IX. | TEXTILE AS SCAFFOLD¶

| CRYSTALLIZATION |¶

- Feathers

- Eggshells

- Lemon peel

ALUM¶

About¶

An alum is a type of chemical compound, usually a hydrated double sulfate salt of aluminium. They are soluble in water, react acid to litmus, and crystallize in regular octahedra. They are astringent and acidic. Alum crystals are colorless, non-toxic crystals that are easy to grow. Large crystals somewhat resemble diamonds, although they are much softer than the gemstones. Uses: Aluminium-based alums have been used since antiquity, and are still important in many industrial processes. The most widely used alum is potassium alum. It has been used since antiquity as a flocculant to clarify turbid liquids, as a mordant in dyeing, and in tanning. It is still widely used in water treatment, in medicine, for cosmetics, in food preparation, and to fire-proof paper and cloth.

01 - EGGSHELLS¶

About¶

Calcium, as the largest constituent of eggshell, affects the hardness of the eggshells. The thickness of its outer and inner eggshell is 0.55 and 0.015 mm.

| a. | b. | c. | d. |

|---|---|---|---|

| Magnesium carbonate | Calcium phosphate | Organic matter | Calcium carbonate |

| 1 % | 1 % | 4 % | 94 % |

Ingredients - Alum solution¶

- TEST 01

| a. | b. | Additives |

|---|---|---|

| Alum | Destilated water | - |

| 200 g | 1 l | - |

- TEST 02

| a. | b. | Additives |

|---|---|---|

| Alum | Destilated water | Black colorant, Mica |

| 200 g | 1 l | 1-2 g |

Tools¶

- cooking pot, stirring spoon, weight, paper filters, cooking stove, glass jars, aluminium foil, thread

Process¶

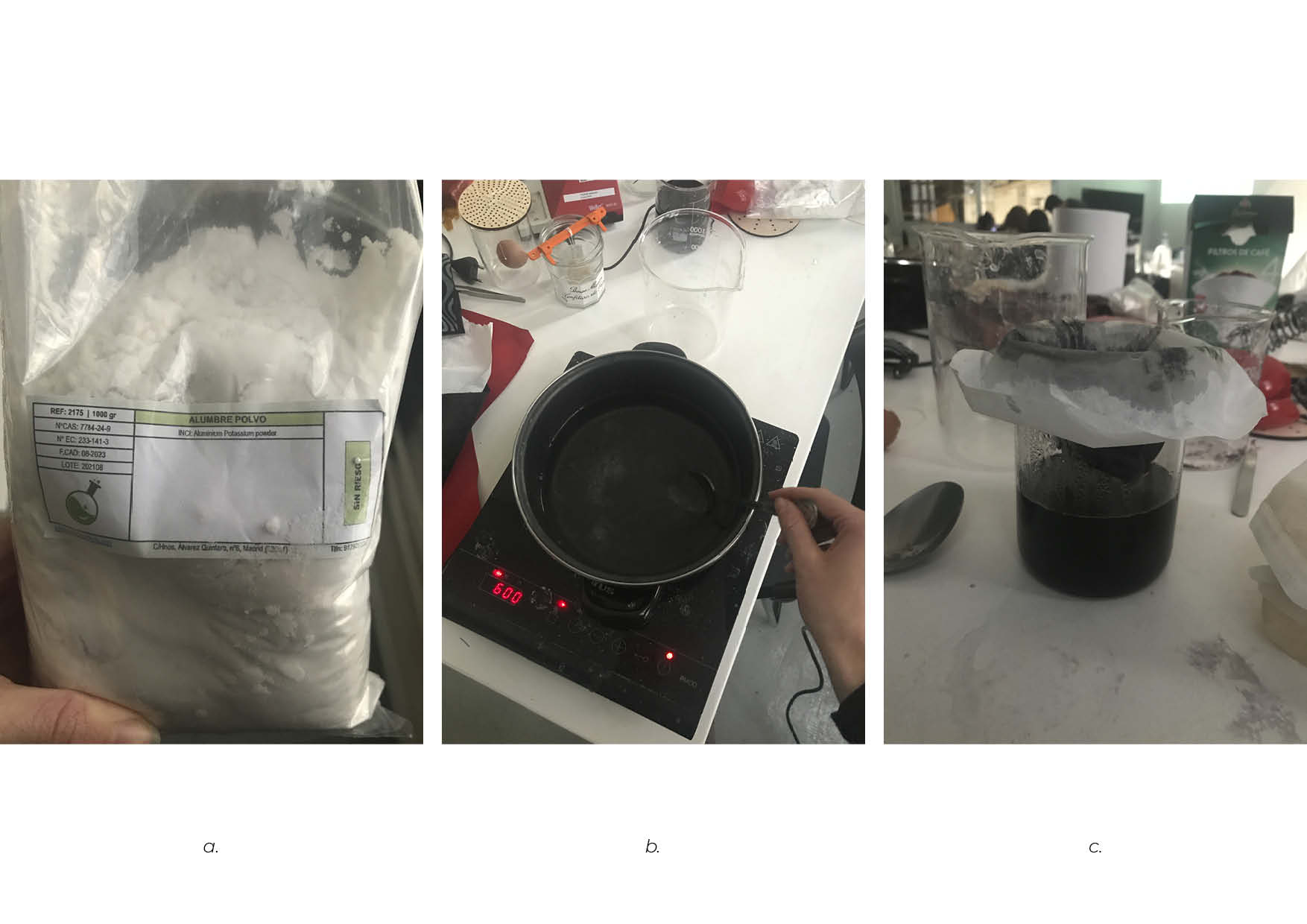

- Measure 1 l of water and 200 g of aluminium potassium powder (ALUMBRE POLVO - a.).

- Preheat the water (not boiling - b.) and add alum. Stir constantly until all is dissolved. If you stop stirring, the crystallization process will begin.If you stop stirring, the crystallization process will begin.

- OPTIONAL: Turn off the stove and add food coloring or other additives to color the crystals.

- Place the paper filter in the glass jar (c.) you want to use for crystallization and filter the alum solution through the filter. * Put the eggshells hung on the thread in the solution and cover it with aluminum foil.

- Find a safe and stable place where you can let it sit and wait overnight for your crystals. * Once the crystallization is done or not really successful, you can preheat the alum solution and add a little more alum powder to repeat the process.

- Or if you want to grow larger crystals, you can repeat the process as many times as you want.

Results¶

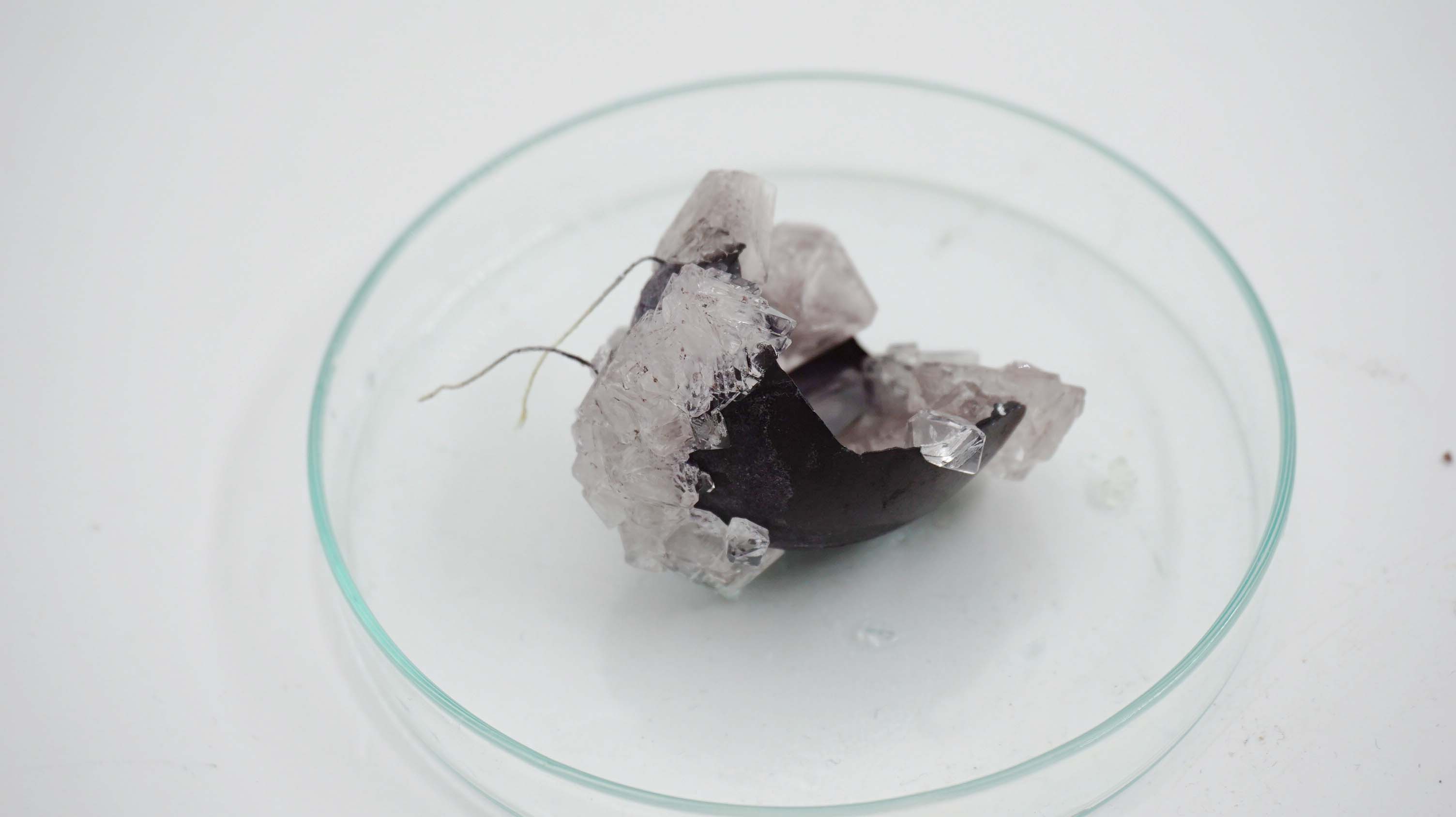

-

Without additives

-

Dyed with black food coloring and Mica

Material Parametres¶

| Viscosity | Curing time | Melting point | Stickiness | Structural properties | Visual | Structure | Texture | Strengh |

|---|---|---|---|---|---|---|---|---|

| High | Naturally: 1 week, Dehydrator: 30 h | Fireproof >300ºC | Low | Flexible | Opaque | Water resistant | Gelatinous | Resistant |

