Video: Tutorial of how to make pure mycelium leather. The Purhyphae Project.

Leather growht on liquid medium¶

In order to make mycelium leather, I contacted Maud Bausier from Domingo Club who used to be an instructor at WAAG. She told me the protocol they used when she was an instructor which consisted in preparing sterile liquid nutritious media, pouring it on a sterile surface and inoculating it with a chunk of mycelium grown on agar. Then, she told me to let it grow on the liquid surface until it colonizes it and gets thicker.

Liquid state surface fermentation¶

My first attempt of making mycelium leather grown on liquid culture was with Ganoderma lucidum (Reishi) since this is the most widely used strain for mycelium leather production for its resistance and thickness.

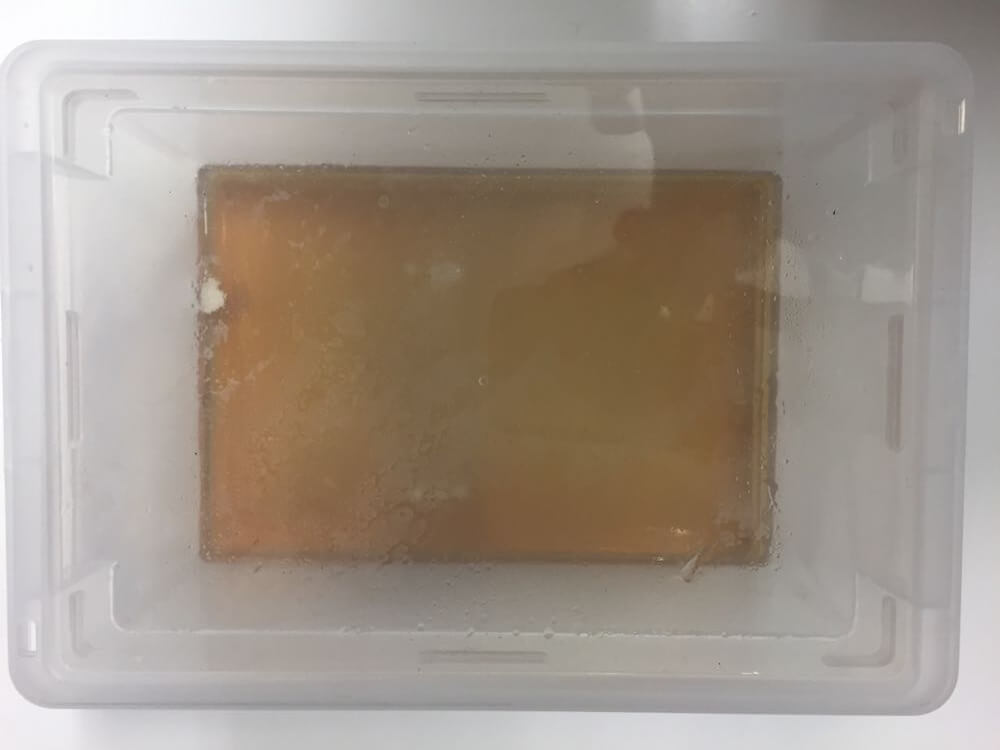

Image: Liquid state surface fermentation box on day 1. Reishi mycelium on malt liquid medium

I first prepared 500 mL of liquid malt medium by adding 10g malt extract and 5g of yeast extract to 500 mL of deionized water. I then sterilized the medium and sterilized a plastic box by cleaning it with ethanol (sprayed ethanol in it and closed the box for 30 min). In a sterile environment, I poured the liquid medium (cooled to room temperature) and finally inoculated it with a chunk of Reishi mycelium grown on agar. The mycelium was left to grow still for 20 days.

Video: liquid state surface fermentation of Reishi mycelium on malt medium, day 20.

After 20 days, the Reishi mycelium had colonized the entiere box but the pelicula it was forming at the top was not very thick. In order to make the mycelium grow thicker, I needed to feed the mycelium with more liquid malt medium. I prepared 500 mL sterile liquid medium and fed the mycelium with it mediating a srynge. Unfortunately, I did not manage to put the 500 mL of additional liquid medium under the mycelium sheet and sunk it/broke it. In order not to waste it, I poured everything in a bottle and sterilized it (to keep it on the long term), with the goal of centrifugating it and making a bioplastic out of it, like VTT technical research of finland do. But for that, I needed to build a centrifuge...

