12. Soft robotics¶

Unlike rigid robots we are mostly used to, soft bodied robots have similarities and performance characteristics similar to living organisms or the human body. Soft-robotics are based in Bio-inspired design or biomimicry and have applications in wearables, rehabilitation prosthetics, surgical robots, rescuing and others.

Inspiration¶

Using Vinyl and the Heat Press Machine¶

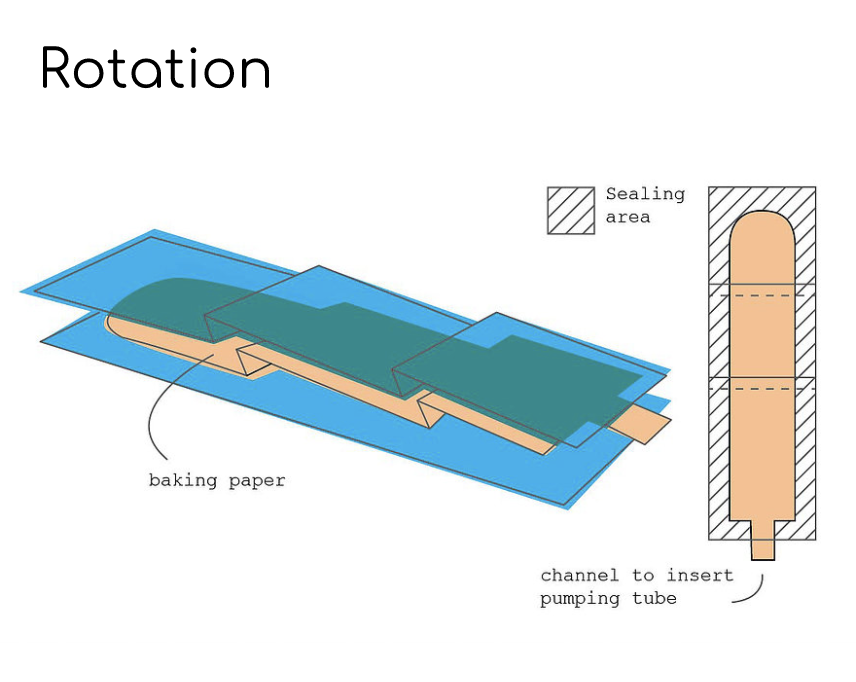

I really liked the inflatables which result in Rotation. I like how it creates such a prominent movement just by limiting the amount of airflow and direct it in this way. Also the fact that this feature can be used in so many sectors now. Here's a video where I took inspiration from and learnt how to make it.

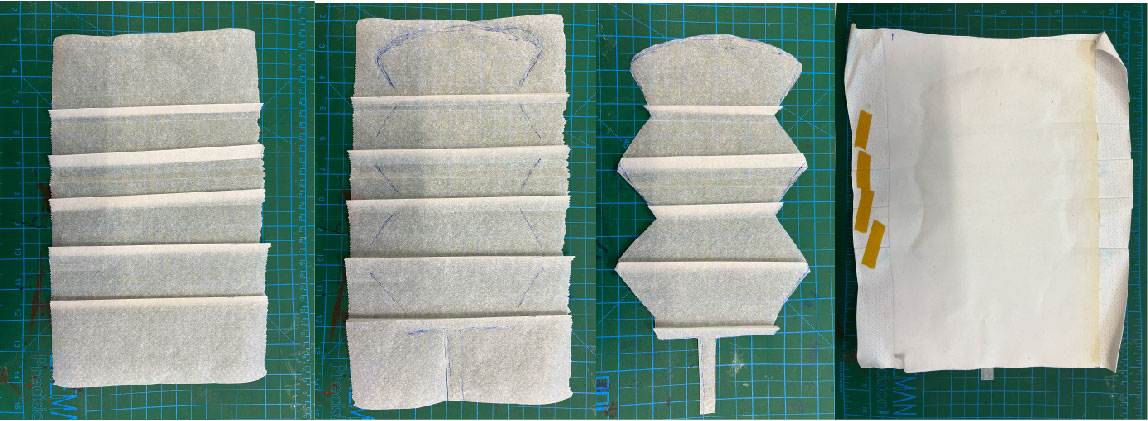

I wanted to try it first using Vinyl to see how it works before I try it by making a silicon mould. Here are the steps I followed to make it -

- You need a sheet of Vinyl and Baking paper.

- Fold the baking paper at equal distances.

- Cut it in the desired shape.

- Cut 2 rectangular pieces of the sheet which cover the entire shape of the paper well.

- Place them over and under the baking paper and fold exactly as the paper. (From one side the vinyl touch each other and limits any movement while the top is free to move, this results in rotation)

- Put tape to make it stay.

- Place them in the heat pressing machine with a baking paper on top and below.

- The heat makes the vinylt melt and stick to itself.

