Week 11 | Implications and Applications¶

Project Proposal¶

My creative background specializes in multiple textile practices, ceramics, and an education in Industrial Design. Combining my skill set I am going to explore:

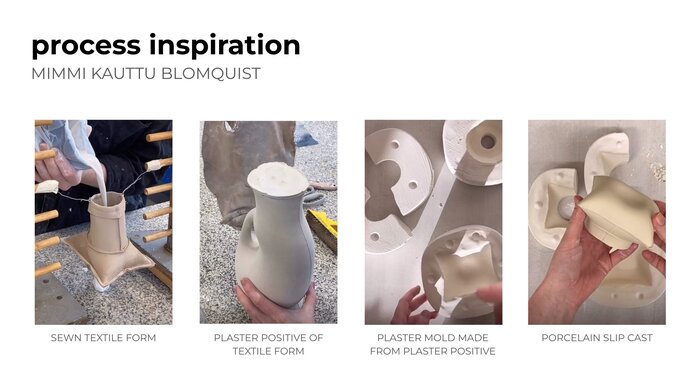

The inspiration of the process for my project came from Mimmi Kauttu Blomquist where she sews a textile form, casts it in plaster to then make a mold from which she creates porcelain slip casted forms.

Taking inspiration from Mimmi’s process I will be researching and developing different computationally designed textile forms, a bio material to replace plaster and a bio material to replace the ceramic slip.

The tools I will be using consist of the 3D printer, laser cutter, knitting machine, looms, sewing machine, and bio kitchen at the fablab and textile center here in Blonduos. Computationally I will be using the adobe suite programs, rhino and grasshopper, solidworks, and clo3D.

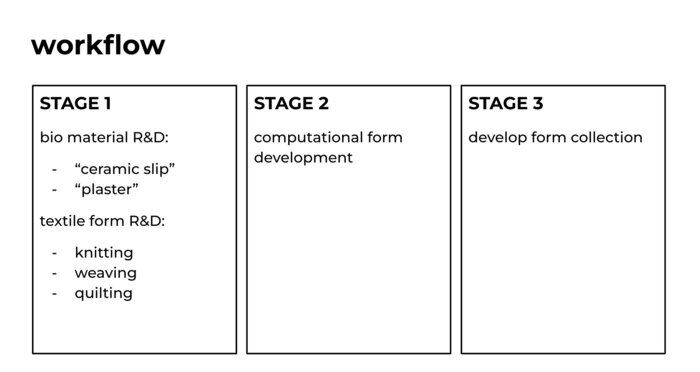

I am breaking my workflow into 3 stages, most heavily focusing on stage 1 where I will be researching different biomaterials and how they are compatible with each other and the different textile construction methods. Stage 2 will involve using undecided data parameters to develop the form and textures of the selected textile method. And Stage 3 will be the development of a collection of forms or applying the process to something function.

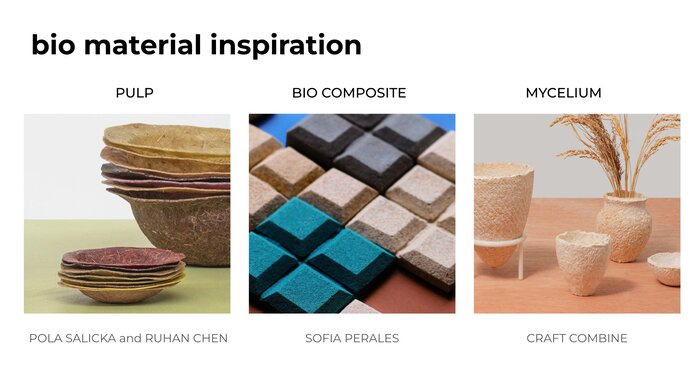

The plaster like biomaterial will need to have the structural elements of reusability and moisture absorbing properties. And the ceramic slip like biomaterial will need to be moldable and not dissolve the plaster like mold it will be poured into. These biomaterials could range from being pulp based to bio composites to mycelium and will involve partnering with local restaurants to use their food waste. The point of using bio materials is to eliminate the need for a ceramic kiln and allow more accessibility of the ceramic creative process

In stage 1 the exploration of the initial textile form itself will involve machine knitting, jacquard weaving, and/or quilting to understand the compatibility the biomaterials have with the textiles in picking up textural details and the structural elements of stretch and ability to hold thick liquids. I will also be using natural or reclaimed fibers to have a smaller impact on the resources I use for my project.

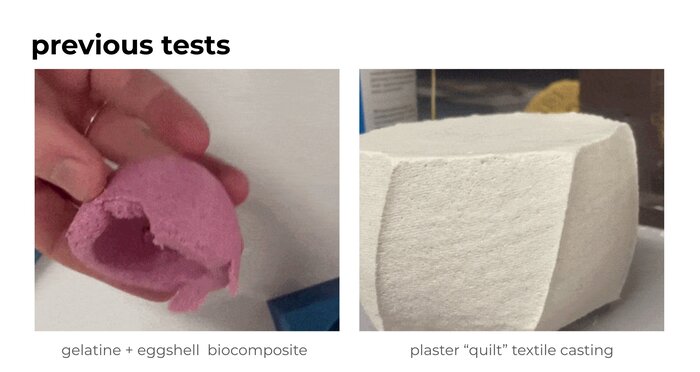

During our past weeks I have tested out different biocomposites that have the potential to be the “ceramic slip” and explored plaster casting in textile forms and had successful results. See weeks 6 and 9 for prototype tests.

As my project is looking to be more research based my goals are to develop libraries that record the tests of the different biomaterials and what their properties, compatibility with one another and the textiles are, drying rates and so on are. And have an accompanied library of textile patterns and textures swatches and how they worked with the bio materials.