Textile as scaffold#

October 30th, 2018

Anastasia Pistofidou

Technical textiles have various applications, among which agrotech, building, clothes, geotech, sports. In this class we will use textiles for composites, polymerisation, solidification, fabric formwork, crystallization, composites and biocomposites, agglomerates.

This class focuses on exploring techniques and applications of technical textiles in the industry. It introduces the concept of designing custom processes that require the design of a set of tools, processes and workflow.

Program outline#

- Technical Textile applications

- Composites

- Biocomposites

- Crystallization

- Fabric formwork & Concrete or Plaster Casting

- Wood + Textile Composite

Materials#

- Bio Resin and Resin

- Borax, Rochelle salt, Potasium sodium, Epsom Salt, Sugar,

- Concrete and Plaster

- Veneer Wood

- Fabric

- White Glue

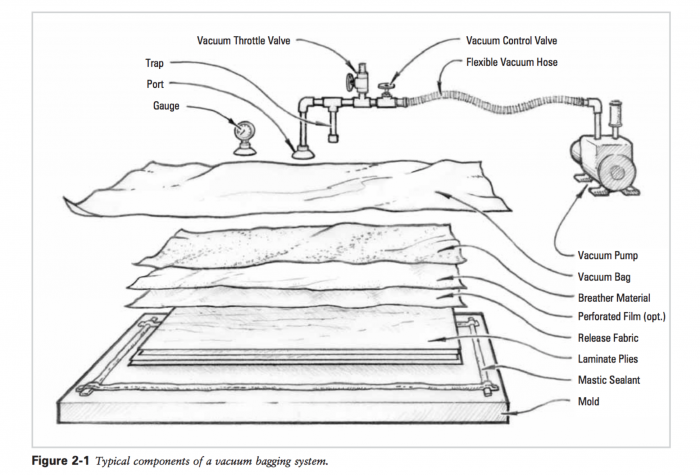

- Vacuum bags or vacuum machine

Assignment#

- Document the concept, 3D model of the piece and document the design process

- Make two samples with 2 out of the 5 techniques to make a prototype of a textile form: fabric formwork with casting crystalization wood-textile resin-textile leather molding or other

- Document the process from CAD to CAMM, document how to use the CNC mill and prototype your textile composite

- Upload your 3D model and CAMM file

- Document the 2 processes you have followed step by side from design to machine and hands-on making, materials you used, your mistakes, failures and achievements

- Use 3D modeling software to simulate your fabric deformation

For this assignment you will require to build up your tools (container for molding, vacuum bag set up, frames, matrix, recipients) and process for your workflow.

How will it be evaluated?#

- References : tutorial , links, inspiration

- Design : sketch , 3D modeling skills, Parametric modeling skills

- Fabrication : Capable of executing from file to production workflow, from 3D modelling to 3D printing , parameters, materials

- Documentation : Anyone can go through the process and understand

- Final outcome : Is the project assembled, functioning and complete

- Originality - Aesthetics : Has the design been thought through and elaborated

Textile Composite#

You need to make your textile composite with the binder of your choice and document all the materials needed, recipe, step by step process. Either flat or formed on a 3D dimensional surface. 3D model and CNC mill your mold and create your final textile composite

Fabric Formwork#

Maximum size 40x40x40cm

Create a pattern to sew and use as fabric formwork for casting

Materials: lycra, leggings, geotextile, any fabric plaster, microconcrete, fiberglass fibers, natural cotton fibers, hydraulic concrete, liquid marble

Wood+Textile Composite#

Prepare your wood and textile composite and laser cut or cnc mill your design

Materials: - Veneer wood, flexible wood - White glue - Fabric

Crystallization#

Choose one of the recipes or a new one to add in the handbook and create your structure from threads or textile to grow your crystals.