2. Contextualization¶

As I have been exposing in the concept, I would like to use a PROXIMITY WASTE MATERIAL to cook a Biomaterial in order to create handbags.

We start to think about the Final Project on November so in this season the farming area (the place I life) there are not any plant to use as a waste, all of them it's needed to feed the animals. So I need to investigate some plants from Catalonia that grows and are harvest during this season (December/January) to be available to collect.

Furthermore, Cellulose is the most abundant natural polymer and can be sustainably produced from various biomass. The global annual output of cellulose is approximately 75 to 100 billion tonnes. The development and utilization of cellulose is of great significance to the sustainable development of human society, especially the energy scarcity in the future.

Research of a waste material¶

A little introduction...

Corn husk¶

So, after some research around Catalonia fields and making some calls, I get an intresting material:

THE DRY HUSK OF CORN IS A LOW-COST BIODEGRADABLE AGRICULTURAL WASTE MATERIAL.

However, the green corn husk isn't a real waste material cause they are used to feed the animals, so I will use just the dry ones.

HUSK PROPERTIES:

FLEXIBLE / STRENGTH / TENSILE / ECONOMIC / FLAME RETARDANCY

-

Flame retardancy and textiles made of fiber from corn husks.

-

A polyester composite reinforced with 30% maize husk fiber also demonstrated the highest tensile strength and modulus.

