11. Implications and applications¶

This week we are going to talk about the final project. I still have a lot of doubts and ideas to work on during these 3 months so let's talk about them!

Research¶

How might we?¶

- FOCUS ON A SPECIFIC PROBLEM/ BE PRECISE

- WRITE OPEN-ENDED QUESTIONS

- YOUR QUESTIONS NEED TO BE SIMPLE

Question everything:

- What materials were used to manufacture this product?

- Where did the material come from?

- What is the impact on nature?

- What happens at the end of the useful life of this product?

- Can we conserve the materials and reuse/recycle them?

- What could this object be improved?

RETHINK

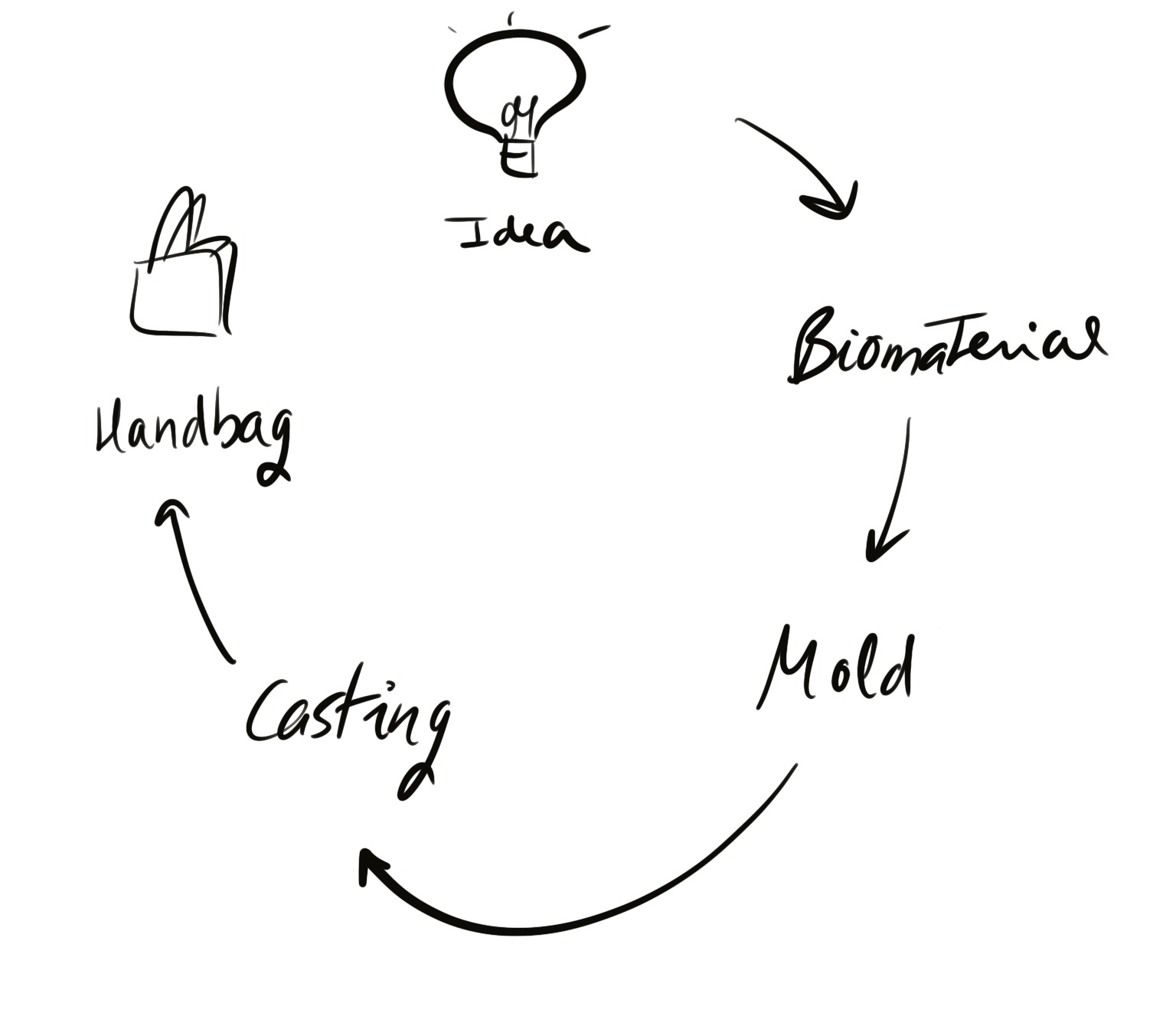

The idea¶

For the project, I have been thinking about creating a little handbag collection with surrounding raw materials, being selfefficent.

So, my next quiestion is:

How?

As you already know, my background is a fashion desgner specialist in pattern maker, so create a 2D shapes and convert in a 3D figure is a metodh that I have alreday work on it.

Then, let's change!

For the few lasts weeks, I have been working in the molding technique and with the Vacuum machine. A process that I enjoyed and open my mind to the way to design accessories and develop them. Also, this process lets you create interesting shapes in an optimal time. It could be an improvement for the accessory fabrication method, to be capable to produce on-demand and in small production.

Could I make some handbag samples as a sculptures?

Trying new shapes and different molds.

On the other hand, I would like to experiment with other materials instead of leather.

So, my next question to solve is:

Can I mold with biomaterials?

After talking with Anastasia, she suggests to try with the following recipes:

- Alginate

- Bio leather (as the apple/mango skins)

WASTE AS RESOURCE

It's time to start the tests!

Which kind of forms can I do? I will need the positive/negative mold, both of them.

As a plus, I have in mind the idea to create a final product with biodegradable or compostable properties. The idea to create a product with 100% natural material, needs to come back to earth in an easy way. The product must have a next use/life or completely disappear in the grown.

