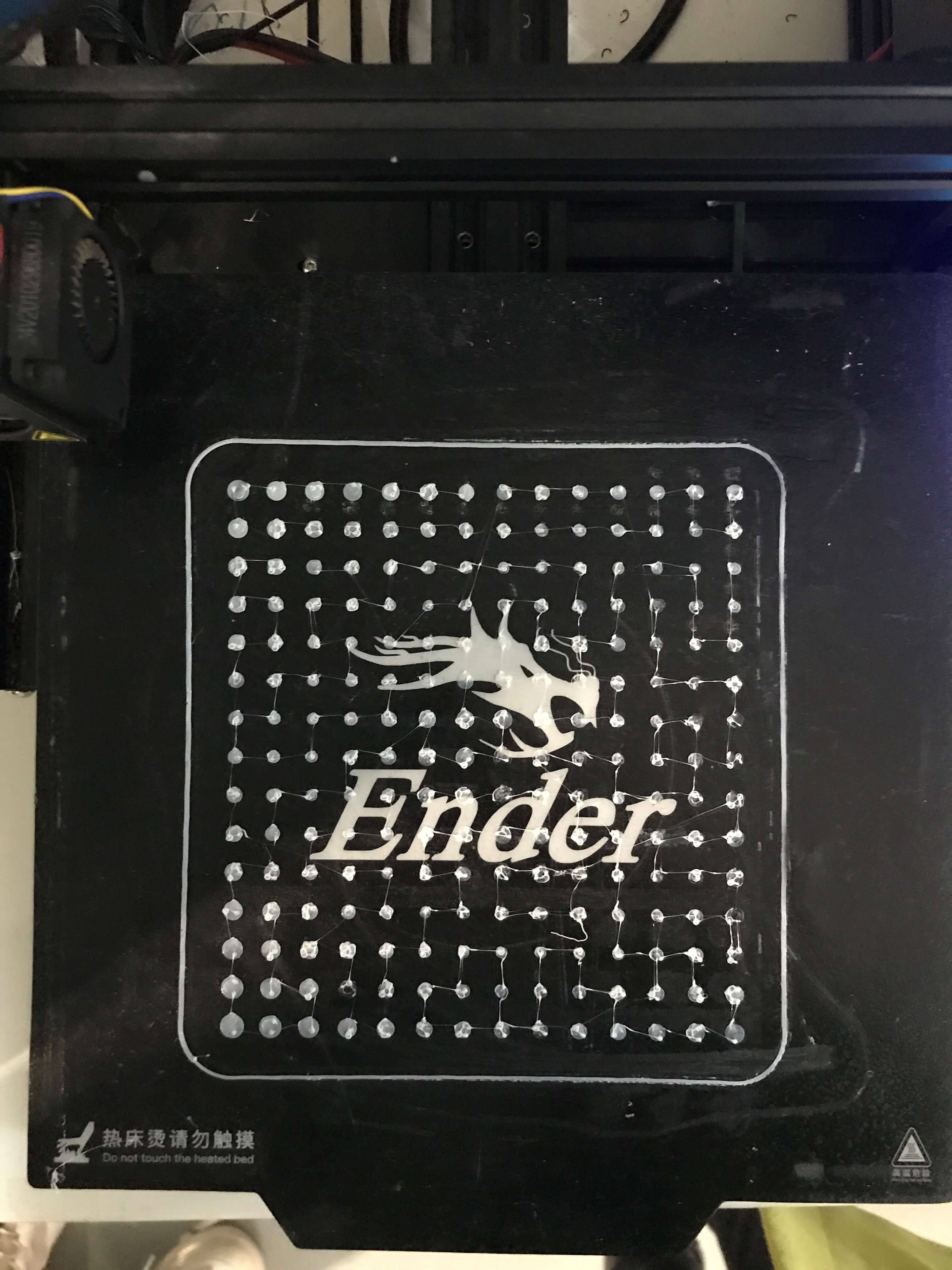

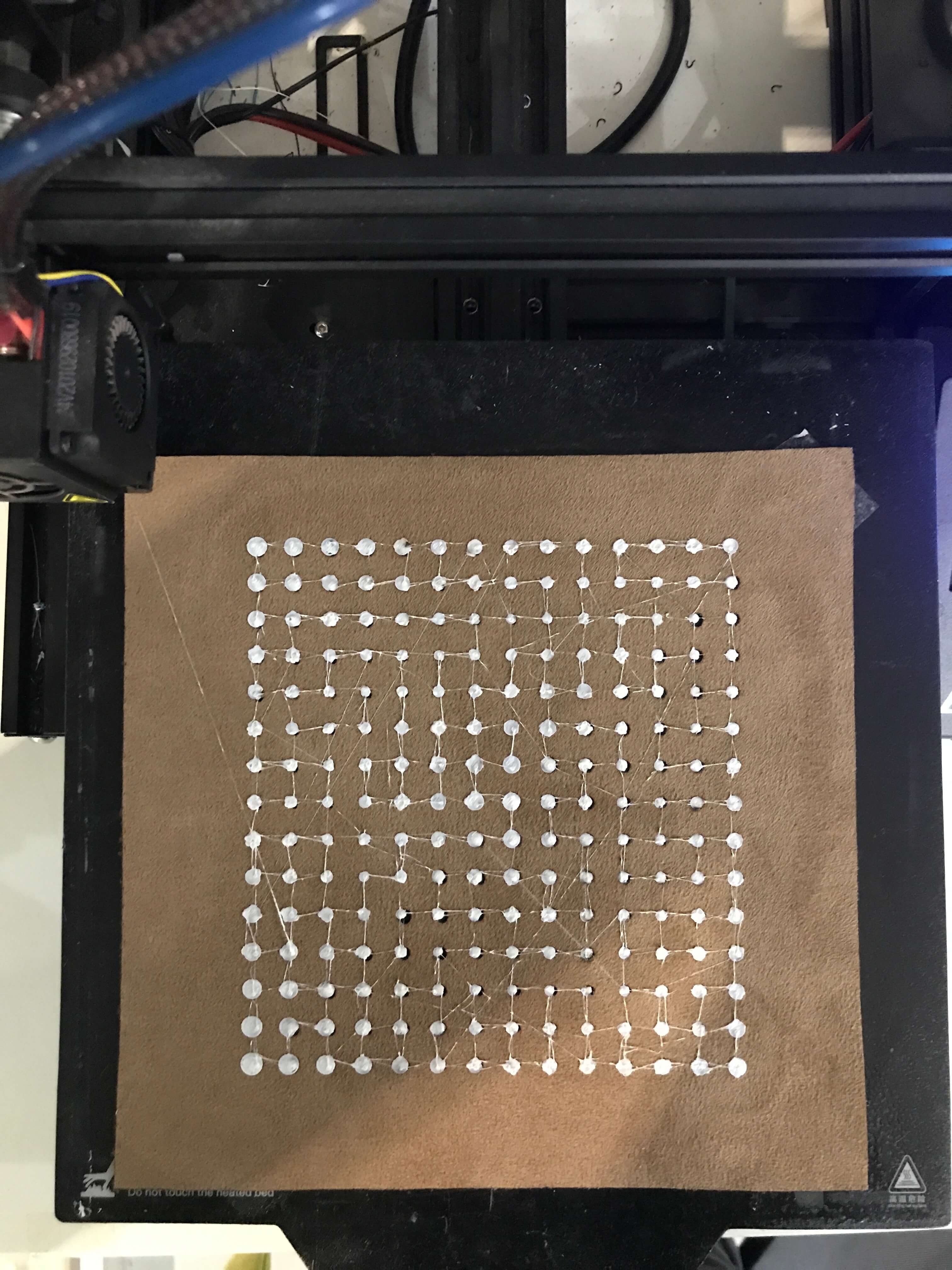

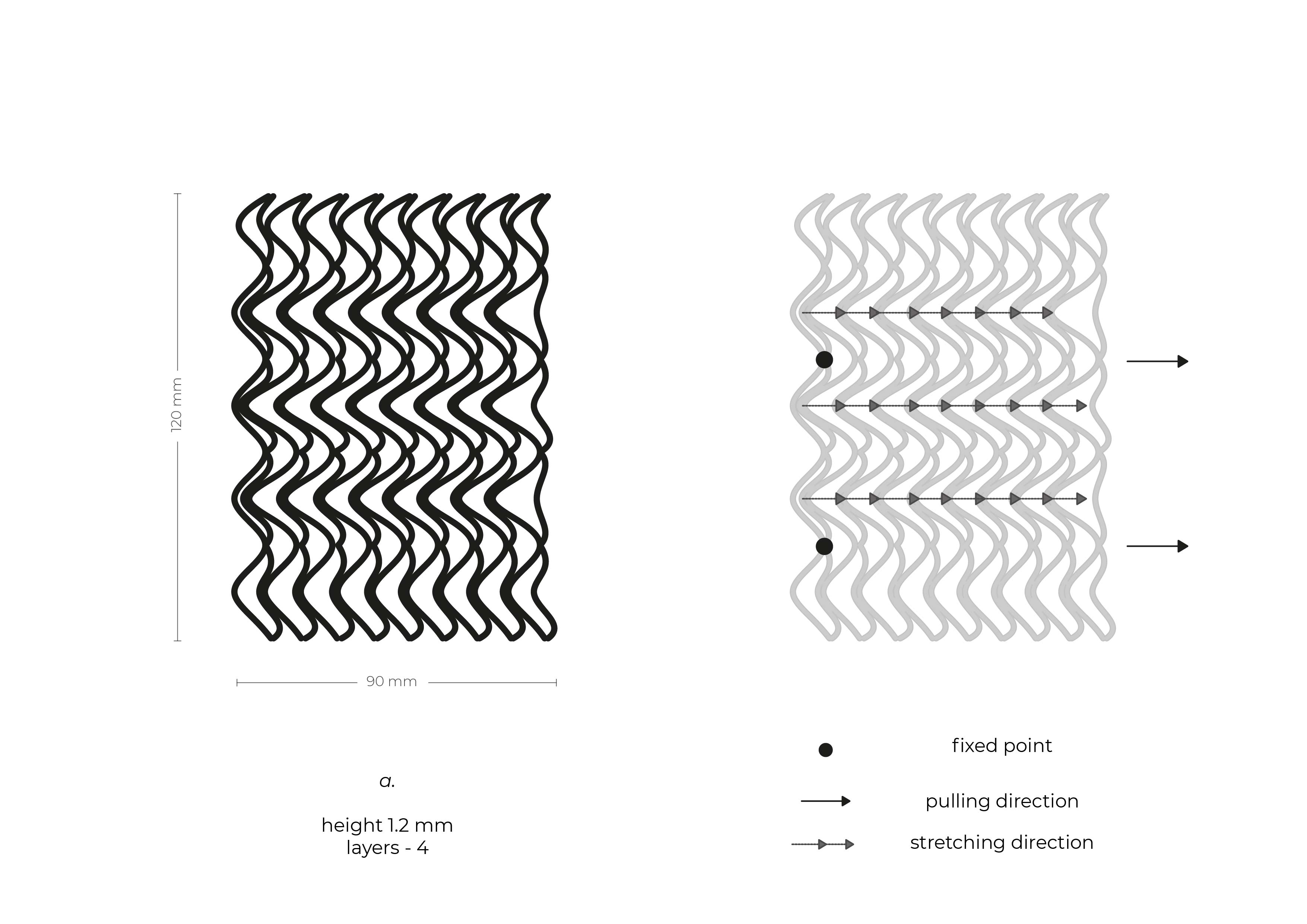

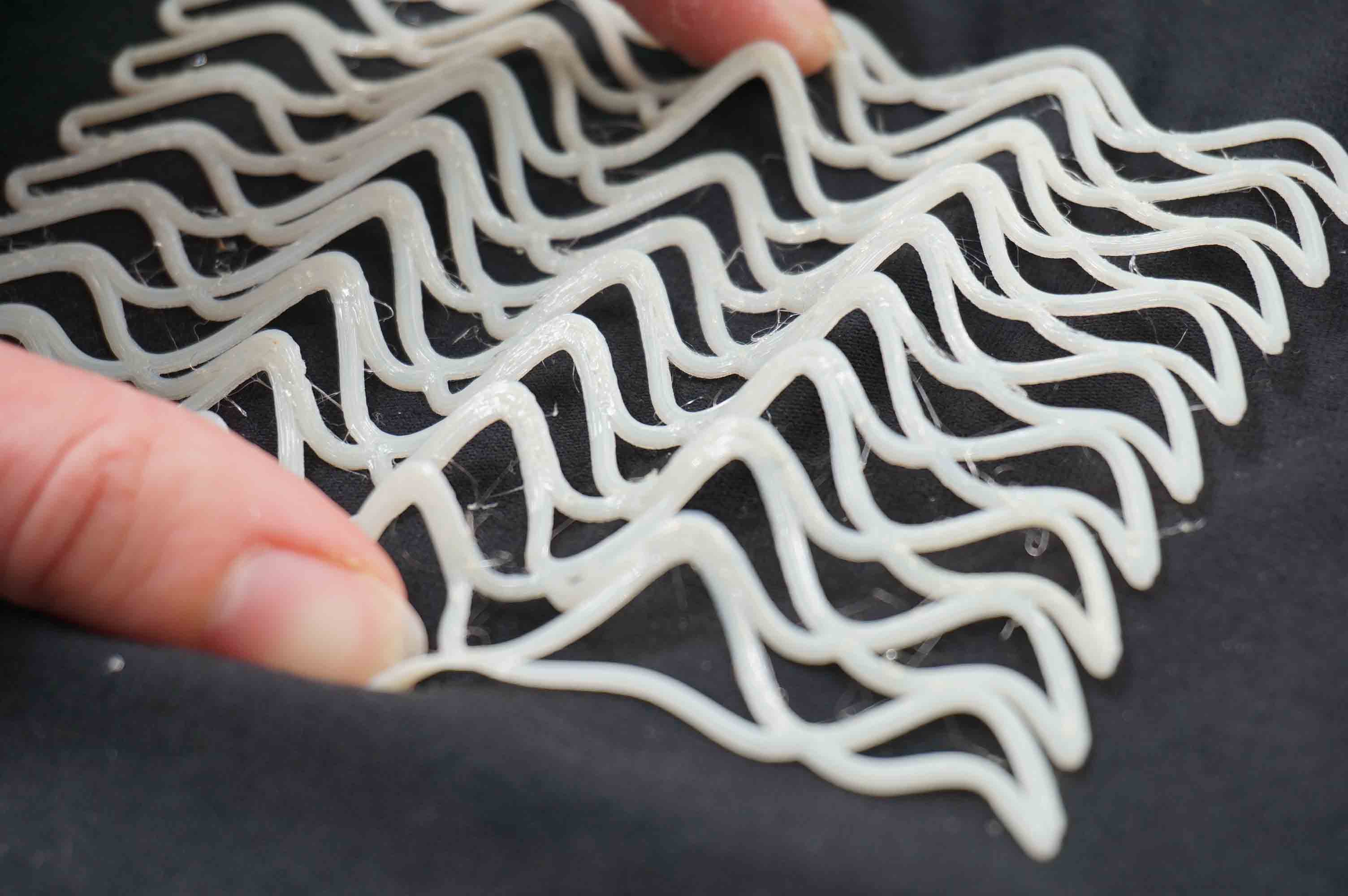

PROCESS - TPU 3D printing¶

-

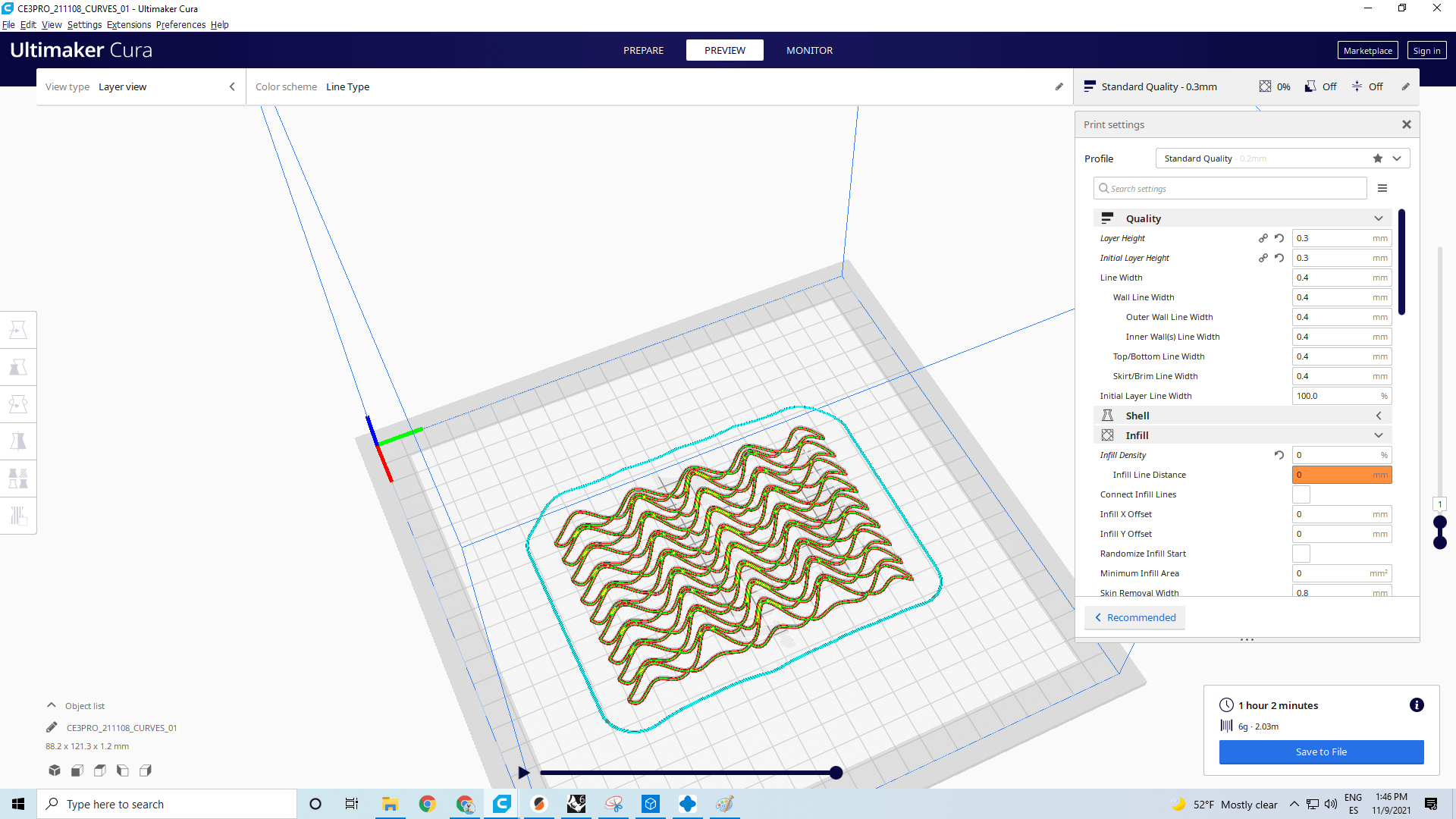

