10. Open Source Hardware¶

This week we were asked to work together as a team to build a machine using digital fabrication and open source platforms, and we decided to build a printing press machine, because we thought it can have many different applications, on the biochromes week we tried to give our fabrics some prints manually and it was very difficult so we thought this can help, plus printmaking is fun so we can experiment curving materials and print them

Printing Press Machine¶

References & Inspiration¶

Credits:

Research¶

A printing press is basically a sandwich of the medium you want to print or emboss and a stamp that gets pressed between a roller and a flat surface. We looked into different presses to understand how the machine works and what to consider when designing one.

Mind Mapping¶

We used a shared Miro board to put our ideas together so each one of us can edit, add or change anything

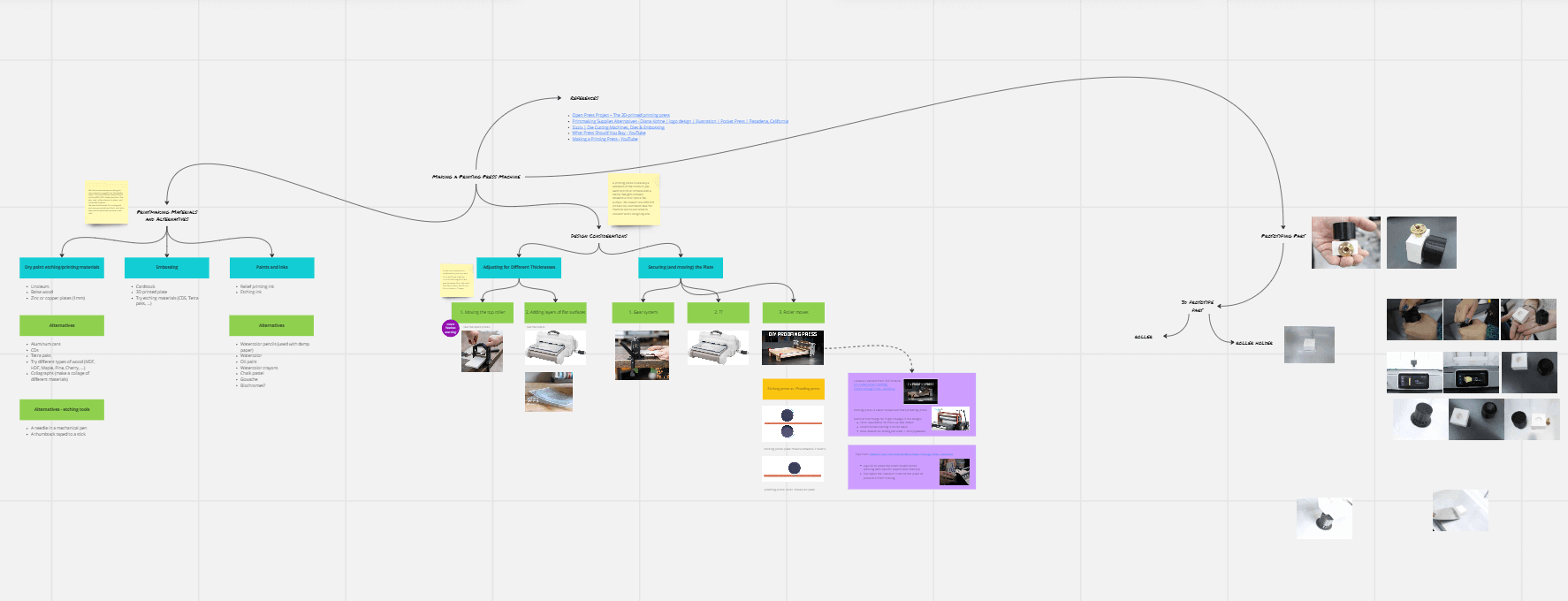

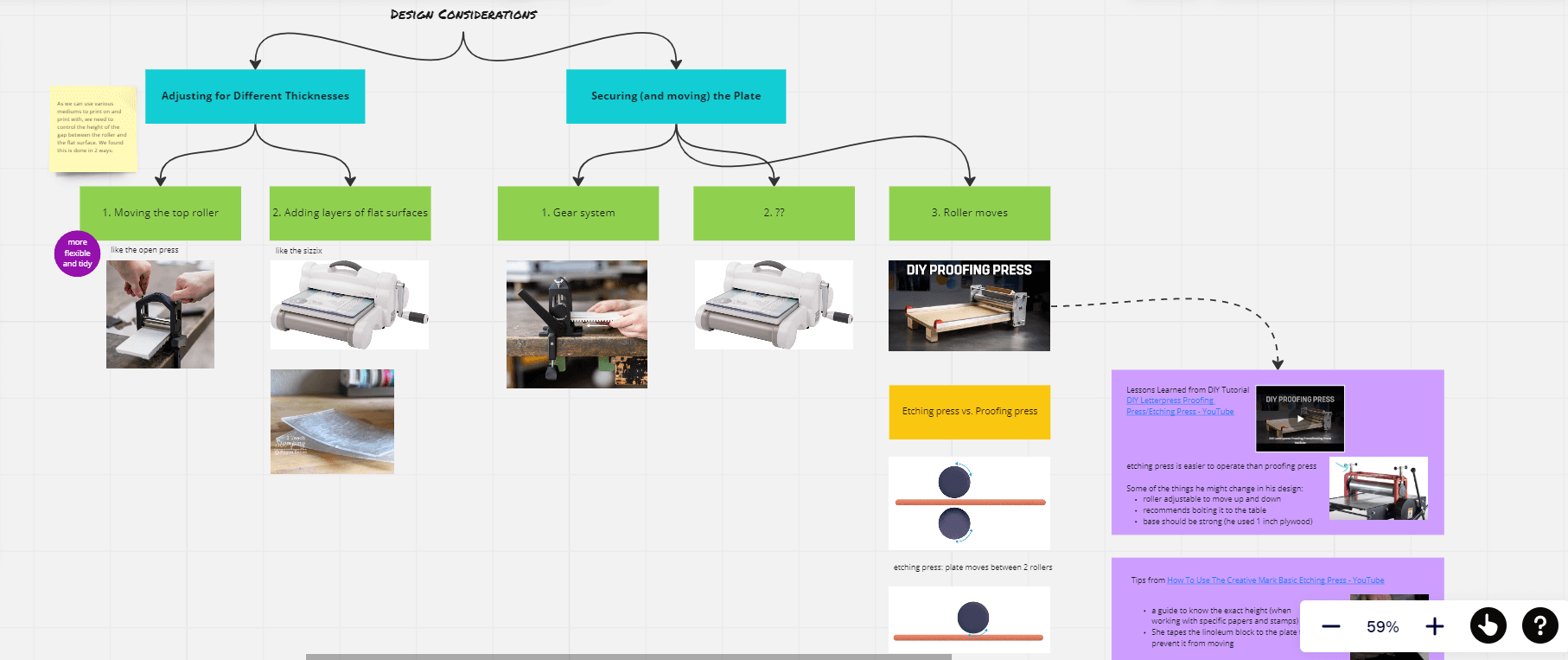

Design Considerations¶

In order to make a new design you need to think the design before starting, the mechanism, tools, and features. and this is what we did here we did not start from scratch we used some open source platformers to help us start, we watched videos, read some studies and saw some designs to be able to build our own machine they are all linked in the end of the documentation

Feel free to scroll through our Miro Board below..

