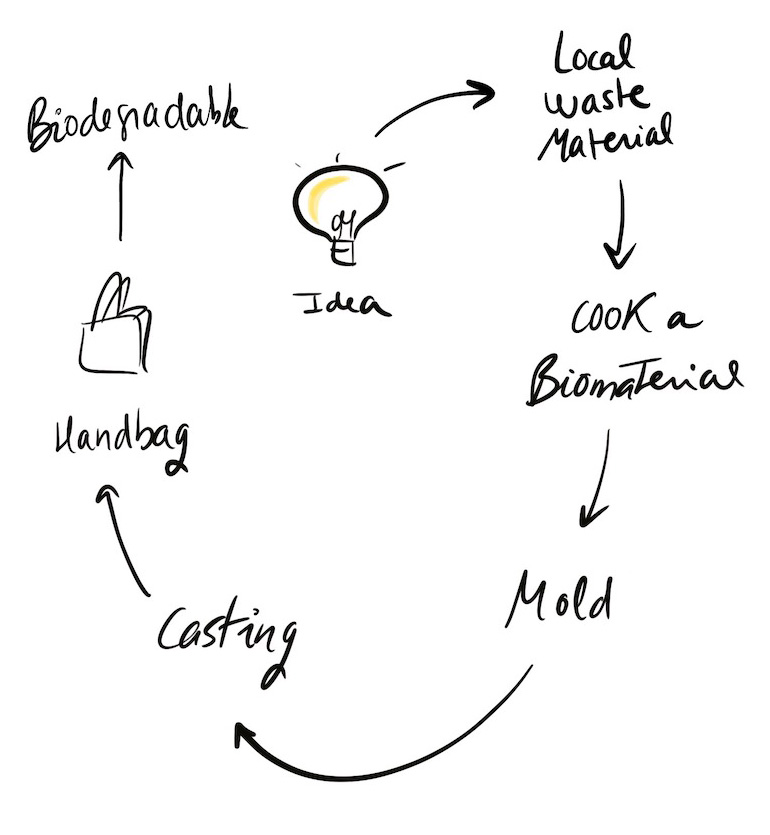

1. Finding a concept¶

The idea¶

A little introduction:

As you already know my background is a fashion designer specialised in pattern making from a small farm in the mountains near Barcelona. The farm has been in my family for generations with a long legacy in agriculture and livestock.

Let's make my scene an opportunity.

For the final project, I have been thinking about...

WHAT?

Create a young accessories brand:

I will create a small accessories collection with surrounding waste material being able to come back to the grown (biodegradable) and being more:

EFFICENT / SUSTAINABLE / LOCAL

Research¶

STATE OF ART:

How to be more

Sustainable¶

Pollution in the fast fashion industry¶

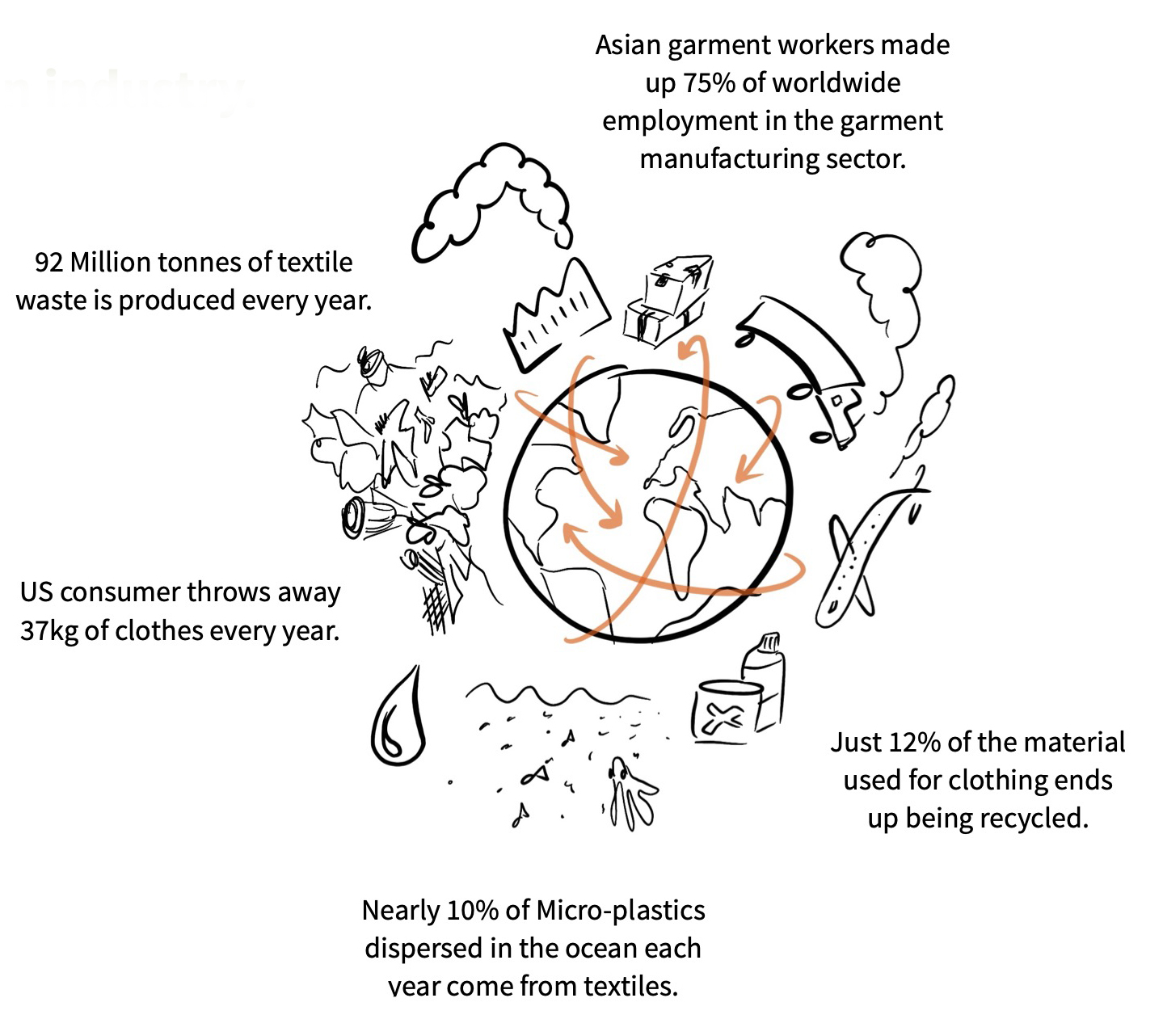

Some consequences in the fashion industry that be need to consider in order to imporve it:

So, if 75% of the garment production is made in Asia, how many transports do we need to distribute all the products to arrive in USA, UK, and UE?

We are recycling just 12% of the production because the components of the fabrics are mixtures and it's so hard to separate them. Should we change the base material to a purer one...

How many years we will continue over producing and creating tonnes of trash around the world?

Moreover there are the leather industry:

- Leather tanning using chromium are not biodegradable.

- The chemicals are very harmful for water and local communities.

WHAT ABOUT OUR PLANET?

References:

Could it be more efficient, local and without a trace on the Earth?

And achieve total transparency in the process of making the product?

The costumers are asking to know more about the trasavility of the product but it's so hard to get the list, there are a lot of people envolved in a typical fashion product!

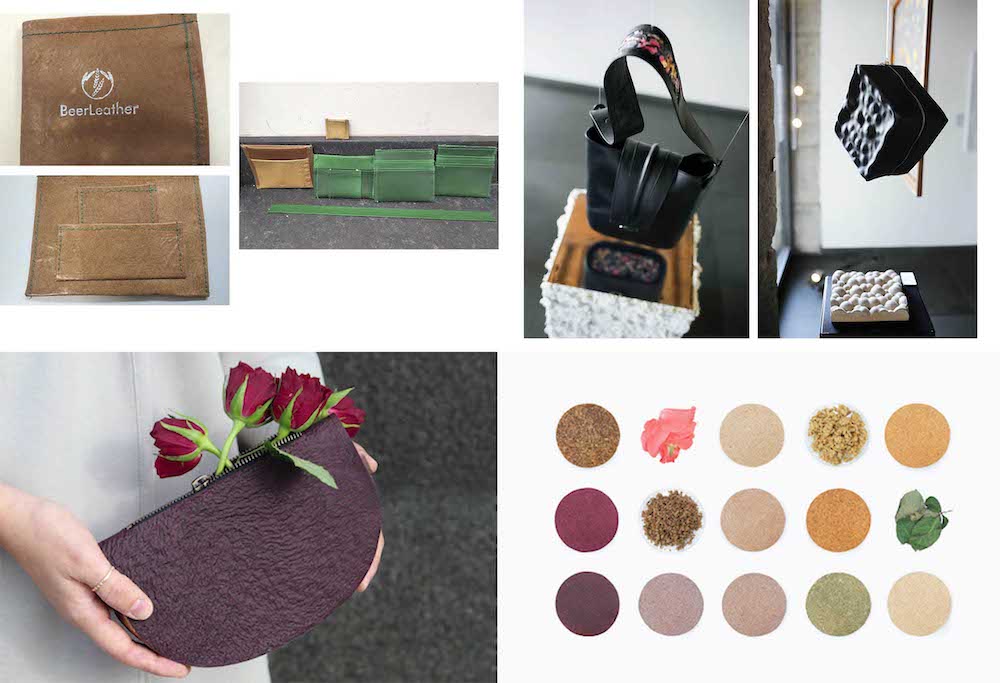

Biomaterial waste brands¶

Some real examples of brands using waste material to create their own handbags or material:

-

LUCIA JAVICOLI: Gravité project.

