The Purhyphae Project¶

During the implications and applications week, I made a first concept of what I wanted to explore for my final project. Here is the video of the story I wanted to tell behind this project.

Video: storytelling of the final project.

As it was a first shoot, I put all the ideas I wanted to explore but as usual, there were a lot. During the first week of January, I had time to do some work on what I really wanted to do and what was feasable, managing some bibliographic research in parallel.

Out of the three axis I wanted to explore (detailed in the week 11 tab), I had quite a hard time figuring out which experiments to run. They had to be feasable, consistent with the story I wanted to tell and my values.

The only real way to counter this ecological disaster would be to reduce the production of fast fashion clothes and reduce our textile consumption habits but would mean fight against ones of the most powerful lobbies of the world, change the entire consumption system and in all change the rules of the society we live in, which is a very slow process. So I was wondering, how can I tackle the issue of the overproduction? I am not that powerful as compared to the giants of the industry. Changing the production and consumption habits can also be made by playing with the rules of the capitalistic world we live in. That would in this case mean finding a new, more competitive alternative to the fast fashion model we currently have. If a cheaper and more ecological alternative to fast fashion was found, it could gradually replace this ladder managing some wise marketing.

Project conceptualisation after bibliographic research¶

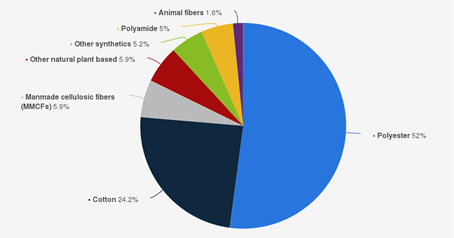

Mainly used fibers in the textile industry are polyester and cotton fibers. These fibers either need petroleum or specific climatic conditions and a lot of water to be produced, along with a lot of post-treatment. However, since these products have been used for the past decades, production means have already been optimized and scaled up for massive production of these textiles, their cost is very low. Finding a process using cheaper, more ecological raw materials that would use simple or pre-existing processes would offer a good alternative to fast fashion products. Waste is a free, ubiquitous, and abundant raw material that can be revalorized when used properly. It does not need specific climatic conditions nor pesticides to grow and can be locally sourced everywhere.

Image: Distribution of textile fibers production worldwide in 2020 by type. Source: Textile Exchange, Statistia 2021. Additional Information: Worldwide; 2020; based on production volume.

Microorganisms are rapidly evolving mini-factories able to break down molecules and turn them into other ones. Evolving in different contexts, they can adapt to any conditions, developping amazing abilities such as resisting to gamma radiations (Deinococcus radiodurans), living in extreme temperature conditions (bacteria of the genus Aquifex), breaking down toxic compounds such as PCB chlorinated molecules (Dehalococcoides mccartyi (Bedard 2014)), phenols (bacteria from the genus Azoarcus (Schie and Young 1998)) or even PET plastics (Ideonella sakaiensis (Yoshida et al. 2021)).

Fungal species are also rapidly adapting organisms capable of breaking down a large range of molecules. Soil-associated filamentous fungi have the natural capability to degrade ligno-cellulosic biomass (Hawksworth and Lücking, 2017), but some species have also demonstrated some remarkable proprieties. Pestalotiopsis microspora is an amazing fungal strain originating from the amazons capable of using PET as sole carbon source (Russel et al., 2011). Pleurotus ostreatus (Oyster) and Schyzophilium commune are some more common fungal strains and were both reported to be able to break down green polyethylene (Rodrigues da Luz et al., 2012 and 2019, Perera et al., 2020) and were used in the Fungi Mutarium project, growing on agar and plastic to make edible mycelium. The oyster mushroom was also reported to be able to grow on oil contaminated soil (Mycoremediation: can fungi help to save the world?, Biomar MT, 15 April 2019). Fungi also have the advantage of being usable for various purposes: food, medicine, mycelium materials and leather. Especially, Ganoderma lucidum (Reishi) is used for vegan leather production.

Image: fungal species previously mentionned.