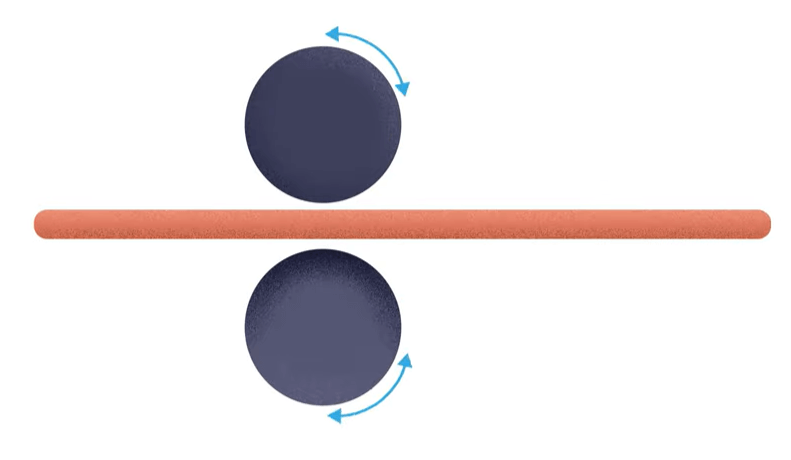

Etching VS. Proofing¶

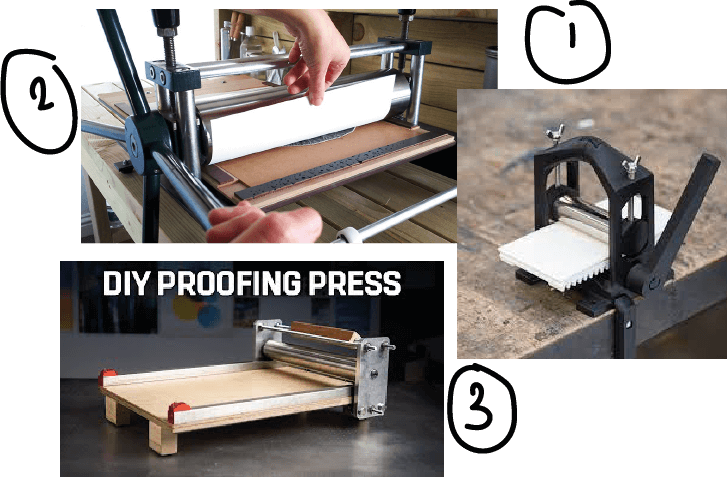

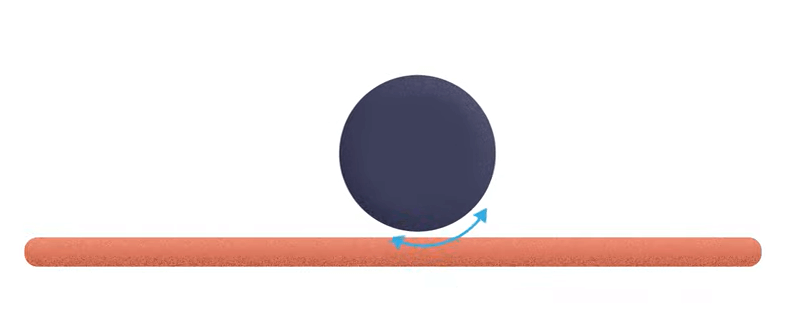

We had two options for the mechanism:

- proofing press: roller moves on plate

- etching press: plate moves between 2 rollers

We decided on Etching press because etching press is easier to operate than proofing press

Why Is Our Design Special¶

- It is adjustable

- Easy to assemble

- Portable

- Affordable

- minimal

- customizable

- open source

Print Making Materials and Alternatives¶

As we can use various mediums to print on and print with

Dry point etching/printing materials

- Linoleum

- Balsa wood

- Zinc or copper plates (1mm)

Alternatives

- Aluminum cans

- CDs

- Tetra packs

- Try different types of wood (MDF, HDF, Maple, Pine, Cherry, ...)

- Collagraphs (make a collage of different materials)

Embossing

- Cardstock

- 3D printed plate

- Try etching materials (CDS, Tetra packs, ...)