-

MycoTEX by NEFFA is the groundbreaking seamless manufacturing method allowing clothes and soft goods made from compostable mushrooms.

-

PIÑATEX: It's a Biomaterial company that create a new generation material from agricultural waste such as pineapple leaves.

-

Mylo: Bioleather from mycelium cells.

-

Flower Matter: innovative materials from flower waste by Irene Purasachit.

Flower Matter from Irene Purasachit on Vimeo.

Another method is to reuse the material as:

- Zoombags is made of 100% recycled polyester fiber from plastic bottles or recovered from production surplus.

How to be more

Efficient¶

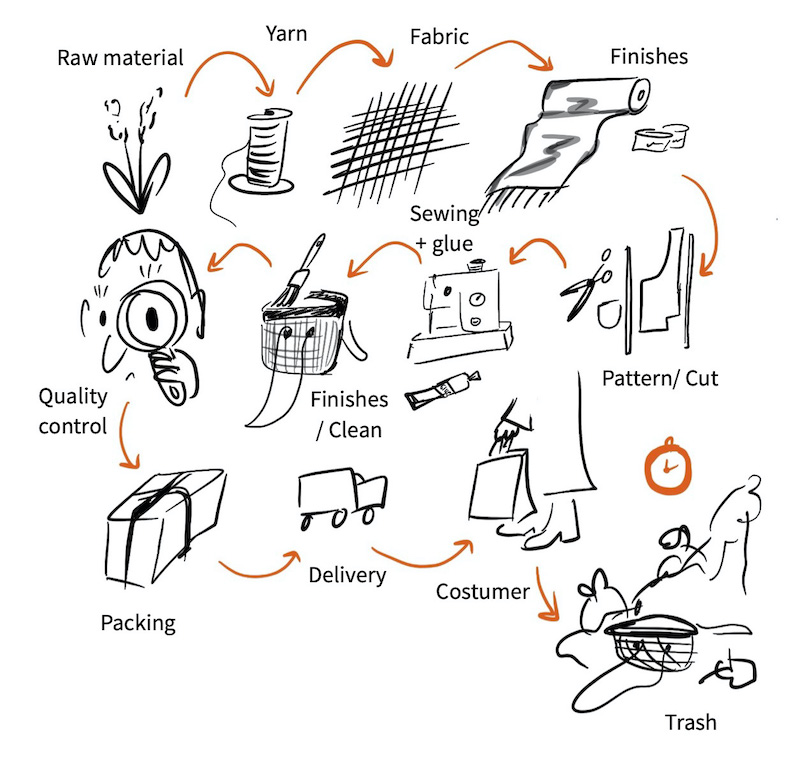

Fast fashion brands' production¶

In 2021 Zara has 1.790 suppliers.

Traditional fashion production requires a lot of suppliers.

HOW MANY STEPS WE NEED TO PRODUCE A PRODUCT?