Nowadays, trendy product is just for one season, so after it, the customers simply throw them away. As a society must rethink! The fashion industry needs urgency to find a solution to solve the mountains of garments trash that we have on our planet! It's insane!

For this reason, to be able on this degradation product, I need to rethink the material to convert it into a biomaterial and the trimming for the accessory in a biocomposite material with the waste material of the handbag or with the pine resin and egg shells recipe...

A lot of things to proceed with and remake.

TO SUM UP:

WHAT:

As a young brand

We will create an accessories collection from waste material to a handbag, being able to come back to the grown (biodegradable).

We will control all the states of the samples.

The sentence:

Playing with the word as the Logo "m", and the "emotllar" (meaning casting in the Catalan language), mold and ready to wear, cause once the sample is removed from the mold it's prepared to be sold.

MESSAGE TO THE WORLD:

Casting ideas to be faster.

Previous work¶

During my Master's degree in accessories, I learn how to fabricate a handbag through the idea of the prototype. Explore the following PowerPoint to know all the steps:

BOUND. Book de Emma

Moreover, during week 9 of this course in Fabrcademy I have been exploring the leather molding method in my project prototype.

Investigation¶

In my case, I need to explore all the points that my project is going to be involved in to be able to improve it and understand all the gaps.

Fabrication of a handbag¶

The production of a handbag in a traditional way requires different materials, the following ones are the most common, however, it will depend on each design:

- Base material for example leather or straw.

- Filler and reinforcement (Cardboard, Eva Foam, wadding, Cuerson)

- Lining material for the inside.

- Trimmings (Zipper, Buckle, Clasp, Carabiner, Regulator, Ring, Eyelet, Rivet, Corner piece, metallic legs, )

- Thread (Polyester or Nylon composite)

How the big companies make a handbag?

In the next videos, you could see the various steps that the Haute Coture brands use to create their IT accessories.

Chanel:

Louis Vuitton:

Hermès:

Reparations:

Making off of the Hermès Kelly bag.

Dior:

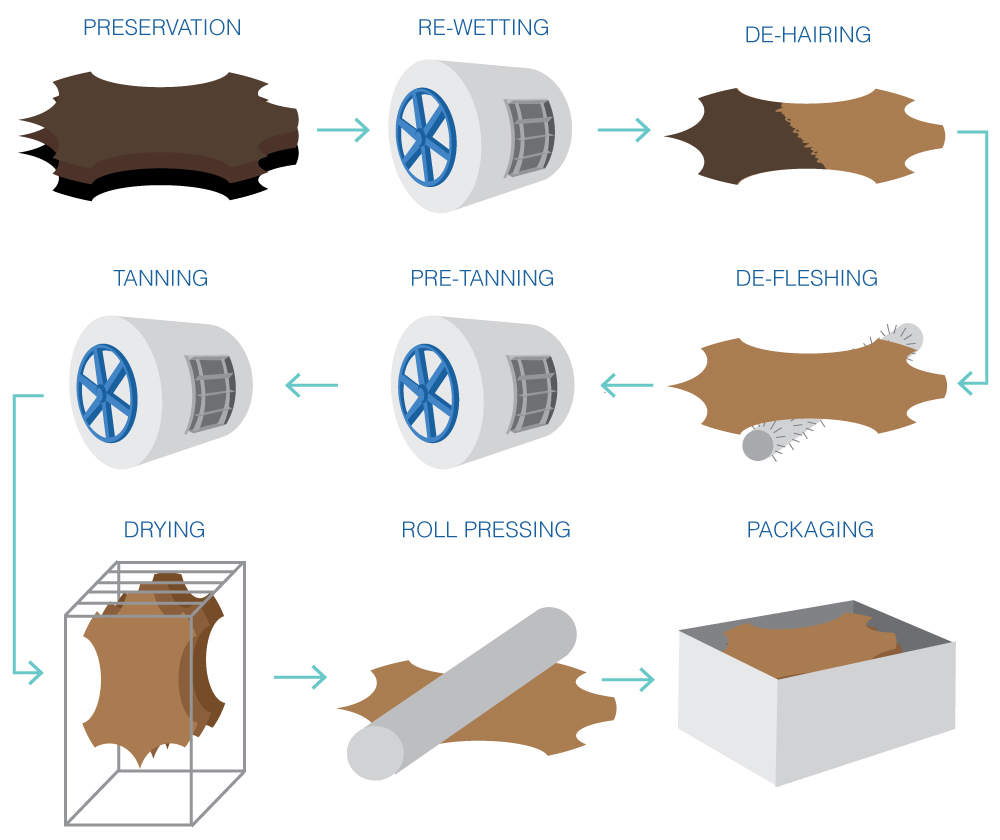

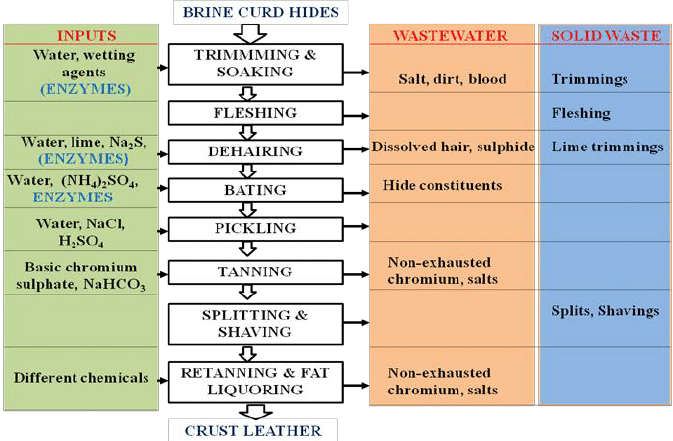

Leathery process¶

References¶

After all the questions come up, I start researching different brands, studios, and designers working on the same items I would like to experiment with.