Considering cotton is composed of 94% cellulose (Chemical Composition of Cotton Fiber, 18 October 2014, Mazharul Islam Kiron), the hypothesis that mycelium can feed on cotton and other cellulose based textile waste (viscose, hemp, banana and other plant based fibers) can be made. In a previous experiment, I managed to make G. lucidum (Reishi) mycelium grow off different types of combinations of waste (combinations of textile, food and CMC), suggesting Reishi was able to digest denim textile and food waste. Considering P. ostreatus (Oyster) and P. microspora are also capable of breaking down different types of plastic, they are good candidates for the bioremediation of synthetic textile waste.

This project is focusing on the use of mycelium for the bioremediation of textile and food waste, assessing the ability to grow and produce Pure Mycelium Materials (PMM) textiles (mycelium leathers) out of it. This would not only offer a new, more sustainable, biodegradable alternative to current leathers, but also enter in the field of regenerative design with the bioremediation of the accumulating waste to make a new valuable product out of it.

Image: wastes used during the project (from left to right: food waste, denim textile waste, coffe grounds, synthetic textile waste and gain).

To do so, I want to try the efficacity of G. lucidum, P ostreatus and P. microspora on various mixes of denim textile waste, synthetic textile waste and food waste and coffee grounds. The textiles are supposed to serve as the prime carbon source, whether it is cellulose from natural fibers or polyester. The food waste is used to provide additional amino acids and sugars when the strain cannot use the textile as only carbon source. The coffee grounds are used for their richness in oligo-elements (Liu 2011) when the strain can use the textile as only carbon source.

Objectives of the 12 next weeks¶

- Make zero waste bioremediation mycelium material samples. The samples would be made out of unsellable waste textile found in local charity store. The textile scraps will be used for the growth of mycelium threads (or just leather if thread making is unsucessful), used as an accessory (purse or bags).

- Find the adequate coatings for optimal texture.

- Make a scientific report of the differents protocols and different recipes and publish it on ResearchGate.

- Analysis of the lifecycle of the product, economic and ecologic impact quantification. Design of the required facilities for the scale up production process.

Inspirations, moodboards and Frankenstein model¶

In order to have an idea of what I am doing for the next months, I made some moodboards, drawings and a frankenstein model for an attempt of threads.

Here are pictures of the existing different techniques I would like to master and products I would like to achieve during these 3 months, including liquid culture, mycelium foam, agar culture, solid state fermentation and mycelium bioplastic casting.

Image: mycelium materials obtained using different substrates and growth techniques.

Here is a drawing of a garment with mycelium growing on it. This garment would be a manifesto: by wearing such a growing garment, we are reminded that we can not be disconnected from nature and everthing we own comes from it. For this garment, I would like to make some mycelium grow on a dress made out of old cotton or hemp curtains. The tip of the dress where I want to grow the mycelium would be dipped in a nutritious liquid medium and the mycelium would grow on the textile, partially digesting it.

Image: moodboard of the mycelium garment manifesto.

