10. Open Source Hardware - From Fibers to Fabric¶

This week we learned how to make our own machines in groups of two or three. The assignment was to make a Hilo Spinning Machine. Studio HILO’s open-source projects challenge the process of textile production in the same way 3-D printers revolutionised manufacturing. Open knowledge on textile hardware and software enables experimentation, innovation and rapid prototyping for local yarn manufacturing. Everything we need, from the step by step guide, to the files for parts required and the codes for the circuit too and you can find it here

Unfortunately, all the parts did not arrive this week so we started working on another machine which we really wanted to make which is a Bioreactor.

DIY Bioreactor¶

Research¶

A bioreactor refers to any manufactured device or system that supports a biologically active environment. In one case, a bioreactor is a vessel in which a chemical process is carried out which involves organisms or biochemically active substances derived from such organisms.

Quoting from https://www.motherearthnews.com/green-homes/diy-algae-bioreactor-from-recycled-water-bottles-ze0z1809zcoo We tried to make a photo-bioreactor that uses algae to convert carbon dioxide and sunlight into energy. The energy that is produced is in the form of algae biomass. The photo-bioreactor is built from plastic recycled water bottles. By designing the apparatus to be compartmentalized, we are able to do many experiments in parallel. By using algae as a biofuel, we can increase the world’s supply of oil while at the same time we decrease the amount of atmospheric carbon dioxide used during its production. The resulting product is a sustainable biofuel whose carbon footprint is neutral in as much as the CO2 produced on consumption is essentially balanced by the CO2 used in its production.

According to https://www.mixerdirect.com/blogs/mixer-direct-blog/10-surprising-uses-of-algae Algae has emerged as a popular element in industries like cosmetics, pharmaceuticals, food and beverage, biofuels, and more. Most recently, the benefits of algae has been making waves in sustainable energy and environmental technology. Algae has numerous benefits that make it an ideal choice for creating a variety of interesting products for example algae is efficient to create biofuel, algae can use land that would otherwise go to waste, Using Algae as Fertilizer, et, and many more.

Lets look at what all is required to make a bioreactor and what steps we have to follow:

Steps to follow¶

- Prepare conatiners with an inlet and an outlet

- Make Carbon dioxide delivery system

- Make LED circuit

- Assembly

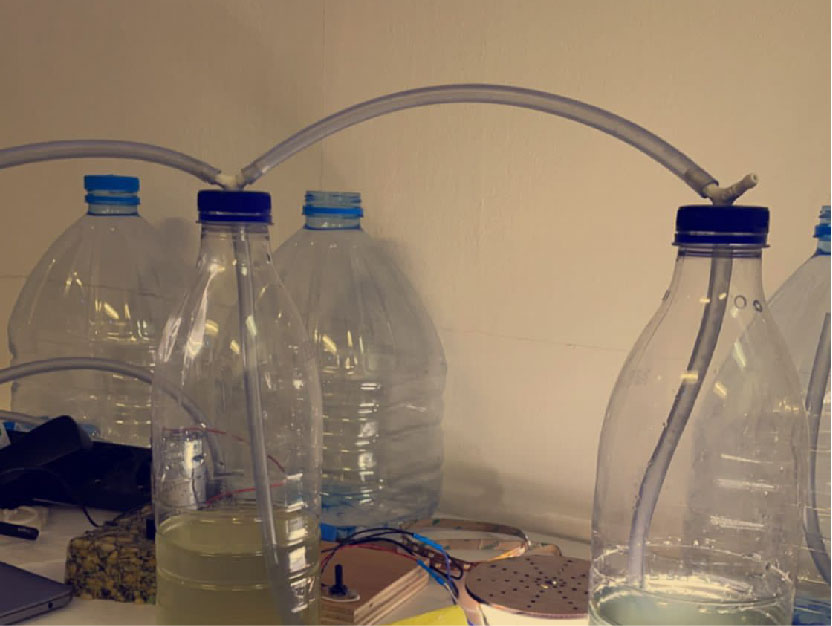

We used waste plastic water bottles to make the machine because first we wanted to test it and see if the mechanism is correct and if the machine is working so we can then make a better one with proper laser cut parts.