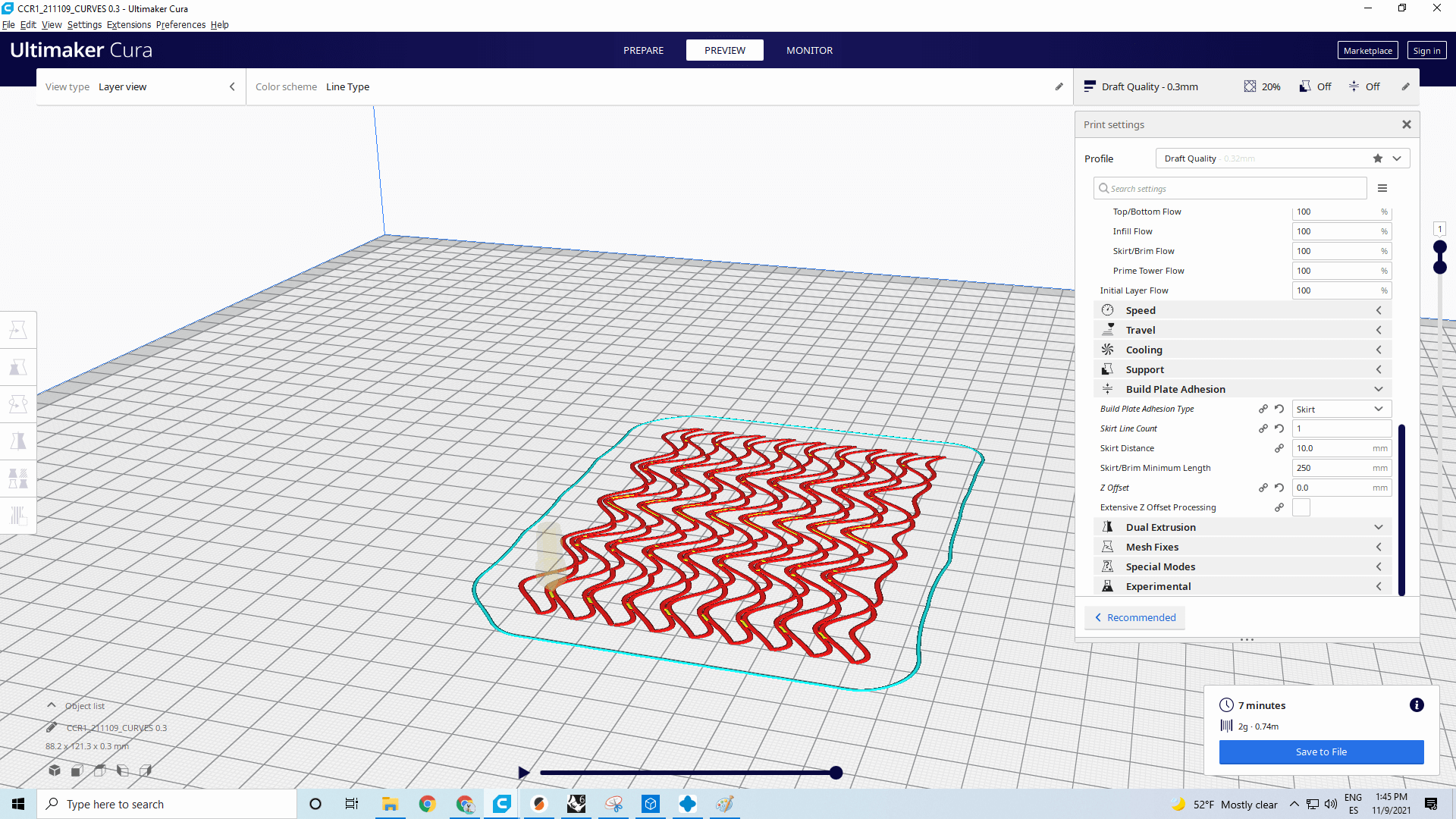

Slicing in Cura

-

1./ prototype - height 1.2 mm

- 2./ prototype - height 0.3 mm

- Export your geometry from Grasshopper / Rhino as a closed mesh - .STL or .OBJ file and import it to Cura.

- 3D printing settings: FLEX material, height of layers, Z offset (3D printing onto textiles), infill, speed, skirt (3D printing without textile), temperature of the bed

- Check your settings in preview mode and export G-code to your SD card.