Mylo material: Mycelial cells feed them sawdust and organic material while controlling the humidity and temperature among other variables. The mycelium grows into a foamy layer. Once the mycelium is harvested, the remaining material is composted. Then process and dye that sheet of mycelium and it becomes the Mylo material that gets used to make footwear, handbags, wallets, phone cases, and other gorgeous products. However, Mylo material is not currently available for sale, just for exclusive consortium partners.

Mylo material is not currently biodegradable, which is the case for pretty much all leather and alternative leathers that we are aware of.

-

Scarlett Yang Biodegradable material made with algae extract, and also intresting for the varios shapes/textures she creates with a layer mold.

Experimenting with organic forms.

More about:

Nomad coffee is a brand located in Barcelona, where I can get waste food to create biomaterials.

Design for the Real World book

Biomaterials¶

As a young brand, I think it's super important to have its biomaterial to be identified for it and also the opportunity to be independent of the big industry. So, we need to create a unique biomaterial from waste local material as an alternative to leather.

Alginate¶

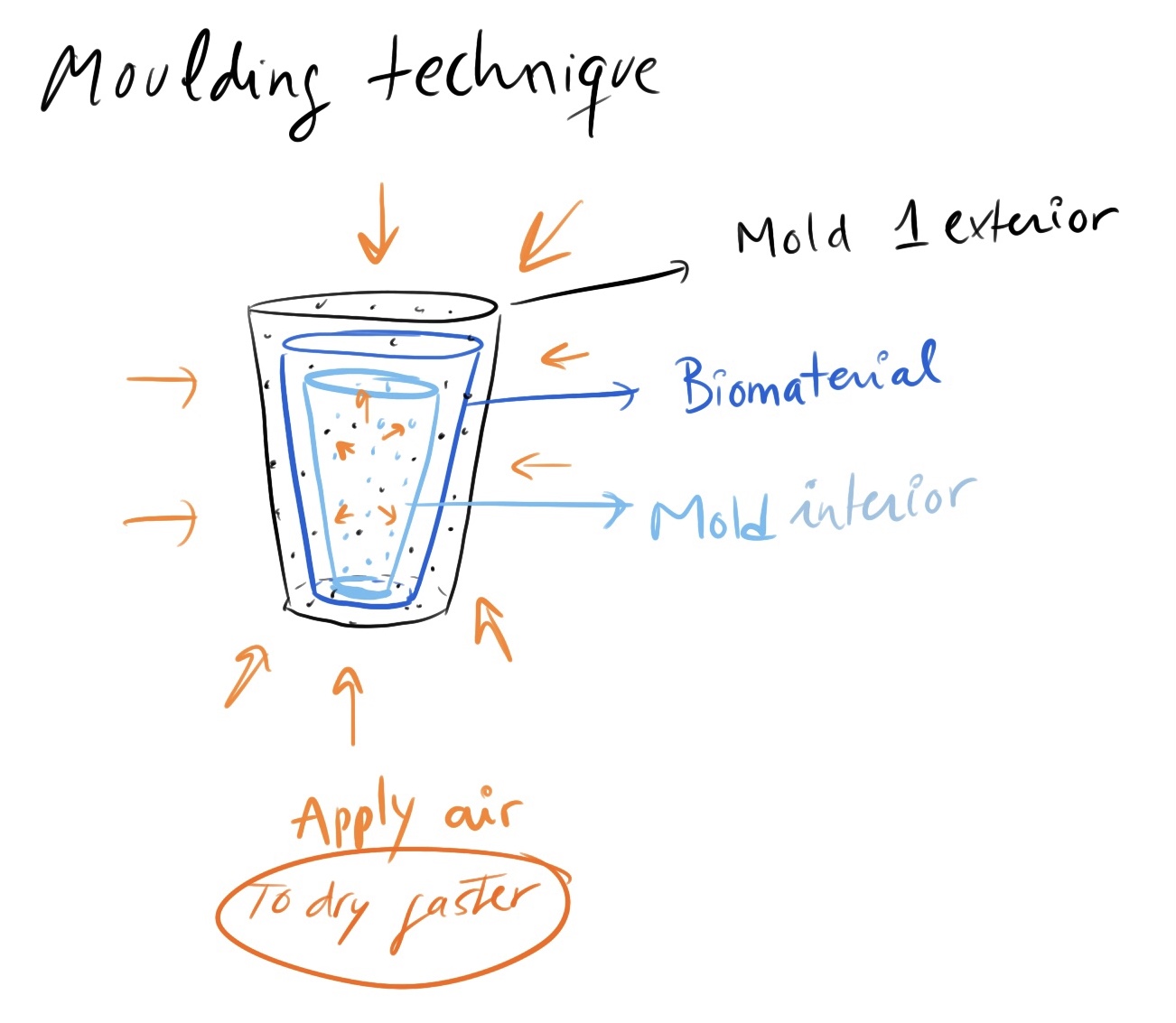

For this reciepe it probably need to use 2 molds the possitive and the negative to do not to let the material shrink while is drying.