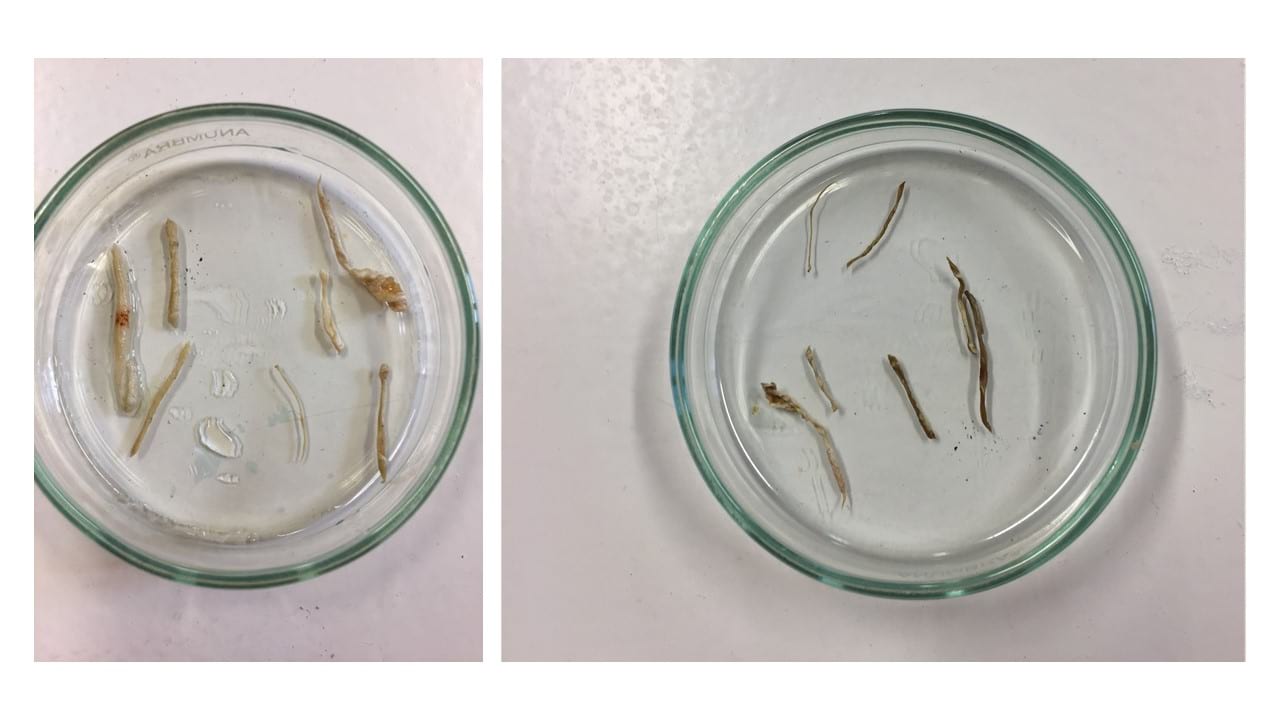

Concerning the mycelium threads, I had made some experiments during week 9: textile as scaffold. I then used some of the mycelium that had grown flat and attempted to make threads with it before killing the mycelium. Here is a video of me making the threads and a picture of the small threads before and after drying.

Video: attempt of making threads out of Reishi mycelium grown on agar.

After the drying, the threads became very brittle and dry. After some bibliographic research, I found the post processing currently used for mycelium leather, and will try on my further threads attempts.

Image: mycelium threads attempt before and after drying. Dried threads are VERY brittle.