Alternatives - etching tools

- A needle in a mechanical pen

- A thumbtack taped to a stick

Paints and inks

- Relief printing ink

- Etching ink

Alternatives

- Watercolor pencils (used with damp paper)

- Watercolor

- Oil paint

- Watercolor crayons

- Chalk pastel

- Gouache

- Biochromes

Ink Making¶

We used Charcoal to make a printing ink

Recipe

-

Dye stuff: charcoal

-

Solvent: 2 Cups Water

-

Arabic gum: I Cup

Tools¶

* Glass Jar

* Wooden Stick

* Roller brush

* Scale

* Coffee Filters

* Acrylic board

* Dye Stuff

* Pipettes / Syringes

* Test tubes

* Petri dishes

* paper cups

* Solvents ( water / Alcohol )

* Paper

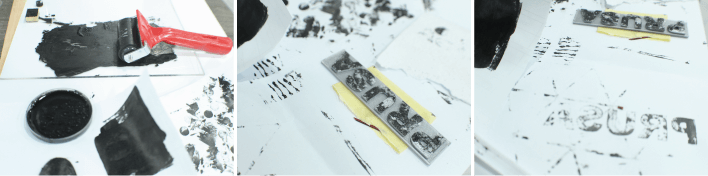

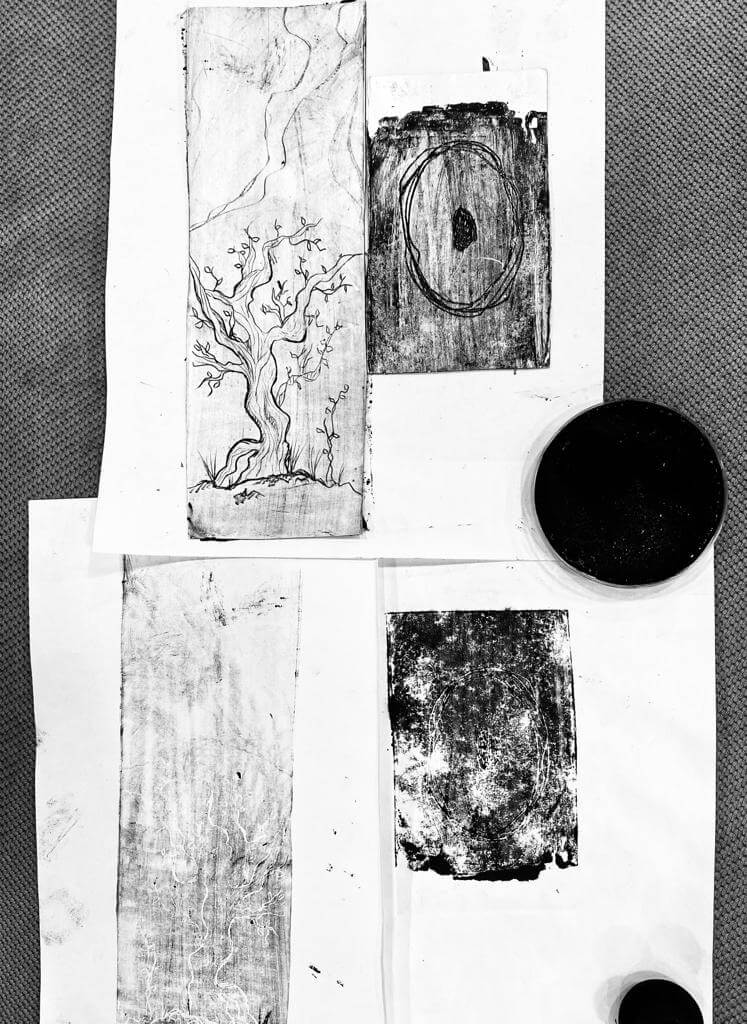

Some Prints We Made¶

Experiments¶

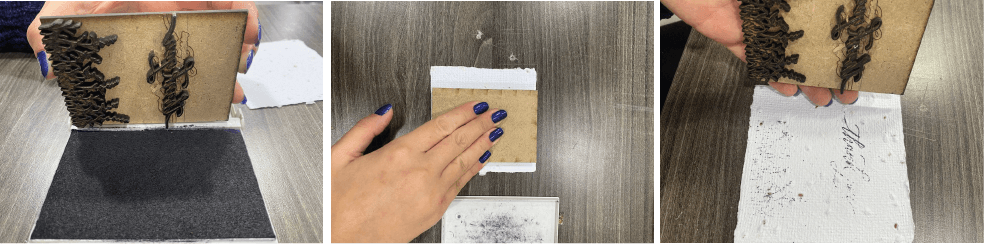

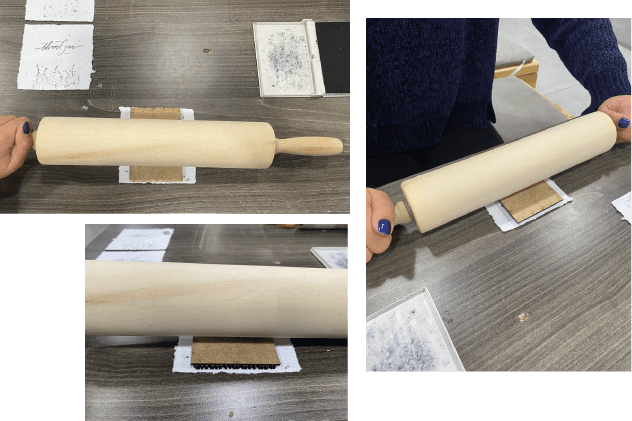