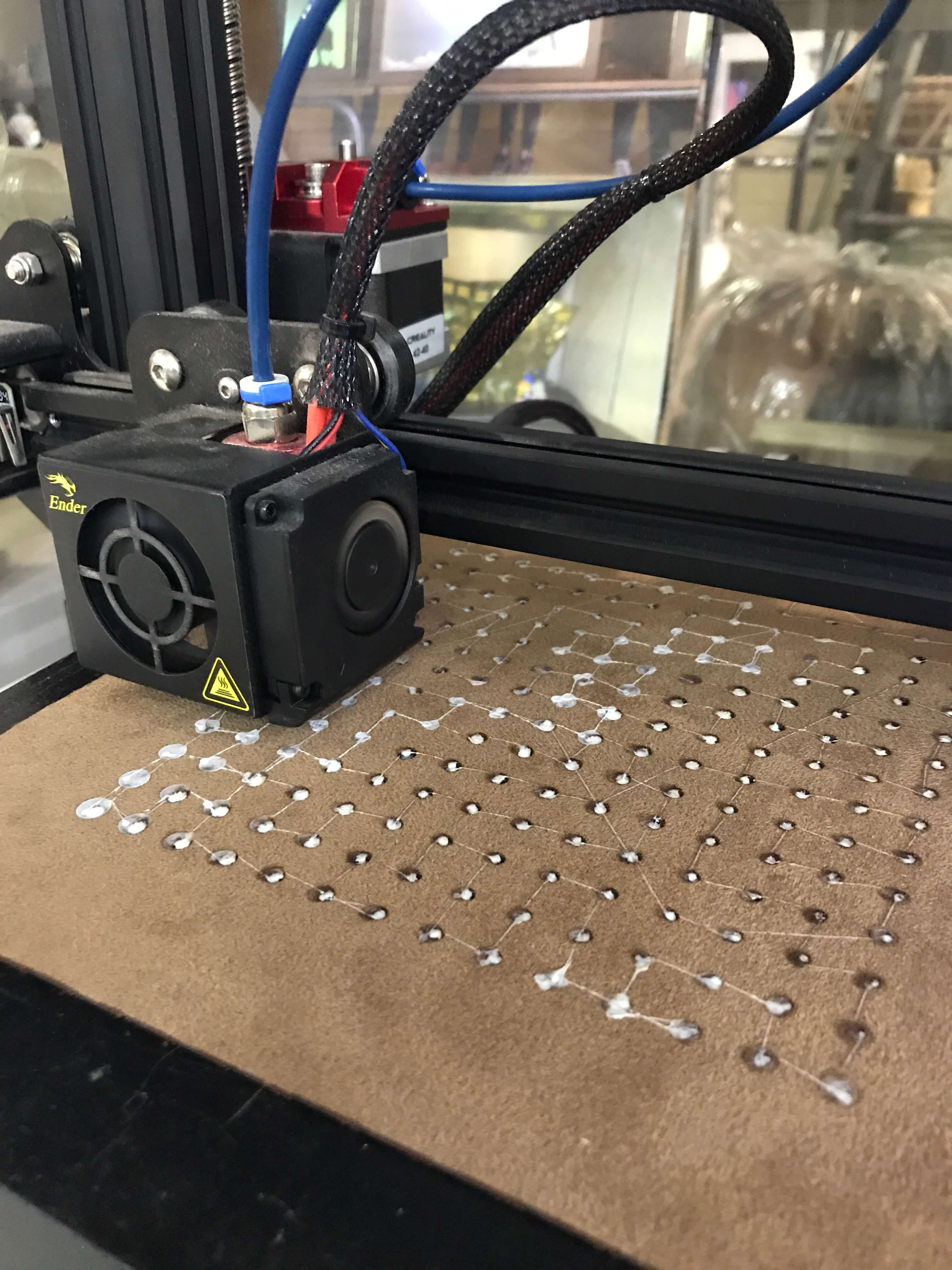

3D Printing¶

- IMPORTANT INFORMATION:

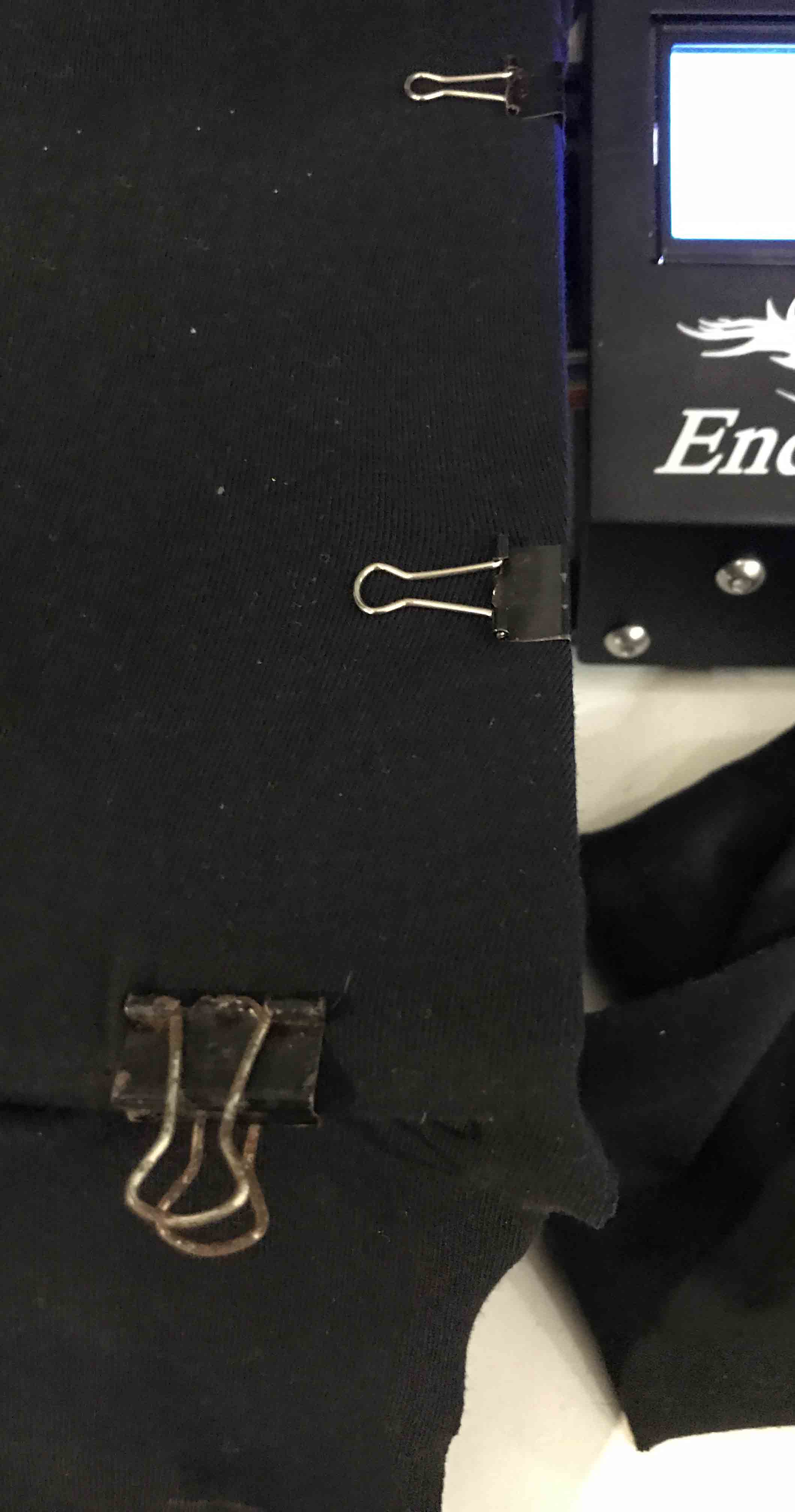

- option a. - you can attach the fabric using pliers or holders on the edges of the 3D printer

-

option b. - you can use double-sided tape

-

The first layer will be squized on the fabric, so it means that it probably will not be very visible.

-

Control filament speed and temperature. It may be that it is printing too fast or is too hot or not hot enough.

- Be aware of filament retraction on your final design. You can remove it after with a hot needle or a soldering iron.

When your printhead moves from one point to another during printing, the heat of the nozzle combined with any pressure in the hot end results in some excess filament being forced out. This event is a form of over-extrusion and often leaves faint strings along the printhead’s path between points. These strings can be removed with tools and heat after printing, but they’re still a bit annoying to deal with.

-

Check the feeder - clicking / slipping extruder. With some types it is possible that they can be stuck during printing.

-

FILAMENT STORAGE - ALWAYS store the filament in a plastic resealable bag. It depends on how old the filament is and where you store it.

3D PRINTING SETTINGS & PROCESS¶

- 1/ Import your SD card to the 3D printer. Preheat your 3D printer - PLA or FLEX - check temperatures bellow.

| Name | Material temperature | Print bed temperature | Speed | Z offset | Cooling | Build surface |

|---|---|---|---|---|---|---|

| PLA | 190-220 °C | 45-60 °C | 100 % | 0 mm | Part Cooling Fan - Speed: 100% | Glass plate, Glue stick |

| FLEX - TPU | 225-245 °C | 45-60 °C | 80 % | 1 mm | Part Cooling Fan | PEI, Painter’s Tape |

- 2/ Open menu on the 3D printer screen and select PRINT FROM SD CARD. Find the name of your file and press the button.

- 3/ First your 3D printer has to do a calibration process and it will start printing from the home position.

- 4/ Check the first layers of your design and height of the nozzle. You can also change it during 3D printing.