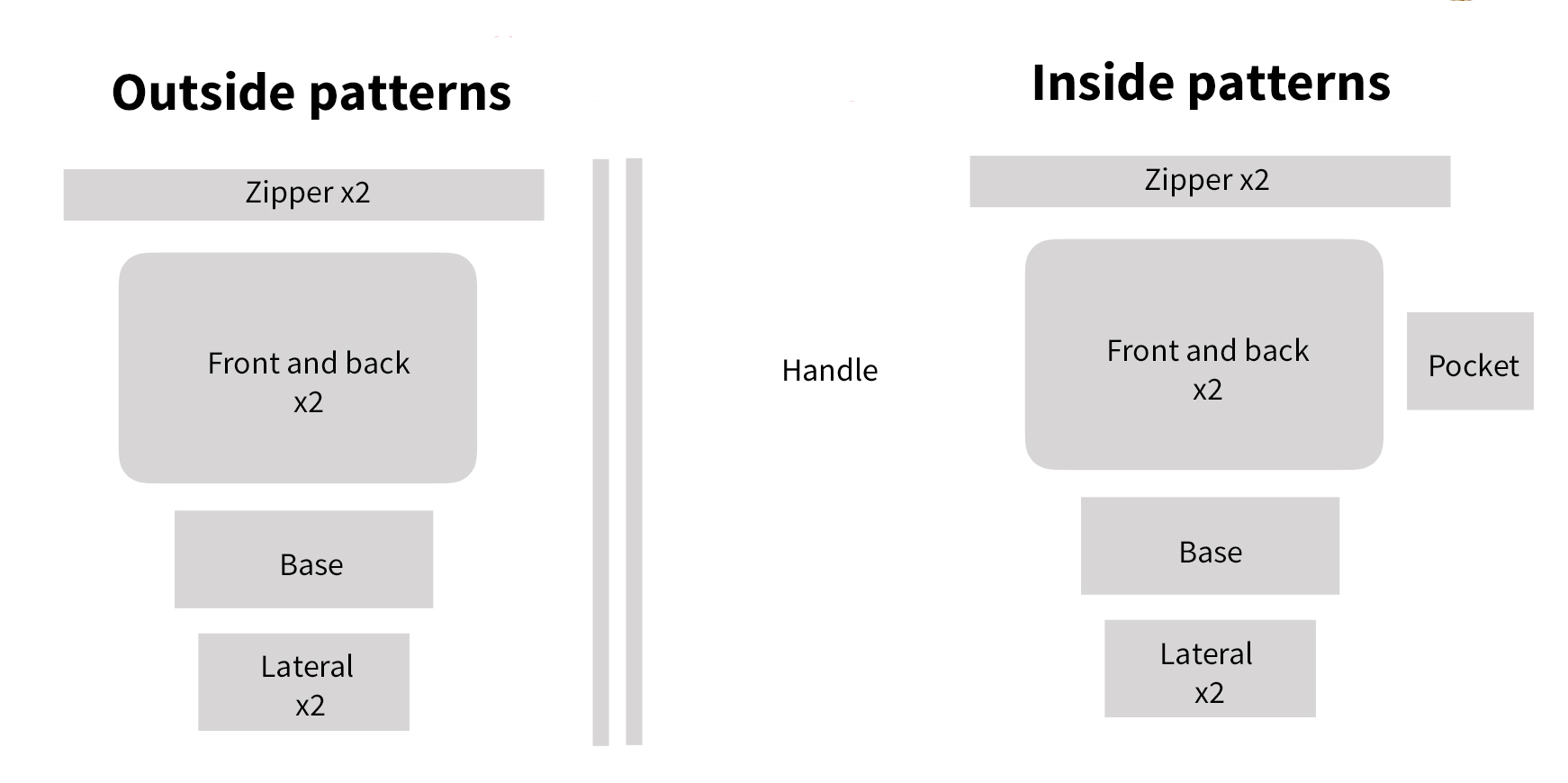

Current accessories production¶

The process to produce handbags as a young brand requires a lot of steps, infrastructures and suppliers.

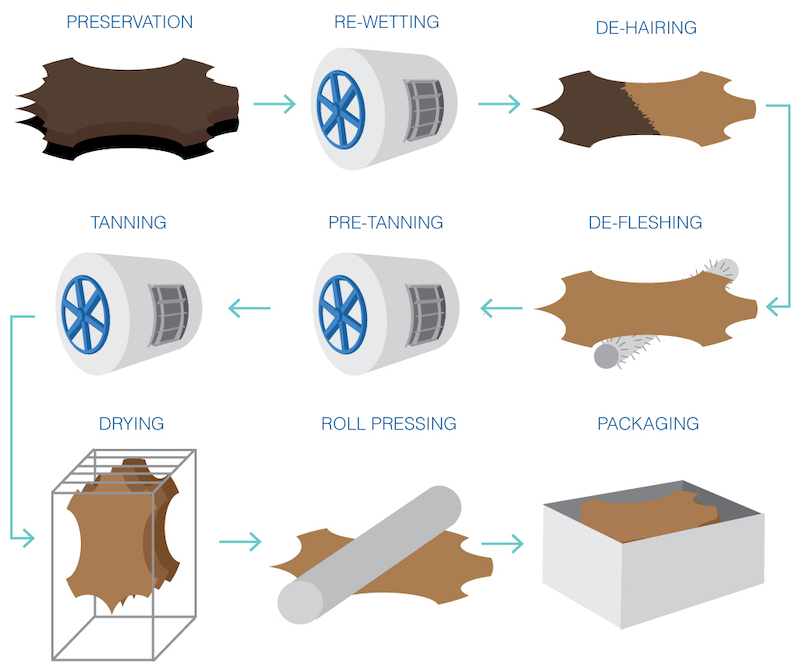

As an example the leather process requires various steps to get a leather prepared to be used.