Preparing Containers¶

We sourced 3 discarded identical plastic bottles and perfomed the following steps to get them ready. - Drill a hole in the caps of all bottles (For carbon dioxide intake) - Drill 3 equidistant holes on the bottles near the cap (For airflow)

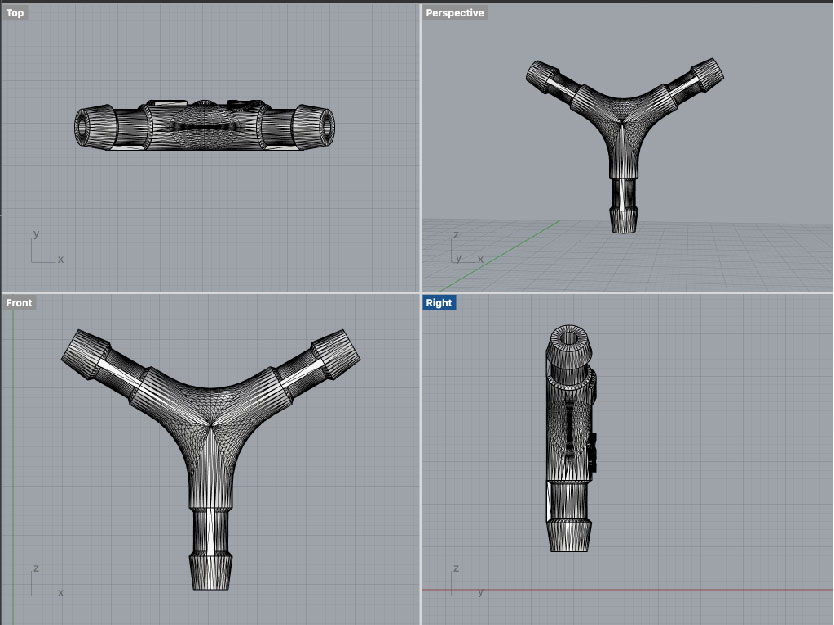

3D printing T-connectors¶

We 3D printed T-connectors to attach them on the caps of every bottle for the flow of carbon dioxide throught the machine.

And then connected them with pipes.