Liquid state fermentation (turning into Liquid state surface fermentation)¶

Growth¶

As one of the axis of my project was to make mycelium threads, I wanted to experiment growing fluffy mycelium in liquid medium. For the process, I got inspired by this video.

Video: How to make a liquid mushroom culture (easiest method), by EasyBreezy Grows.

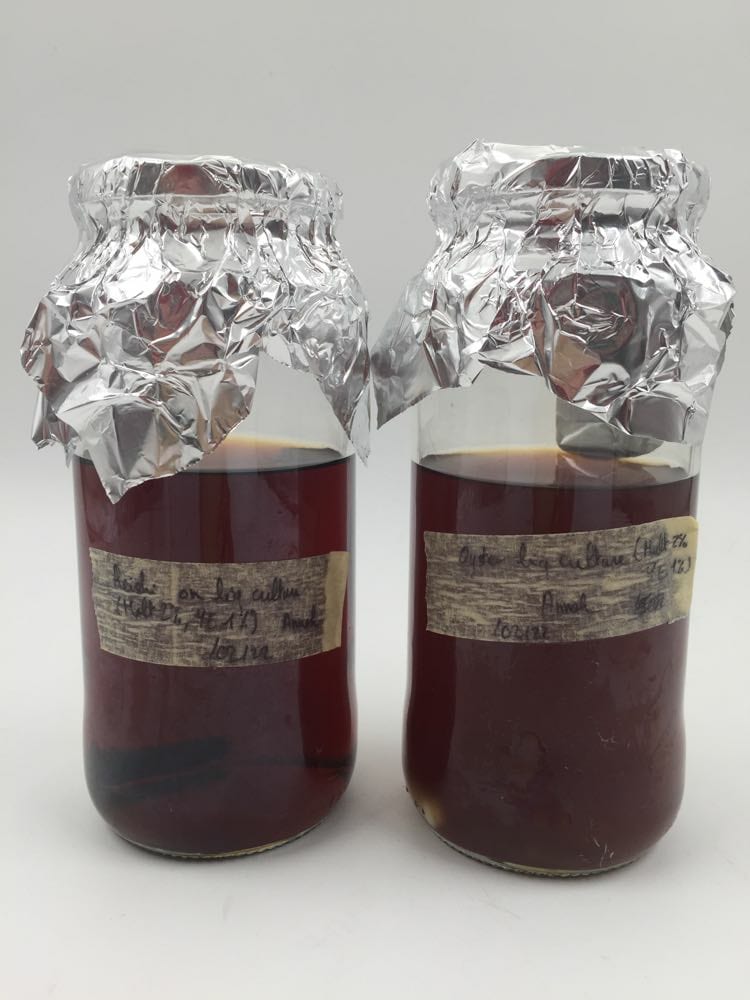

In order to try and make this mycelium liquid fermentation, I used 2 jars (same as the spawn jars) and filled them with 300 mL liquid malt medium (2% m/v malt, 1% m/v yeast extract). The jars were covered with an aluminium foil during the 20 min pressure cooking sterilization to avoid moistening the filter and thus avoid contamination. After cooling down to room temperature, each jar was inoculated with a 1cm² chunk of Oyster or Reishi mycelium grown on agar and incubated at 27°C ± 4°C for 34 days.

Image: Liquid state fermentation jars on day 1 (right: reishi, left: oyster).

After 30 days, only the Reishi jar had grown and the Oyster jar got contaminated. It first started growing submerged and fluffy and then started pointing towards the oxygen and finally colonized the entiere top of the liquid surface, leading to a liquid state surface fermentation.