We stared by experimenting the very traditional wat of printing, putting a stamp in ink and use your hand to put pressure on it to be printed on a piece of paper, and it works perfectly if you put enough pressure but it takes a lot of effort and time

Then we tried another way to print using a rolling pin it makes the process a bit easier in terms of pressure but still needs a lot of time and have a larg error margins

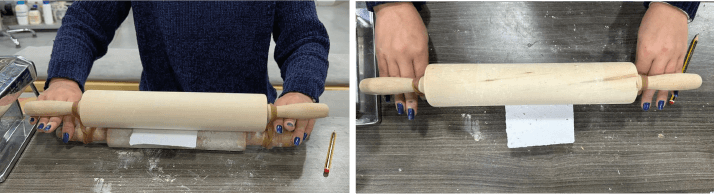

To understand the mechanism better we used the pasta making machine to print on a paper using a stamp and it worked perfectly, so we started building our first low fidelity prototype

(Low - Fidelity) Prototypes¶

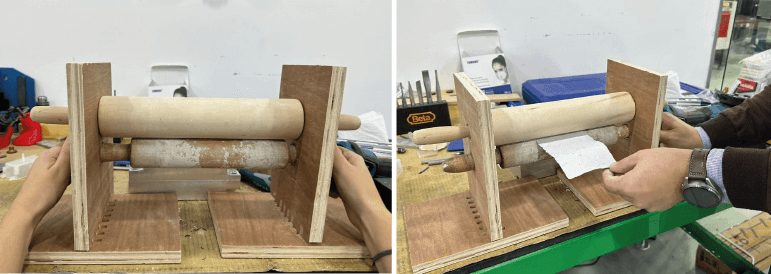

Following the pasta making machine we built this prototype using to rolling pins and two bands

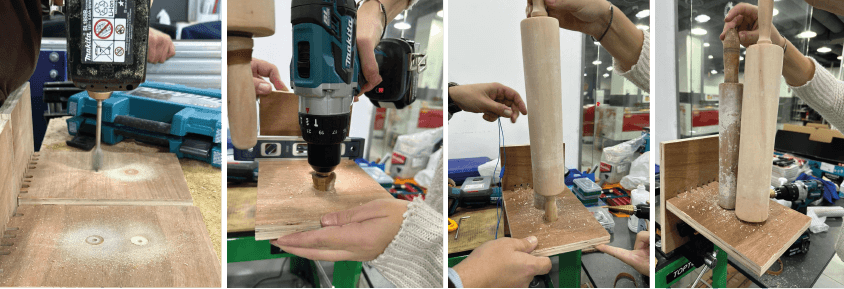

When we made sure it is working we upgraded the prototype to this, we laser cut the sides and the bottom, made holes according to the size of the rolling pin handles using drill