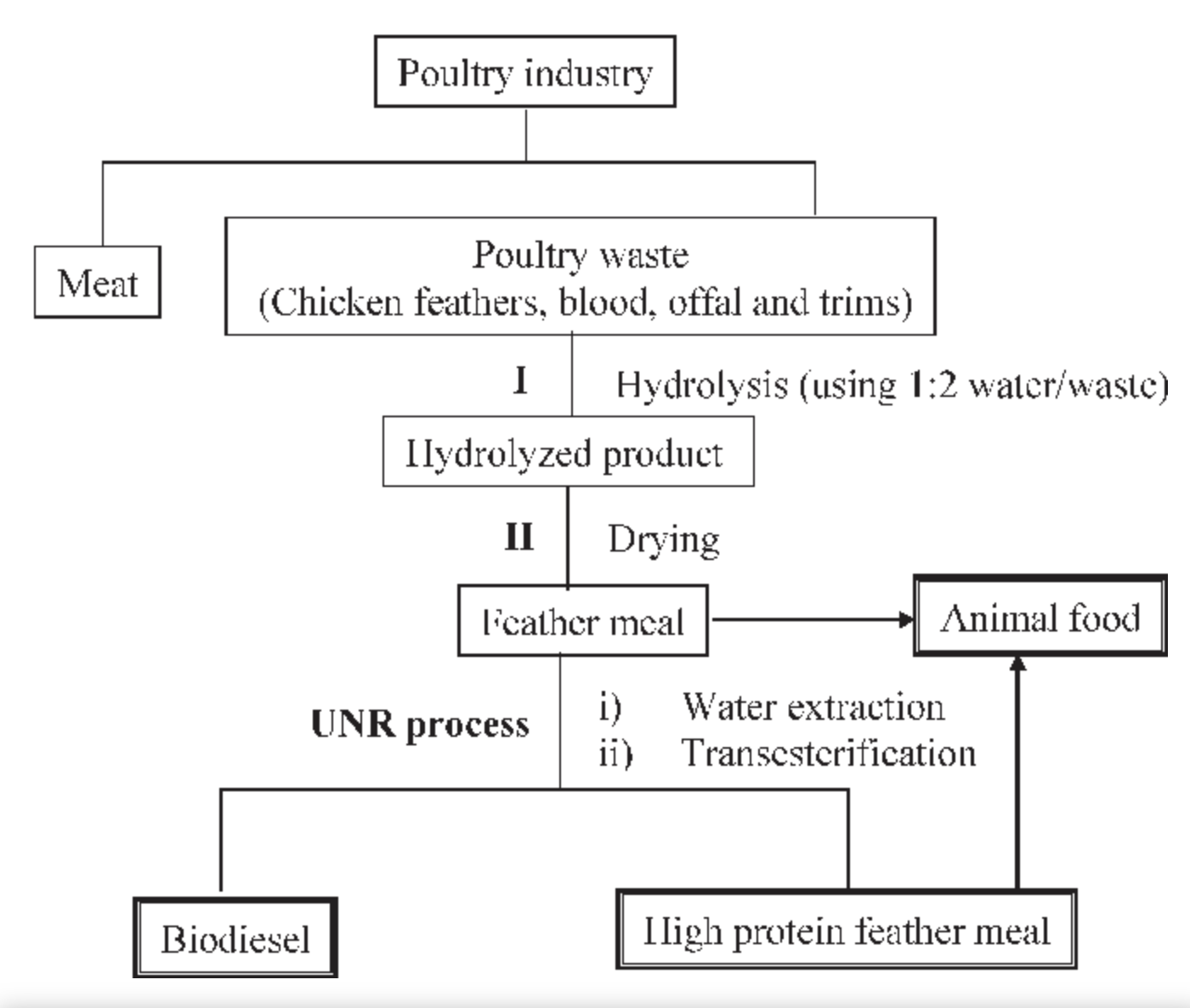

02-01 - FEATHERS¶

About¶

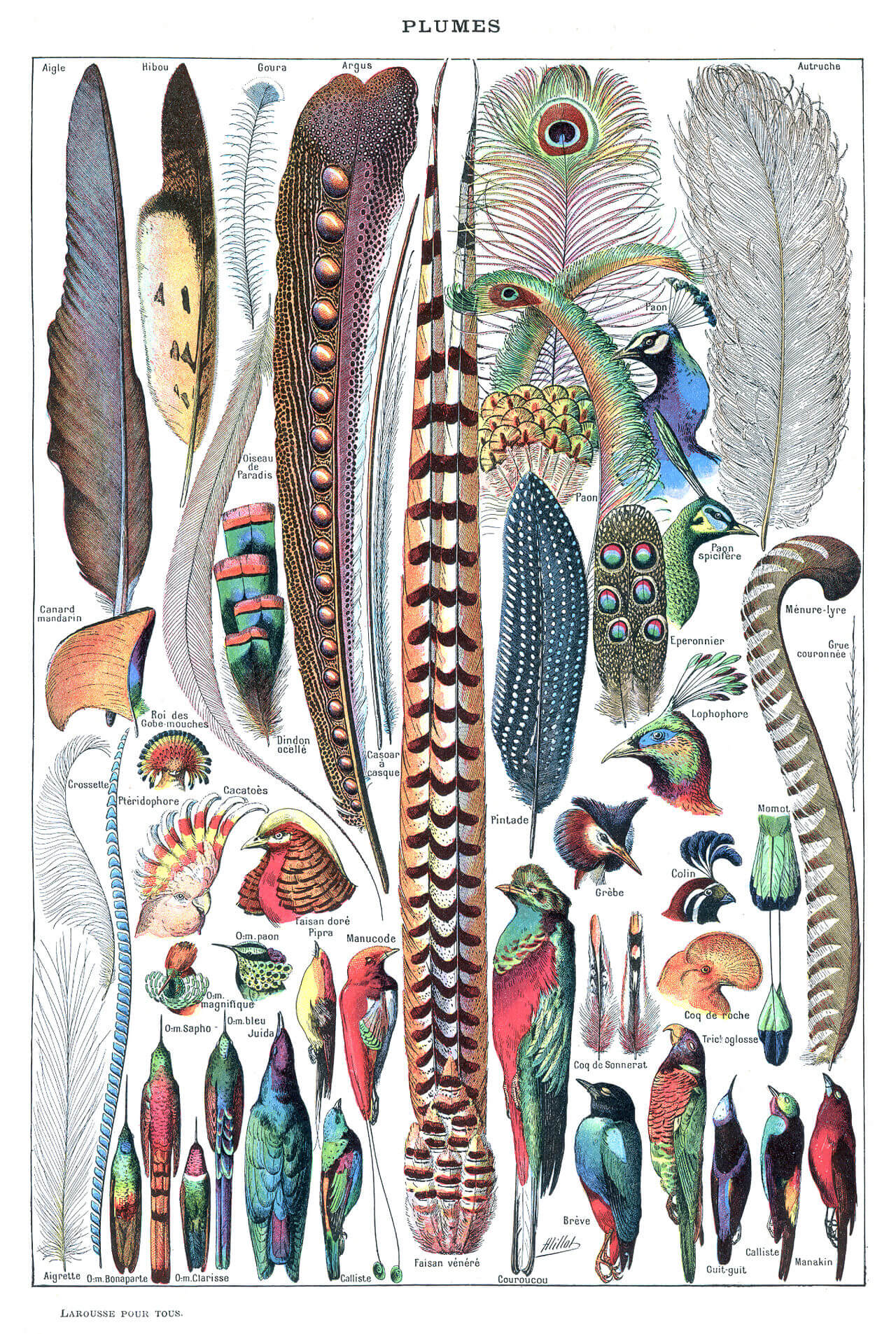

Feathers are both soft and excellent at trapping heat. They are also used as filling for winter clothing and outdoor bedding, such as quilted coats and sleeping bags. Feathers used in fashion and in military headdresses and clothes are obtained as a waste product of poultry farming, including chickens, geese, turkeys, pheasants, and ostriches. These feathers are dyed and manipulated to enhance their appearance, as poultry feathers are naturally often dull in appearance compared to the feathers of wild birds.

Food Waste - Food Industry¶

“The project has clearly demonstrated that feathers can no longer be viewed as a waste product,” adds Montes. “Instead, they should be seen as a source of valuable raw materials and an essential component to the circular economy.”

Ingredients¶

| a. | b. | Additives |

|---|---|---|

| Alum | Destilated water | Black colorant |

| 200 g | 1 l | 1-2 g |

Tools¶

- cooking pot, stirring spoon, weight, paper filters, cooking stove, glass jars, aluminium foil, thread

Process¶

- Measure 1 l of water and 200 g of aluminium potassium powder (ALUMBRE POLVO - a.).

- Preheat the water (not boiling - b.) and add alum. Stir constantly until all is dissolved. If you stop stirring, the crystallization process will begin.If you stop stirring, the crystallization process will begin.

- OPTIONAL: Turn off the stove and add food coloring or other additives to color the crystals.

- Place the paper filter in the glass jar (c.) you want to use for crystallization and filter the alum solution through the filter. * Put the feathers hung on the thread in the solution and cover it with aluminum foil.

- Find a safe and stable place where you can let it sit and wait overnight for your crystals. * Once the crystallization is done or not really successful, you can preheat the alum solution and add a little more alum powder to repeat the process.

- Or if you want to grow larger crystals, you can repeat the process as many times as you want.