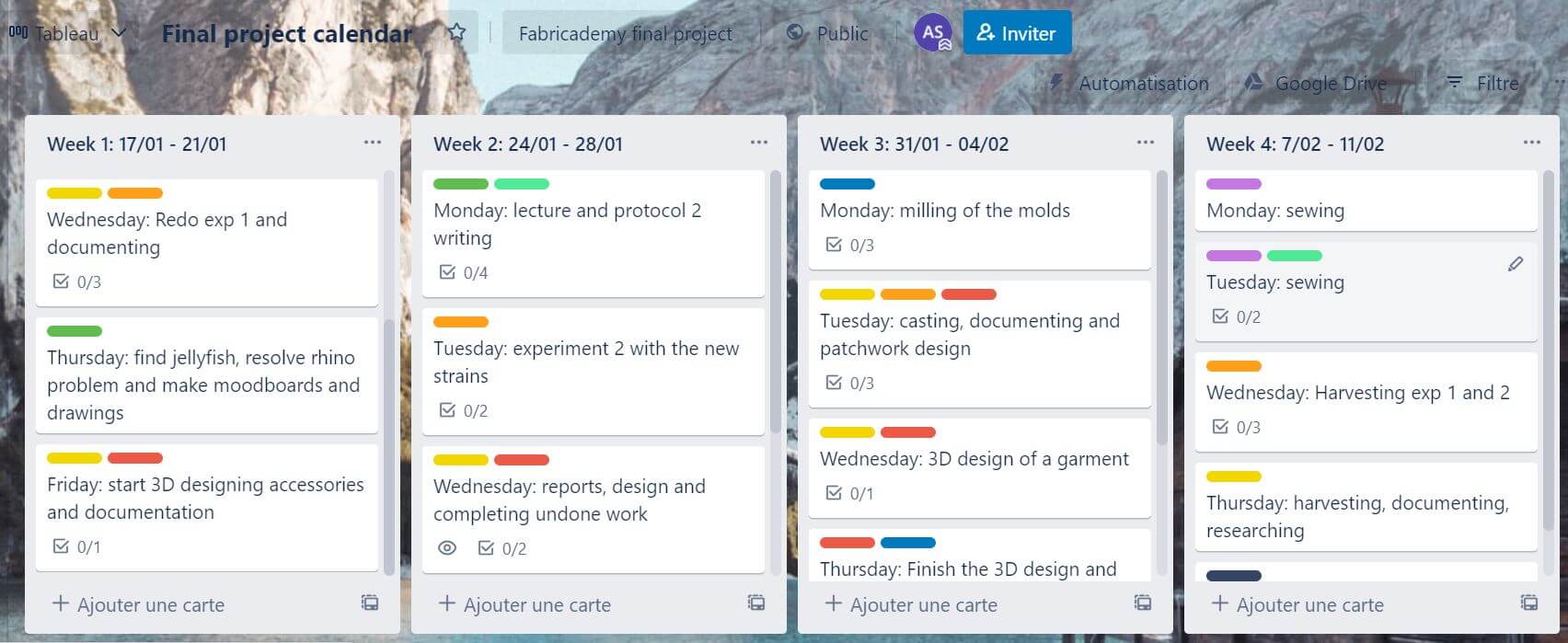

Weekly planning¶

Before I could do a day by day planning, I used a Trello board to list my ideas and then created a second board to do my planning day by day. I only planned the first month since the planning relies so much on the result of the first experiments.

Materials used¶

Here is a list of the materials I used for my final project and where I sourced them.

The most important ones are the following:

- Ganoderma lucidum (Reishi) mycelium, kindly provided by Jessica Dias from Biobabes studio.

- Pleurotus ostreatus (Oyster) mycelium, kindly provided by Jessica Dias from Biobabes studio.

- Pestalotiopsis microspora mycelium, bought from mushbank on ETSY.

- Petri dishes, bought at pidiscat

- Glass jars (8x17 cm), found at the local bazar or reused from my green beans jars.

- Denim textile and other textiles, kindly provided by fabricademy's Fabtextile lab.

- Foodwaste and coffee grounds from my personnal consumption.

| Qty | Description | Price | Link | Notes |

|---|---|---|---|---|

| 1 | Pestalotiopsis microspora | 23.00 € | ETSY https://www.etsy.com/fr/listing/702013116/pestalotiopsis-microspora-culture | Comes in an eppendorf tube. The Omphalatus nidiformis strain was a gift from the supplyer to make up to the shipping delay |

| 7 | Glass jars 8x17 cm | 1,20€ x 7 | BASAR COSA I COSES | https://g.page/BZ-Cosa-I-Coses?share |

| 18 | Petri dishes (10 cm x 1,5 cm) | 25.41 € | Pidiscat https://www.pidiscat.cat/ca/484-p-09-vidre-cientific/206-capsules-petri-vidre/6702-capsula-petri-vidre-amb-tapa-mides-15x100-mm.html?search_query=petri&results=17 | |

| 6 | Petri dishes (20 cm x 2 cm) | 22.40 € | Pidiscat https://www.pidiscat.cat/ca/484-p-09-vidre-cientific/206-capsules-petri-vidre/7165-capsules-petri-vidre-amb-tapa-20x120-mm-capsa-18-unitats.html?search_query=petri&results=17 | |

| 1kg | Calcium carbonate | 4,80 € | Quimics Dalmau https://quimicsdalmauonline.com/tienda/carbonato-calcio-1-kg/ | 1kg was the smallest quantitiy available but I actually did not need that much |

| 250g | Agar agar | 20.00 € | Quimics Dalmau https://quimicsdalmauonline.com/tienda/agar-agar-polvo/ | |

| 1L | Glycerine | 13.00 € | Quimics Dalmau https://quimicsdalmauonline.com/tienda/glicerina-bidestilada-usp-1-l/ | |

| 1L | Ethanol | € | Quimics Dalmau | |

| 1 | Heat resistant silicone | € | Quimics Dalmau | |

| 1,5 kg | Organic wheat grains | 7€ | La Graneria del Poblenou https://goo.gl/maps/y8G6pgFL64krz4JW7 | |

| 1kg | Citric acid | 7.25€ | Quimics Dalmau https://quimicsdalmauonline.com/tienda/acido-citrico/ | |

| 1 | Heater | 15€ | Ferreteria Bonet https://goo.gl/maps/hBS85fT8f9TsEqET9 | |

| 1 | Gas proof HDPE plastic tank | 25€ | Basar regalos https://goo.gl/maps/ckg2txskQXiUVJDp7 |