Fabrication Process¶

Designs¶

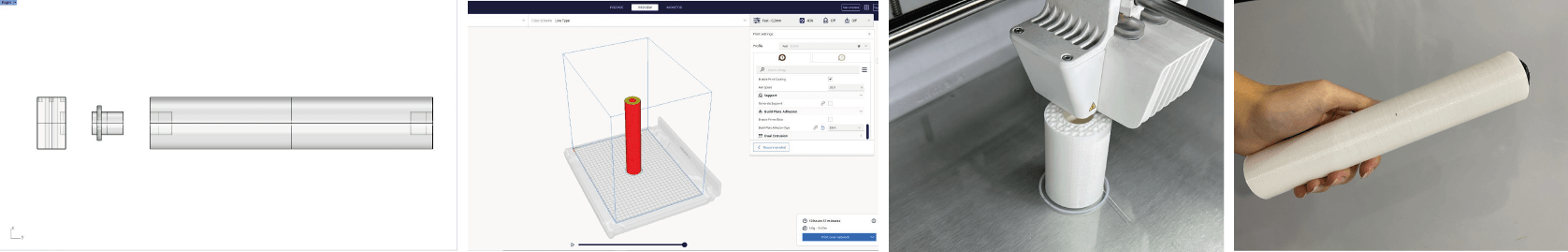

1) 2 Rollers¶

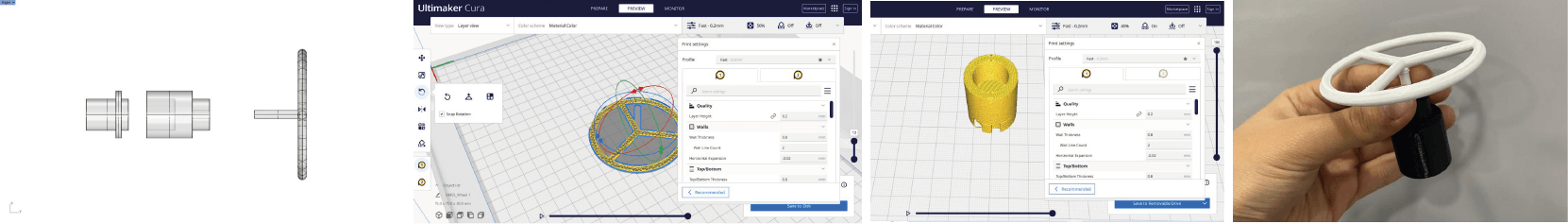

We used TPU Filament to print the roller because it is smoother and leaves no marks on the papers we are printing and is a bit flexible and can take more pressure than PLA

