6. BioFabricating Materials¶

Inspiration¶

Scarlett Yang used algae extract and silk cocoon protein to create a glass-like dress that grows over time and can decompose in water within 24 hours.

The biomaterial dress changes shape in response to different humidity and temperature levels, twisting and creasing as these conditions increase.

Scarlett Yang used algae extract and silk cocoon protein to create a glass-like dress that grows over time and can decompose in water within 24 hours.

The biomaterial dress changes shape in response to different humidity and temperature levels, twisting and creasing as these conditions increase.

When exposed to water, the garment is able to decompose within hours. For example, the material decomposes within one hour when soaked in alkaline water at a temperature of 80 degrees celsius, or in less than 24 hours if soaked in 60-degree-celsius water.

Alternatively, the garment would degrade naturally in rain, river or sea water.

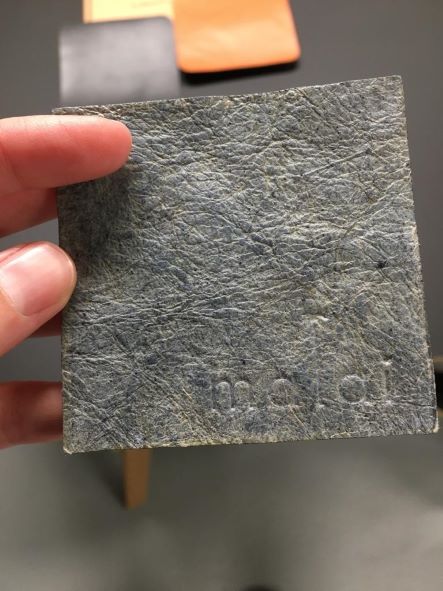

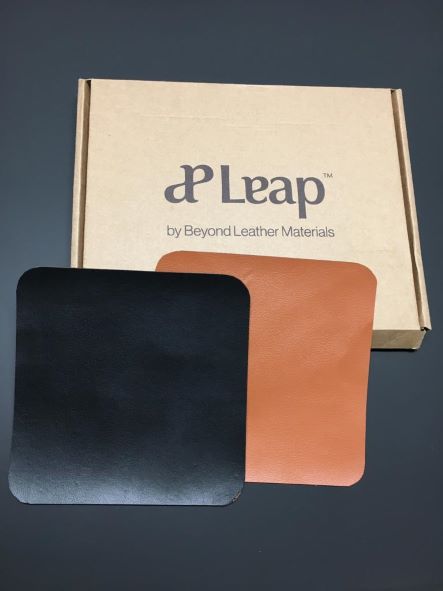

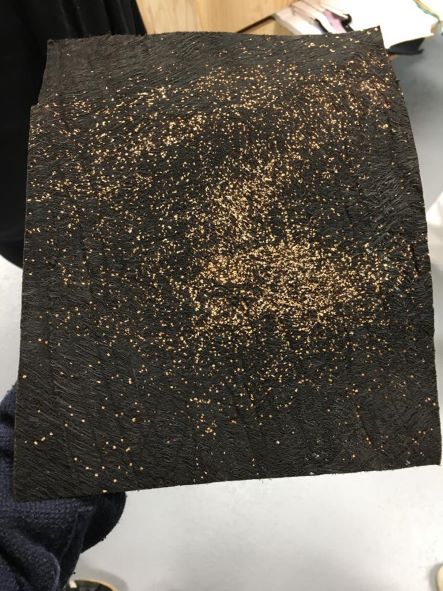

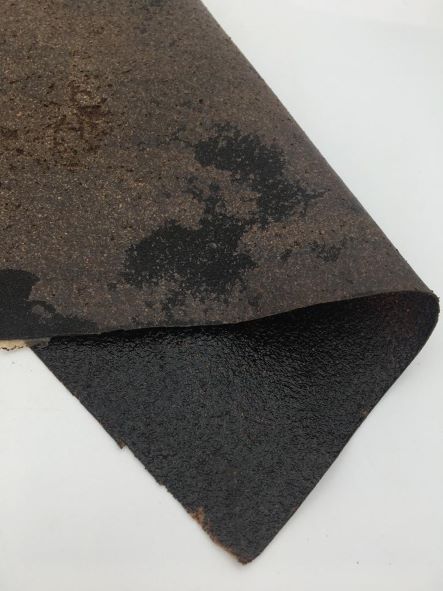

At the Basque BioDesign Center we have a library full of innovative materials what is called Materioteca. Here I show part of the materials that come from different raw materials. It is very inspiring to be able to observe the infinity of possibilities that we have within our reach.

|

|

|

|

|

|

Biomaterials Recipe¶

This week has been very experimental, discovering new recipes.

Gelatin¶

* 250ml H2O

* 25gr Gelatin

* 12,5gr Glycerin

* Pour 250 ml of cold water into your pot.

* Measure the ingredients with a scale and add it to the mixture. Quantities can be adjusted as long as the ratio is more or less the same.

* Continue stirring the mixture as it heats up during 10 minutes.

* Take off the heat when it starts to foam. Continue stirring for a few more minutes.