Fruit leather¶

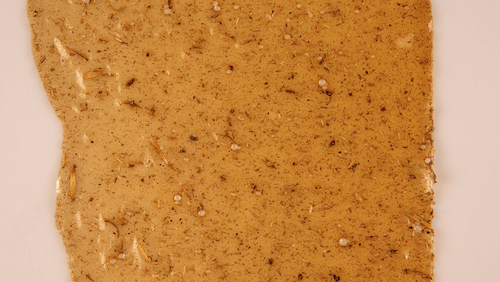

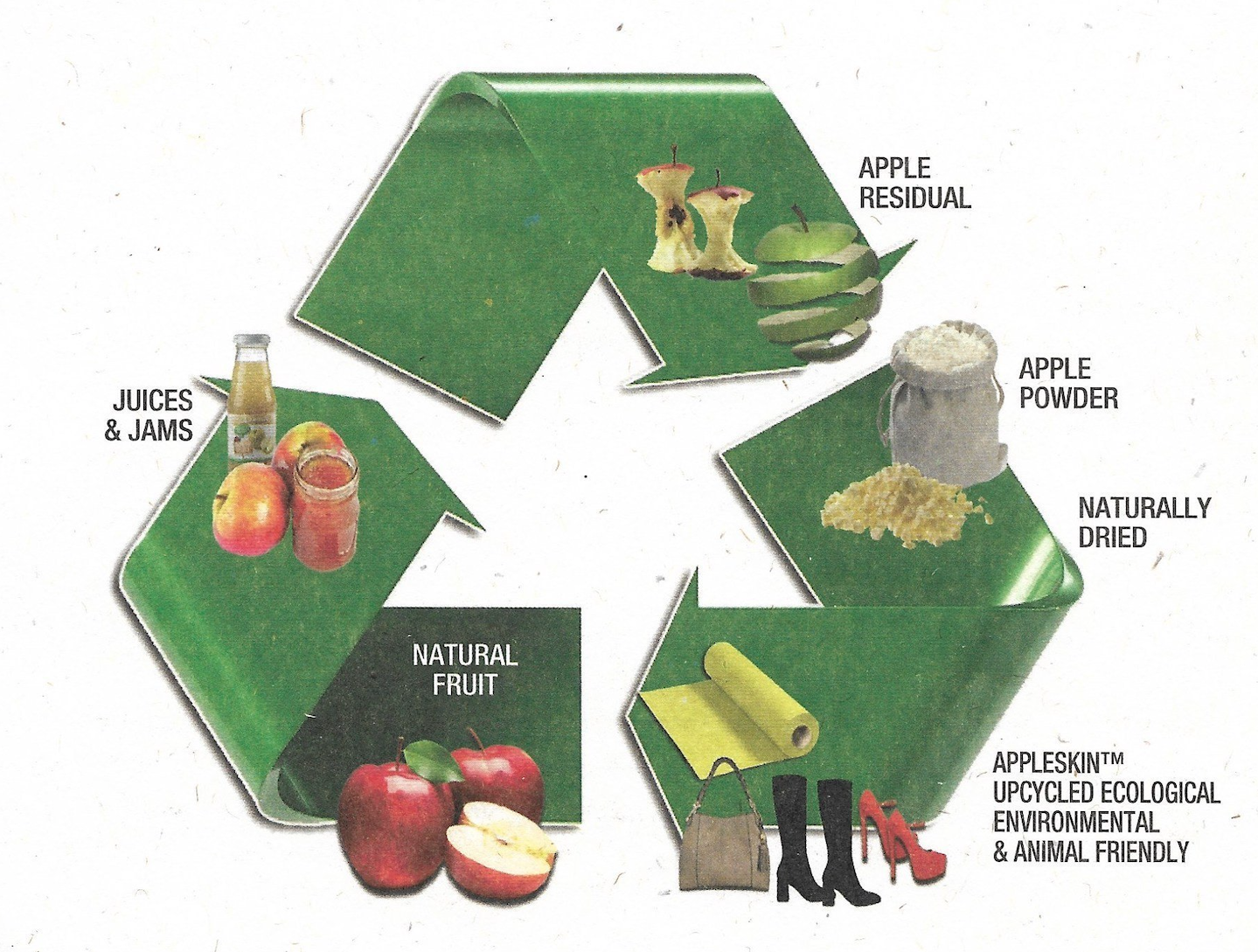

- Apple skin:

Frumat‘s Apple Skin is a bio-based leather alternative derived from the apple industry food waste. Born in the Tyrol (Italy) a region renown for the production of apples and which every year is faced with a significant amount of waste, Frumat developed a new raw material to answer both the local apple-waste issue and the increasing demand for ecological alternatives to leather.

The result is a cellulose-based material featuring a variety of textures, thicknesses and embossing and laser prints, allowing for it to be used across industry and that can easily it can be produced on demand and easily personalised. Currently, they are being used in the fashion and furnishing industry.

They have two lines of production:

- The softer fibre is ideal for textiles with a direct application in the clothing and apparel industry.

- The thicker version made of 50% recycled apple fibre and 50% polyurethane (PU). Used for shoes and luggage articles as well as furnishing and upholstery.

Moreover, they have the Frumat Apple Paper produced in several versions each one with specific properties. Used as tissue and packaging material.

To know more about follow Vegatex

Process:

- Taking the recovered apple waste and reducing it to a powder.

- Mix the biomass powder with other natural agricultural fibres through a process where it is combined with polyurethane and coated onto a plant based material.

Generally, the biobased content can vary, no less than 50% mixed with 50% waterborne PU.

- The result is a durable, environmentally friendly, breathable material (thanks to its organic composition), which is smooth to the touch and good for hard-wearing small accessories.

- Fruit Leather HQ in Rotterdam.