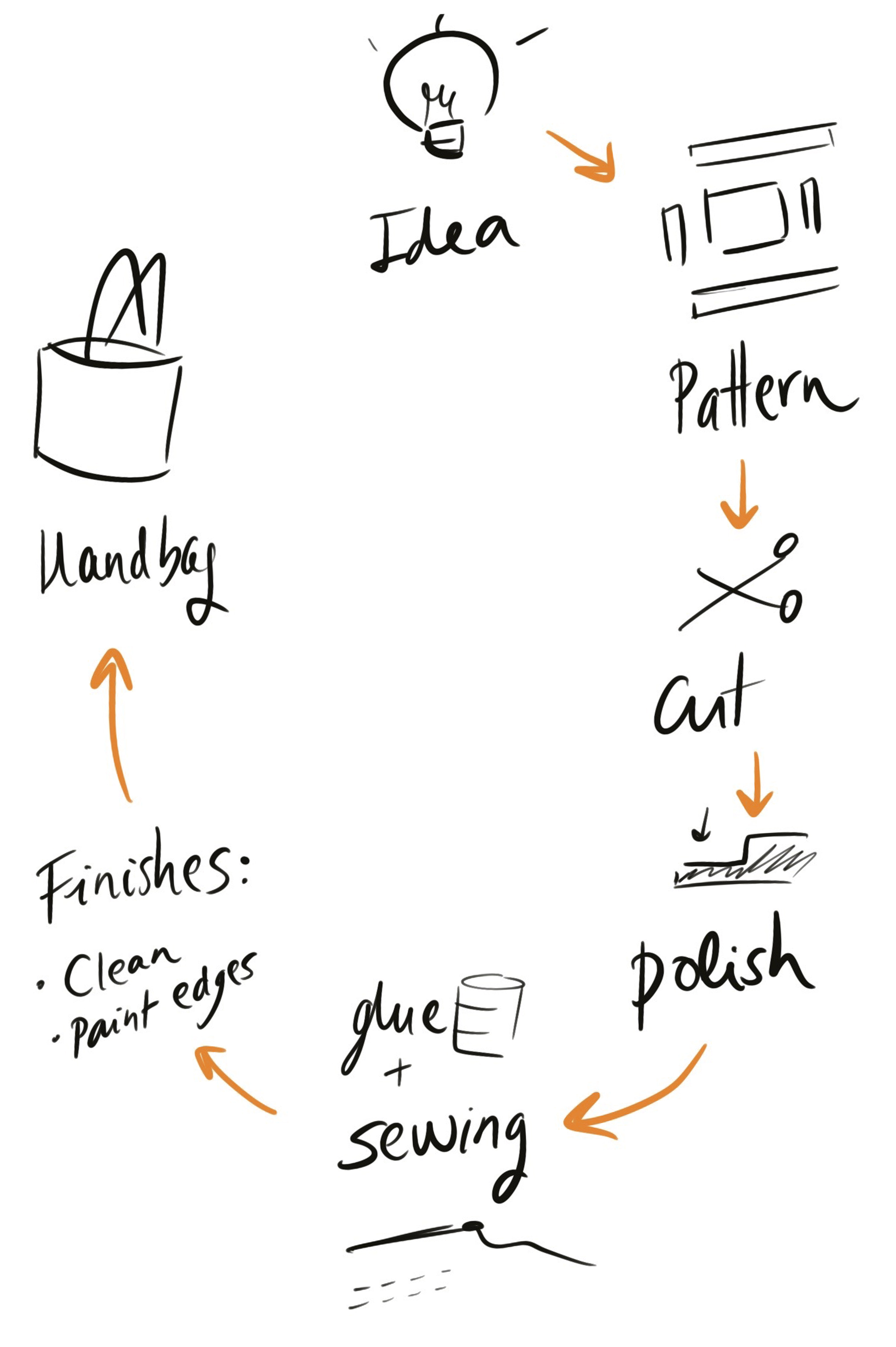

CONVENTIONAL METHOD TO FABRICATE AN ACCESSORY:

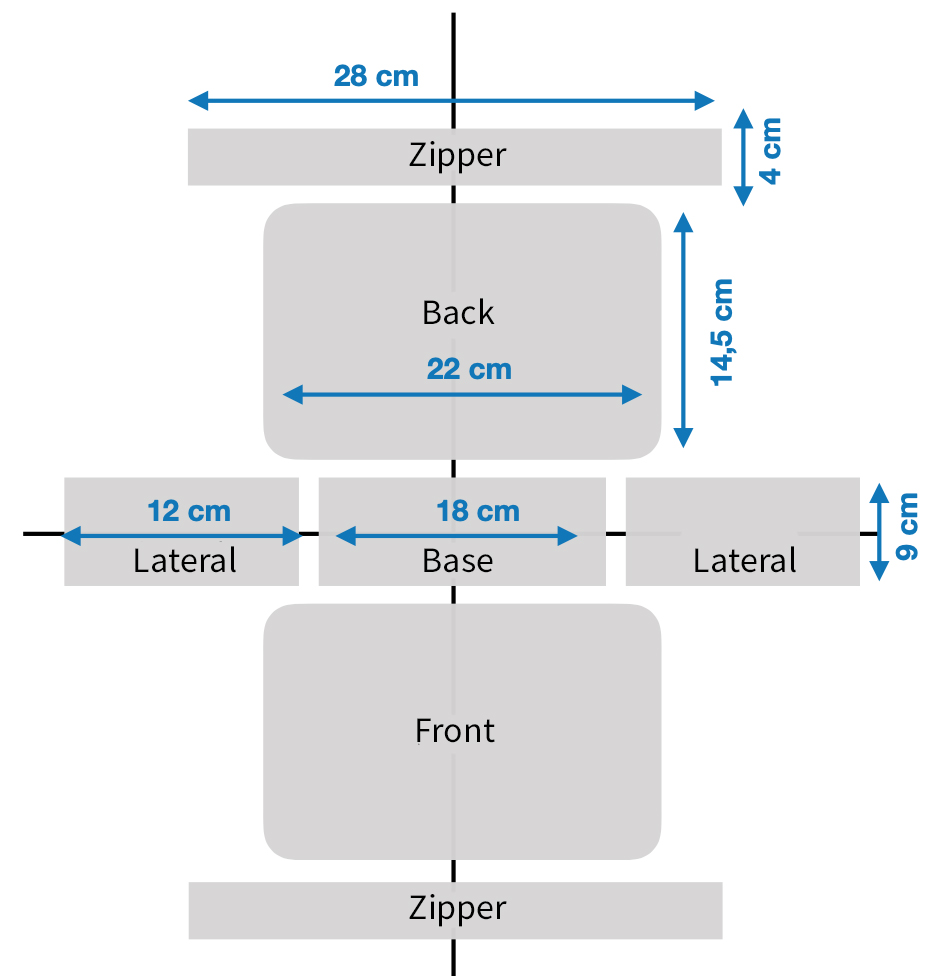

The pattern making is the process between the drawing design of the accessory and the final prototype. It is a long process with several tries to get the perfect scales and shape to easily produce in the industry.

First, they start the bag in 2D scale in the paper, next they build connecting the paper pieces to control all the fitting. Next, they make the corrections to each piece pattern. Then, you could mark them one by one with the name and the observations and repetition needed to get the 3D shape of the bag. After we could proceed with the fabrication of the first sample, so it's time to test this prototype in a leather material. Mark, cut and sew the parts. After it's finished it's common to make more corrections, so then we have to transfer to the pattern improvements. After the design, it's approved you can reproduce and produce it on a big scale.

PATTERN-MAKING WORKFLOW FOR A BASIC PROTOTYPE:

For example, this type of bag is one of the easiest volumes to construct.

To create this simple bag of Bimba y Lola we need more than 15 pieces to join.

So,

My worry is as a young brand,

HOW COULD OPTIMIZE THE PRODUCTION?

To know more about the initial development of the project visit my week 11.