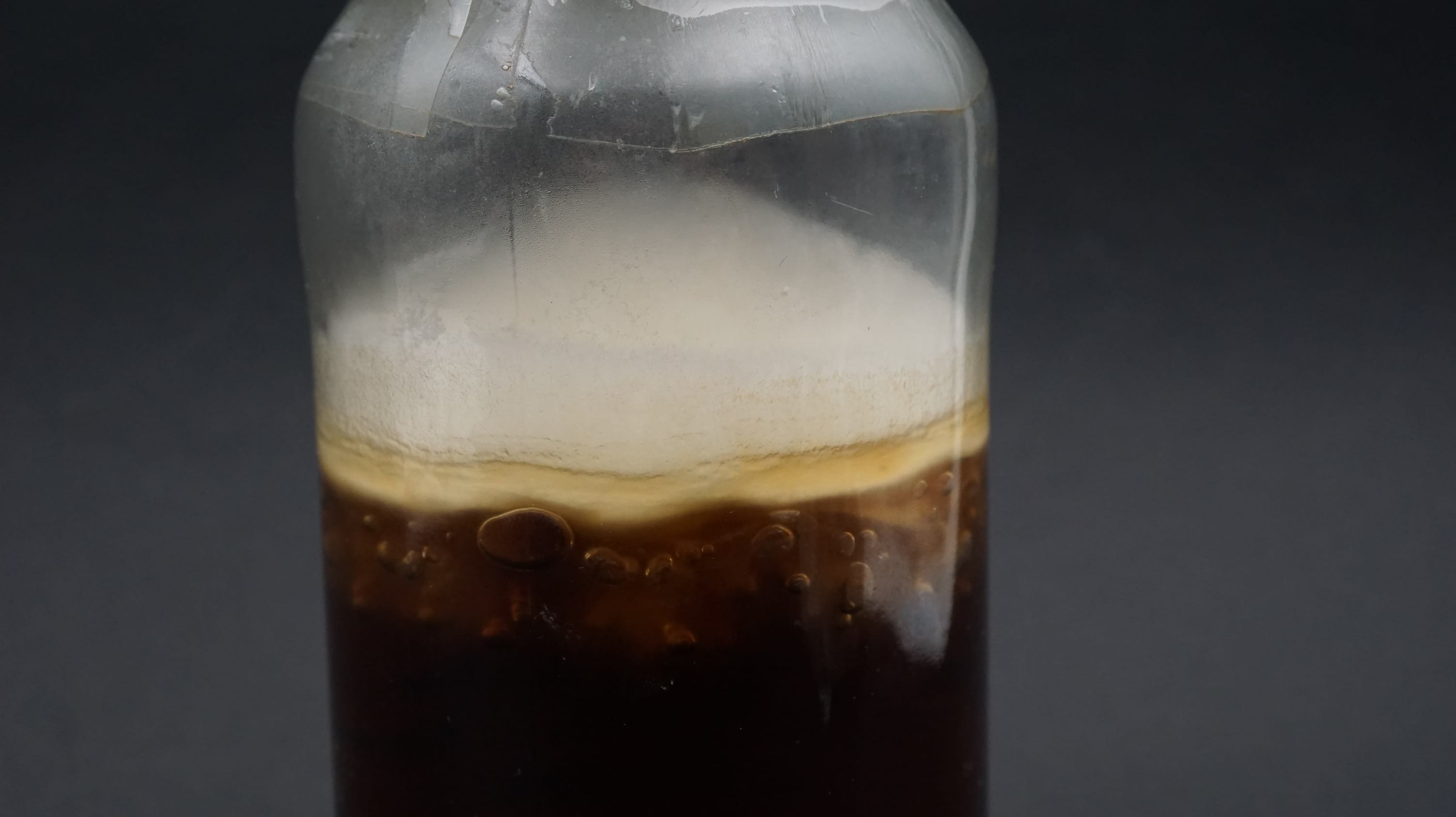

Image: close-up of the reishi liquid state fermentation jar on day 34.

On day 34, the mycelium was approximately 2cm thick and was ready to be harvested.

Video: Reishi mycelium surface state fermentation after being taken out of the jar. The sample grew very thick!

Post processing¶

The harvested mycelium leather was then heat pressed trice at 150°C for 20 seconds between two baking paper sheets. Excedent water was wiped off with tissue paper. Heat pressed mycelium leather was put to soak in a 30% glycerol bath overnight for plasticizing purposes and then dried at 35°C for 8 hours, keeping its flexibility. Melted beeswax was applied to the surface of the leather managing a brush. 3 more cycles of heat press (150°C, 20 sec) were applied to uniformize the beeswax on the sample.

Video: final pure mycelium leather sample.