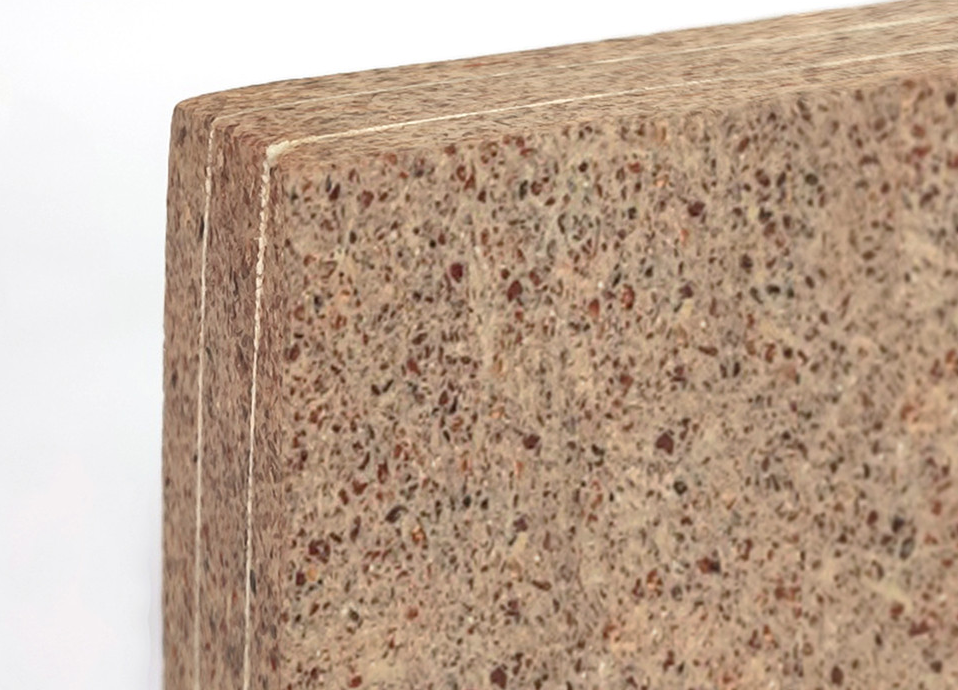

Frumo is a sustainable material made by the product-deigner Mareen Baumeister from food waste and natural resin to create flooring and furniture. Its special formulation allows it to be molded when exposed to high heat. This means that any damaged surface can be repaired by adding Frumo granules and applying heat. In furniture design, non-repairable materials such as plastic-wrapped wood-based panels are normally used frequently and therefore discarded after a short time. These contain toxic binders, and consume masses of forests and fossil resources, so sustainable raw materials are needed - food waste that no longer has a use.

- Beatriz Sandini Mango leather.

Paper method¶

- Paper maché

- Paper with onion skins

- Paper Grass recipe:

Open fibers¶

An other method I could explore is the create the Biomaterial with waste celulouse fibers like:

- Straw

- Maike leaves (high in fibers)

To get a grass structural material.

A possible option to get a type of material could be with the felt process

Additionally, I would like to make the trimmings with the pine resin, so I need to test the different shapes and properties I could get from it.

Inspiration¶

Some inspiration to start with:

Create a craftmanship product without hands.

Moulding technique¶

Why molding?

To produce handbags with complex shapes easily and faster to be ready to wear.

Let's skip some steps as the pattern making.

Advantages and Disadvantages¶

Conventional method:

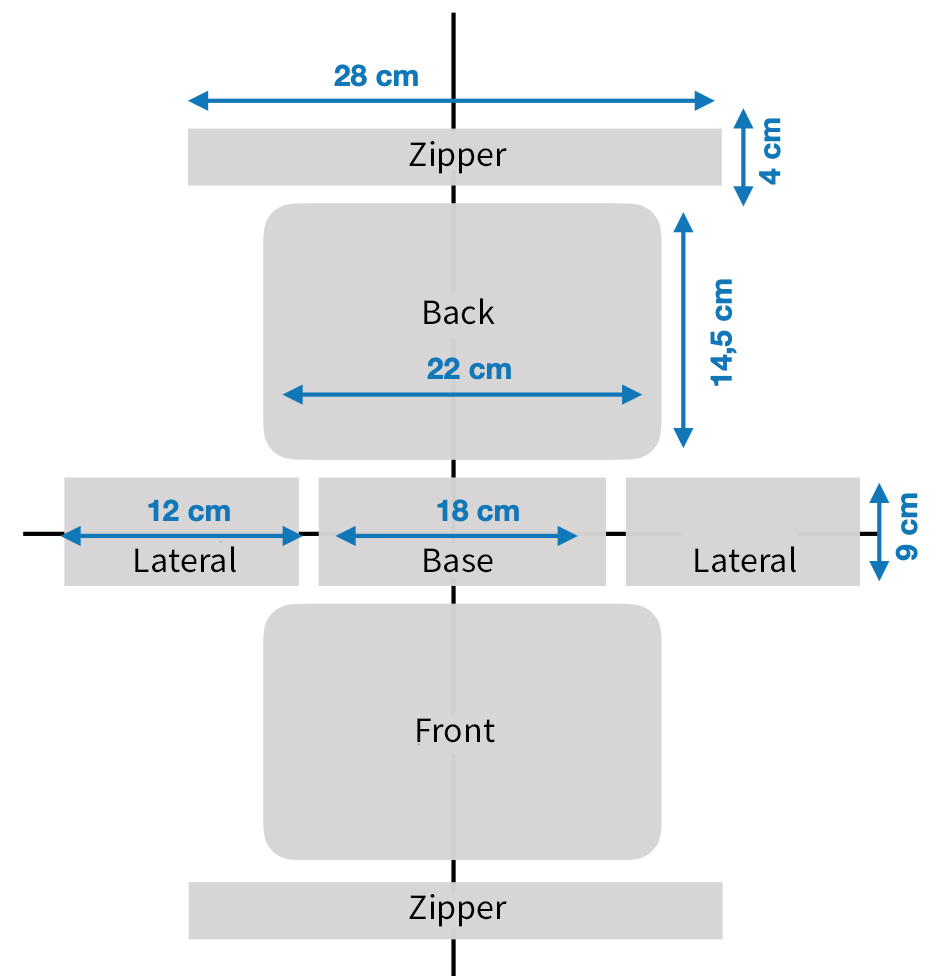

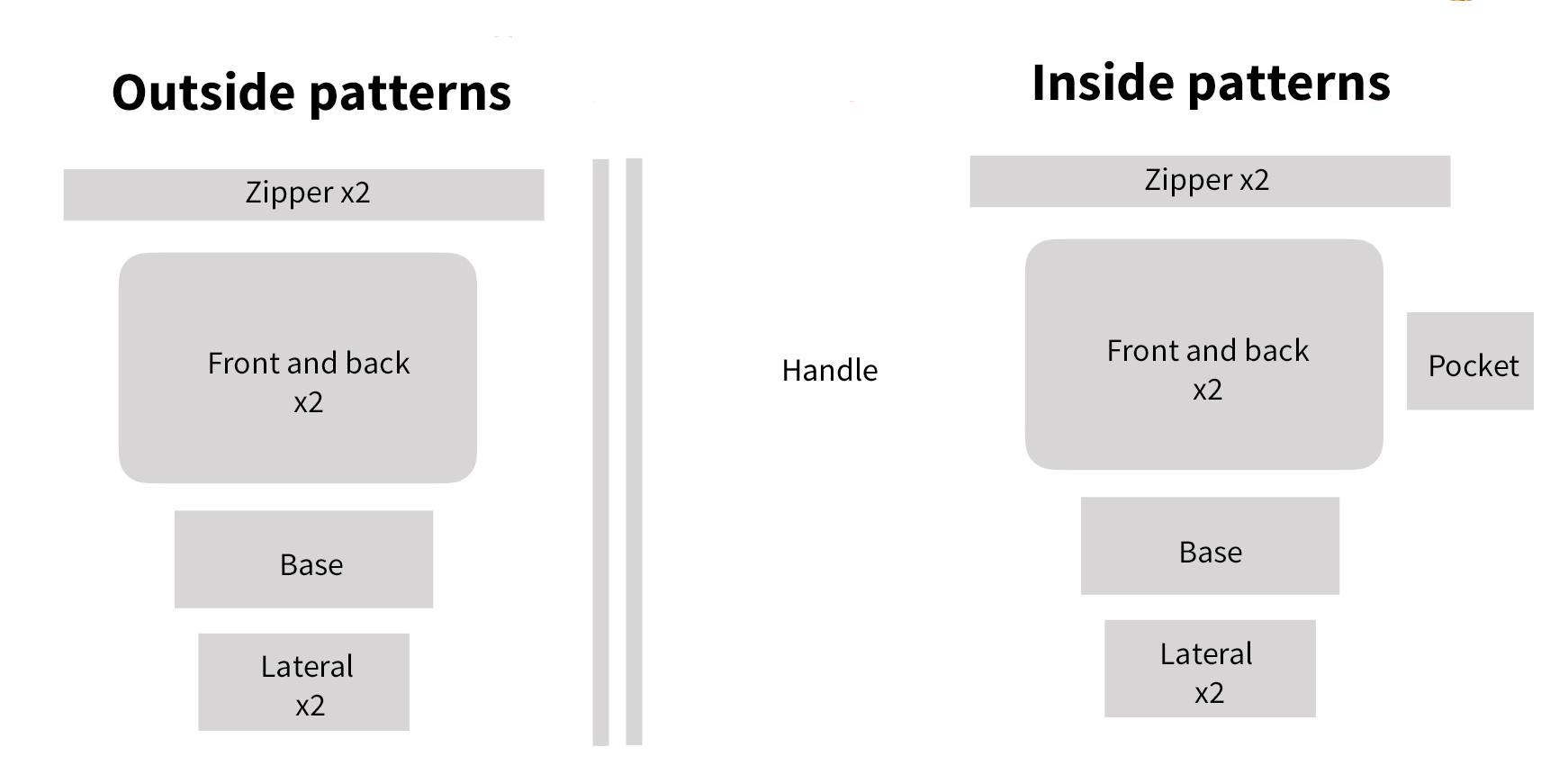

Pattern making is the process between the drawing design of the accessory and the final prototype. It is a long process with several tries to get the perfect scales and shape to easily fabricate in industry. First, they start to itemize the bag in 2D scale, try, and make the corrections to get the proper fit of each piece pattern. Then, you could mark them one by one with the name and the observations and repetition needed to get the 3D shape of the bag. After we could proceed with the fabrication of the first sample, it could have more corrections, so then we have to transfer to the pattern improvements.

Pattern-making workflow for basic sample:

For example, this type of bag is one of the easiest to construct.

To create this simple bag of Bimba y Lola we need more than 15 pieces to join.

Casting method:

-

The technique is subjected to a mold, so every time we need to introduce a new design to the market we will need to do the mold in software such as Rhino, send it to a CNC or laser cutter, and make the corrections if it's required. Moreover to fabricate simultaneously several samples we will need one mold for each one. So we must think about a process of moulding an the way to have te less the ecological impact and make it sure that is better than the traditional fabrication in terms of time and waste material.

-

Less craftsman method and stitches ornaments so the value for the costumers could descend.

-

The typology of the accessories could be distorted for conventional customers. However, it will create new typologies or more freedom for them to play.

Some examples of brands using the mounding technique:

The different molding shapes that we could find in the market nowadays are simple and there aren't a lot of samples.

These are some of the brands which are commercializing this typologies accessories forms:

Machines¶

- Week 10 creating the Vacuum machine in the FabLab

This Vacuum machine is used to mold leather.