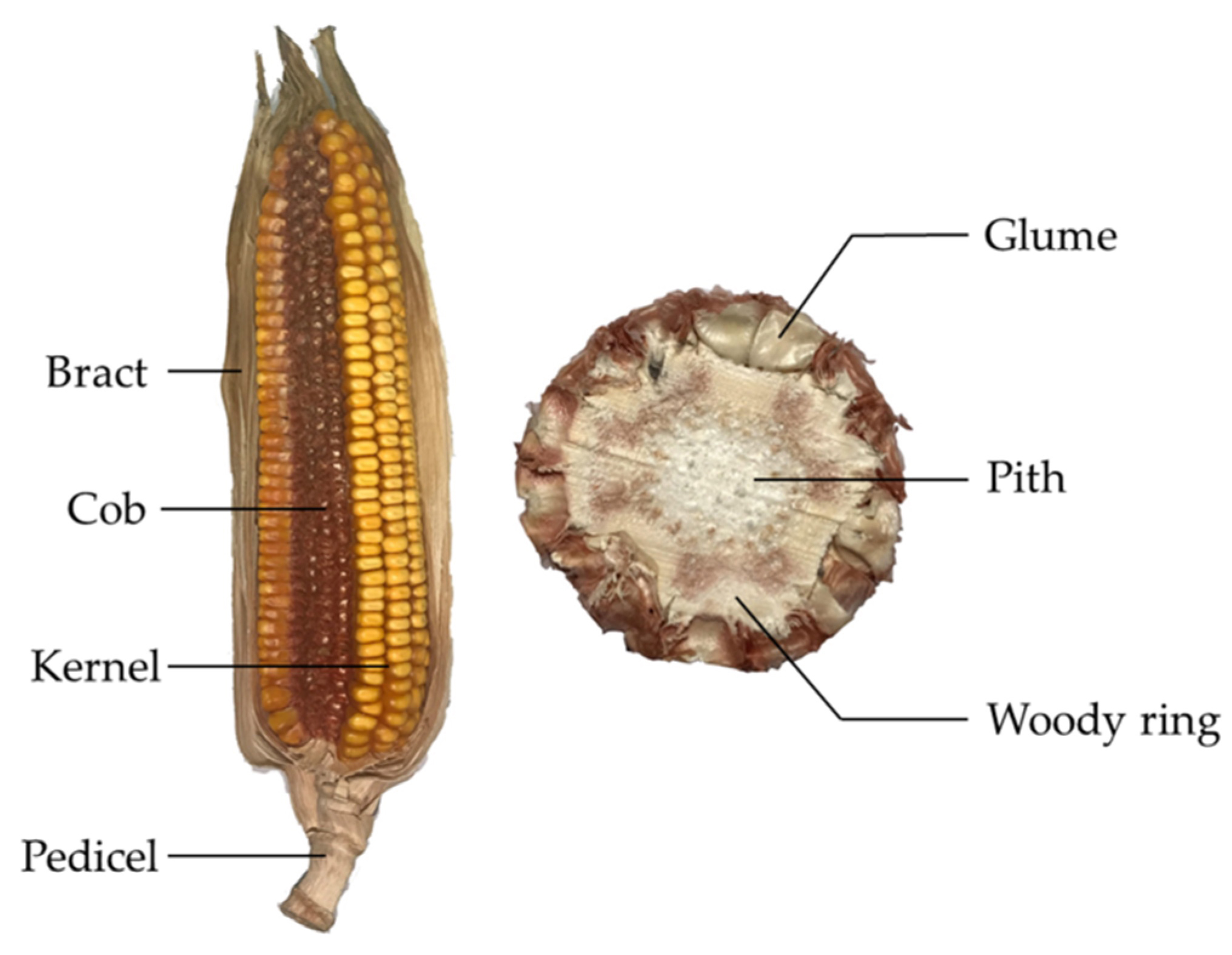

THE PARTS OF THE CORN COB:

THE PROPERTIES OF THE HUSK:

Video of a dry husk to see the real texture and look:

Husk de Emma Picanyol Illa

APPLICATIONS:

-

Corn husk and polyester composite: With 20% of corn husk lignocellulosic exhibited the highest flexural modulus and strength, while the composite with 15% fiber exhibited the highest tensile characteristics. Thermoset polyester composite reinforced with 30% maize husk fiber also demonstrated the highest tensile strength and modulus.

-

Corn husk and polypropylene composite: It's more economic and enviromentally benign than a jute fiber but with an inferior mechanical capabilities.

-

Corn husk and polyethylene composite: Mix manufactured from maize stem and cob fibers had better flexural modulus, tensile modulus, flexural strength, and tensile break strength than composites made from corn husk, leaf, and ear fibers.

More about: "How are Corn Husks Used in Different Materials?" by Chinmay Chari. Read the article.

Projects and references with husks¶

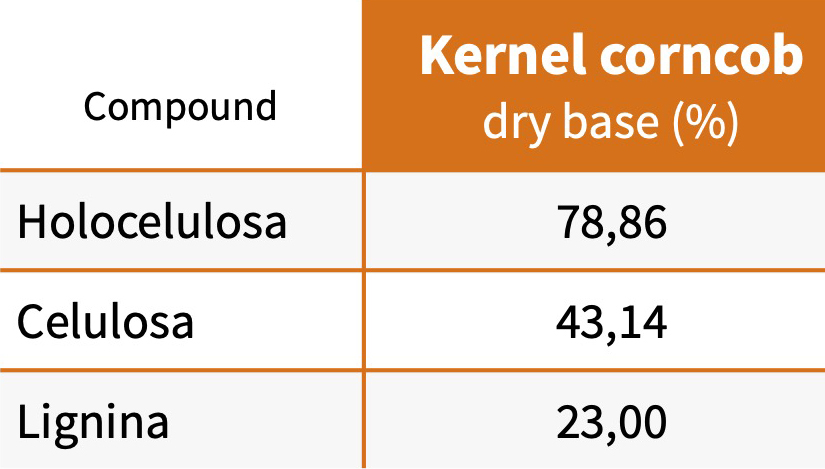

- Fernando Laposse: Create a color palette with the husks of different species of corn.

To know more about click here to follow his page.

- Making materials from Corncob husk:

-

Corn husk bioplastic by Valeria Munoz Cardenas and Diego Nunez Garcia from University of Monterrey, Mexico. They make the material from the husk to create the box for the eggs.

After I decided on the waste material that I am going to use

IT'S TIME TO START!