* Once the mixture is ready, pour it into a mold.

* Let dry for approximately 2-3 days

Final Result

| Transparency | Elasticity | Smell | Flexibility | Resistance | Texture | Impermeability |

|---|---|---|---|---|---|---|

| XXXX | XX | X | XXXX | XXX | X | XX |

Coffee¶

* 250ml H2O

* 25gr Gelatin

* 12,5gr Glycerin

* 20gr coffee

* Pour 250 ml of cold water into your pot.

* Measure the ingredients with a scale and add it to the mixture. Quantities can be adjusted as long as the ratio is more or less the same.

* Continue stirring the mixture as it heats up during 10 minutes.

* Take off the heat when it starts to foam. Continue stirring for a few more minutes.

* Once the mixture is ready, pour it into a mold.

* Let dry for approximately 2-3 days

- It may take several days for the foil to be completely dry. Once the sheet is completely dry, it can be carefully demolded using a scalpel or fine knife.

- Depending on the humidity and temperature in the room, it will take more or less to dry.

- Make sure the environment is as dry as possible.

- If it's too sticky, next time add less glycerin.

- As your sample dries it will lose a lot of volume and shrink.

- If you want it to be smooth and flat you must stretch it with a frame or put weight on it.

Final Result

| Transparency | Elasticity | Smell | Flexibility | Resistance | Texture | Impermeability |

|---|---|---|---|---|---|---|

| X | XX | XX | XXXX | XXX | XX | XX |

Fresh BANANA Peel¶

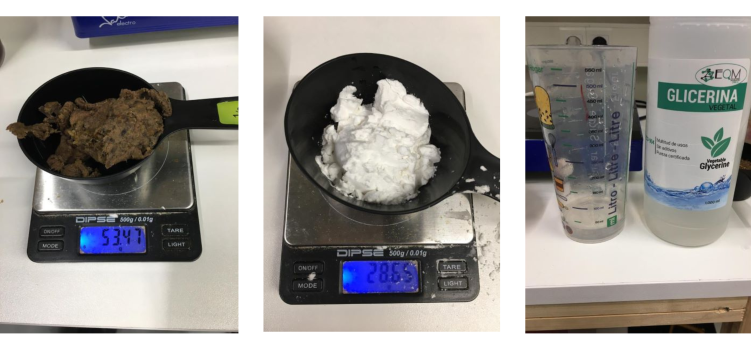

* 53,47gr fresh banana peel (3 bananas)

* 28,57gr Potato Starch

* 30ml Glycerin

* 250ml H2O

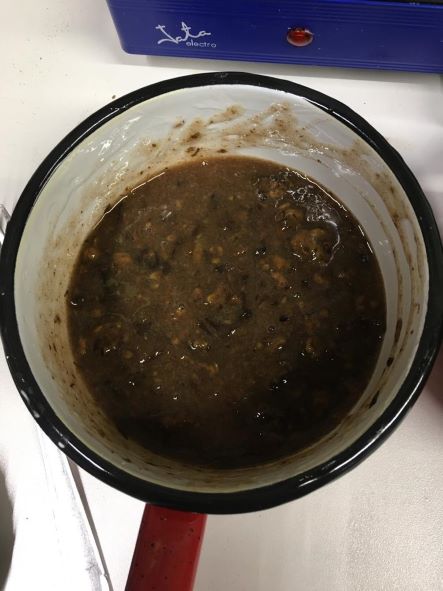

* Cut the banana peels into tiny pieces, as small as possible. The softer the shell, the easier it will be to break open and release the starch it contains.

* Add 250 ml of water to the cut pieces and boil them for about 10 minutes. It is about making the shells as soft as possible to be able to turn them into a soft paste.

* Once the pieces are soft, you can use a fork or pestle to turn them into a paste. Try to make it as smooth as possible.

* Add and mix water, Glicerin, Alginato and bring the mixture to a boil. The mixture should have thickened. Turn off the heat and remove.

* You must remove excess water. You can do this by placing the pasta in a colander or sieve and pressing it down, or you can also try to absorb the moisture by pressing the pasta with a sponge. Now you have the extracted starch. You should aim to have 40 grams of the banana peel paste.

* Stir over medium heat until the paste is even and smooth, and most of the water has evaporated.

* Now you can put the paste in a silicone mold. You can also place it between two pieces of baking paper or aluminum foil and roll it out carefully with a rolling pin, or even with your hands.

* Let air dry until dry.