With Silicone¶

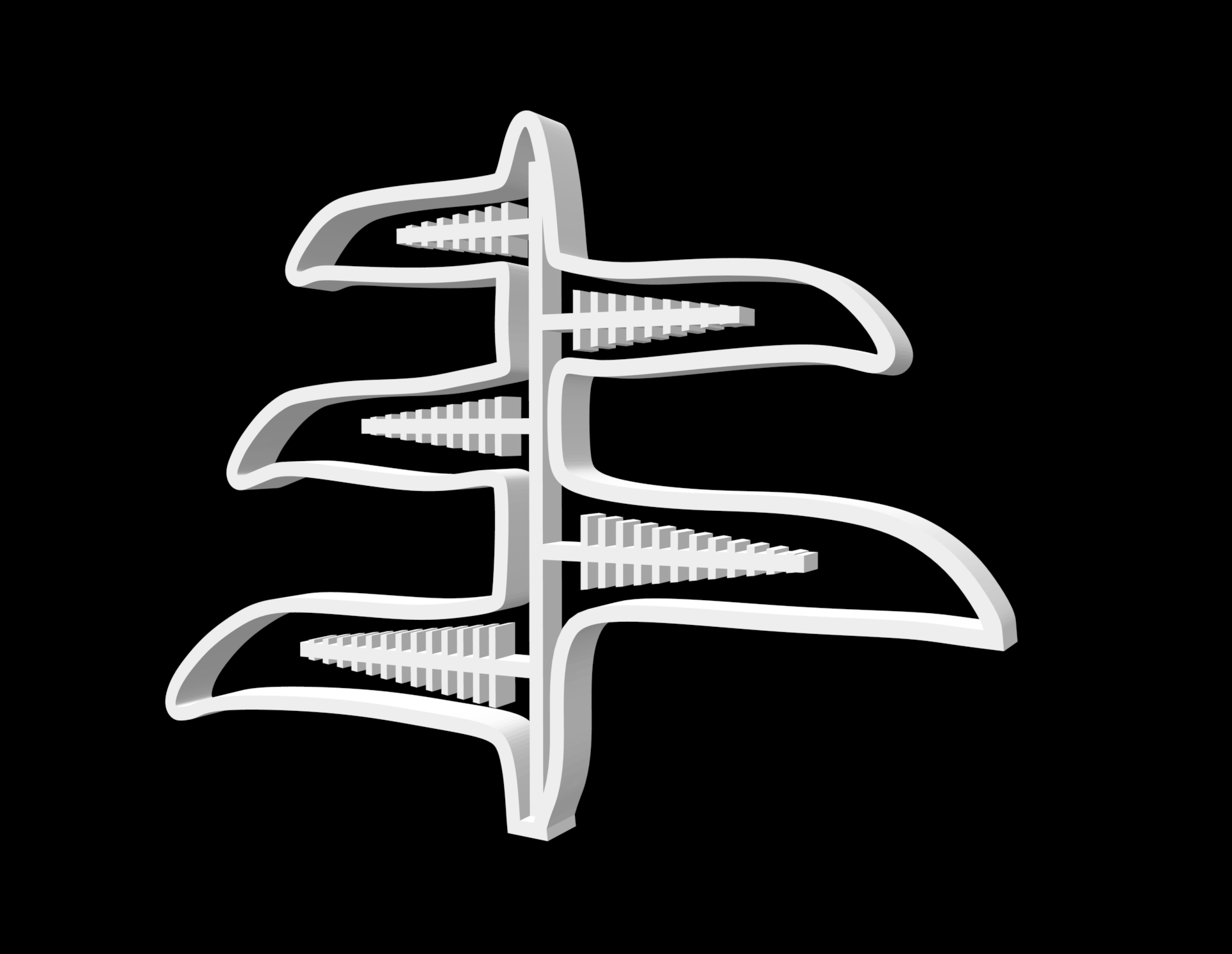

To try the rotation in a silicone mould I modifed the design a little. It looks so much like a christmas tree but I just wanted to see if this design works and how strong the hold is.

Here's an image of the 3D file of the mould on rhino -

Steps to follow¶

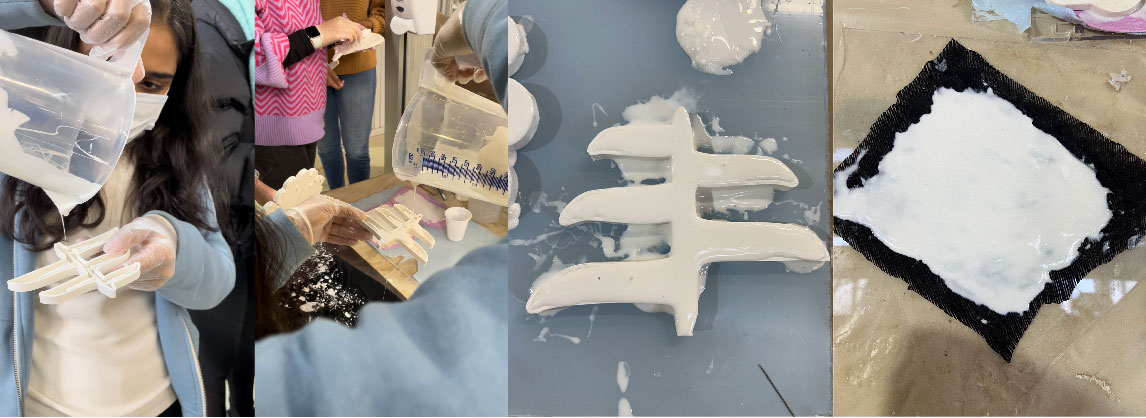

- After you have your mould you need to prepare the silicone.

- For 300ml of Part A of the silicone you will nedd 10ml of Part B.

- Measure the proportion of silicone you want to use in two separate cups. When you will mix A. and B. part you have approx 20 minutes to work. Otherwise, the silicone will be too thick.

- Mix very well.

- Take your mold and start slowly pouring the silicone slowly into one of the corners. To avoid bubbles in the silicone, only pour it on top of the porous silicone. Be careful - do it slowly and keep the cup high.

- Place it on a flat surface and add a little bit more silicone to fill all empty corners or gaps. Hit the table several times to flush out all the bubbles. Use a pin to remove them from the surface.

- Place an acrylic sheet under the piece of textile tbe used as (non)inflatable bottom layer and pour the rest of the silicon on top. Rub it with a spoon.

Conclusion - The mixture was not correct and that's why the mould was very thick and did not inflate.