How to solve¶

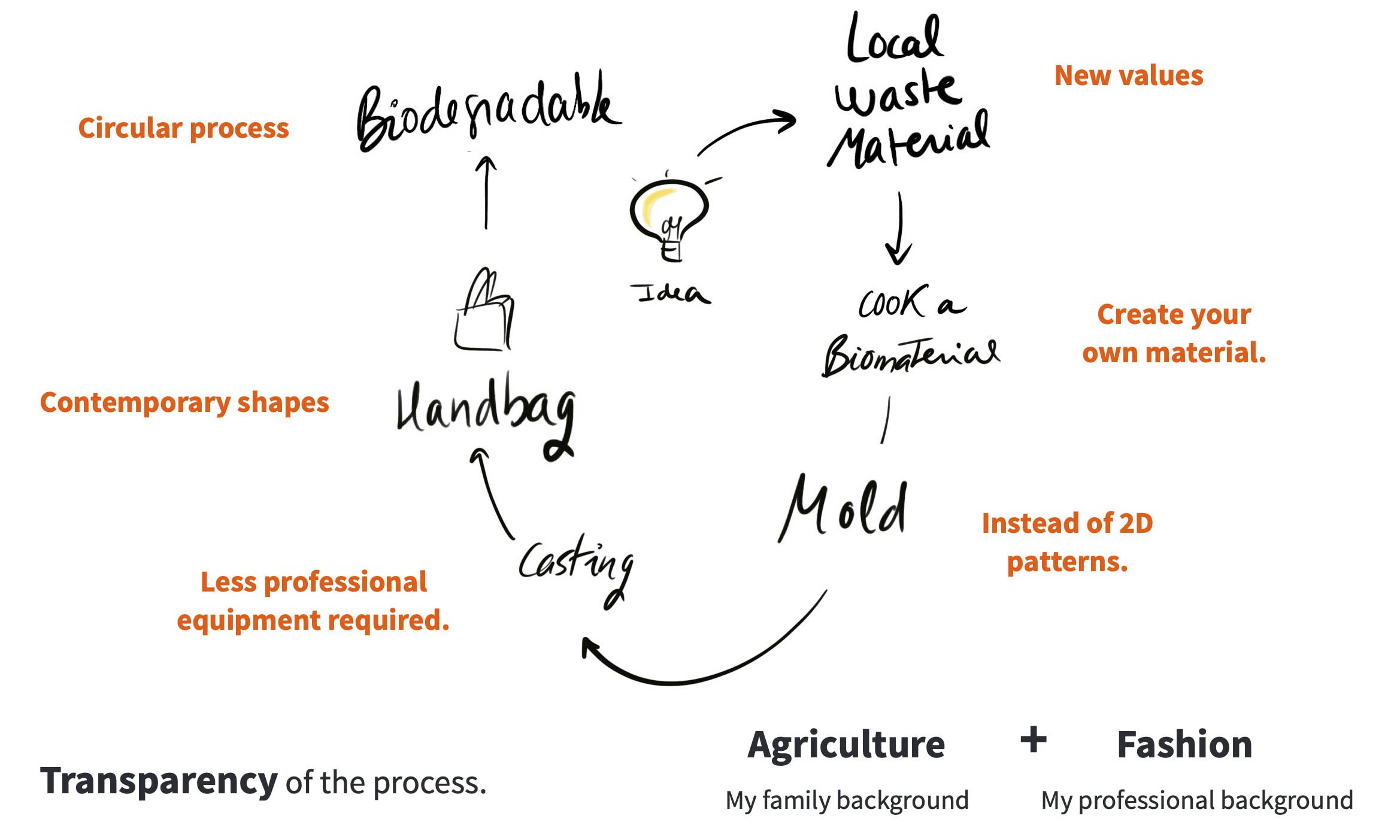

My proposal for my young brand:

Use a local agriculture waste material to create my own Biomaterial using the molding technique to create contemporary shapes for biodegradable handbags, being able to control all the steps of the product.

Bring value from local waste material¶

LET'S USE WASTE AS RESOURCE!

LOCAL CORN CORB HUSKS.

WHY?

Because is the local waste material of this season in Catalonia.

In the future, I would like to experiment with the waste material of my family fields.

Some questions come out:

-

Which recipes I am going to cook? Alginate / Bio leather, as the apple or mango skins...

-

How many husks I will need?

As a plus, I have in mind the idea to create a final product with biodegradable or compostable properties. The idea to create a product with 100% natural material, needs to come back to earth in an easy way. The product must have a next use/life or completely disappear in the grown.

Nowadays, trendy product is just for one season, so after it, the customers simply throw them away. As a society must rethink! The fashion industry needs urgency to find a solution to solve the mountains of garments trash that we have on our planet! It's insane!

For this reason, to be able on this degradation product, I need to rethink ALL the material to convert it into a biomaterial and the trimming for the accessory in a biocomposite material with the waste material of the handbag or with the pine resin and egg shells recipe...

Then, I going to be able to control all the states of the samples!!!

Innovate the method with technology¶

The idea of the material and the characteristics are technically solved to fabricate the bag, but how about changing the method to be faster and not require a lot of equipment. Nowadays, a lot of young brand spends all their starting budget on expensive machines and it makes harder the initial years of the brand.

My idea is to produce by

THE MOULDING TECHNIQUE

For the few last weeks, I have been working with the molding technique and with the Vacuum machine. A process that I enjoyed and open my mind to the way to design accessories and develop them. Also, this process lets you create interesting shapes in an optimal time. It could be an improvement for the accessory fabrication method, to be capable to produce on-demand and in small production.

Could I make some handbag samples as a sculptures?

Trying new shapes and different molds.

So,

Why molding?

To produce handbags with complex and contemporany shapes easily and faster to be ready to wear.

Let's skip some steps as the pattern making and change the typology of the handbag and be able to create any shape.

Casting method:

-

The technique is subjected to a mold, so every time we need to introduce a new design to the market we will need to do the mold in software such as Rhinoceros, send it to a CNC machine or the laser cutter, and make the corrections if it's required. Moreover, to fabricate simultaneously several samples we will need one mold for each one. So we must think about a process of molding as a way to have less ecological impact and make it sure that is better than traditional fabrication in terms of time and waste material.

-

Less craftsman method and stitches ornaments so the value for the costumers could descend.

-

The typology of the accessories could be distorted for conventional customers. However, it will create new typologies or more freedom for them to play.

-

Can I really mold with biomaterials?