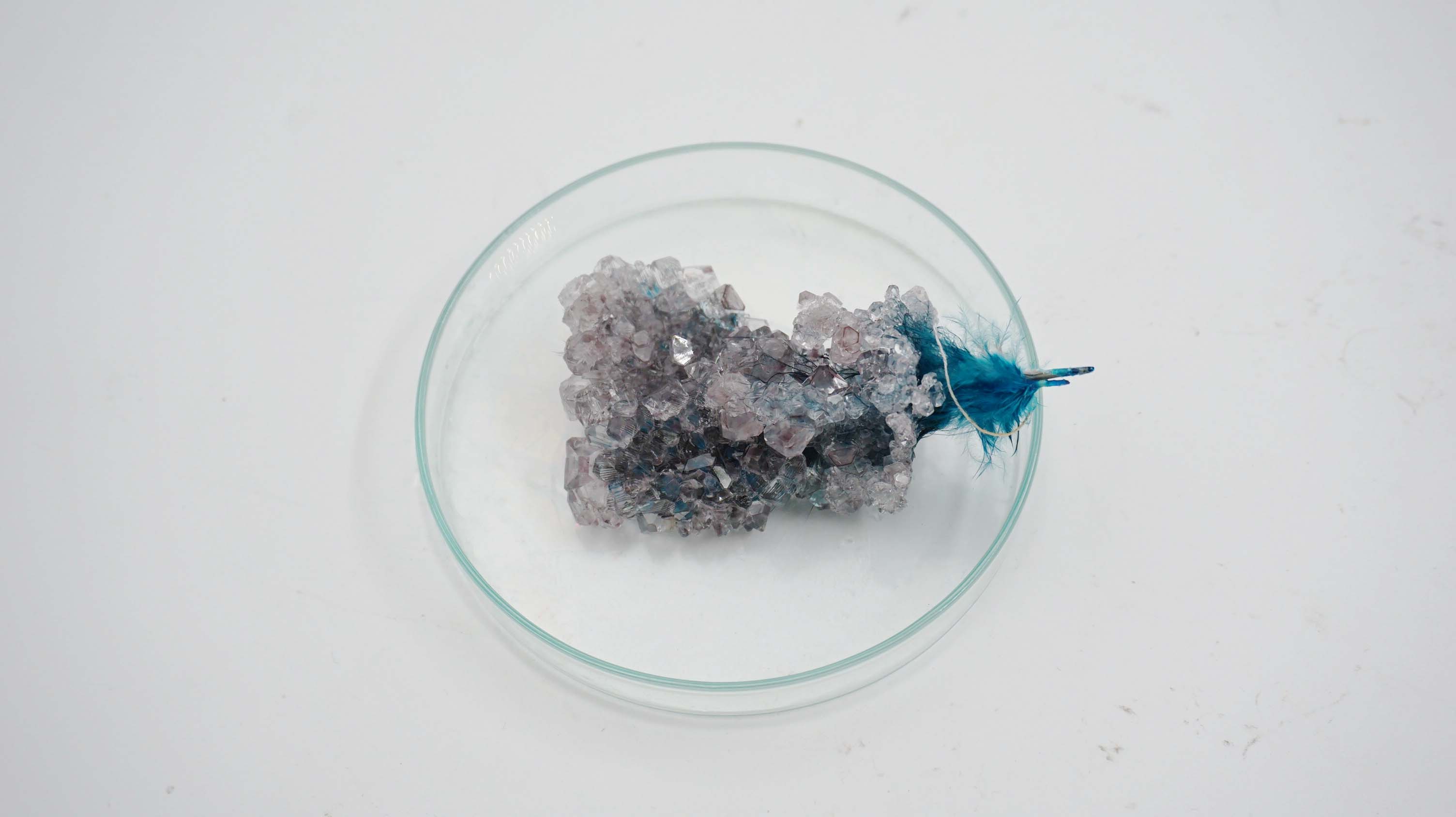

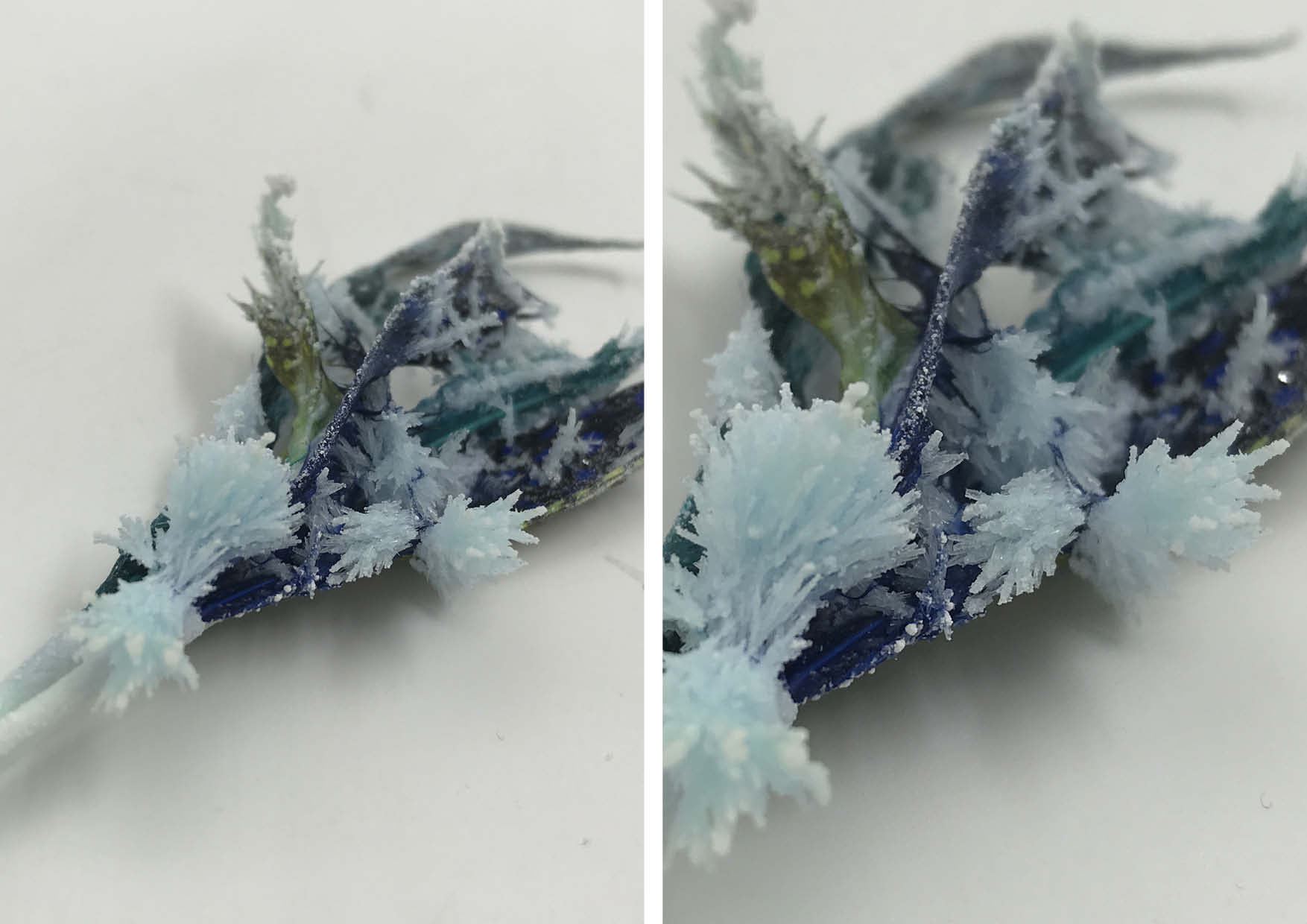

Results¶

02-02 - FEATHERS¶

Ingredients¶

| a. | b. | Additives |

|---|---|---|

| Alum + Borax | Destilated water | - |

| 200 g + 30 g | 1 l | - |

Tools¶

- cooking pot, stirring spoon, weight, paper filters, cooking stove, glass jars, aluminium foil, thread

Process¶

- Measure 1 l of water and 200 g of aluminium potassium powder (ALUMBRE POLVO - a.).

- Preheat the water (not boiling - b.) and add alum. Stir constantly until all is dissolved. If you stop stirring, the crystallization process will begin.If you stop stirring, the crystallization process will begin. Accidentally add borax and mix them together.

- OPTIONAL: Turn off the stove and add food coloring or other additives to color the crystals.

- Place the paper filter in the glass jar (c.) you want to use for crystallization and filter the alum solution through the filter. * Put the feathers hung on the thread in the solution and cover it with aluminum foil.

- Find a safe and stable place where you can let it sit and wait overnight for your crystals. * Once the crystallization is done or not really successful, you can preheat the alum solution and add a little more alum powder to repeat the process.

- Or if you want to grow larger crystals, you can repeat the process as many times as you want.

Results¶

03 - LEMON PEELS¶

Ingredients¶

| a. | b. | Additives |

|---|---|---|

| Alum | Destilated water | - |

| 200 g | 1 l | - |

Tools¶

- cooking pot, stirring spoon, weight, paper filters, cooking stove, glass jars, aluminium foil, thread

Process¶

- Measure 1 l of water and 200 g of aluminium potassium powder (ALUMBRE POLVO - a.).

- Preheat the water (not boiling - b.) and add alum. Stir constantly until all is dissolved. If you stop stirring, the crystallization process will begin.If you stop stirring, the crystallization process will begin.

- OPTIONAL: Turn off the stove and add food coloring or other additives to color the crystals.

- Place the paper filter in the glass jar (c.) you want to use for crystallization and filter the alum solution through the filter. * Put the lemon peels hung on the thread in the solution and cover it with aluminum foil. (I dried my lemon peels in the oven for 30 min on 90ºC)

- Find a safe and stable place where you can let it sit and wait overnight for your crystals. * Once the crystallization is done or not really successful, you can preheat the alum solution and add a little more alum powder to repeat the process.

- Or if you want to grow larger crystals, you can repeat the process as many times as you want.

| TEXTILE SCAFFOLD |¶

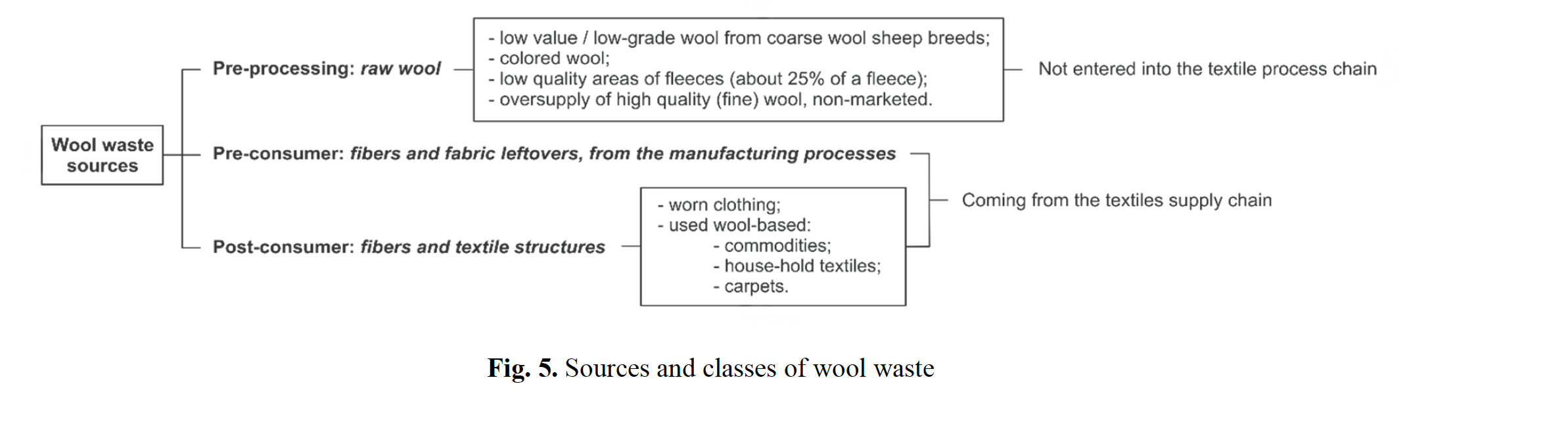

WOOL WASTE¶

WOOL PROPERTIES¶

- Absorbancy - moisture

- Insulating - optimal temperature controling

- UV protection

- Water repellent

- Wrinkle resistance

- Resilient and durable

- Non-allergenic

- Fire-retardant

- Resists dust, dirt, mildew and mold * Renewable

| Material name | Fabric composition | Breathability | Moisture-wicking abilities | Heat retention abilities | Stretchability | Washing temperatures |

|---|---|---|---|---|---|---|

| Cashmere, fleece, fur, hair, tweed | Hair animmal fibers | Moderately breathable | High | High | Medium | Cool or warm |