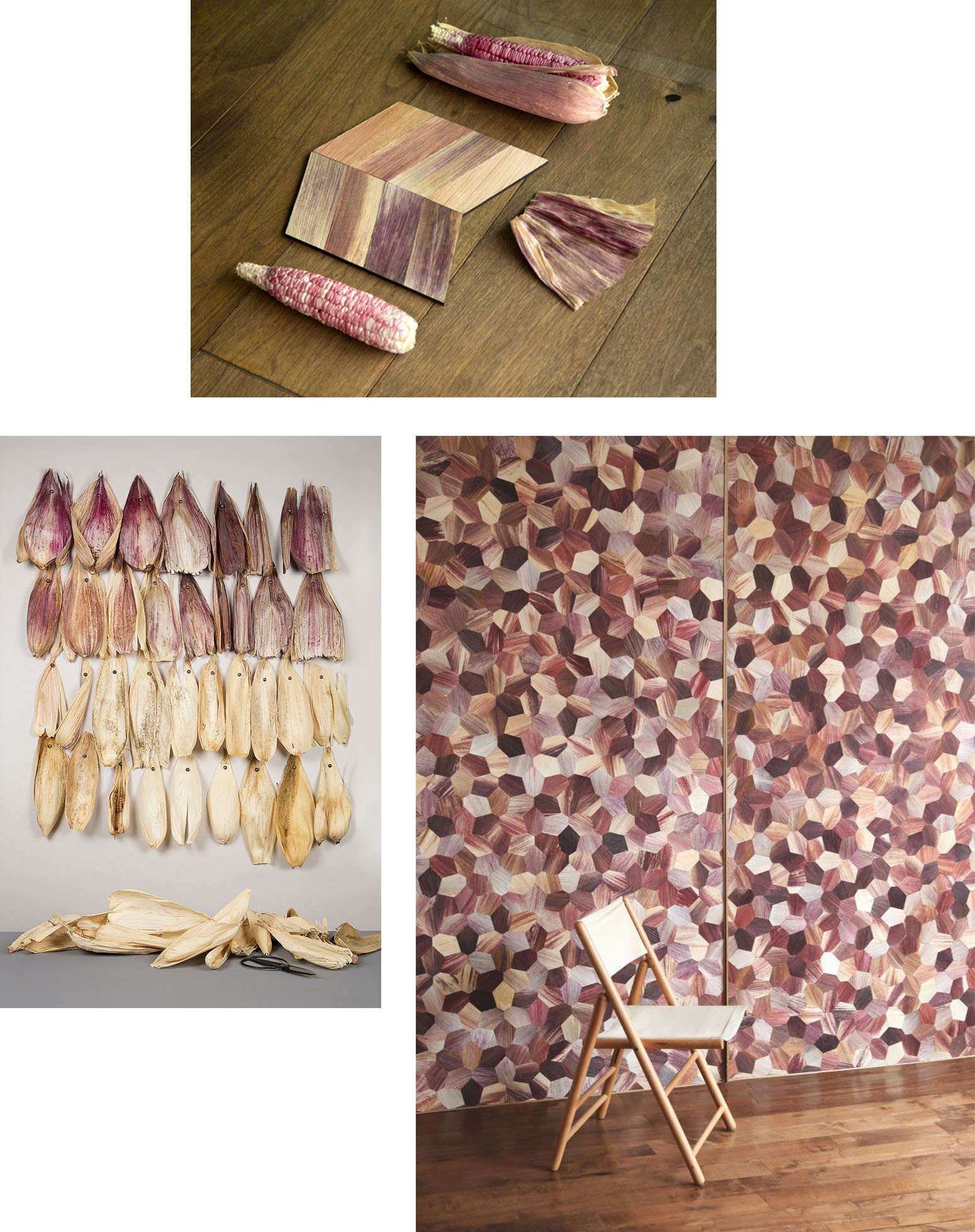

Collect¶

So grateful to my brother and his friend Alba Pons to help me to find and get some husks corn material in the last fields that still not gathering in the sud of Catalonia. Because of the season, it was so hard to find husk already in the plant so I need to travel 2 hours far away from my home to get them.

The most favourable moment to pick up them is when they are harvesting cause the husk doesn't get humidity from the floor. I went two times to have enough material to make some tests and the final samples.

Collecting time!

TOTAL COLLECTED DAY 1: 10 sacks.

Meanwhile, I was cooking some husks in the BioLab from Barcelona I realized that I will need more quantity, cause after I boiled and grinded it reduce considerably, so I need to recollect before the corncob season finished to make sure to have enough for the Final Project.

On the second day when we were collecting it also started raining, so the husks had a high humidity rather than the first pick-up... So these husks get a darker color.

TOTAL COLLECTED DAY 2: 2 big bags.

Dry¶

I keep all of them in several boxes to let them dry and take out all the humidity they could have. To accelerate the process I increase the room's temperature to 25ºC approximately.

After they are completely dry I could keep them in sacks or big bags instead of boxes to take up less space.