Video: The Purhyphae Project presentation. Video scripted by myself, filmed by IAAC communication team and edited by myself using DaVinci resolve.

Final outcomes¶

Finished products gallery¶

Overview of the different leathers achieved during The Purhyphae Project. Pure mycelium leathers and composite mycelium, textile and food waste leathers.

During this final project, I managed to create two types of mycelium leathers: the composite one and some pure mycelium leather samples. Here is a photo and video gallery of what I created.

Composite mycelium leather. Denim textile waste, food waste, coffee grounds and P. ostreatus (oyster) mycelium leather.

Composite mycelium leather dyed with indian ink. Denim textile waste, food waste, coffee grounds and P. ostreatus (oyster) mycelium leather, heads and tail.

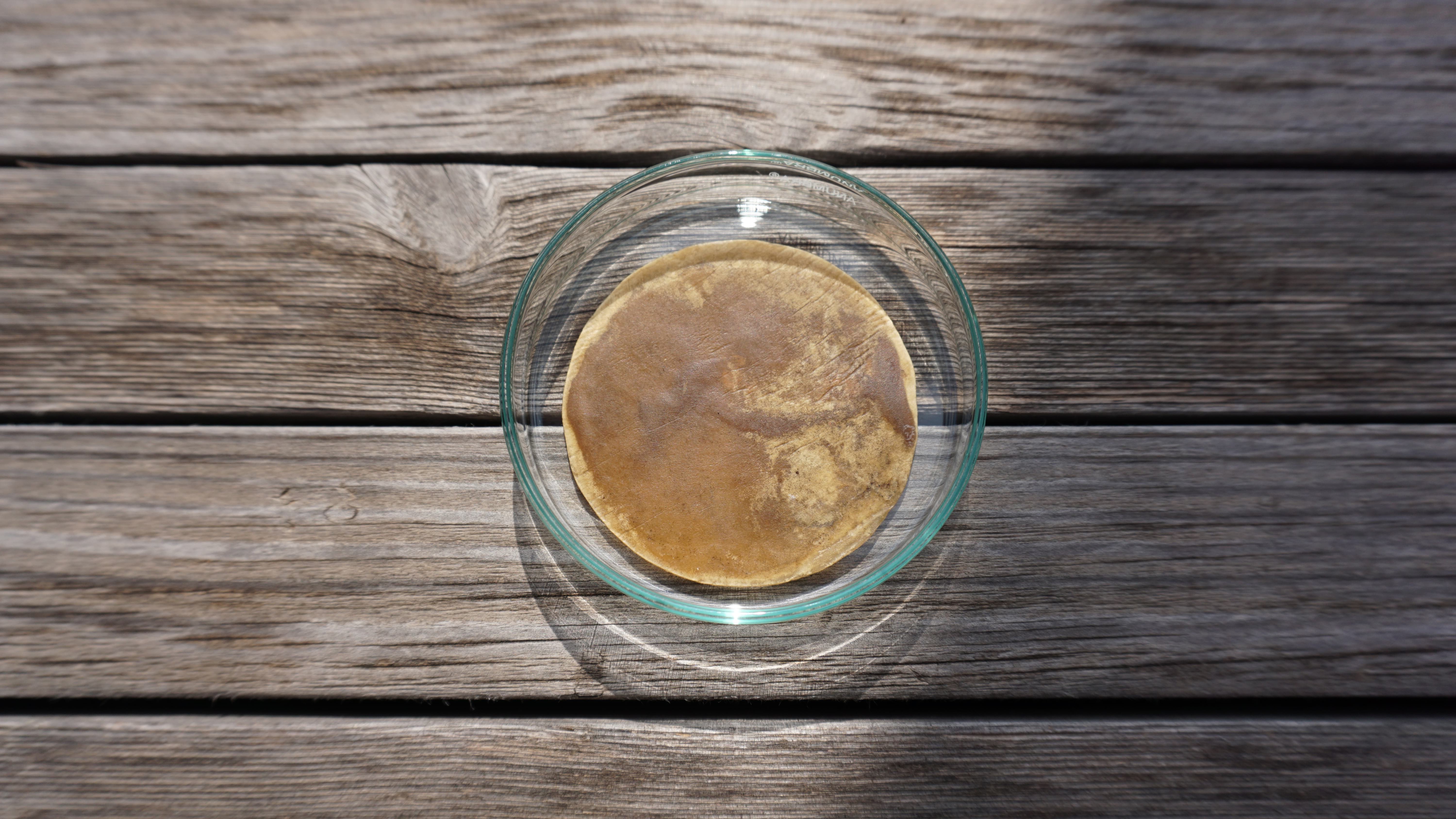

Pure G. lucidum (reishi) mycelium leather grown on liquid medium.