Food Industry - Textile Industry¶

Add informaton

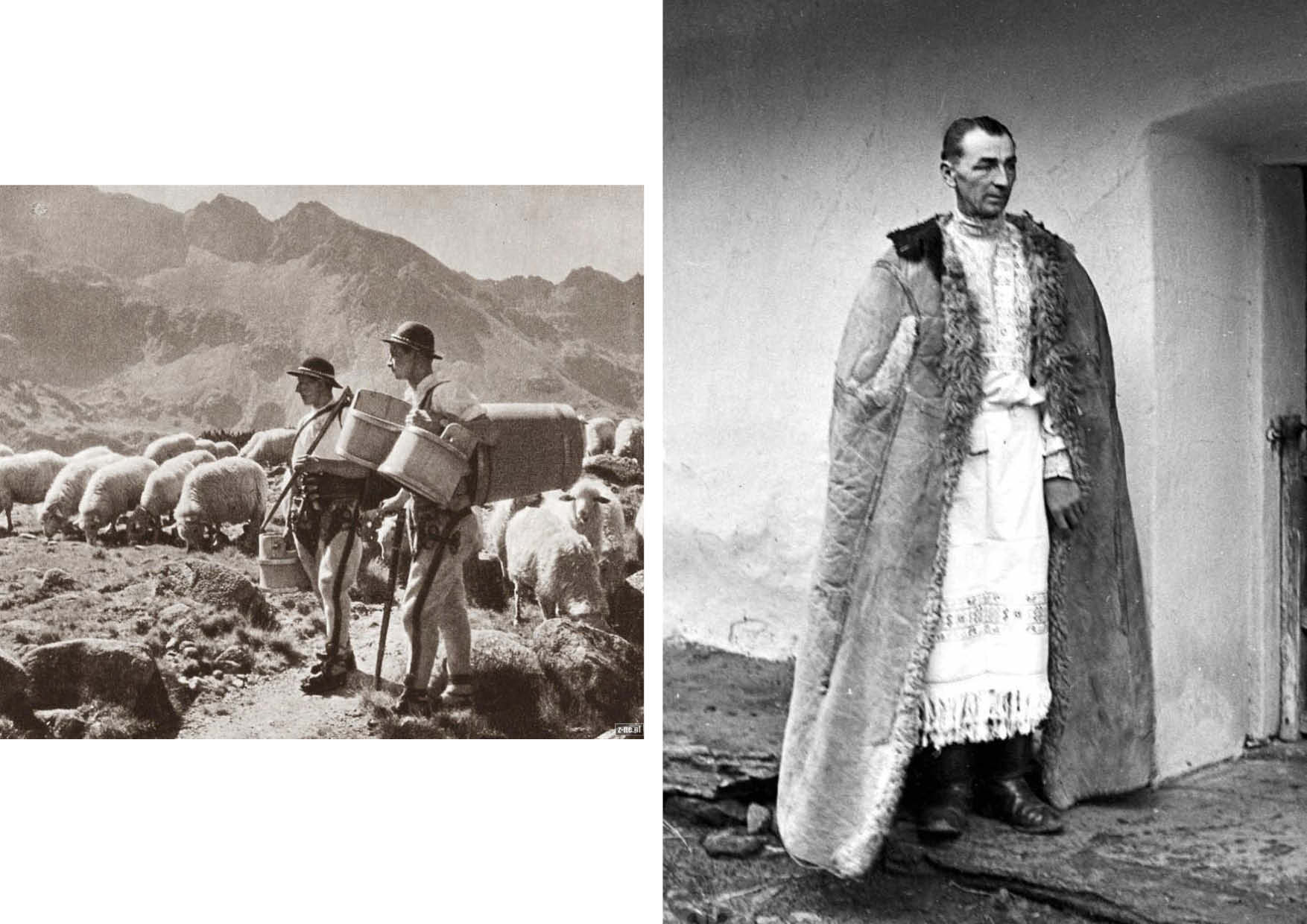

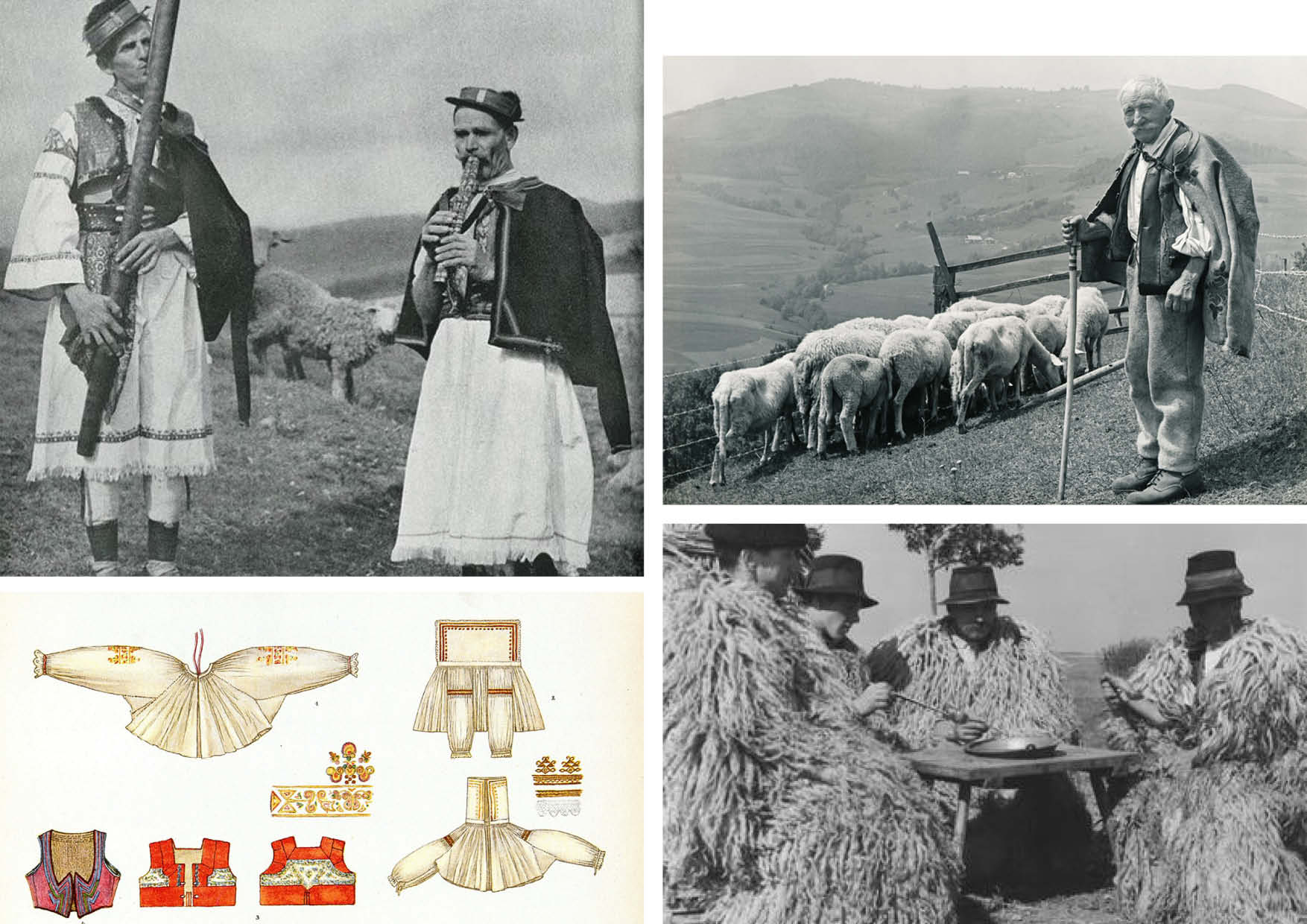

MOODBOARD & INSPIRATION¶

sheep shepherd is a person who tends, herds, feeds, or guards herds of sheep. Inspiration of Slovak landscapes and traditional clothing of sheeps shepherds. About their lifestyle.

Slovak folklore clothing¶

folk - digital embroidery - the embroidery had a social status and carried historical value. Nowadays - parametric value and digital production.

coats and architecture - From wool insulation to wool coat. Its connection between clothing and architecture. Both form a kind of protection linked to the human body.

About FELTING¶

It is the process of turning a protein - animal fiber such as sheep wool, alpaca, mohair, yak, etc. into a piece of fabric by connecting the individual fibers. Also you can describe it as is the process of producing a textile or fabric by combining and compressing the loose fibers, wool or hair. To produce a piece of felt, you have to cause the hair or fibers to interlock with each other creating a matted fabric. This can be accomplished by applying water and agitation or by physically tangling the wool using special felting needles.

-

WET FELTING

Hot water, sometimes with added soap, is sprayed onto layers of wool, while repeated agitation and compression causes the fibres of the wool to hook and weave together into a single piece of fabric.

-

NEEDLE felting

This method doesn’t require any water. You use a special needle that has notches along its shaft; these catch the wool fibres and tangle them with other fibres to produce felt.