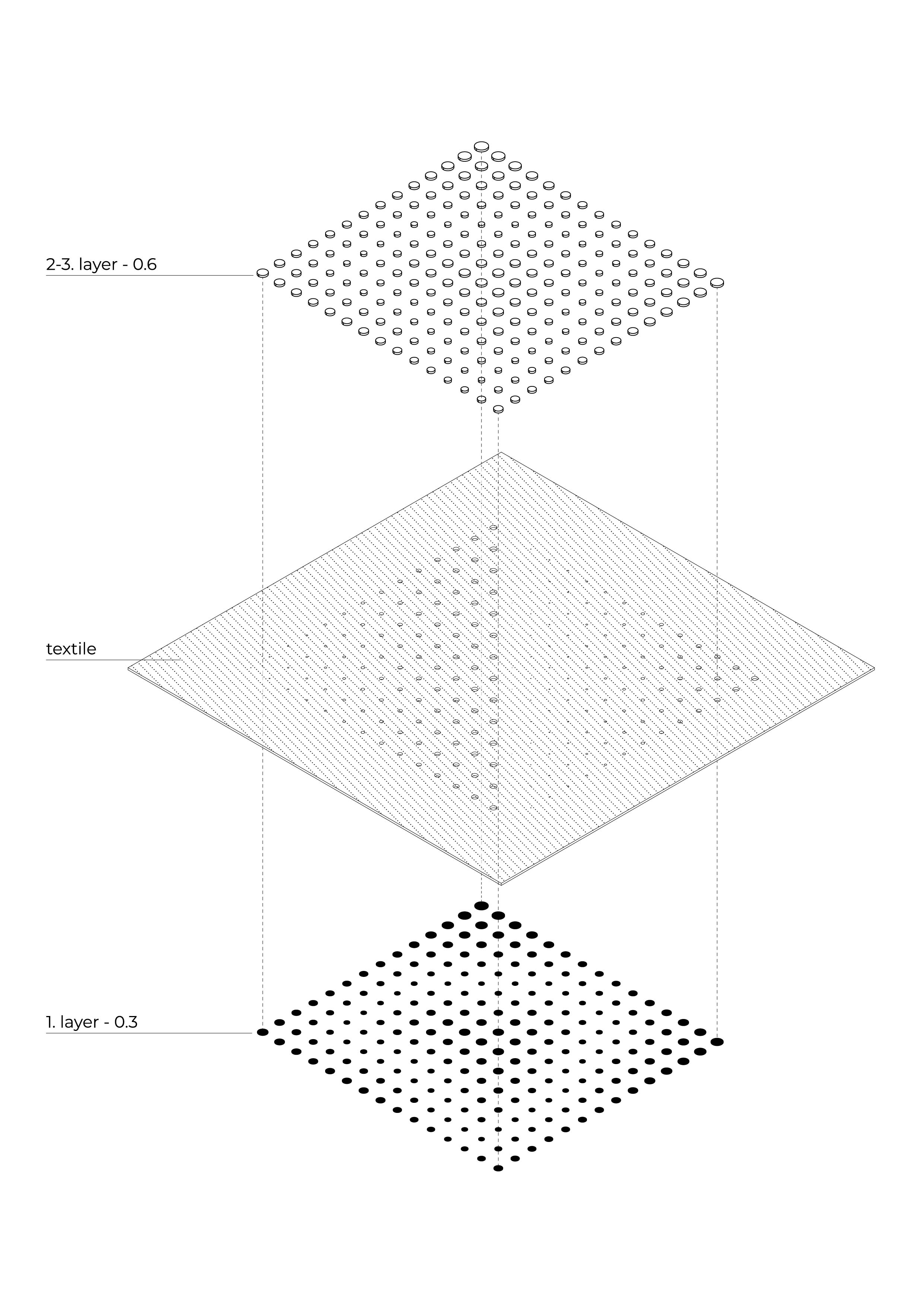

AXONOMETRY¶

-

a. textile prototype

-

1./ layer - height 0.3 mm

| Textile | Filament | 3D printer | Layer | Temperature | Printing speed | Printing time |

|---|---|---|---|---|---|---|

| Scuba ante | TPU | Ender 3 | 0.3 mm | 240°C | 30 mm/sec | 11 min |

- 2-3./ layer - height 0.6 mm

- Place the laser-cut fabric (size 150 x 150 mm) on the heating bed and fix it in the corners and edges with double-sided tape.

| Textile | Filament | 3D printer | Layer | Temperature | Printing speed | Printing time | Weight |

|---|---|---|---|---|---|---|---|

| Scuba ante | TPU | Ender 3 | 0.3 mm | 240°C | 30 mm/sec | 29 min | 180 g |

CONCLUSION¶

- Not every dot from the first layer was melted with the upper layers.