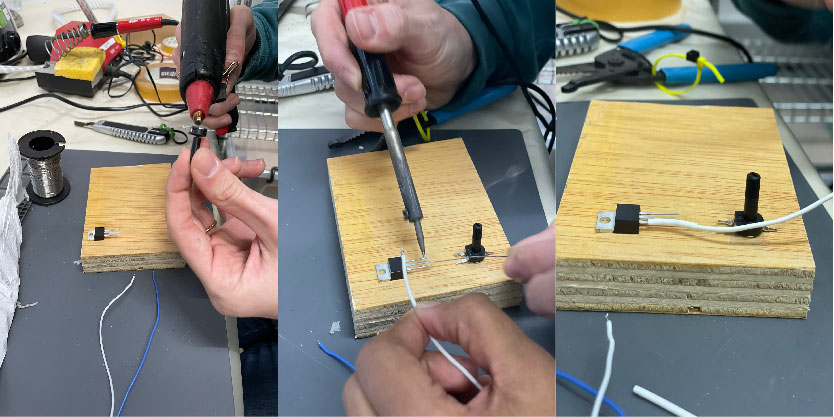

Circuit¶

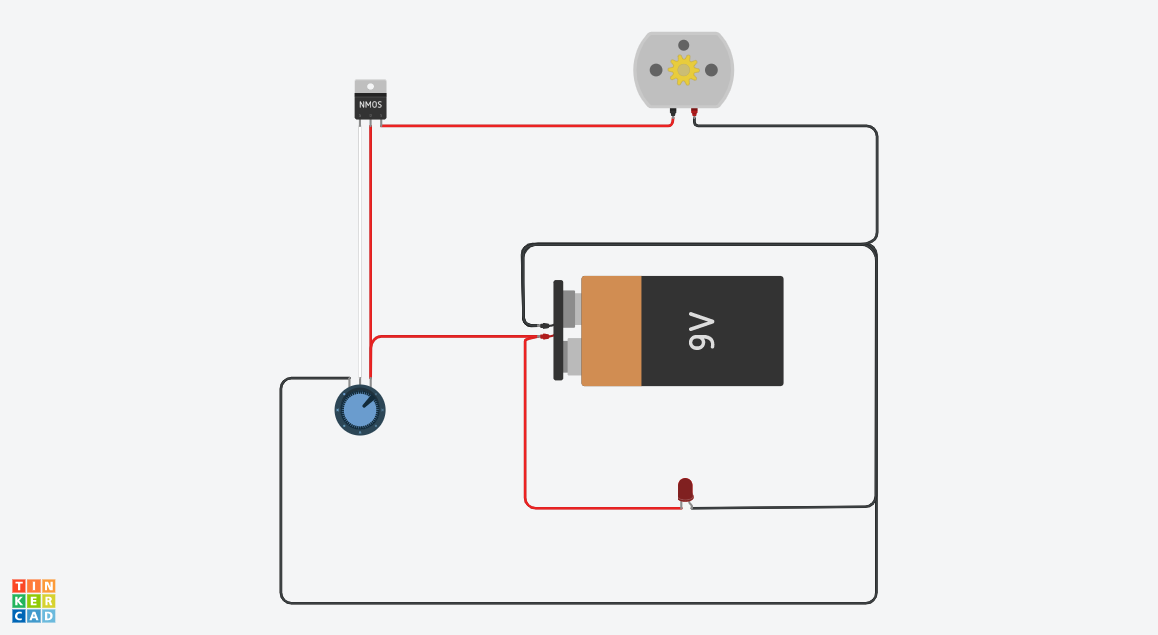

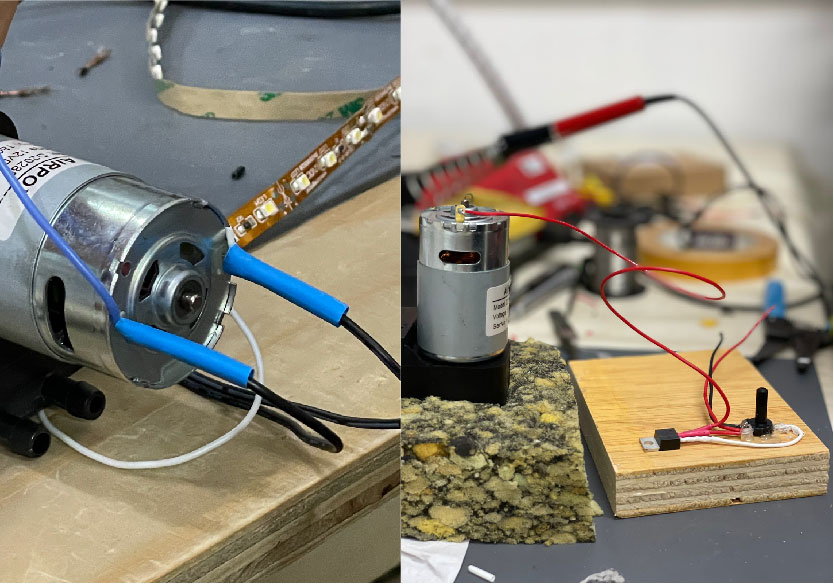

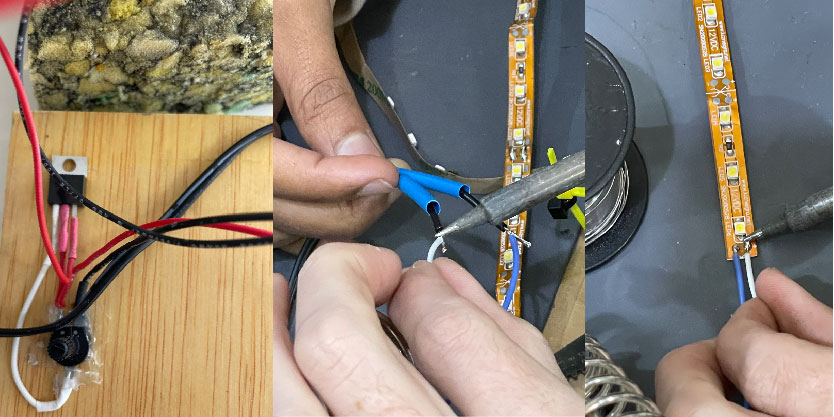

We used an airpump for the supple of carbon dioxide to the machine which has has one inlet and one outlet. The circuit was made using a

- Mosfet

- Potentiometer

- Neopixel.

The circuit diagram looked like this, where the airflow can be controlled but not the intensity of light being emitted from the neopixel.

Final Assembly¶

Experiment¶

We then put two types of algae in 3 different bottles Spirulina and Salina with different fertlizers to examine their growth. Unfortunately, we finished this just before the holidays and over that period the circuit stopped working due to some reason so the experiment wasn't successful but it's a work in progress and we will keeo you updated about the progress.

Useful links¶

- https://www.instructables.com/An-Algae-Bioreactor-from-Recycled-Water-Bottles/

- https://materiability.com/algae-photo-bioreactor-diy/