- Upper Roller

- Bottom Roller Bottom roller has the same design but a different connections

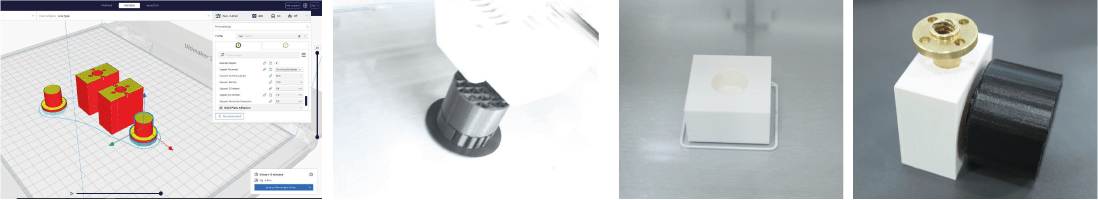

2) Roller Holders¶

The holders were 3D printed using PLA filament

- Upper Roller Holders

- Bottom Roller Holders

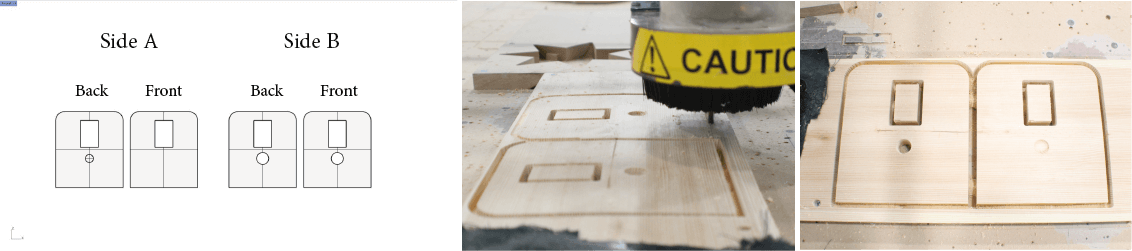

3) Side Walls¶

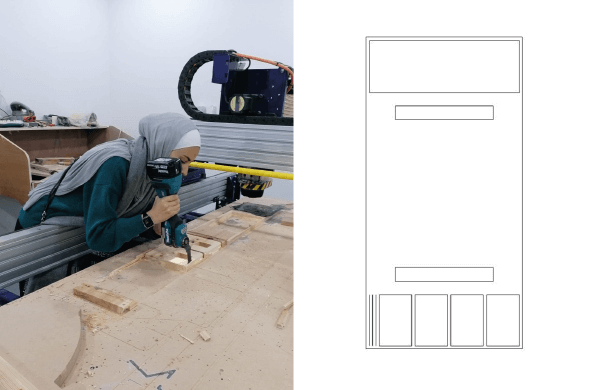

We used the CNC Milling machine to cut the side walls, that are made out of 22mm plywood

4) Bed¶

The bed as well was cut using the CNC milling machine using 22mm Plywood

Super quick guide to CNC¶

Check out the detailed explanation I wrote for week09 about the CNC we have in the lab and how to use it.

For the bed and the side walls we used the following settings:

| Toolpath | Cut Depth | Tool | Feed Rate | Spindle Speed | Plunge Rate | Stepover | Machine Vectors |

|---|---|---|---|---|---|---|---|

| Profile | 24.5 mm | 1/4 inch End Mill | 1.8 inches/second | 14000 r.p.m | 0.9 inches/second | 40% | Outside the lines |