REFERENCES - Tutorials¶

3D PRINTED TEXTILES¶

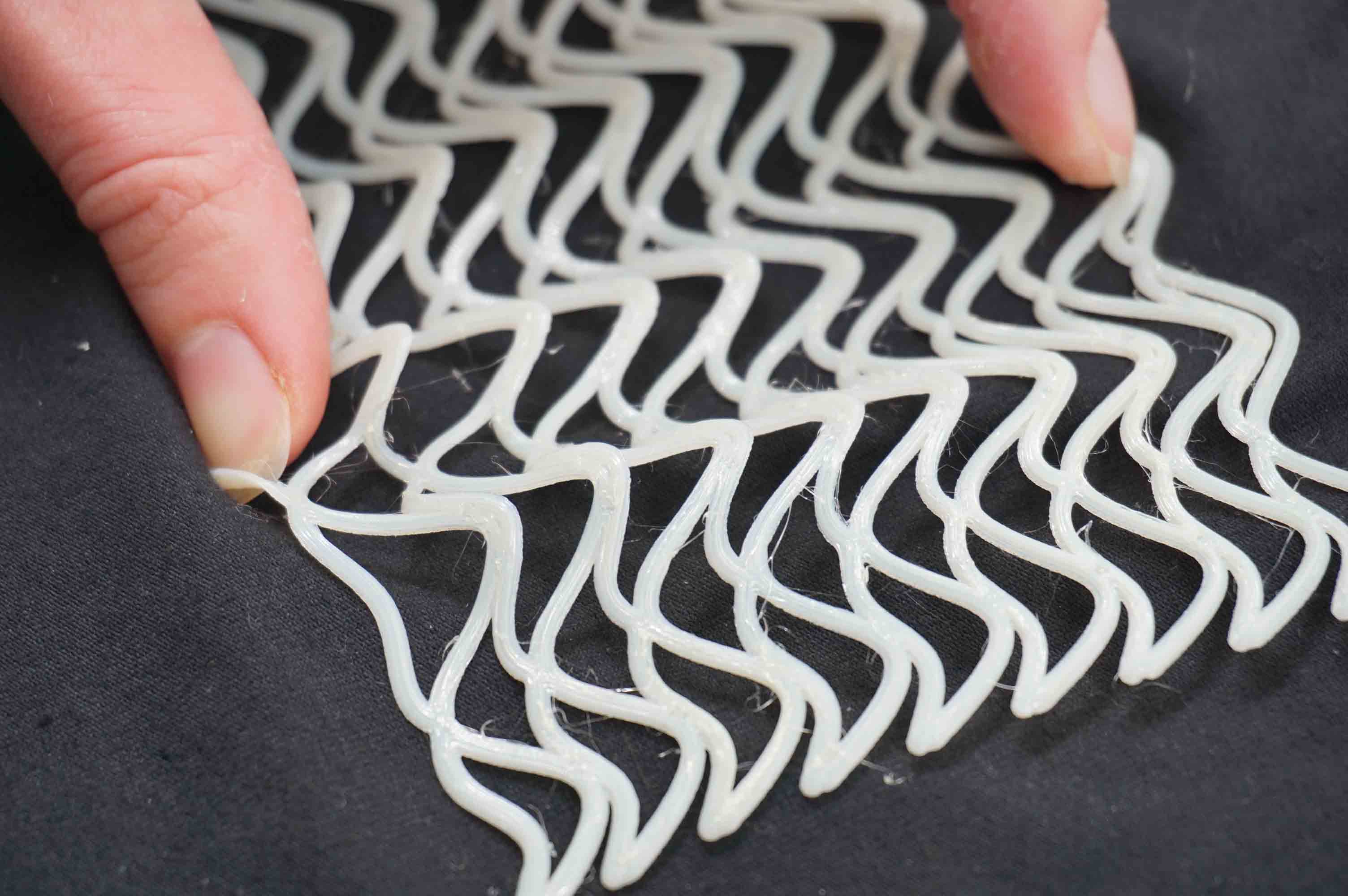

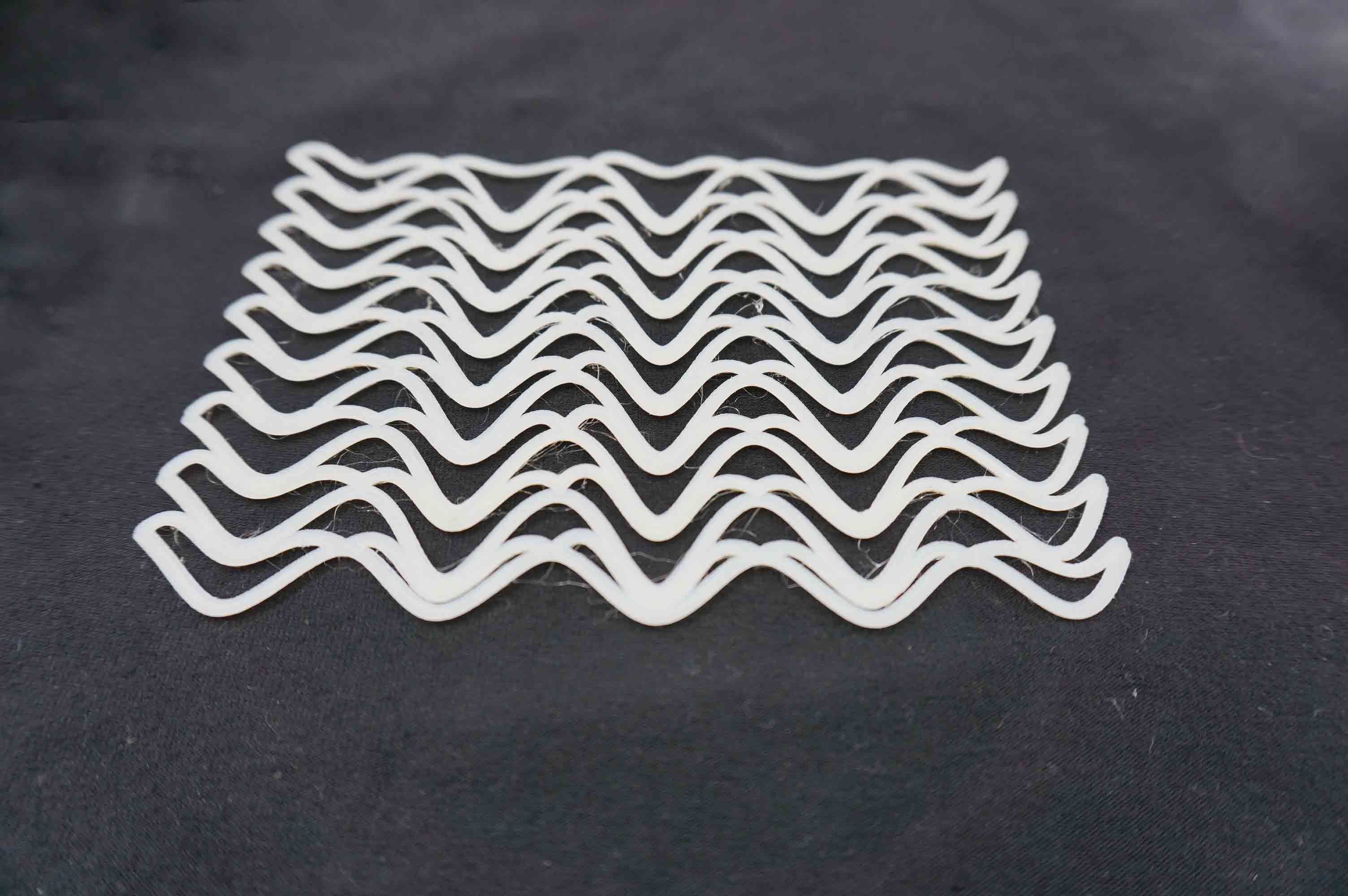

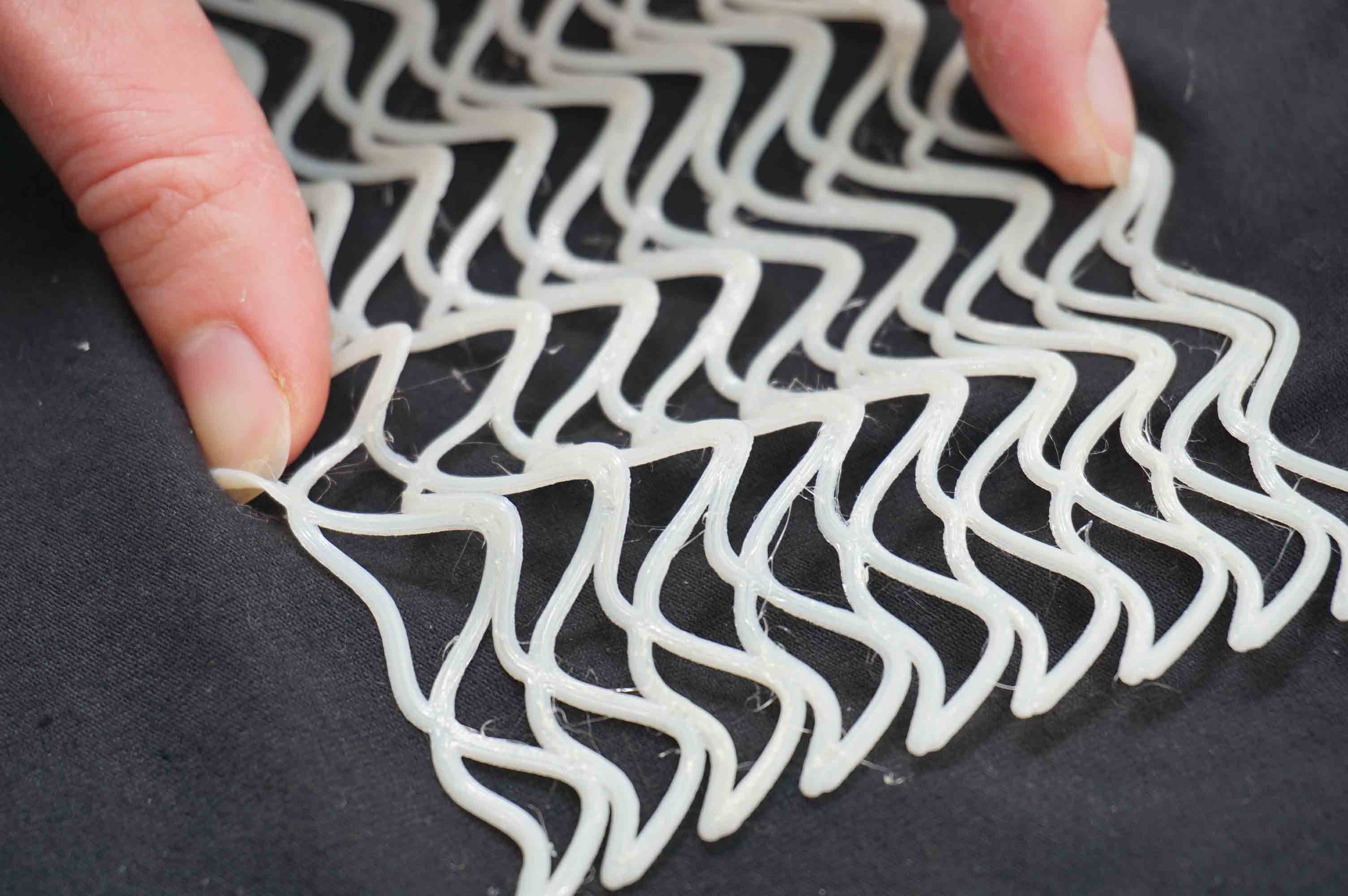

Flexibility testing¶

- a. textile prototype

Material Parametres - Settings¶

| Filament | 3D printer | Layer | Temperature | Printing speed | Printing time | Weight | Infill |