REFERENCES¶

- How to Wet Felt Wool Fabric, Wet Felting Techniques

- The Bartlett School of Architecture, UCL, Flextiles, 2015-2016

SCAFFOLDS¶

- Fleece - hot water and pressure

- Wet felting - fulling

- Needle felting

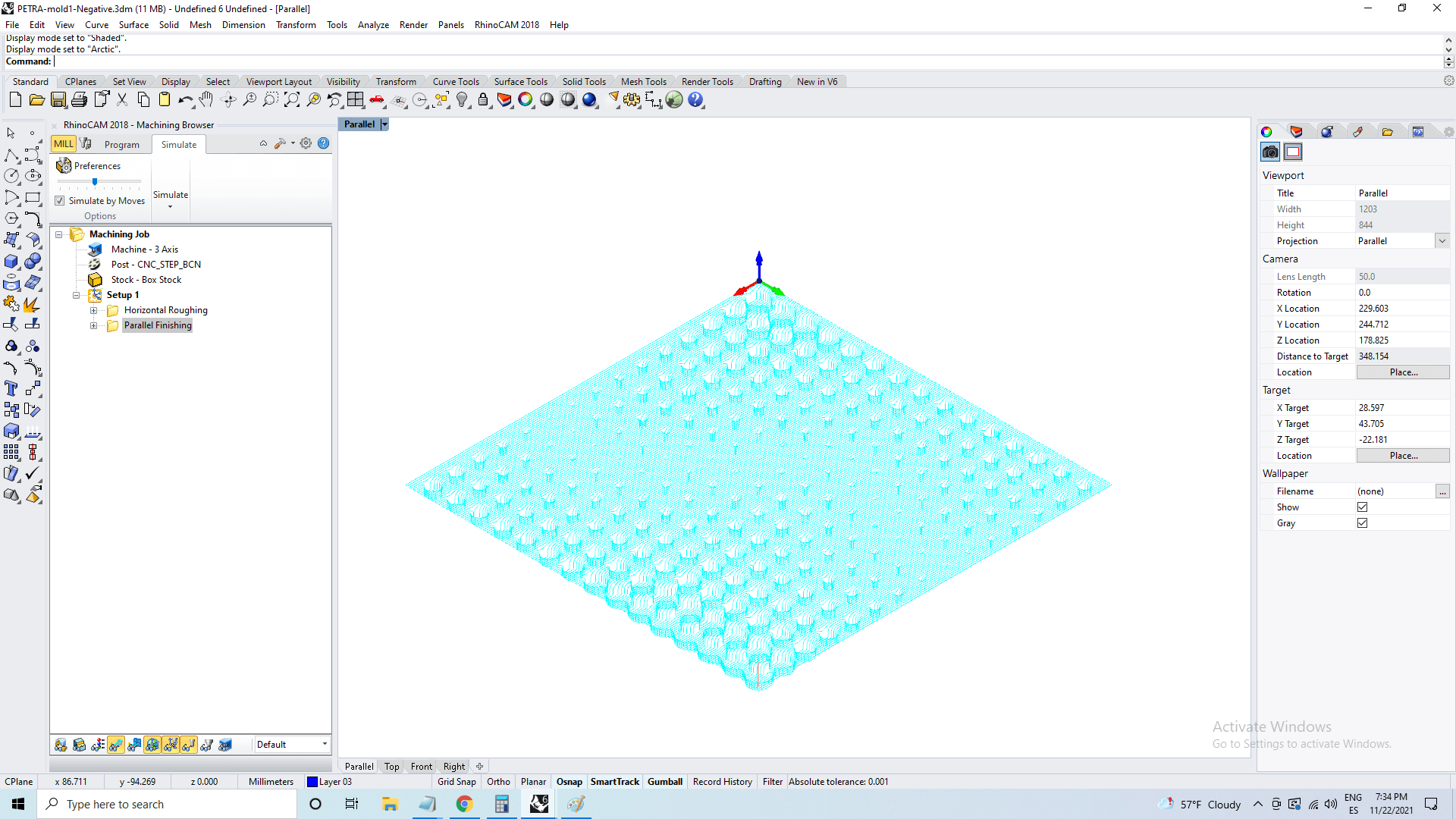

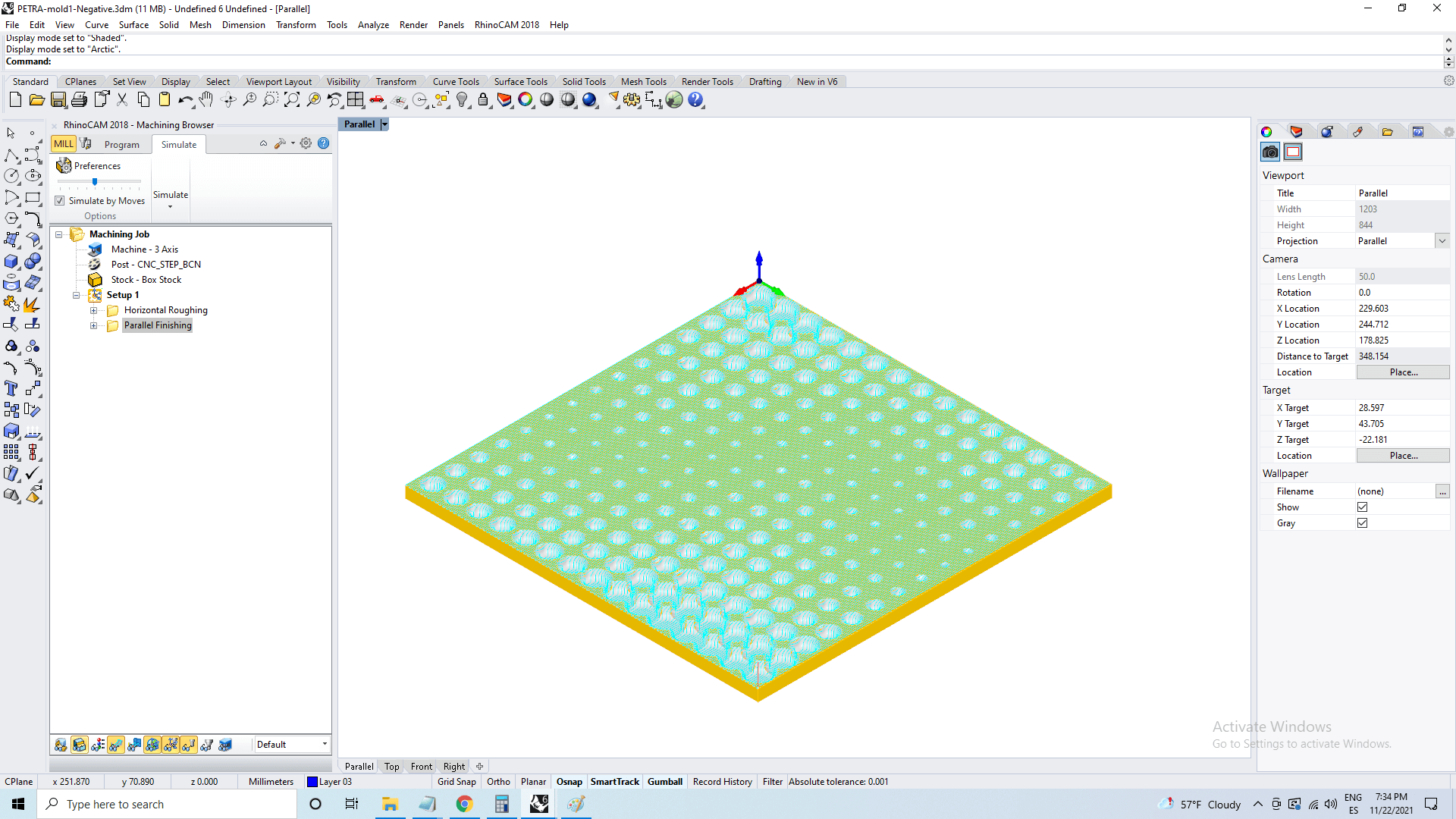

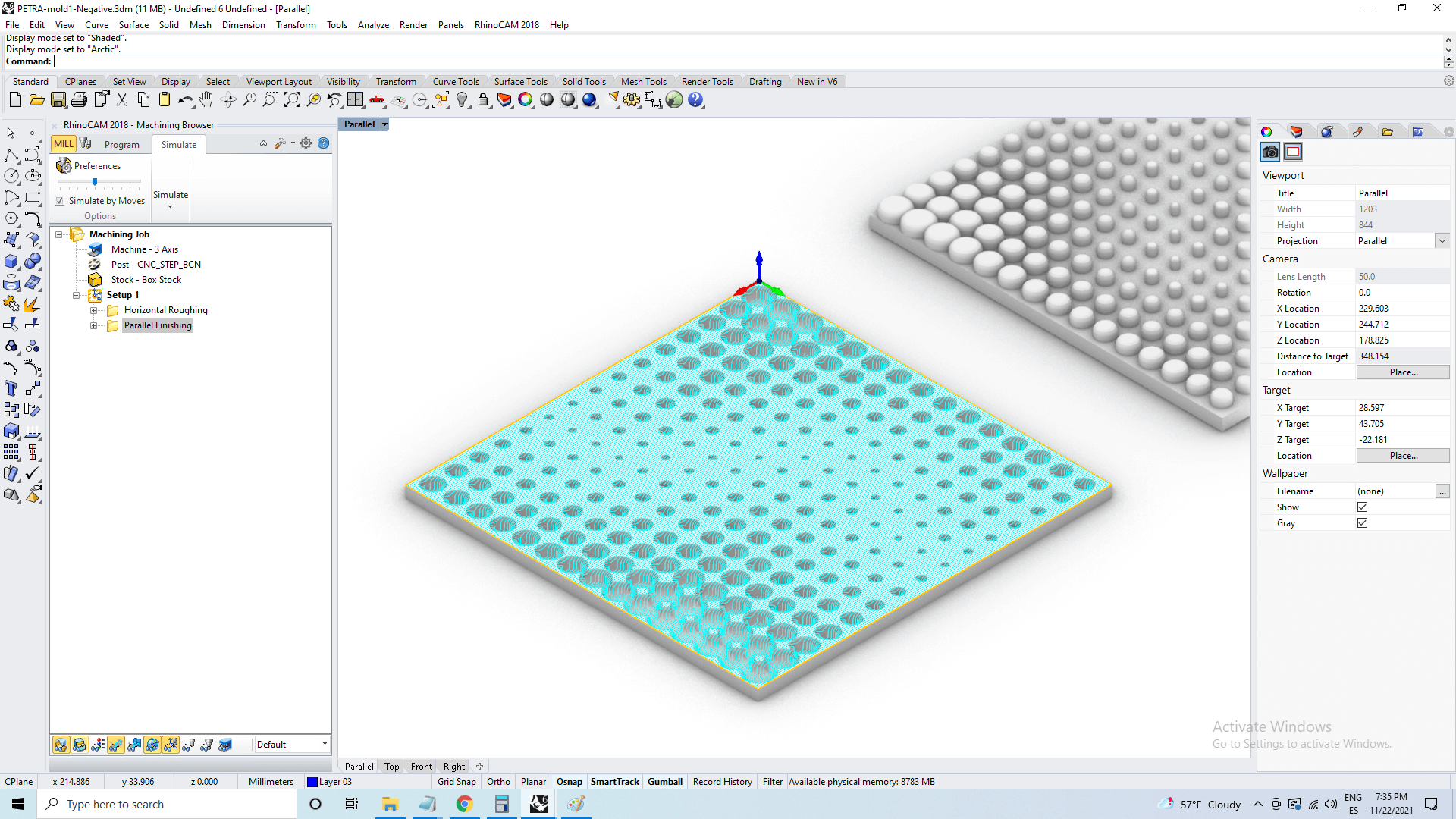

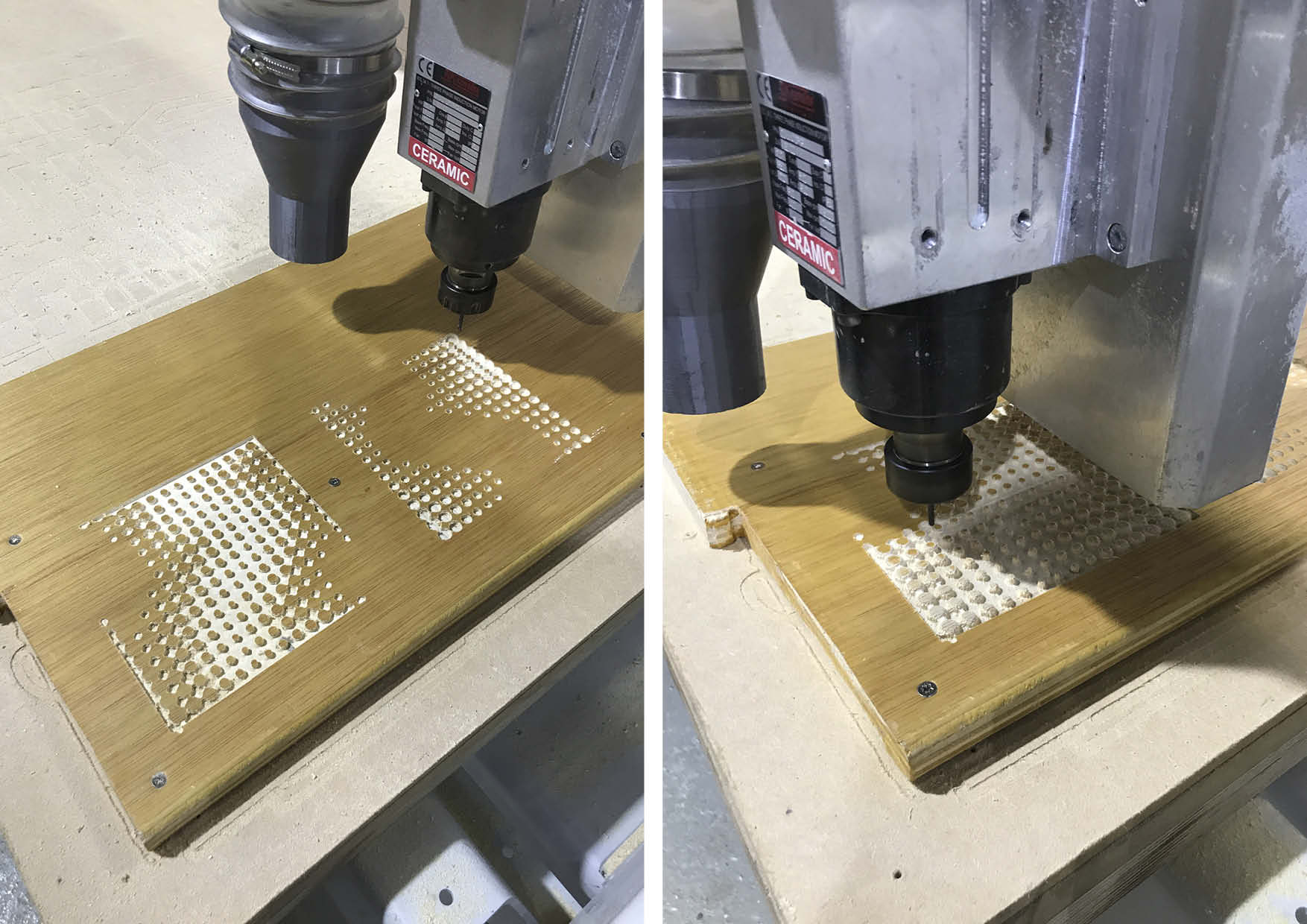

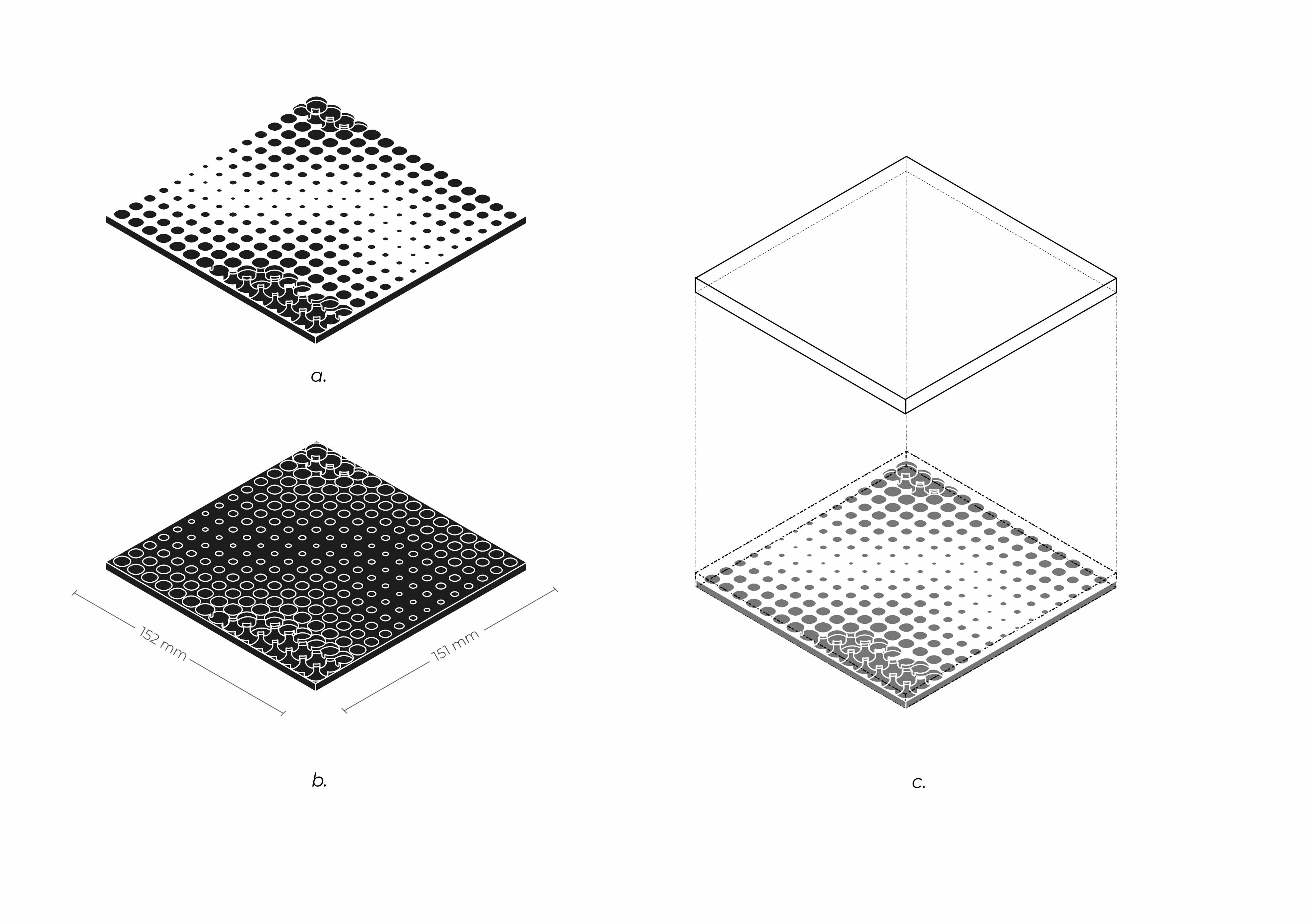

3D Modeling and parametres¶

Model 01 - positive¶

- 01 - Horizontal Roughing

| Material | Drill size | Drill type | Speed | Milling time | Bounding box size |

|---|---|---|---|---|---|

| Polywood 10 mm | 6.000 mm | Flat | 5000 s | 3 min 6 s | 151 x 152 x 9 mm |

- 02 - Parallel Finishing

| Material | Drill size | Drill type | Speed | Milling time | Bounding box size |

|---|---|---|---|---|---|

| Polywood 10 mm | 3.175 mm | Flat | 5500 s | 3 min 6 s | 151 x 152 x 9 mm |

Model 02 - negative¶

- 01 - Horizontal Roughing

| Material | Drill size | Drill type | Speed | Milling time | Bounding box size |