Final Result

| Transparency | Elasticity | Smell | Flexibility | Resistance | Texture | Impermeability |

|---|---|---|---|---|---|---|

| X | X | XX | X | X | XXX | XX |

Dehydrated and ground BANANA¶

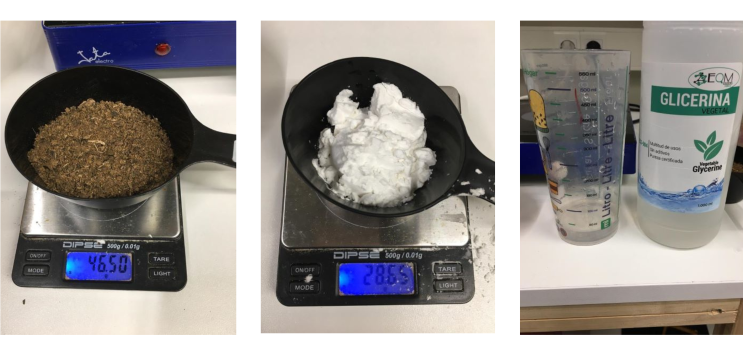

* 46,50gr Dehydrated and ground banana (3 bananas)

* 28,57gr Potato Starch

* 30ml Glycerin

* 250ml H2O

* Dry the banana peels in the dryer to speed up the process.

* Add and mix water, Glicerin, Alginato and bring the mixture to a boil. The mixture should have thickened. Turn off the heat and remove.

* Stir over medium heat until the paste is even and smooth, and most of the water has evaporated.

* Now you can put the paste in a silicone mold. You can also place it between two pieces of baking paper or aluminum foil and roll it out carefully with a rolling pin, or even with your hands.

* Let air dry until dry.

Final Result

| Transparency | Elasticity | Smell | Flexibility | Resistance | Texture | Impermeability |

|---|---|---|---|---|---|---|

| X | X | XX | X | X | XXX | X |

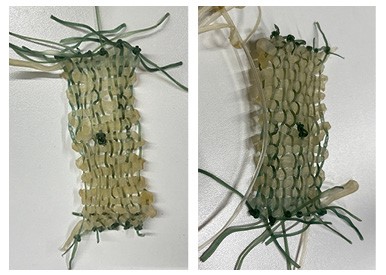

Alginate threads¶

* 25 gr Sodium alginate powder

* 50/60gr Glycerin

* 600ml H2O

* Weigh the ingredients for the alginate thread (alginate, glycerin, water).

* Put the alginate and glycerin in a blender and add a splash of water. Mix until you get a thick and homogeneous paste.

* Then add the rest of the water and beat again.

* Cure Solution: apply Sodium Cloride either with a spray bottle or immerse alginate within it.

I have taken this image from Lisa's documentation. In this example, Laura weaved fresh alginate which reduced by 30% over 7 days.

| Transparency | Elasticity | Smell | Flexibility | Resistance | Texture | Impermeability |

|---|---|---|---|---|---|---|

| XXX | XX | X | XXXX | XXX | X | XX |

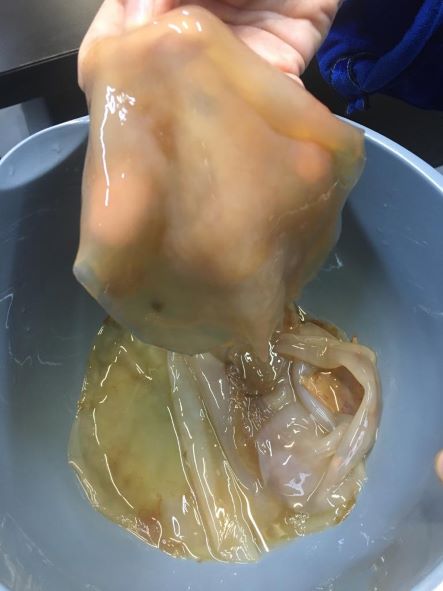

Scoby Celullose¶

* 7 cups of H2O

* 1 cup of sugar

* 4 tea bags

* 1 bottle of beer

* Boil water and pour into large container.

* Add tea bags and sugar.

* Stir until ingredients dissolve.

* Add SCOBY.

* Let sit for several weeks and remove SCOBY when you feel it is as thick as you like.

* Clean scoby with soapy water and allow to dry on a wooden surface if possible.

As you can see in the video, instead of adding a colorant, I add a bottle of beer as part of the food and see what happens.

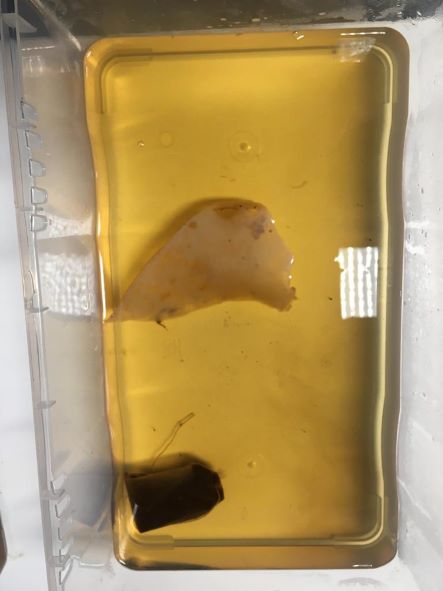

1 month later...

| Transparency | Elasticity | Smell | Flexibility | Resistance | Texture | Impermeability |

|---|---|---|---|---|---|---|

| XX | XX | XXX | XXXX | XXX | XX | XX |

This is the final result of the kombuchas after the drying period. Usually the kombucha is left on wood to dry, it is the most appropriate way for the water to be absorbed.