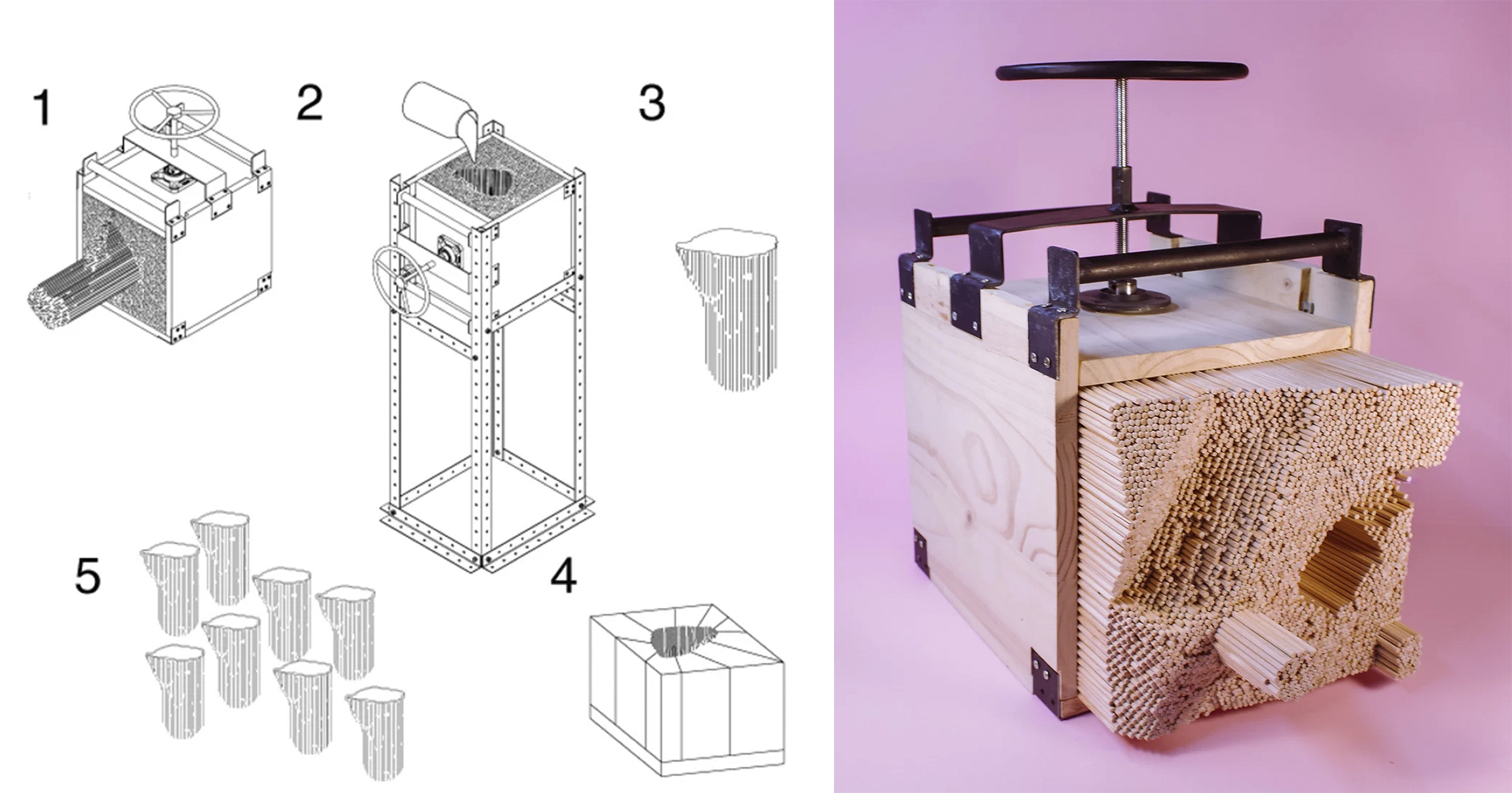

New crafts process through a tool that allows generating natural forms by extrusion of profiles. From the form products or molds are obtained by tracing with materials.

POLYMORPHIC MOLD:

New crafts process through a tool that allows to generate natural forms by extrusion of profiles. From the form products or molds are obtained by tracing with materials.

With the negative tool shape.

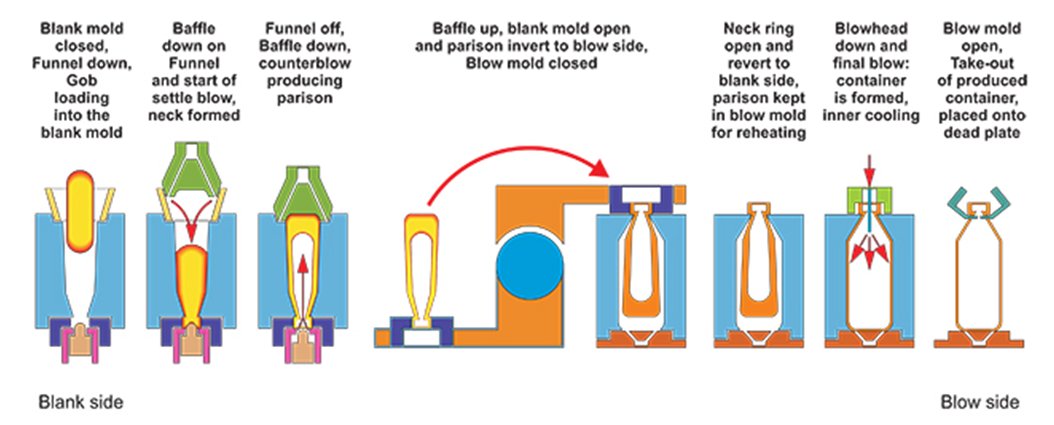

- Bottle process:

Plastic pellets are poured into a machine that heats them to a very high temperature, so it becomes a thick liquid. Then injected into moulds, where the plastic hardens and sets into a bottle shape.

Difficulties¶

-

The Alginate when it's dry shrinks so I will need to tie it with nails or cords to the mold.

-

Is the bio leather waterproof? As an accessory material, it needs to be resistant to utility day by day.

-

The different biomaterial recipes are fluid when you create so, to get dry and get a shape maybe we need to find another method.

This first idea could be a solution to work with different biomaterials and be able to mold them.