|---|---|---|---|---|---|

| Polywood 10 mm | 3.175 mm | Flat | 5000 s | 30 min 6 s | 151 x 152 x 9 mm |

- 02 - Parallel Finishing

| Material | Drill size | Drill type | Speed | Milling time | Bounding box size |

|---|---|---|---|---|---|

| Polywood 10 mm | 3.175 mm | Round | 3000 s | 40 min 26 s | 151 x 152 x 9 mm |

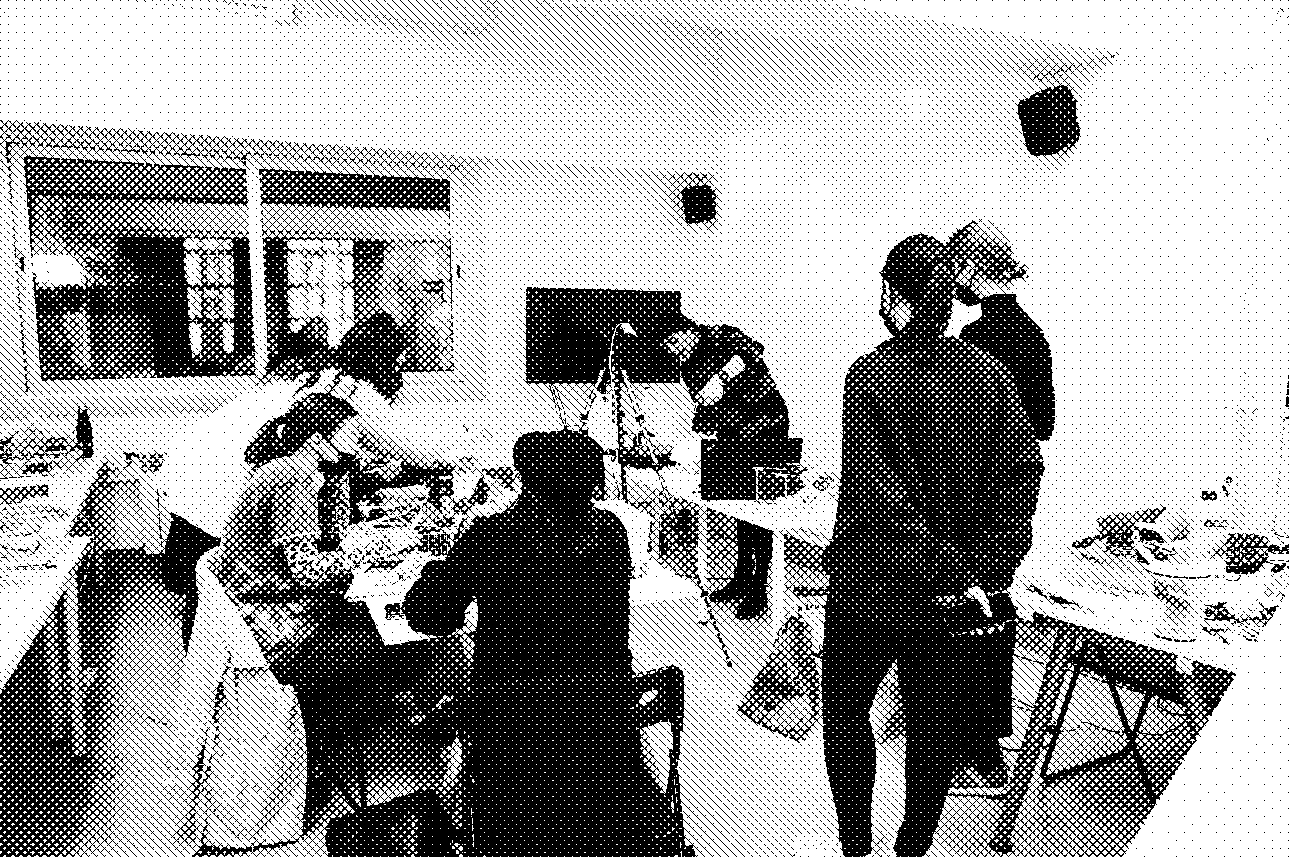

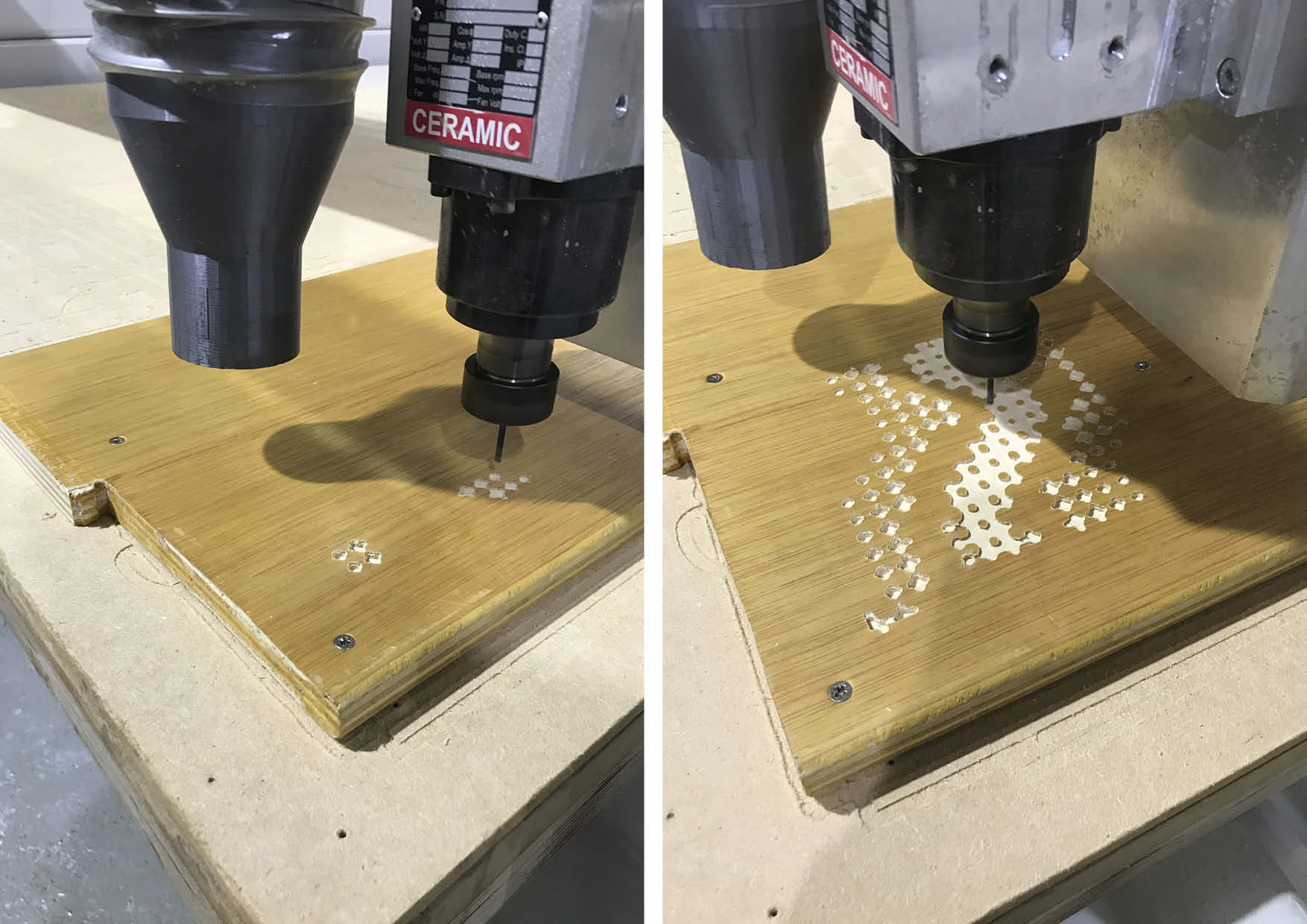

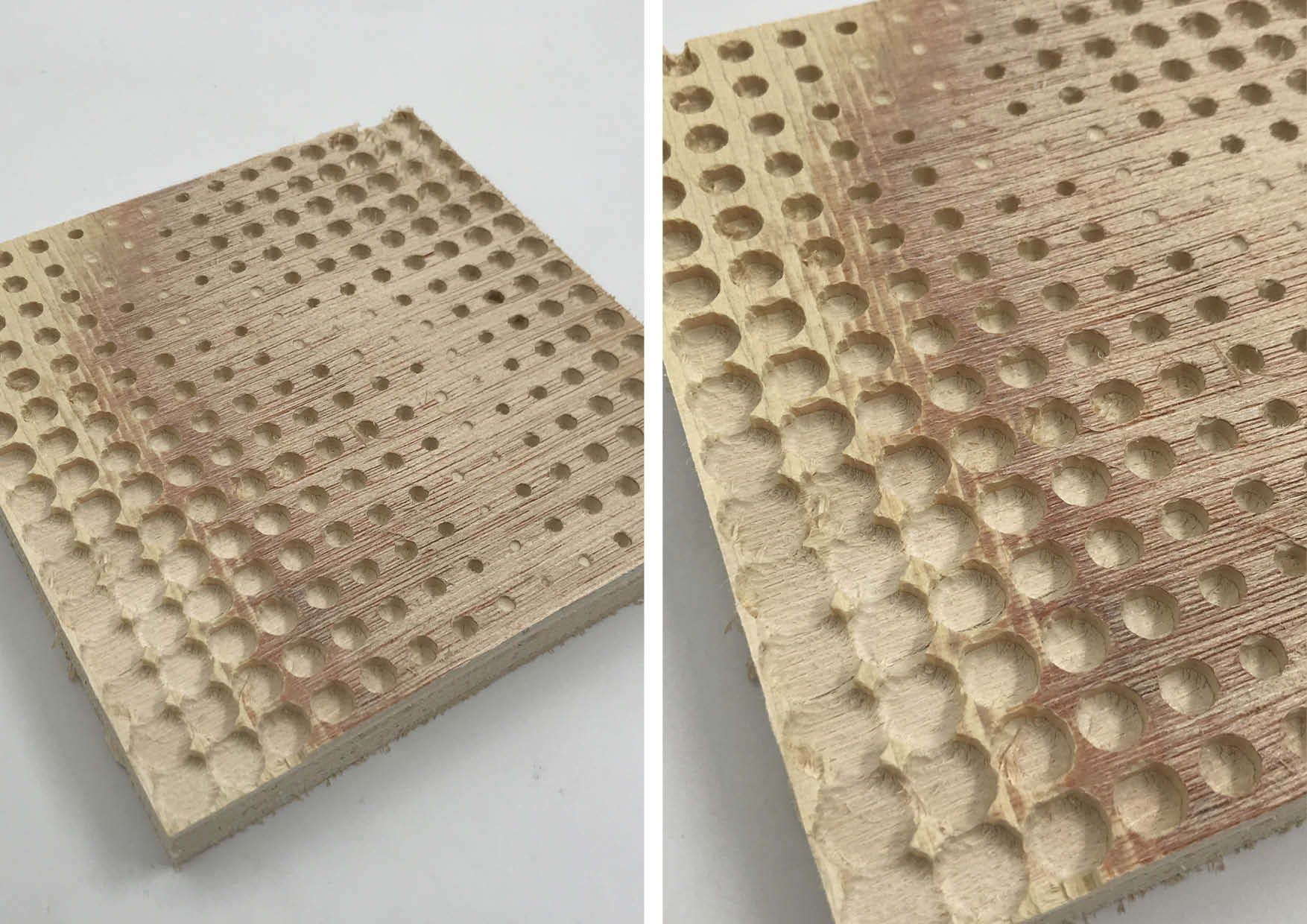

CNC Milling¶

Process¶

- Place the polywood on the CNC milling machine and check the X and Y axes. You must measure your 0.0 starting point - Home and the height of the Z axis.

- Use a flat drill 3.175 mm and calibrate the nozzle - with the Z button tool.

- /1. layer - Engraving (screws) 3 mm deep - 5 holes for screws to attach the polywood to the CNC board. Use a drill to put screws to the board.

- Measure again the height of the Z axis.

- /2. layer - Horizontal Roughing - to mill three layers.

- Change the drill for round drill 3.175 mm and calibrate Z axis again.

- /3. layer - Parallel Finishing - smoothing part.

- Change the drill once again - 6 mm and calibrate the Z axis again.

-

/4. layer - Profiling - cutting the milled pieces out of the polywood board.