Pure G. lucidum (reishi) mycelium leather grown on liquid medium.

Mycelium leather grown on agar. Mycelium from Ganoderma lucidum (reishi), Pleurotus ostreatus (oyster) and Omphalatus nidiformis.

Knowledge diffusion¶

During my final project, I struggled a lot with finding out how to make my experiments since the information I got was either very DIY or very technical (patents). The goal of this project is to find a way to revalorize textile waste and promote the use of mycelium materials. This can not be done if knowledge is unavailable. That is why, as a part of my final project, I decided to gather all the knowledge I had accumulated for those 3 months and make simple and easy to understand tutorials on how to grow those two types of leather with simple stensils. For people wanting a deeper understanding of the project, I also made a more technical document detailing all my experiments in a more scientific way that will be made accessible to all on my ResearchGate profile. Here is a link to my thesis and its supplementary data.

Video: Tutorial of how to make the Purhyphae composite leather, a mycelium leather grown on textile and food waste. The Purhyphae Project. Video scripted, filmed and edited by myself.

Video: Tutorial of how to made the pure mycelium leather. The Purhyphae Project. Video scripted, filmed and edited by myself.

Final presentation of the project¶

Here are the slides I presented for my final project defense at IAAC barcelona. The shorter 10 min version I presented for the online final Fabricademy presentation can be found on this link.

Image: Local final presentation at IAAC, FabLab BCN. Table featuring final products, growing mycelium, bioremediation and spawn jars and DIY scientific tools.

Conclusions¶

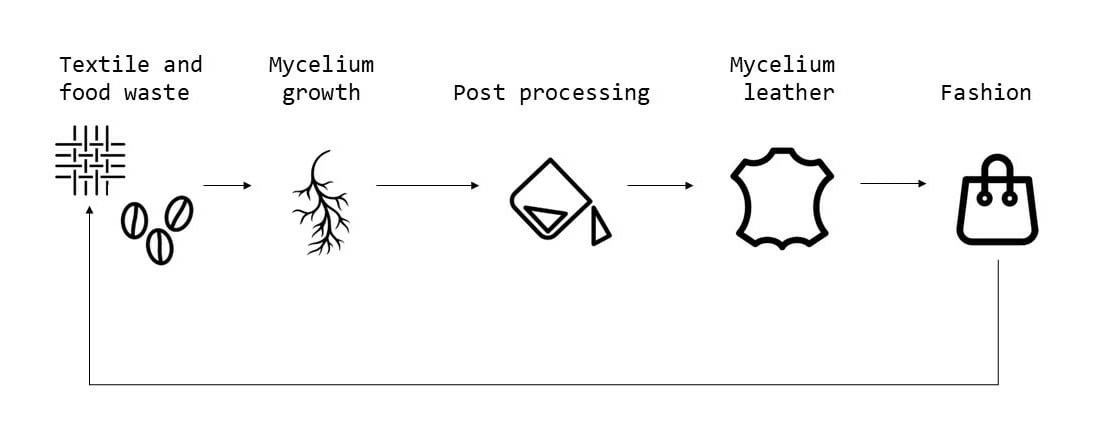

During my final project, I managed to combine biology, upcycling, digital fabrication, chemistry and electronics to come out with a process of bioremediation and upcycling of textile waste for the production of mycelium textiles. I produced samples of composite mycelium leather, samples of pure mycelium leather, tutorial videos for knowledge diffusion, created a DIY centrifuge hacking a food processor, created a magnetic stirrer, optimized the mycelium cultivation conditions of the incubator in the lab and found a way to significantly increase the quantity of CO2 in a confined environment.

Chart: Upcycling process of textile waste from the fashion industry for the growth and production of composite material.

Some of the explorations I would like to continue and points I would like to explore further are:

- reaching the 40 000 ppm concentration in the CO2 barrel;

- make the centrifuge safer to be able to use it for several minutes;

- make fruiting experiments out of the bioremediation jars and check if the new mycelium digests the textile waste more efficiently;

- post process the optimized growth samples once they are done growing;

- grow bigger samples and try their resistance to tearing at Eurecat center;

- scale up and make bigger sheets to make a design product out of it (bag or purse).

Further things I would need to work on is to make sure I am not overlapping with existing patents, which is an exhausting work normally done by an intellectual property office.

Video: The Purhyphae Project, short sneek-peak video.