|---|---|---|---|---|---|---|---|

| TPU | Ender 3 | 0.3 mm | 240°C | 30 mm/sec | 60 min | 15 g | 0 % |

Material flexibility¶

Final result¶

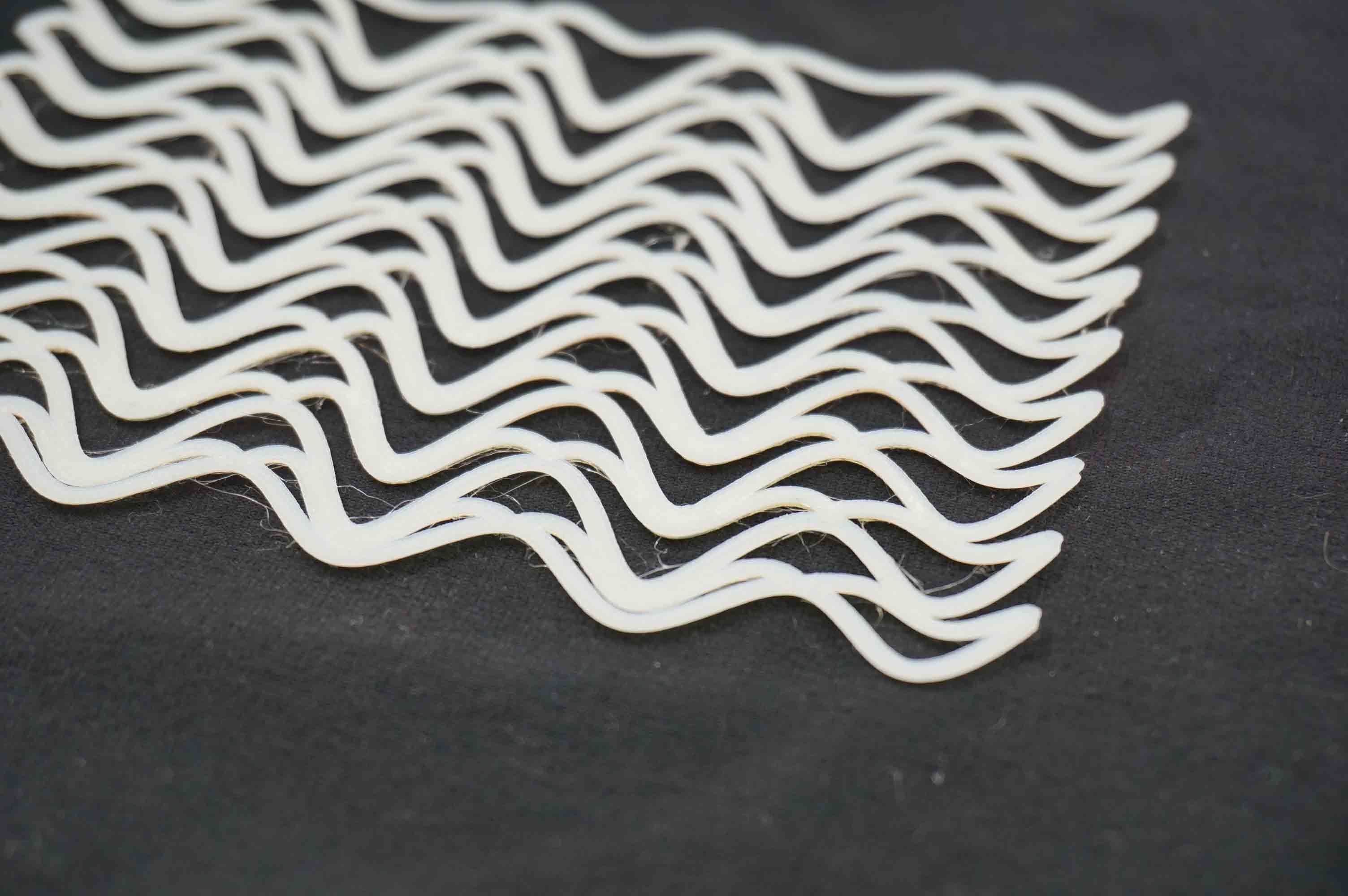

Visibility testing¶

Material Parametres¶

- a. textile prototype

| Filament | 3D printer | Layer | Temperature | Printing speed | Printing time | Weight | Infill |

|---|---|---|---|---|---|---|---|

| TPU | Ender 3 | 0.3 mm | 240°C | 30 mm/sec | 1 h 10 min | 22 g | 0 % |

- b. textile prototype

| Filament | 3D printer | Layer | Temperature | Printing speed | Printing time | Weight | Infill |

|---|---|---|---|---|---|---|---|

| TPU | Ender 3 | 0.3 mm | 240°C | 30 mm/sec | 2 h 38 min | 25 g | 0 % |

- c. textile prototype

| Filament | 3D printer | Layer | Temperature | Printing speed | Printing time | Weight | Infill |