-

/2. layer

-

/3. layer

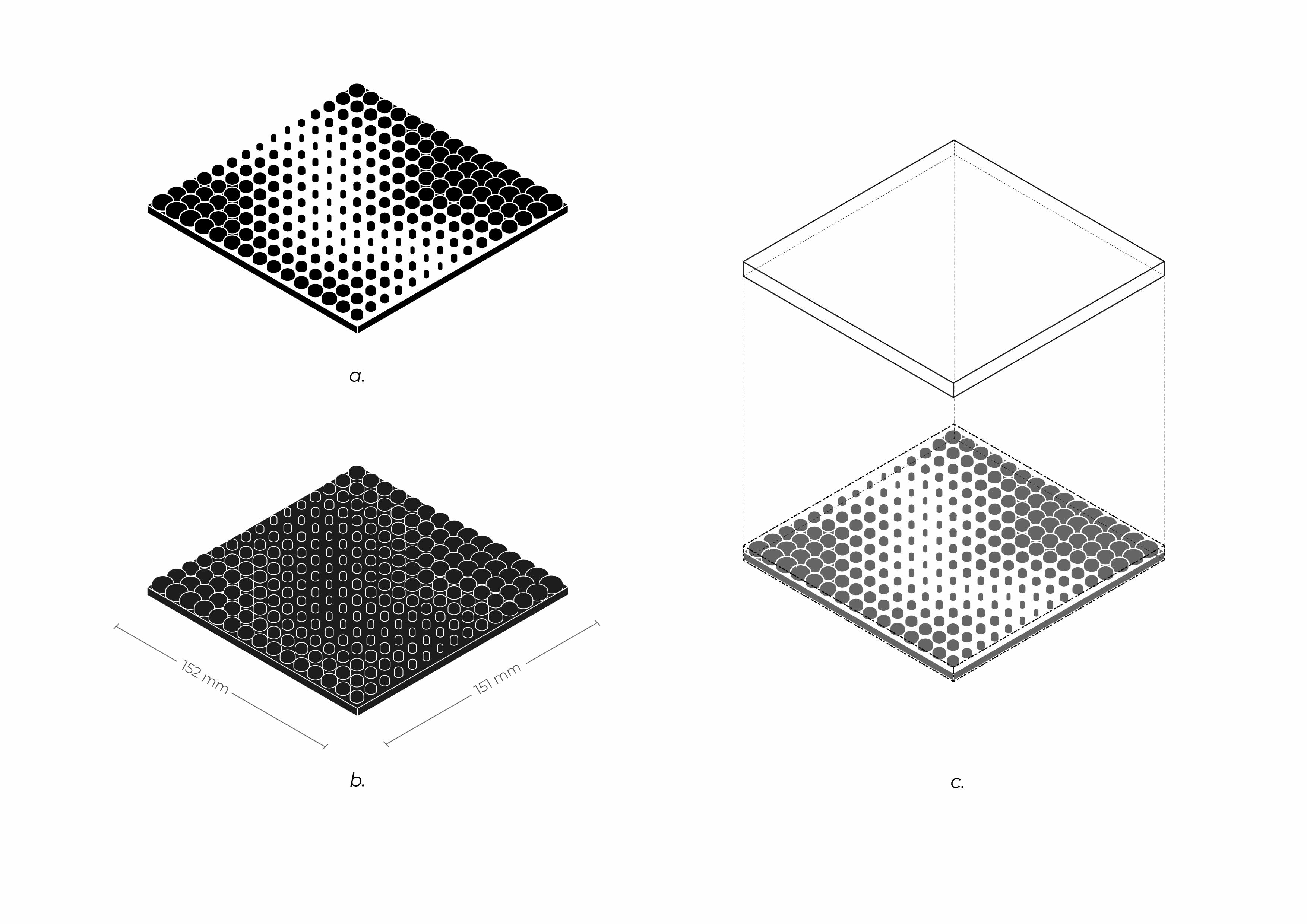

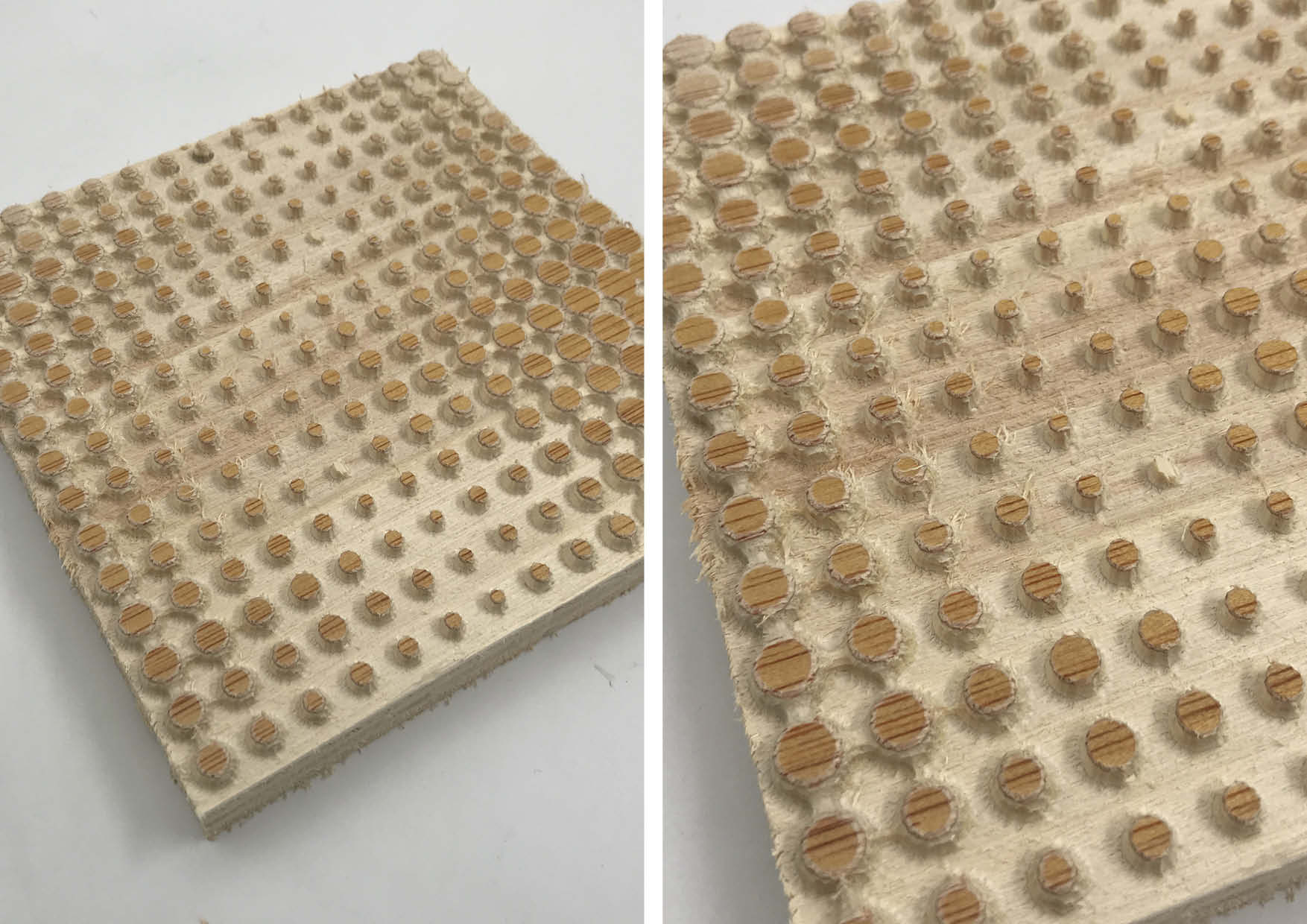

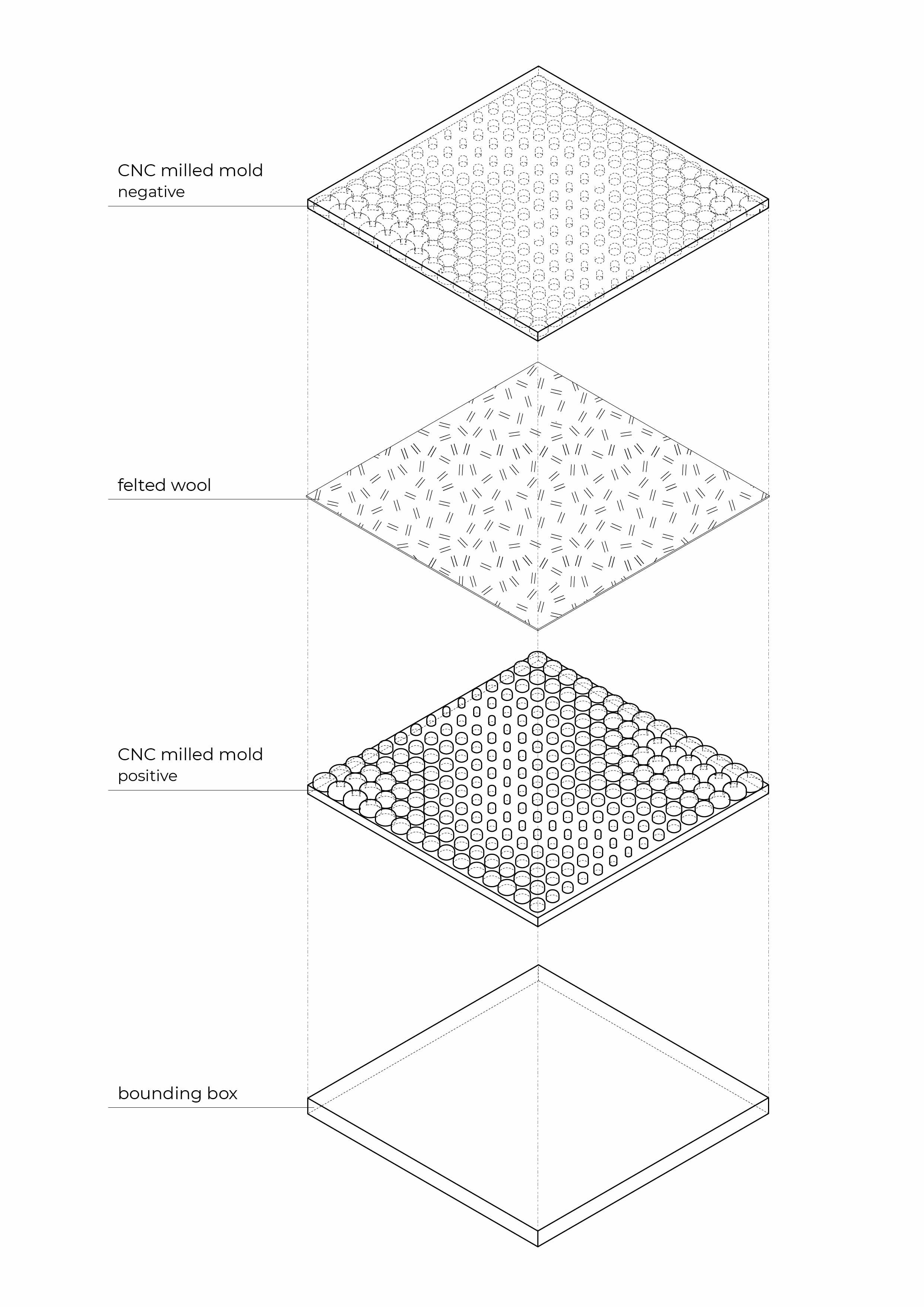

Wool composite¶

-

Model 01 - positive

-

Model 02 - negative

-

Composite diagram

Wool - WET FELTING¶

Tools¶

- soap, spray bottle, kettle, plastic foil, mesh fabric, dough roller

Process¶

- Place the plastic foil on the table and start placing the wool fibers next to each other (a.). Try to separate them. You can create multiple layers in different directions. Measure the size of the "textile" you want to prepare (it will shrink during the process).

- Preheat the water in the kettle and add soap. Fill the spray bottle with the soap mixture.

- Spray the soap mixture on the wool (b.) and cover it with a mesh fabric (c.). You can start "massaging" / felting the wool over the fabric to create a compact texture. * You can also use a dough roller to press and felt wool (d.). Keep rolling and be patient! Nothing happens overnight.