- Scale product, start with a little scale as an accessory, to have the opportunity to increase in the future as furniture, some product.

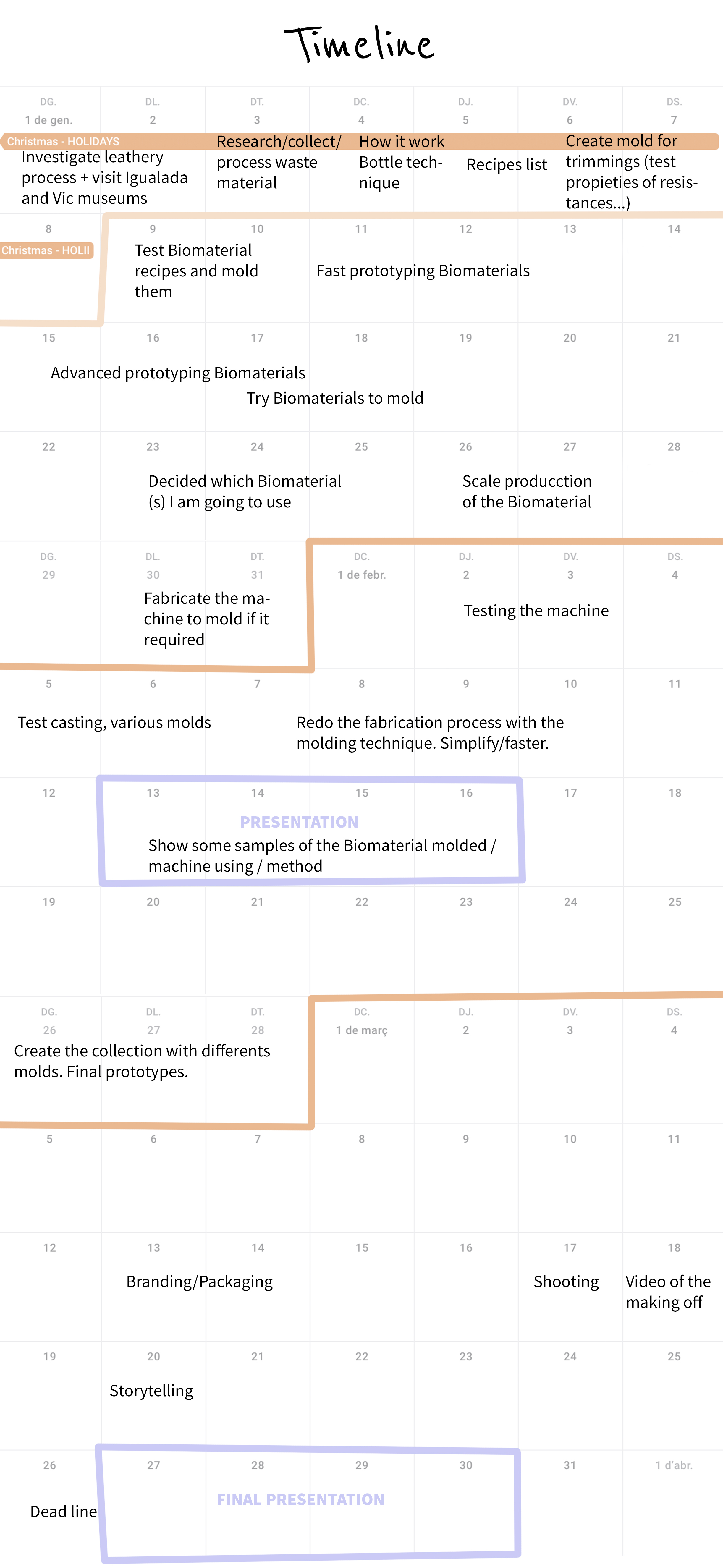

Timeline¶

Organization of the different points to work on it:

Possible tours/interviews¶

To know more about conventional accessories fabrication and learn some tips, I would visit two Museums of Leather, one from Igualada and the other one from Vic.

Moreover, it could be useful to interview some specialists in accessories fabrication/ designs/brands to know more about what kind of gaps they found in this business to improve and present my idea.

Some feedback about the projet idea¶

After explaining my idea for the final project they ask me to investigate more in detail about the problem of the fabrication and all the steps that are required to get an accessory in a real-scale industry to be able to compare with a young brand's necessities. Another feedback to explore more about was the leathering process, to easily show the problematics and be able to get an alternative more efficient and sustainable, as in my case is to use biomaterials from agricultural waste. An additional point to get into consideration was to search recipes and their properties to start doing some experiments in the molds, knowing more about the final texture and shapes that my product could get it. Finally, they ask me to have into consideration that the molding fabrication generates a lot of waste material, and which kind of material will be to be more sustainable and fast compared to the traditional method of working in 2D patterns as a young brand handbag.

First presentation for the final project¶

Keep in mind:

- (WHAT) The project: title and phrase that describes it (vision/mission).

- (WHAT) A poster (like a pager, advertisement, or design overview).

- (WHY) Inspiration and State of the art: timeline of projects/research that is relevant to your state of art.

- (WHY/WHO) Numbers/statistics (optional - if you have conducted an inquiry).

- (WHY/WHO) References: Case studies and existing similar projects. (4 max)

- (For WHO) Case study - user experience, make an assumption of a person (character) that uses it (if applicable).

- (HOW) How does your prototype/project manifest your idea, what it tackles, improves or changes from the state of the art.

- (HOW) Technical research: Outline of how it materializes the goal/focus of the project

- (HOW/DOCUMENTATION) User manual if it is a machine or kit

- MESSAGE TO THE WORLD: what is the project’s message? in one line define the future possibilities of the project.

Project first presentation de Emma

Still, a lot to process...

🔍📚See you the following week!🧠👀