|---|---|---|---|---|---|---|---|

| TPU | Ender 3 | 0.3 mm | 240°C | 30 mm/sec | 2 h 57 min | 15 g | 0 % |

REFERENCES - Tutorials¶

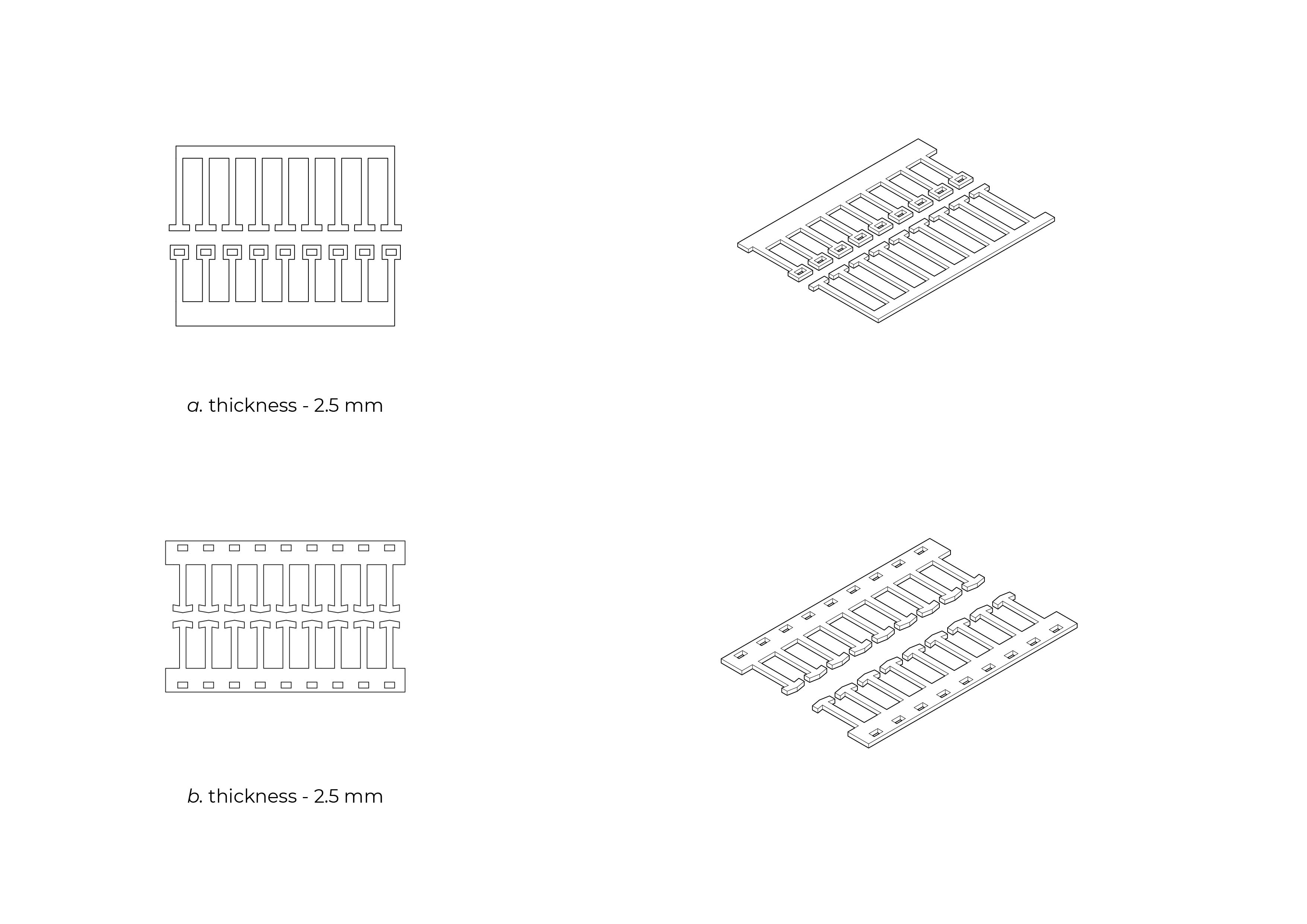

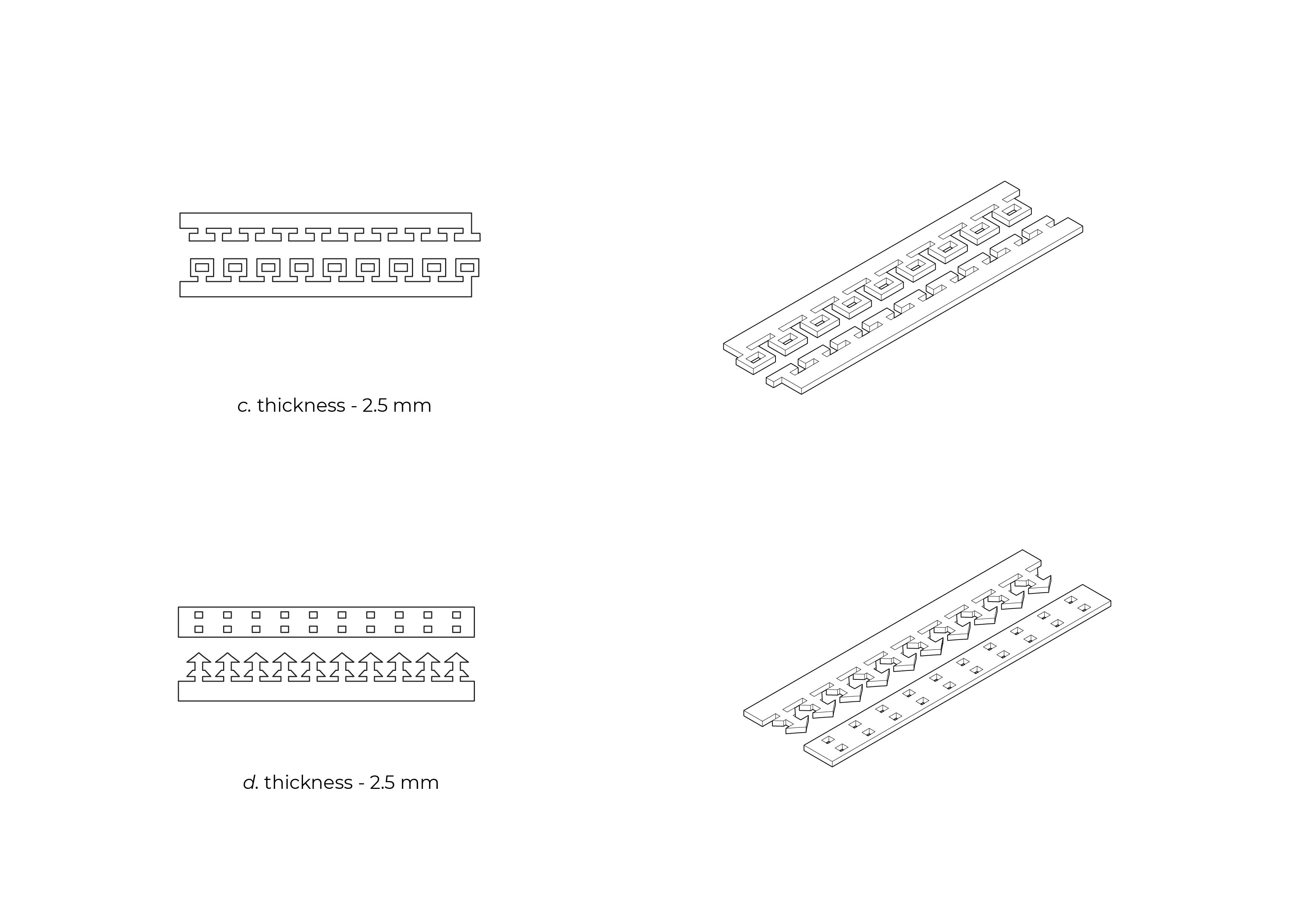

JOINING 3D PRINTED TEXTILES¶

MALE & FEMALE¶

- 3D printed connections, instead of sewing fabric together

MELTING¶

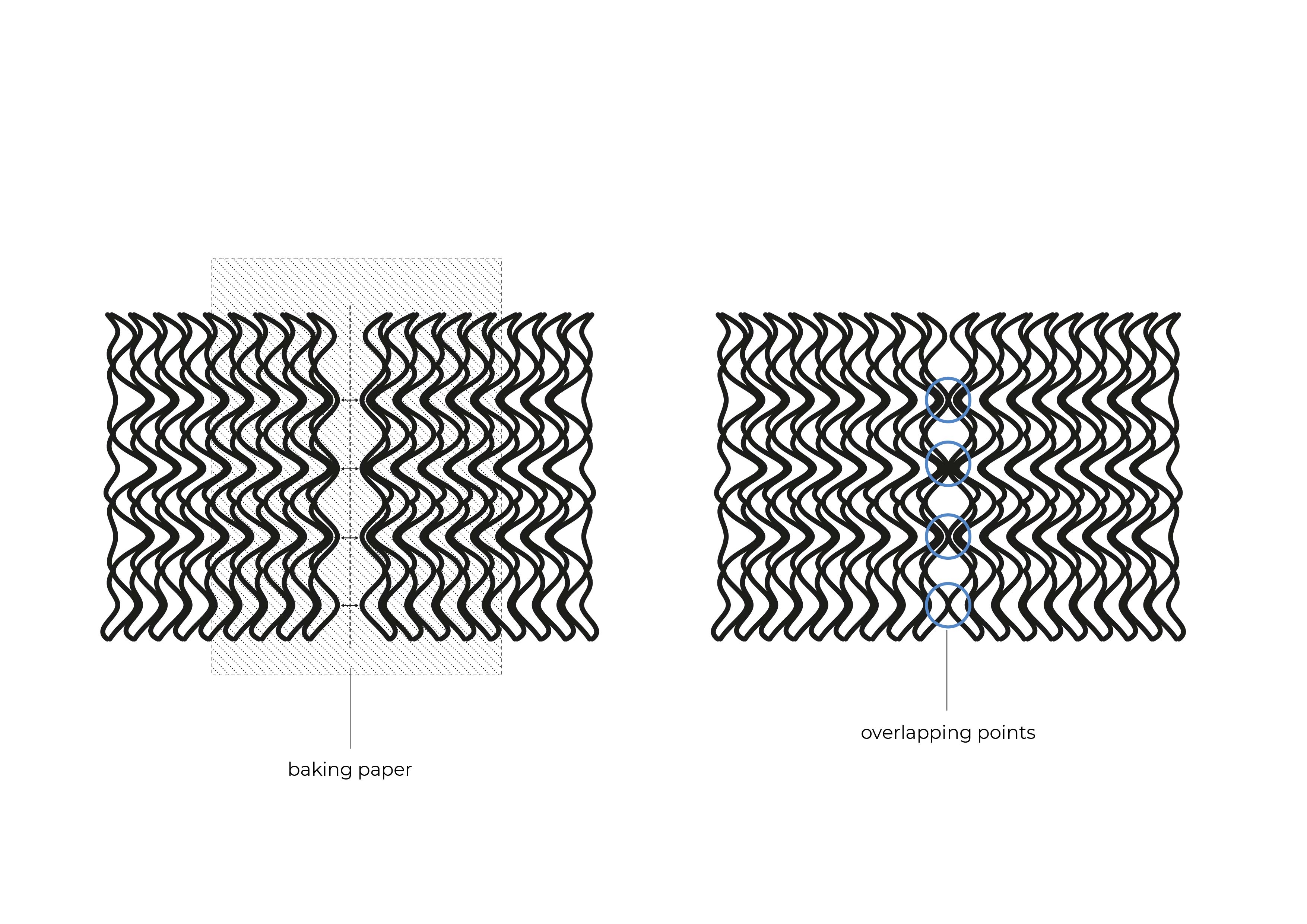

- Using iron and baking paper you can melt 3D printed pieces together.

3D PRINTED BUTTONS¶