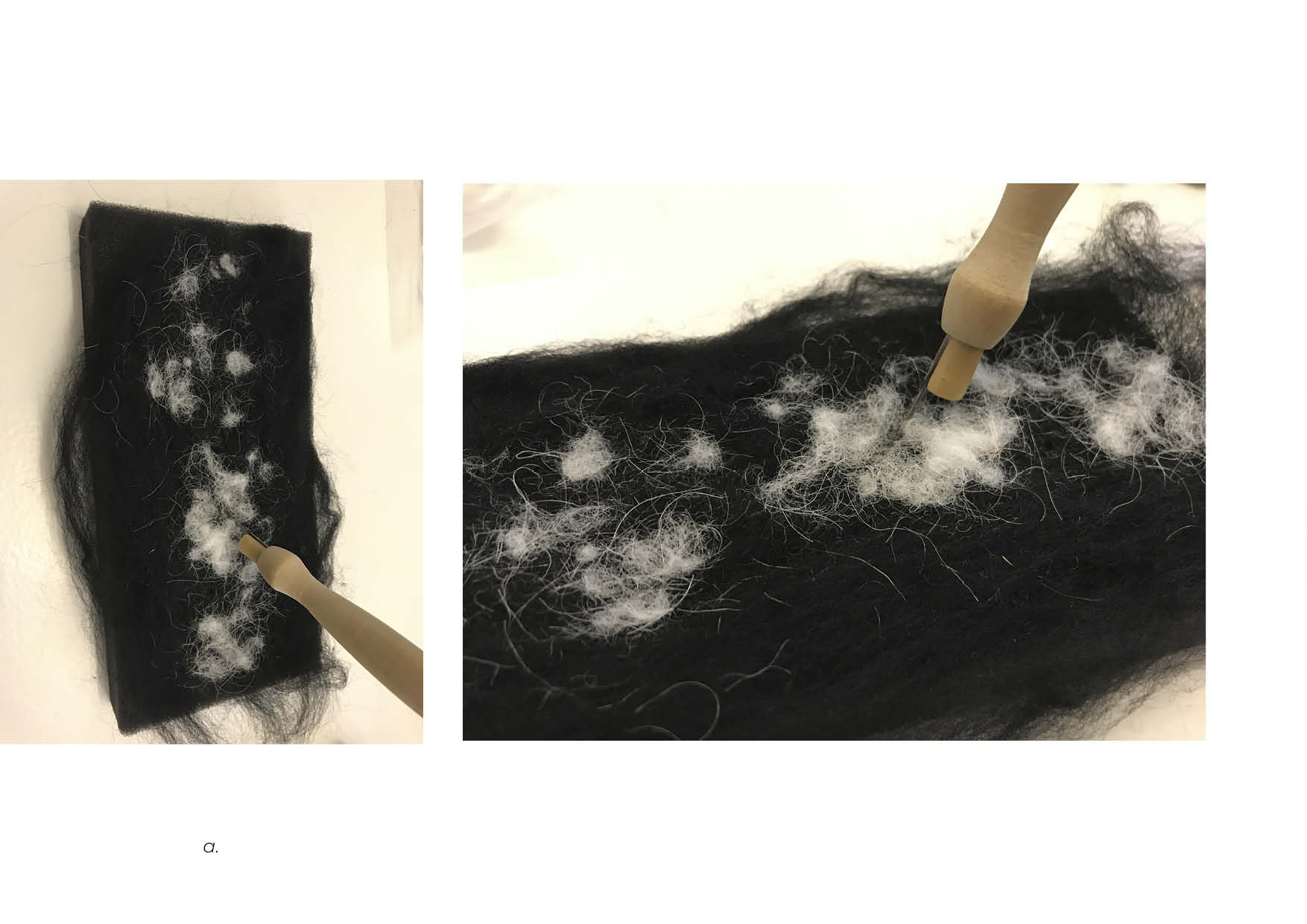

Wool - NEEDLE felting¶

Tools¶

- felting needle, foam (felting base)

Process¶

- Place the foam under your piece of wool - you can use different types of colors - that you want to felt (a.).

- Prepare a needle - different sizes - and start felting at an angle.

- Watch out your fingers.. * Keep felting and be patient! Good things are worth waiting for.

RESULT¶

- CONCLUSION:

REFERENCES¶

FILES - OPEN SOURCE¶

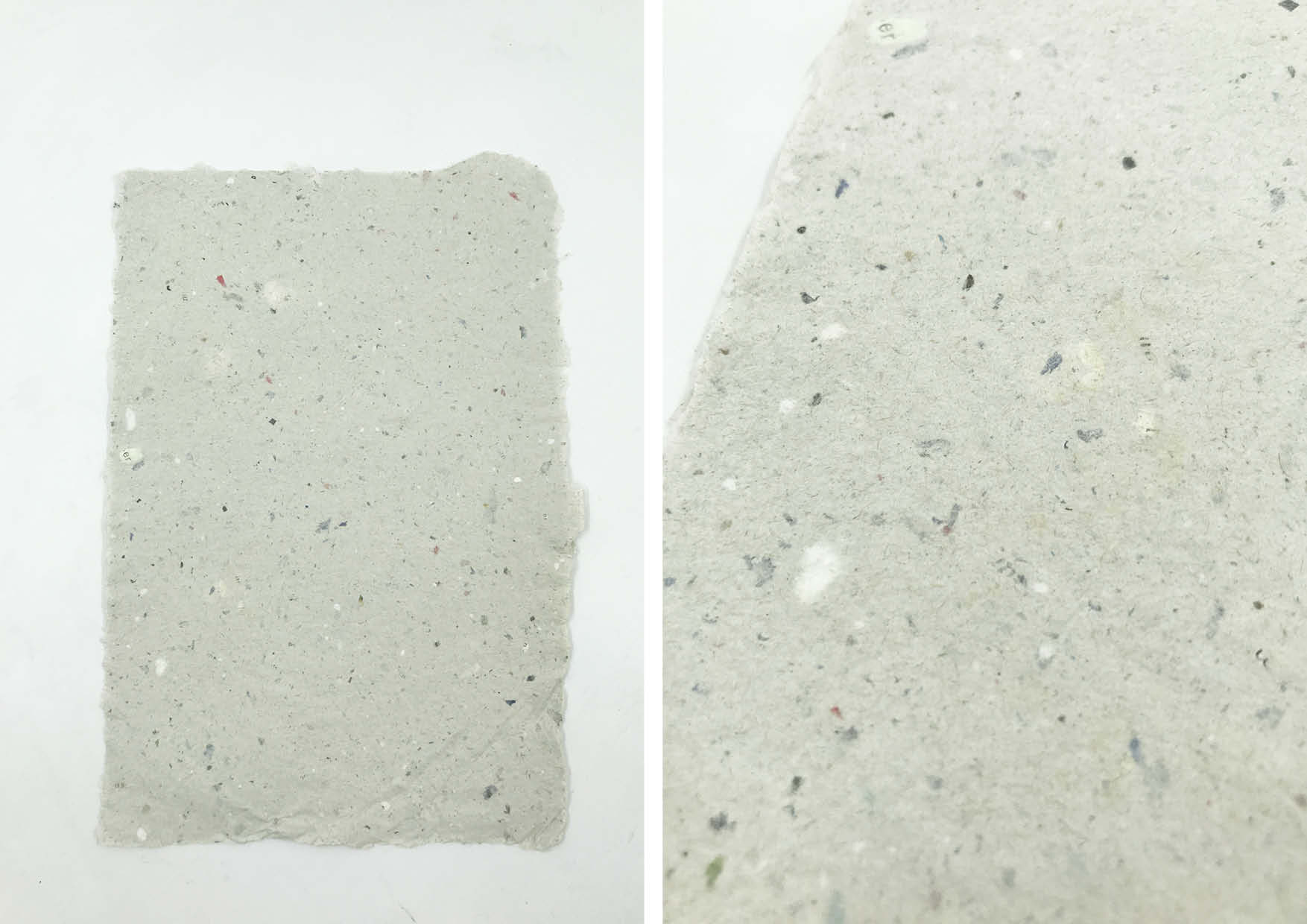

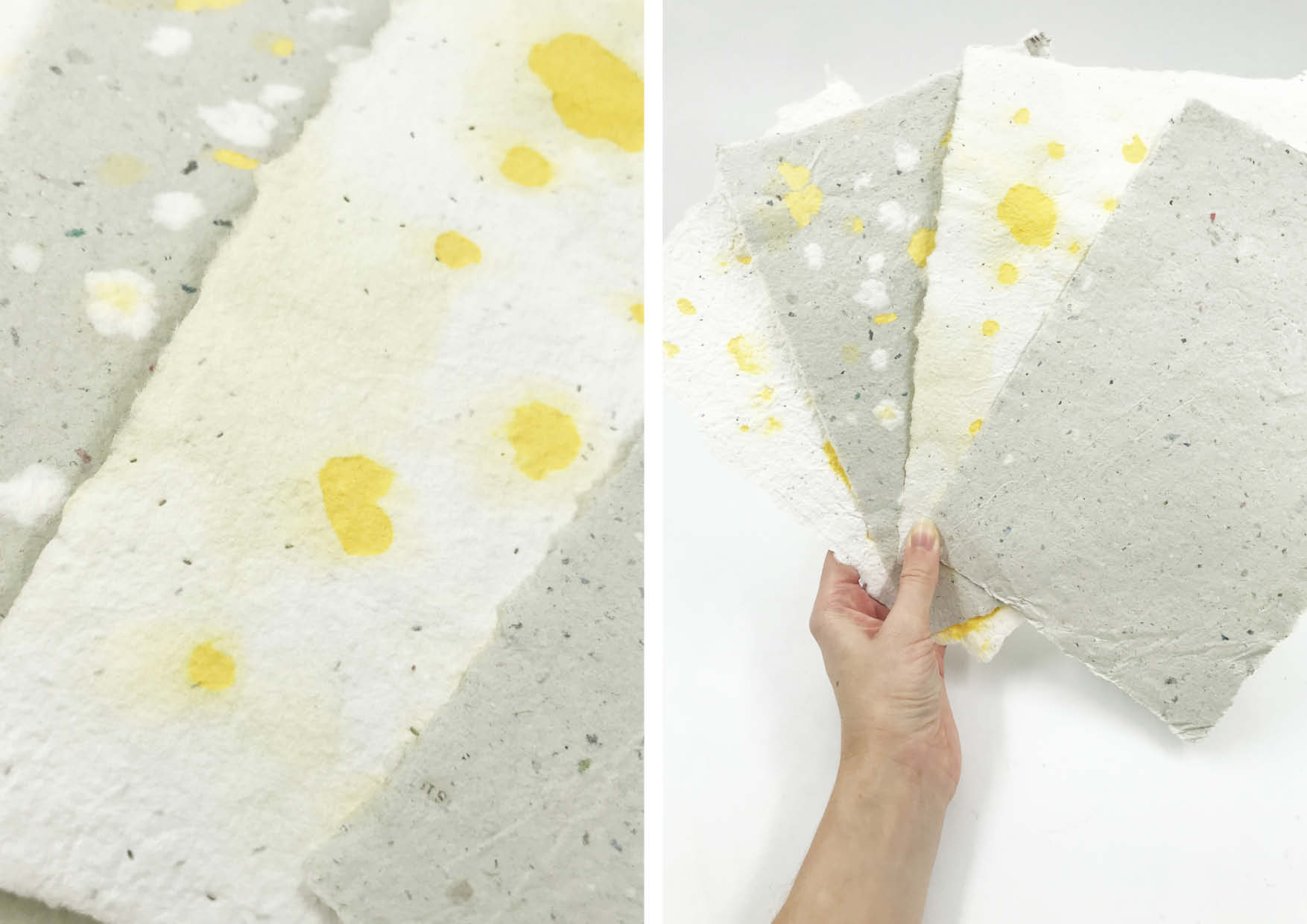

| FROM TEXTILE TO PAPER |¶

PAPER WORKSHOP in the Museu Molí Paperer de Capellades, España - textile recycling (cellulose).

Process¶

* Immerse the frame vertically in a container with textile and water. Hold it with your thumbs on both sides of your hands. * Remove it from the water in a horizontal position and shake gently. * You can set aside the top of the frame and use dyes to decorate the paper. * Place a soft cloth on the bottom where you will fold the wet paper to avoid damaging it. * Flip the rest of the frame onto the fabric and cover the damp part with another layer. * After several repetitions, place all the layers on top of each other under the press and squeeze out the remaining water. * Then divide the papers and allow them to dry in a horizontal position for two days. * After drying, you can pass them through the iron and reuse the textile at the bottom.

Results¶