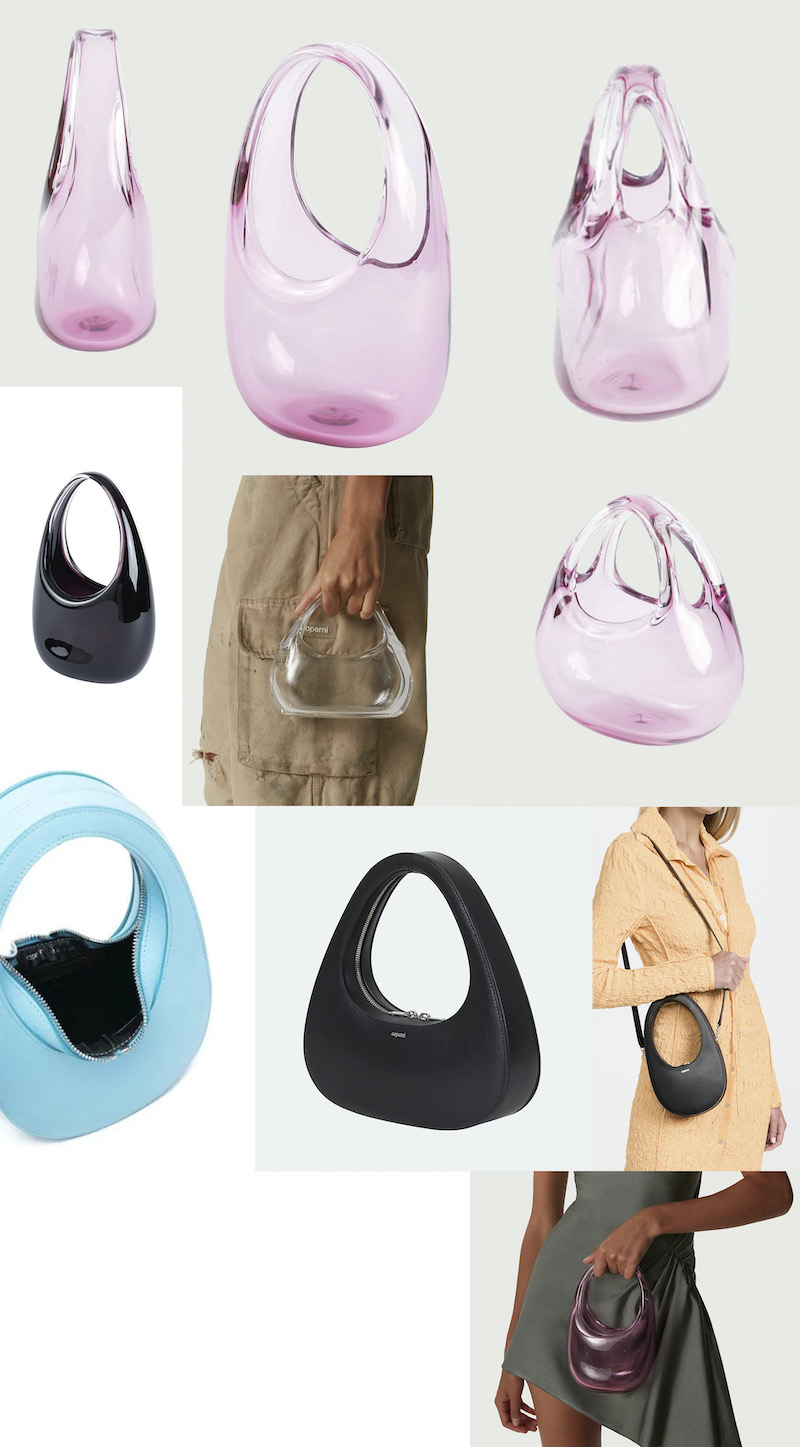

Fast fashion brands using molding technique¶

The different molding shapes that we could find in the market nowadays are simple and there aren't a lot of samples.

Here these are some examples of the brands which are commercializing this typologies accessories forms by moulding technique:

-

LOEWE: Founded in Spain in 1846, they’re approaching 175 years as one of the world’s major luxury houses. Craft is the essence of LOEWE. The most recent chapter has been marked by the appointment of Jonathan Anderson as creative director in 2013.

-

LEMAIRE: By Christophe Lemaire and Sarah-Linh Tran, the LEMAIRE brand offers a timeless Parisian style that is cosmopolitan, sophisticated and rich in influences.

- The vegetable-tanned leather is cut to shape using a template.

- The leather is then soaked and formed in a metal press.

- After several days of drying in the sun, the panels are ready to be crafted into bags.

- COPERNI: Is a Parisian ready-to-wear and accessories brand designed by Sébastien Meyer and Arnaud Vaillant, established in 2013.

This french brand also sells the iconic Swipe Bag re-imagined as a unique, glass handblown object. Each piece is handmade so the shape may vary slightly change from the picture.

A new value of accessories and buyers is coming.

Moodboard¶

Some inspiration to start with:

Create a craftsmanship product without hands?