5) Handle¶

This handle and it's holders were 3D printed using PLA Filament

6) The lead screw¶

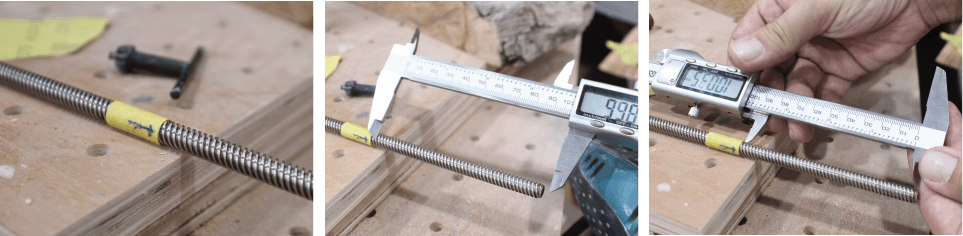

This 8mm * 100mm Lead screw was cut using a Metal cutting saw

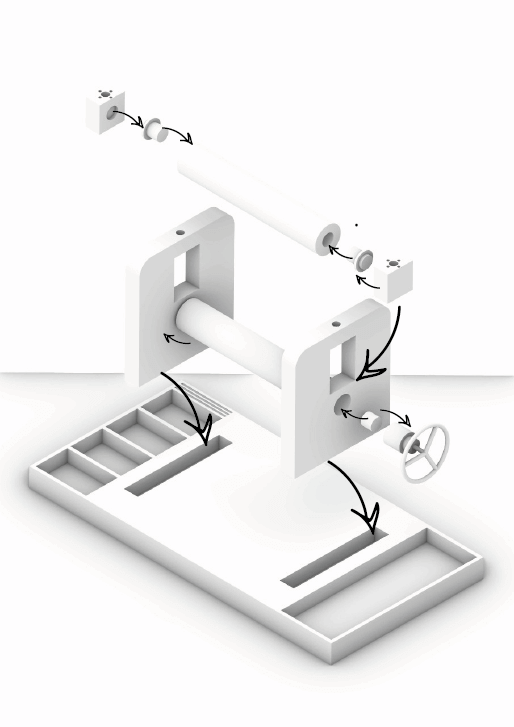

Assembly¶

Final¶

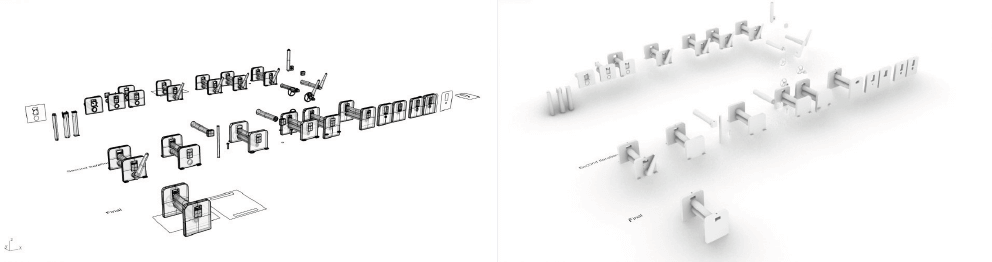

3D Model¶

Machine Anatomy¶

| Parts | Quantity | Technology | Files | Notes |

|---|---|---|---|---|

| Body ( Structure ) | 2 | CNC Plywood Profiles | You can use any other material | |

| Feet ( Body Holders ) | 4 | 3D Printed PLA/ABS | - | |

| Roller Press | 2 | 3D Printed TPU | - | |

| Roller Holder | 4 | 3D Printed PLA\ABS | - | |

| Handel | 1 | 3D Printed PLA\ABS | - |

Printing Press 2.0¶

While we were proud of what we accomplished so far, we took a break and then we gave it another go, and it was then when we realized that the pressure coming from the rollers was as not good as we hoped it would be. The reason for that was the properties of the TPU, it's soft and somewhat elastic. That's why we decided to replace the 3D-printed rollers with metal ones that we found in a local store, we also rethought the rest of the materials we used and the methodology behind our printing press.

Ala designed an easier-to-fabricate model that can be laser cut and 3D printed only. Check out the detailed process here. Below is a gif with the output.

Printing Press 2.0 B.O.M¶

All of the materials below are probably cheaper from local stores, so keep that in mind.

| Qty | Description | Price | Link |

|---|---|---|---|

| 2 | Metal Rollers | 30$ | Link |

| 1 | 5mm MDF Board | 5$ | Link |

| 4 | Screw Bar (8mm) | 1$ | Link |

| 2 | Screws (R4mm) | 0.25$ | Link |

| 18 | Bolts (8mm) | 0.1$ | Link |

Printing Press 2.0 Fabrication Files¶

Printing Press 2.0 Laser Cutting File

Roller Holder

Equipment needed to replicate the machine¶

MACHINES¶

- 3D PRINTER FDM

- LASER CUTTER

- CNC MILLING MACHINE

TOOLS¶

- HAND DRILL

- CALIPER

- METER

- PENCIL / MARKER

Materials To Buy For The Low Fidelity Prototype¶

| Qty | Description | Price | Link | Notes |

|---|---|---|---|---|

| 1 | Print Making Ink | 17.00 $ | Link | You can find alternatives |

| 1 | Rolling pins | 19.50 $ | Link | - |

| 1 | plywood Board | 47.00 $ | Link | We Used plywood waste |

Materials To Buy For The Final Machine¶

| Qty | Description | Price | Link | Notes |

|---|---|---|---|---|

| 1 | Print Making Ink | 17.00 $ | Link | You can find alternatives |

| 2 | Lead Screws Nuts | 14.99 $ | Link | - |

| 1 | PLA TPU Filaments | 15.99 $ - 27.99 $ | Link - Link | - |