TESTING ON THE SKIN¶

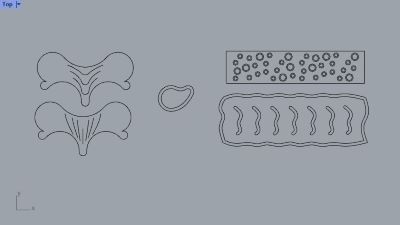

2D Design¶

Commands:

-

Circle

-

Polyline

-

Mirror

-

Offset

-

Trim

-

Join

Laser cutting (Molds)¶

| Material Type | Material Thickness | Speed | MinPower | MaxPower |

|---|---|---|---|---|

| Methacrylate | 5 mm | 30 mm/s | 60 % | 65 % |

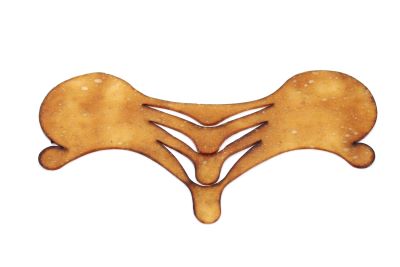

I have obtained different results with the tests carried out with the alginate. On the one hand, when making a design through a mould, when applying the design in this case to the wrist, the photo below shows that the material does not tolerate it.

Laser cutting (Biomaterial)¶

The table shows all the parameters in which the biomaterial can be laser cut. Ranked from highest to lowest speed.

| Speed | MinPower | Maxpower |

|---|---|---|

| 250 mm/s | 48 % | 50 % |

| 200 mm/s | 52 % | 54 % |

| 150 mm/s | 28 % | 30 % |

| 150 mm/s | 40 % | 42 % |

| 150 mm/s | 33 % | 35 % |

| 100 mm/s | 33 % | 35 % |

| 60 mm/s | 42 % | 44 % |

| 20 mm/s | 68 % | 70 % |

Below is a table of parameters in which the biomaterial is cut in the most optimal way.

| Material Type | Material Thickness | Speed | MinPower | MaxPower |

|---|---|---|---|---|

| Alginate | 1-3 mm | 100 mm/s | 33 % | 35 % |

BOM¶

| MATERIAL | QTY | DESCRIPTION | PRICE | LINK |

|---|---|---|---|---|

| PLEUROTUS OSTREATUS | 30 | commercial funghi | 24€ | Village market |

| LENTINULA EDODES | 30 | commercial funghi | 30€ | Village market |

| COPRINUS COMATUS | 1 | Wild funghi | Forest | |

| LACTARIUS DELICIOSUS | 16 | Wild funghi | Forest | |

| ALGINATE | 100gr | Polymer | BDC | |

| CMC | 8gr | Polymer | BDC | |

| AGAR | 5gr | Polymer | BDC | |

| GLYCERIN | 1l | Polymer | BDC | |

| ALCOHOL | 1l | BDC | ||

| GELATINE | 48gr | BDC | ||

| PETRI DISHES | 6 | BDC | ||

| PRESSURE COOKER | 1 | BDC | ||

| NUTRIENT AGAR | 10ml | BDC | ||

| ELECTRIC STOVE | 1 | BDC | ||

| CAMPING GAS | 1 | BDC | ||

| PARAFIL TAPE | 50cm | BDC | ||

| SCALPEL | 1 | BDC | ||

| INCUBATOR | 1 | Incubator that regulates temperature and humidity measurements | Student Project | |

| METHACRYLATE | 50X50cm | Material to make the molds | BDC |

Storyboard¶

When thinking about how to focus the video and be able to communicate the project clearly, I have divided it into the following 4 parts with their corresponding subgroups:

Part 1: Introduction and Contextualization

At an introductory level, on the one hand, I talk about my family tradition in collecting mushrooms and how since I was little I have felt close to nature. Video of the outside, of the forest. On the other hand, I differentiate another Interior section, in which I describe the medicinal mushrooms with which I have worked, mentioning their medicinal properties and characteristics.

Part 2: Extraction Medicinal Properties

In this part, I talk about the process of extracting the medicinal properties, for this, I clearly show the steps to follow and the result of the mushrooms before and after the staining process. Voice in off and music.

Step 1. Funghi Powder

Step 2. Measuring ingredients

Step 3. Cooking for 12 hours

Part 3: Fabrication

Step 1. Casting Biomaterials. Different recipes, creation of different biomaterials with their respective characteristics and properties. Alginate, CMC, Agar, Bio Foam

Step 2. Laser Cutting

Step 3. Molding

Part 4: Testing on the Skin

I show different applications once the biomaterials have been created. Voice in off and music.

Part 5

Phrase: Understand the fact of dressing as a momento of self-care and personal well-being. outdoor background

Part 6

Acknowledgment